IMA E-COMMERCE: THE ROOTS OF A NEW PACKAGING ERA

E-Commerce has become a vital part of the retail industry and it is projected to continue its growth in the coming years.

Advanced packaging automation will be necessary to help e-tailers improve both throughput and their cost position as labor markets remain tight.

To compete on this fast-moving market, and thanks to its 60-years packaging expertise, IMA designed advanced technologies to automate the packaging process.

The range of automatic box packaging machines dedicated to the E-Commerce, E-Fulfillment, Intralogistics and 3PL sectors showcases our commitment to innovation and efficiency.

IMA E-COMMERCE updates

E-CO FLEX | Automated packaging solution

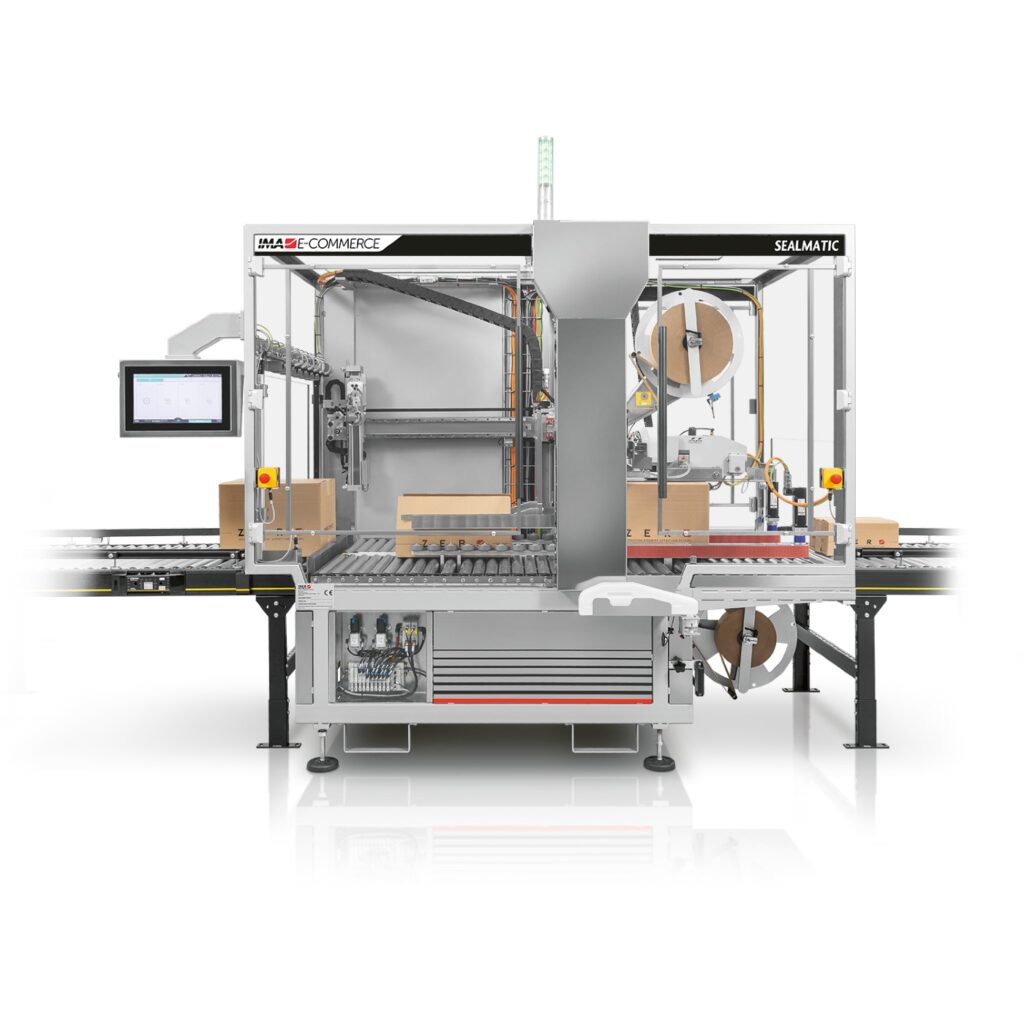

E-CO FLEX SEALMATIC | Fully automated random case sealer

DISCOVER THE E-COMMERCE PORTFOLIO

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[embed_iframe] =>

[form_price] =>

[contact] => simone.capponcelli@ima.it, eleonora.sarti@ima.it

[thread_tag] =>

[tile_description] => E-commerce activities demand perfect syncronisation among every task in the supply chain: products need to be prepared and shipped quickly, to be at pace in such extremely speed-driven market. E-CO Flex is the perfect answer to E-commerce packaging activities.

[tile_speed] => Up to 10 boxes/minute

[cover_macro] => 343

[cover_name_type] => txt

[cover_name] => E-CO FLEX

[cover_descriptor] => FLEXIBLE AUTOMATED PACKING STATION FOR E-COMMERCE

[cover_focus_on] => 1

[news] =>

[thumbnail] => 304

[tag_line] => At the forefront of advanced packaging automation.

[overview] => E-CO Flex is an automated packaging station to support the operators in the boxing of e-commerce products.

The E-CO Flex is capable to select from a magazine the pre-made case of the correct size basing on the products to be packed inside, thanks to the interaction with the customer’s management system or after inspecting the incoming products via scanner.

The equipment erects the pre-glued case, closes the bottom (WAT tape or glue) and applies the box ID label, so the operator can easily place inside products and void fill. Finally the case is pushed by the operator inside the closing station, which is also capable to properly resize the case height if necessary, and finally closes the case (WAT tape or glue).

