Products

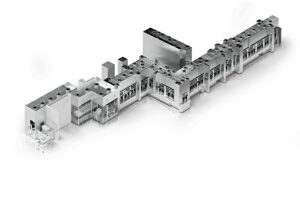

GIANT5 breaks the mold of traditional blister packaging concepts by combining exclusive advantages such as high speed and flexibility. High speed blister machine designed specifically for large batches production even with fast and frequent changeovers.

As an alternative to the IMA LIFE fully automatic robotic opening of sterile RTU primary packages, handling of primary materials can be either performed semi-automatically or in part manually.

By embracing new robotic technologies adopted throughout all production operations, from outer/inner bag opening to the downstream handling process, IMA LIFE solutions enable a very smooth production process, reducing cross-contamination risks.

Fully robotised denesting of sterile Ready-To-Use vials performed by specially designed six-axis robots. ROBOTIC D-NEST accomplishes all critical operations in aseptic environments.

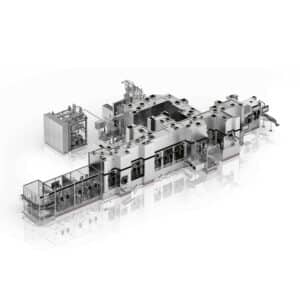

INJECTA 36 is a fine-tuned solution to enhance aseptic fill-finish capabilities and maximise processing line performance. Handling up to 36,000 RTU components per hour, in particular syringes, the system adopts innovative robotic and automation technologies.

However well an ampoule is labelled, the clinical outcome of any injection depends on the correct drug being administered and the only certain way of achieving this is for the label to be appropriately applied and clearly red.

IMa Life’s patented Fusion TM shelves bring innovation to the heart of the freeze drying process. FusionTM technology enhances freeze dryer performance whilst reducing operating costs.

Designed with an extremely compact layout to save space in the production area, PRECISA combines very high production speeds with an outstanding weighing system in terms of precision.

Designed in the 1970s, ZANASI and ZANASI PLUS are IMA’s first automatic capsule fillers to have made history. Still sought-after for their simple configuration, they offer maximum versatility in terms of combined dosing within the same capsule.

Exclusively used for the production of Press-Fit® and Xpress-Fit® gelcaps, ZANASI 70C is the ideal solution to produce a unique gelatine-coated tablet. The gel-enrobing technology combines the advantages of the hard gelatine capsule with those of the tablet.

HYDRA was created after many years of research and development focusing on container decontamination for injectable drugs. Designed according to the cGMP guidelines, the machine features the highest quality standards required by the pharmaceutical industry.

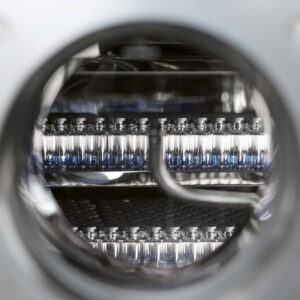

Containers coming in contact with parenteral preparations must be rendered sterile and non-pyrogenic, process resulting particularly successful with the VEGA Series, where the easy configurable washing sequence enhances the efficiency of the cleaning procedure

All pharmacopoeia indicate Escherichia Coli type 5 as the endotoxin to be used for checking that a de-pyrogenation process is accomplished correctly. A de-pyrogenation process has to initially guarantee at least a log 3 reduction of endotoxins.

Syringe, vial and cartridge-based injectables have nowadays evolved into a manageable dosing strategy for a variety of medical conditions. The STERIFILL RS series allows for flexible production methods for injectable pharmaceuticals.

Responding to the GMP Annex 1 notes, whereby risks linked to sterility assurance must be minimised during material transfer and supported by high-capability transfer technology, Nebula accomplishes what no other solution has done before.

Offering cost and time-efficient, high-capacity filling, STERIFILL satisfies the increasing demand for ampoule fillers. Filled with a measured quantity of liquid, ampoules are considered ready-to-inject solutions with the advantage of being 100% tamper proof.

Time and ease of use are of the essence with small to medium batch production, but with SMART, IMA expertise has gone even further, combining proven technology with high quality standards and the reliability required for all aseptic filling needs.

The fast filling of products in aseptic environment is a very critical operation not only with regard to the accuracy, but also to strict quality parameters required during production. With the aid of mass flow meters XTREMA LV answers this very hectic issue.

The use of single-dose containers to package sterile, pharmaceutical or cosmetic products is becoming increasingly popular thanks to the numerous advantages that this type of container offers in terms of product safety, administration accuracy and ease of use.

The rising demand for operator safety in aseptic processing, when handling high-potent powdered substances, has boosted the research and the adoption of innovative aseptic dosing technologies replacing the traditional methods.

Today certain bacteria have developed resistance to antibiotics that were once commonly used to treat them. The implementation of more powerful antibiotics, and new aseptic technologie, like SMART PWD contribute to solving this serious public health issue.

