Everything gained in years of experience and expertise in the industry has been carefully channelled into PREXIMA, the new series of tablet press machines. Available in three models, PREXIMA is the best solution to handle all production volumes.

Everything gained in years of experience and expertise in the industry has been carefully channelled into PREXIMA, the new series of tablet press machines. Available in three models, PREXIMA is the best solution to handle all production volumes.

All our skills. Compressed.

Powered by IMA Active’s knowledge of the sector, designed with unique Italian style, built to deliver top-level performance, PREXIMA drives productivity to a higher level of efficiency. PREXIMA ensures optimal performance even with the most difficult-to-manage powders, keeping the tablet uniform in terms of weight and hardness.

Sustainability

An in-depth evaluation has been carried out on different types of main motorisation to choose the one that provides the best performance, while always keeping an eye on energy saving in order to obtain high efficiency, maximum control, advanced diagnostic and reduction of consumption (elimination of motor cooling system). PREXIMA applies brushless motorisation to ensure energy efficiency while granting high machine performance.

Moreover PREXIMA guarantees waste reduction. Advanced machine learning functions are used for more efficient self-adjustment of process parameters: less waste, better product quality. All this maximises machine functionality, keeping the machine performance on target and allowing the single rejection of products out of specification.

PREXIMA Highlights

PREXIMA VERSIONS

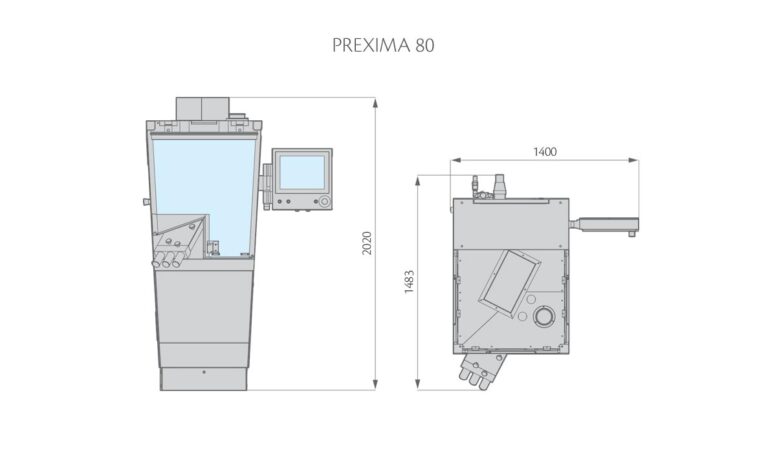

PREXIMA 80

PREXIMA 80 tablet press is designed for R&D applications and small scale production. In R&D configuration the machine offers wide range of tools to characterize the tablet; it furthermore offers flexibility on any tablet dimension, as the MIX turret fits four stations B and four station D. Mating this machine with IMAGO R&D software, available as an option, makes the ideal choice for R&D departments.

An equivalent machine model is available also for high containment installation in OEB 5 configuration.

PREXIMA 300

PREXIMA 300 is the single side tablet press for medium production. Beside excellent accessibility, its clever design makes the turret removal quick thanks to the rotating arm completely housed inside the mechanical compartment, while the built-in electrical cabinet enables for an easier installation. Sturdy, efficient and flexible, it is available also for the production of big tablets up to 39 mm diameter.

PREXIMA 800

PREXIMA 800 is the double sided tablet press for high production and is suitable also for bilayer tableting. The excellent accessibility which characterizes the PREXIMA series ensures a complete access to the process area all-around the machine. The construction of the machine is based on four columns linked together by two strong cast iron structures which directly support the four compression rollers from both sides. This ensures all the forces are transferred to the product to achieve the highest tablet compression and stability at maximal speed.

- Technical Data

- Machine Layout

| TECHNICAL DATA PREXIMA 80 | ||||

| Die type | B+D | D | B | BB |

| Tool type | B+D | D | B | B |

| Number of press stations | 4+4 | 13 | 16 | 19 |

| Maximum tablet diameter (mm) | 16+25 | 25 | 16 | 13 |

| Maximum die filling (mm) | 18 | |||

| Maximum output (tablets/hour) | 20,400 | 66,300 | 81,600 | 96,900 |

| Revolution per minute (min -1) | 85 | |||

| Maximum pre-compression force (kN) | 10 | |||

| Maximum compaction force (kN) | 60 | |||

| Maximum installed power (kW) | 75 | |||

| Standard voltage | 400V (+/- 10%) 50-60 Hz | |||

| Pitch circle diameter (mm) | 180 | |||

| TECHNICAL DATA PREXIMA 300 | |||||

| Die type | IMA 32 | D | B | BB | IMA 8 |

| Tool type (EU and TSM) | IMA 32 | D | B | IMA 8 | |

| Number of press stations | 18 | 27 | 33 | 41 | 55 |

| Maximum tablet diameter (mm) | 39 | 25 | 16 | 13 | 10 |

| Maximum die filling (mm) | 24 | 20 | 19 | ||

| Maximum output (tablets/hour) monolayer | 97,200 | 194,400 | 237,600 | 295,200 | 396,000 |

| Revolution per minute (-1) | 120 | ||||

| Maximum pre-compression force (kN) | 100 | ||||

| Maximum compaction force (kN) | 100 | ||||

| Electrical power requirement (kW) | 14 | ||||

| Standard voltage | 400V (+/- 10%) 50-60 Hz | ||||

| Pitch circle diameter (mm) | 380 | ||||

| TECHNICAL DATA PREXIMA 800 | ||||

| Die type | D | B | BB | IMA 8 |

| Tool type (EU and TMS) | D | B | IMA 8 | |

| Number of press stations | 53 | 65 | 81 | 105 |

| Maximum tablet diameter (mm) | 25 | 16 | 13 | 10 |

| Maximum die filling (mm) | 20 | 19 | ||

| Maximum output (tablets/hour) monolayer | 572,400 | 702,000 | 874,800 | 1,260,000 |

| Revolution per minute (-1) | 90 | 100 | ||

| Maximum pre-compression force (kN) | 100 | |||

| Maximum compaction force (kN) | 100 | |||

| Electrical power requirement (kW) | 27 | |||

| Standard voltage | 400V (+/- 10%) 50-60 Hz | |||

| Pitch circle diameter (mm) | 745 | |||