The E-CO Flex has a very compact footprint, so it can be integrated in existing layouts, and it follows the speed of the operator, making the packing operations easier and smoother.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => LEARN MORE AND GET A FREE TICKET

[icon] => explore

[internal_link] =>

[link] => https://ima.it/en/exhibition/packexpo-las-vegas/

[link_page] =>

[tab] => 1

)

)

)

[sustainability] => Case dimensions optimized thanks to downsizing function: reducing void fill required and the overall dimension of the case allows for smaller packs to be shipped, thus reducing shipping costs and CO2 consumption.

Water-activated taping is a sustainable solution to close cases, still ensuring perfect adhesion and eliminating plastic.

[highlights_on] => 1

[focus_on] =>

[versions_on] => 1

[addon_on] =>

[output_on] =>

[technical_data] => | E-CO FLEX TECHNICAL DATA | |

| Throughput speed (cases per minute) | Up to 10 CPM |

| Bench Height | 33.5” (85 cm) |

| Boxes size range | from 7″ x 6″ x 3″ (178 x 152 x 76 mm) to 21″ x 15″ x 13″ (533 x 38 1x 330 mm) |

| Box Type |

Standard or multi – depth box – RSC – 0201 |

| Adhesive Technology | Water-activated (or gummed) tape |

| Tape Width | 3” core width max roll diameter 20” |

| Corrugated Box Layout | Right hand or left hand |

| Installed power | 480V (±10%), 3 Phase + 1 Ground, 60Hz, 10A Air |

The case forming and case closing modules can operate as standalone equipment, adapting to any plant configuration. [versions] => Array ( [0] => Array ( [version_label] => WMS INTEGRATED PUT-TO-WALL CONFIGURATION [version_title] => WMS INTEGRATED PUT-TO-WALL CONFIGURATION [version_thumbnail] => 491 [version_overview] =>

The E-CO Flex Forming case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) [1] => Array ( [version_label] => WMS INTEGRATED TOTE-BASED CONFIGURATION [version_title] => WMS INTEGRATED TOTE-BASED CONFIGURATION [version_thumbnail] => 492 [version_overview] =>The E-CO Flex Forming module forms, closes and divertes to the two manual packing stations.

The right-size box for the order can be selected using the customer’s WMS or measuring the volume required for the products with a dimensioning system.