The continued emergence of multi-drug resistance bacteria is a global issue.

The development of new antibiotics, especially those with new modes of action, is imperative to help treat new infections. This is the scenario where XTREMA PWD has been designed.

The longstanding experience in the development and production of capping machines for vials has been channelled into ALU. Unique in style and built to deliver top-level performance, this machine will drive your productivity to a higher degree of efficiency.

Automated vial loading & unloading systems for industrial freeze-dryers reduce the risk of contamination from humans and the operative costs while enhancing efficiency. But if you add to this the unique design concept of the DA VINCI loader you get much more.

The aim of advanced aseptic processing is the elimination and absolute control of all sources of human contamination.

IMA Life’s fully automated vial fixed and flexible loading systems are the right technologies to advance this initiative further.

The aseptic production of pharmaceuticals usually takes place in cleanrooms in order to prevent contamination. IMA Life semi-automatic systems provide a controlled solution for loading fences in/out of a freeze dryer, avoiding manual interactions with vials.

Macro PWD is the result of over 50 years of experience in pharmaceutical powder filling and over 100 machines installed worldwide. Able to satisfy the current safety requirements, it is the answer to the increasing demand for the dosage of dry syrups.

Lyophilisation is a time-consuming, energy-intensive and expensive process requiring constant monitoring of the system and process variables. Sentinel-LYO provides advanced analytical capabilities through strategically located sensors inside your freeze-dryer.

Designed to meet the requirements of the pharmaceutical industry in aseptic processing, EASYFILL is the right answer when a high degree of flexibility and modularity is required in sterile liquid filling.

Much more than a simple, stand-alone filling machine, the IMA LIFE Multifill F57 is a monobloc multifunction machine handling many pharmaceutical applications for syrups, suspensions, oral drops, oral & ear pumps, intranasal devices and ophthalmic products

Have you ever thought about the huge variety of liquid pharmaceutical and nutraceutical products? And about their capping styles? Unquestionably, to handle them it is imperative flexibility and modularity: the proper characteristics of the MULTIFILL F500.

Nowadays drug production requires top flexibility, samely does its processing equipment. Even with large-batch manufacturing, improved automation, broader product handling capabilities and quick changeovers are a must. Here the MULTIFILL F800 comes into play.

Where great performance and high-speed labelling of vials and bottles are required, Sensitive Roto comes into play. Versatile and reliable, it ensures an extremely precise application of labels providing information related to the content of the containers.

A simple label is essential when it comes to drug identification, as it contains vital information. In response to this need, IMA has developed the Sensitive 350, boasting design simplicity and effectiveness when handling cylindrical containers.

With its essential design and small footprint, the SENSITIVE ECO is the most competitive solution among the linear labelling machines in the IMA Life range. Accurate and easy-to-use, it responds to the needs of standardised labelling.

The SENSITIVE ECO LV is the answer to the needs of the pharmaceutical and non-pharmaceutical industries dealing with the labelling of tall or high-capacity containers. Compact yet robust, it ensures high performance and precision.

Many pharmaceutical applications require complete, validated control over all elements of the packaging process including not only filling but also container closing and handling. Flexifill is the right solution for low to medium performance.

The assembly and labelling of pre-filled glass syringes is a delicate process that must preserve the syringe and the drug it contains. Recently developed by IMA Life, MODULA is the converging element between aseptic filling and secondary packaging.

KryoAir is a new technology, 100% green refrigerant, using air as the refrigerant used in freeze dryers. The system is based on a series of compression/cooling/expansion steps of AIR, which can be cooled to a temperature as low as -100°C.

Conceived for outer surface decontamination of pharmaceutical containers after the filling process, Hydra 100/300/400 minimizes the legal risk of long-term exposure for packaging operators and medical personnel handling cytotoxic products or potent compounds.

The pharmaceutical industry and safety regulators are placing more importance on external washers to remove product particles from the outside of containers after filling. Vega 400 complies with the present requirement and ensures complete decontamination.

In the pharmaceutical sector the need to protect the product from contamination due to the presence of personnel or the environment is one of the major drivers for containment. What matters most in aseptic processes is the max. reduction of contamination risk.

Open RABS represent the first solution available in the barrier technology scenario, introducing the concept of product protection.

Closed RABS provide minimal protection during manipulation of mildly potent products.

Designed to pack the widest range of products, VERTICARE P, allows for an extremely gentle handling of all components of the package through the entire packaging process. The 360° accessibility of the machine simplifies the cleaning and format changeover.

A horizontal, continuous motion, high-speed rotary cartoner for flat blanks, the FCW600 is the ideal choice for processing new packaging shapes.

An ideal complement to high-speed filling equipment or buffering systems granting excellent line efficiency, the compact FTC578-C vertical cartoner is designed to enable huge machine configuration flexibility and later implementation of a liner system.

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website