After the boxes are filled, both packers take advantage of the E-CO Flex Closing module with down-sizing capabilities.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) [2] => Array ( [version_label] => CASE ERECTING FOR PICK-TO-BOX CONFIGURATION [version_title] => CASE ERECTING FOR PICK-TO-BOX CONFIGURATION [version_thumbnail] => 493 [version_overview] =>The E-CO Flex Forming case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) [3] => Array ( [version_label] => CASE ERECTING FOR RIGHT-SIZE BOX SELECTION BY OPERATOR [version_title] => CASE ERECTING FOR RIGHT-SIZE BOX SELECTION BY OPERATOR [version_thumbnail] => 494 [version_overview] =>If the customer’s WMS does not have precise product cubing data or if the process requires operator involvement in selecting the right-size box, the E-CO Flex proves highly beneficial. Utilizing the carton magazine, various box sizes are pre-assembled and directed onto separate slipways. Each slipway corresponds to a different box size, allowing operators to visually select the most appropriate case for each incoming order.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) ) [versions_thumbnail] => [versions_tag_line] => [versions_overview] => [versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [focus] => Array ( [image] => [content] => [buttons] => Array ( [buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => [icon] => [form_email] => eleonora.sarti@ima.it [type] => product [private_product] => 11-85 [private_exhibition] => [form_type] => [form_id] => ) ) ) ) [cover_focus_content] =>The E-CO Flex packing station is a flexible solution conceived to streamline and accelerate the packing process, switching from manual to automated operations in a compact footprint.

[buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => product [private_product] => 11-85 [private_exhibition] => [form_type] => [form_id] => ) ) [cover_focus_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => product [private_product] => 11-85 [private_exhibition] => [form_type] => [form_id] => ) ) ) )

Array

(

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[embed_iframe] =>

[form_price] =>

[contact] => eleonora.sarti@ima.it, simone.capponcelli@ima.it

[thread_tag] =>

[tile_description] => The E-CO Flex standalone case erecting and forming module is designed to kick-off the packaging process seamlessly. In its standard configuration, the machine boasts a 12-cassette magazine, the widest available in the market, capable of accommodating various case formats.

[tile_speed] => Up to 10 boxes/minute

[cover_macro] => 365

[cover_name_type] => txt

[cover_name] => E-CO Flex Forming

[cover_descriptor] => Case erector and former

[cover_focus_on] => 1

[news] =>

[thumbnail] => 364

[tag_line] => Automatically selects the right-sized box.

[overview] => The E-CO Flex standalone case erecting and forming module is designed to kick-off the packaging process seamlessly. In its standard configuration, the machine boasts a 12-cassette magazine, the widest available in the market, capable of accommodating various case formats.

The packaging process is streamlined by the machine, which automatically selects the optimal box size, erects it, forms it, and securely tapes it at the bottom. This results in the operator being presented with an open-faced box ready for product insertion.

Bottom taping can be carried out with sustainable Water-Activated Tape (WAT).

If you are in search of an integrated solution for case erecting and closing, click to discover our E-CO Flex Packing Station

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] =>

[focus_on] =>

[versions_on] => 1

[addon_on] =>

[output_on] =>

[technical_data] => | E-CO FLEX FORMING |

||

| Box type | Standard RSC (FEFCO 201) and HSC (FEFCO 200) | |

| Adehesive technology | Water-activated (WAT) or gummed tape | |

| Box range (internal dimensions) |

MIN | MAX |

| 7” x 6” x 3” (178 mm x 152 mm x 76 mm) |

21” x 15” x 13” (533 mm x 381 mm x 330 mm) |

|

| ID label application | Yes, as machine option | |

Thanks to the modularity of the E-CO Flex platform, the case forming module can operate as standalone machine, thus streamlining the initial packaging process. The cassette magazine can be customised according to the manufacturer's request.

[buttons_on] => 1 [cover_focus_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => file_download [link] => 430 [tab] => ) [1] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => file_download [link] => 430 [tab] => ) [1] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) [versions_title] => Two modules, one machine: endless configurations.The case forming and case closing modules can operate as standalone equipment, adapting to any plant configuration. [versions] => Array ( [0] => Array ( [version_label] => WMS INTEGRATED PUT-TO-WALL CONFIGURATION [version_title] => WMS INTEGRATED PUT-TO-WALL CONFIGURATION [version_thumbnail] => 491 [version_overview] =>

The E-CO Flex Forming case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) [1] => Array ( [version_label] => WMS INTEGRATED TOTE-BASED CONFIGURATION [version_title] => WMS INTEGRATED TOTE-BASED CONFIGURATION [version_thumbnail] => 492 [version_overview] =>The E-CO Flex Forming module forms, closes and divertes to the two manual packing stations.

The right-size box for the order can be selected using the customer’s WMS or measuring the volume required for the products with a dimensioning system.

After the boxes are filled, both packers take advantage of the E-CO Flex Closing module with down-sizing capabilities.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) [2] => Array ( [version_label] => CASE ERECTING FOR PICK-TO-BOX CONFIGURATION [version_title] => CASE ERECTING FOR PICK-TO-BOX CONFIGURATION [version_thumbnail] => 493 [version_overview] =>The E-CO Flex Forming case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) [3] => Array ( [version_label] => CASE ERECTING FOR RIGHT-SIZE BOX SELECTION BY OPERATOR [version_title] => CASE ERECTING FOR RIGHT-SIZE BOX SELECTION BY OPERATOR [version_thumbnail] => 494 [version_overview] =>If the customer’s WMS does not have precise product cubing data or if the process requires operator involvement in selecting the right-size box, the E-CO Flex proves highly beneficial. Utilizing the carton magazine, various box sizes are pre-assembled and directed onto separate slipways. Each slipway corresponds to a different box size, allowing operators to visually select the most appropriate case for each incoming order.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) ) [versions_thumbnail] => [versions_tag_line] => [versions_overview] => [versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) )

Array

(

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[embed_iframe] =>

[form_price] =>

[contact] => eleonora.sarti@ima.it, simone.capponcelli@ima.it

[thread_tag] =>

[tile_description] => The closing module of the E-CO FLEX platform embeds the down-sizing operation, reducing the box height to minimum dimensions after scanning content. The machine can tape with the water-activated technology.

[tile_speed] => Up to 10 boxes/minute

[cover_macro] => 368

[cover_name_type] => txt

[cover_name] => E-CO FLEX CLOSING

[cover_descriptor] => Case sealer

[cover_focus_on] => 1

[news] =>

[thumbnail] => 369

[tag_line] => Cut and close FEFCO 201 boxes automatically.

[overview] => After the product is inserted, the open-faced case can be placed into the E-CO Flex closing module, which can operate as automatic standalone equipment. A bank of ultrasonic sensors measures the remaining void within the box. If the system detects the possibility to reduce the height, the enclosed down-sizing group will automatically cut the four corners of the box (up to 270 mm). This allows the case flaps to adapt to the new box dimensions when closed, reducing its height up to 20-25%.

The cases can be sealed on top with sustainable water-activated tape.

The machine is designed to detect the SIOC cases and automatically bypass them.

The E-CO Flex Closing module can be equipped, as option, with a Print & Applt labeller and quality inspection cameras to check flaps folding and taping.

If you are in search of an integrated solution for case erecting and closing, click to discover our E-CO Flex Packing Station

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] =>

[focus_on] =>

[versions_on] => 1

[addon_on] =>

[output_on] =>

[technical_data] => | E-CO FLEX CLOSING | ||

| Machine speed | Up to 10 boxes/minute | |

| Box type | Standard RSC (FEFCO 201) | |

| Box dimensions | MIN | MAX |

| 7” x 6” x 3” (178 mm x 152 mm x 76 mm) |

21” x 15” x 13” (533 mm x 381 mm x 330 mm) |

|

| Adehesive technology | Water-activated (WAT) or gummed tape | |

| Print & Apply labeller | Yes, as machine option | |

| Quality inspection cameras | Yes, as machine option | |

The standalone closing module of the E-CO Flex platform is provided with the down-sizing function, which automatically re-sizes the box height.

[buttons_on] => 1 [cover_focus_buttons] => Array ( [buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) [versions_title] => Two modules, one machine: endless configurations.The case forming and case closing modules can operate as standalone equipment, adapting to any plant configuration. [versions] => Array ( [0] => Array ( [version_label] => WMS INTEGRATED PUT-TO-WALL CONFIGURATION [version_title] => WMS INTEGRATED PUT-TO-WALL CONFIGURATION [version_thumbnail] => 491 [version_overview] =>

The E-CO Flex Forming case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) [1] => Array ( [version_label] => WMS INTEGRATED TOTE-BASED CONFIGURATION [version_title] => WMS INTEGRATED TOTE-BASED CONFIGURATION [version_thumbnail] => 492 [version_overview] =>The E-CO Flex Forming module forms, closes and divertes to the two manual packing stations.

The right-size box for the order can be selected using the customer’s WMS or measuring the volume required for the products with a dimensioning system.

After the boxes are filled, both packers take advantage of the E-CO Flex Closing module with down-sizing capabilities.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) [2] => Array ( [version_label] => CASE ERECTING FOR PICK-TO-BOX CONFIGURATION [version_title] => CASE ERECTING FOR PICK-TO-BOX CONFIGURATION [version_thumbnail] => 493 [version_overview] =>The E-CO Flex Forming case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) [3] => Array ( [version_label] => CASE ERECTING FOR RIGHT-SIZE BOX SELECTION BY OPERATOR [version_title] => CASE ERECTING FOR RIGHT-SIZE BOX SELECTION BY OPERATOR [version_thumbnail] => 494 [version_overview] =>If the customer’s WMS does not have precise product cubing data or if the process requires operator involvement in selecting the right-size box, the E-CO Flex proves highly beneficial. Utilizing the carton magazine, various box sizes are pre-assembled and directed onto separate slipways. Each slipway corresponds to a different box size, allowing operators to visually select the most appropriate case for each incoming order.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => CONTACT US [icon] => mail [form_email] => eleonora.sarti@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) ) ) [versions_thumbnail] => [versions_tag_line] => [versions_overview] => [versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) )

Array

(

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[embed_iframe] =>

[form_price] =>

[contact] => eleonora.sarti@ima.it, simone.capponcelli@ima.it

[thread_tag] =>

[tile_description] => The E-CO Flex SealMatic is a 100% self-driven random case sealer, designed to process FEFCO 201 and SIOC cases. The machine automatically tapes the bottom of the case, while the top is closed and sealed with water-activated tape.

[tile_speed] => Up to 18 boxes/minute - SIOC up to 20 boxes/minute

[cover_macro] => 368

[cover_name_type] => txt

[cover_name] => E-CO Flex SealMatic

[cover_descriptor] => Automatic random case sealer

[cover_focus_on] => 1

[cover_focus_content] => The E-CO Flex SealMatic is a 100% self-driven equipment designed to process FEFCO 201 and SIOC cases. The machine automatically tapes the bottom of the case, while the top is closed and sealed with water-activated tape.

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 450

[tag_line] => 100% self-driven.

[overview] => The E-CO Flex SealMatic is an automated random case sealing solution that seamlessly integrates with IMA’s portfolio for e-tailers. Engineered for efficiency, this machine closes and seals FEFCO 201 boxes across a wide spectrum of sizes, with no need for human intervention.

E-CO Flex SealMatic streamlines the process by automatically folding the top flaps and securely sealing both the top and bottom of each case employing eco-friendly water-activated tape technology, and it can seal up to 20 boxes per minute autonomously, eliminating the need for manual intervention. Additionally, when a Ships-In-Own-Container (SIOC) case is detected, the machine can bypass it without applying tape.

E-CO Flex SealMatic perfectly integrates into the Scan Label Apply Manifest (SLAM) stations.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] =>

[versions_on] =>

[addon_on] =>

[output_on] =>

[technical_data] => | E-CO FLEX SEALMATIC TECHNICAL DATA |

||

| Throughput in cases/minute | Box: 11-18 case/minute Ships In Own Container (SIOC): up to 20 case/minute |

|

| Box type | Taping function: pre-formed box with flaps open in the upper side Bypass function: for SIOC and cases already taped |

|

| MIN | MAX | |

| Case size (internal dimensions) | 7″ x 6″ x3″ (18 cm x 15 cm x 8 cm) |

40″ x 28,5″ x 16″ (102 cm x 72 cm x 40 cm) |

| Case size SIOC | 7″ x 6″ x3″ (18 cm x 15 cm x 8 cm) |

∞” x 29,2 x 19″ (∞ cm x 74 cm x 48 cm) |

| Bypass feature | Yes | |

| Case weight | Max 35″ | |

Thanks to the partnership with Intertape Polymer Group, market leader for water-activated carton sealing tape, E-CO Flex features a Water-Activated Tape (WAT) head, which applies recyclable reinforced paper packaging tape used by top e-commerce retailers. The case can be securely sealed with just one strip on the bottom and one strip of the top of the box.

An immediate destructive bond is generated, resulting in a tamper evident package.

IPG is exclusive distributor of the E-CO Flex in North America.

IMA E-COMMERCE is member of MHI

MHI stands for Material Handling Industry and it is a leading non-profit trade association representing the U.S. material handling, logistics and supply chain industry.

It is the nation’s largest association born to deliver the latest knowledge, the strongest connections, powerful industry leadership, and the best market access for manufacturing and supply chain professionals. Around 975 members and 18 industry groups power research and solution sourcing to drive the innovations.

Since 2024, IMA E-COMMERCE is part of the Solutions Community Group, a pool of Industry’s thought leaders on automation, software, hardware, equipment and services that support a fully integrated supply chain.

Pledging Sustainability

Automated right-sizing solutions like the E-CO Flex ensure a safe transition from weight-based pricing to dimensional (DIM) weight, reducing the cubic footage of cases to the minimum, significantly reducing material use and costs by using less corrugate and often eliminating the need for void fill.

The use of closing tape made of paper eliminates the need for plastic, in compliance with the latest Sustainability policies that IMA adopted. IMA ZERO is the Corporate program dedicated to sustainable development, and NOP is one of its declinations that endorses its commitment to minimizing plastic use in packaging processes.

Take full advantage of Digital power

IMA E-COMMERCE machines can be enriched with IMA’s Digital solutions, that integrate platforms and tools to enhance and support manufacturing activities.

VIRTUAL COMMISSIONING

One of the emerging needs within modern industrial markets is using systems design methods that guarantee time saving and cost saving. On this purpose, virtual commissioning is starting to be one of the most versatile ways to obtain highly functional industrial plants, becoming a valid ally in the realization of complex industrial systems

Virtual commissioning recreates a digital model (or digital twin) which, connected to the controller and sensors, allows the system to be digitally reproduced to bring out design errors and improvements to be implemented.

Thanks to this technology, problems and system bugs can be solved directly in the design phase, shortening production times and optimizing processes.

IMA develops and manufactures automatic machines for the processing and packaging of many markets. IMA E-Commerce designs and produces advanced packaging stations dedicated to on-line retail, offering innovative solutions to solve the complexities related to this fast-changing market.

Production facility:

IMA S.p.A. – E-COMMERCE Division

Via Emilia, 428-442

40064 Ozzano dell’Emilia (BO)

ima.it/e-commerce

Intertape Polymer Group Inc. develops, manufactures and sales a variety of paper and film based pressure-sensitive and water-activated tapes, stretch and shrink films, protective packaging, woven and non-woven products and packaging machinery for industrial and retail use.

Production facility:

Intertape Polymer Group Inc.

100 Paramount Drive – Suite 300

Sarasota, FL 34232

+1 800-972-4675

itape.com