The E-CO Flex packing station is a flexible solution conceived to streamline and accelerate the packing process, switching from manual to automated operations in a compact footprint.

The E-CO Flex packing station is a flexible solution conceived to streamline and accelerate the packing process, switching from manual to automated operations in a compact footprint.

At the forefront of advanced packaging automation.

E-CO Flex is an automated packaging station to support the operators in the boxing of e-commerce products.

The E-CO Flex is capable to select from a magazine the pre-made case of the correct size basing on the products to be packed inside, thanks to the interaction with the customer’s management system or after inspecting the incoming products via scanner.

The equipment erects the pre-glued case, closes the bottom (WAT tape or glue) and applies the box ID label, so the operator can easily place inside products and void fill. Finally the case is pushed by the operator inside the closing station, which is also capable to properly resize the case height if necessary, and finally closes the case (WAT tape or glue).

The E-CO Flex has a very compact footprint, so it can be integrated in existing layouts, and it follows the speed of the operator, making the packing operations easier and smoother.

Sustainability

Case dimensions optimized thanks to downsizing function: reducing void fill required and the overall dimension of the case allows for smaller packs to be shipped, thus reducing shipping costs and CO2 consumption.

Water-activated taping is a sustainable solution to close cases, still ensuring perfect adhesion and eliminating plastic.

E-CO FLEX Highlights

Two modules, one machine: endless configurations.

The case forming and case closing modules can operate as standalone equipment, adapting to any plant configuration.

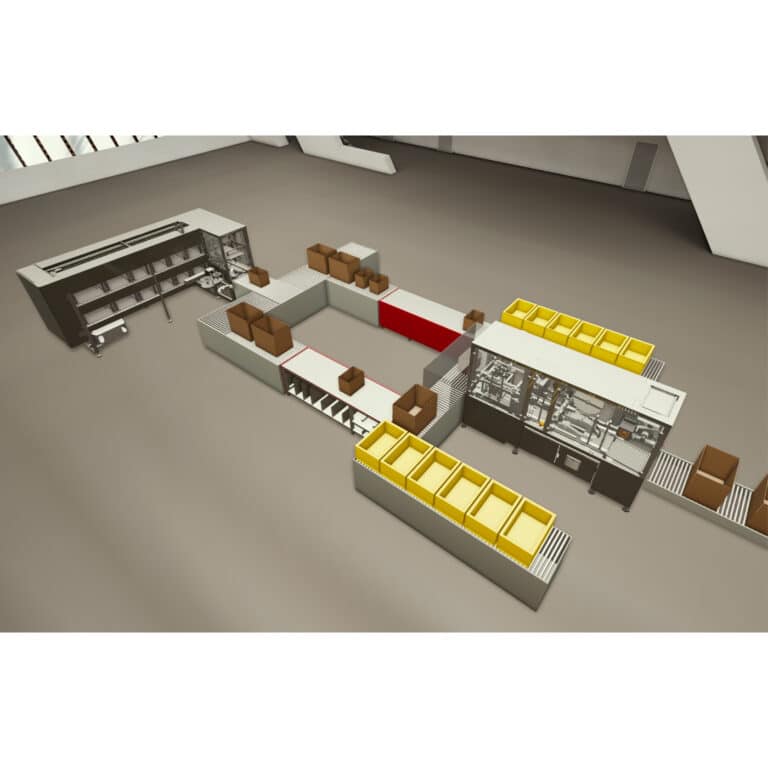

WMS INTEGRATED PUT-TO-WALL CONFIGURATION

The E-CO Flex Forming case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

WMS INTEGRATED TOTE-BASED CONFIGURATION

The E-CO Flex Forming module forms, closes and divertes to the two manual packing stations.

The right-size box for the order can be selected using the customer’s WMS or measuring the volume required for the products with a dimensioning system.

After the boxes are filled, both packers take advantage of the E-CO Flex Closing module with down-sizing capabilities.

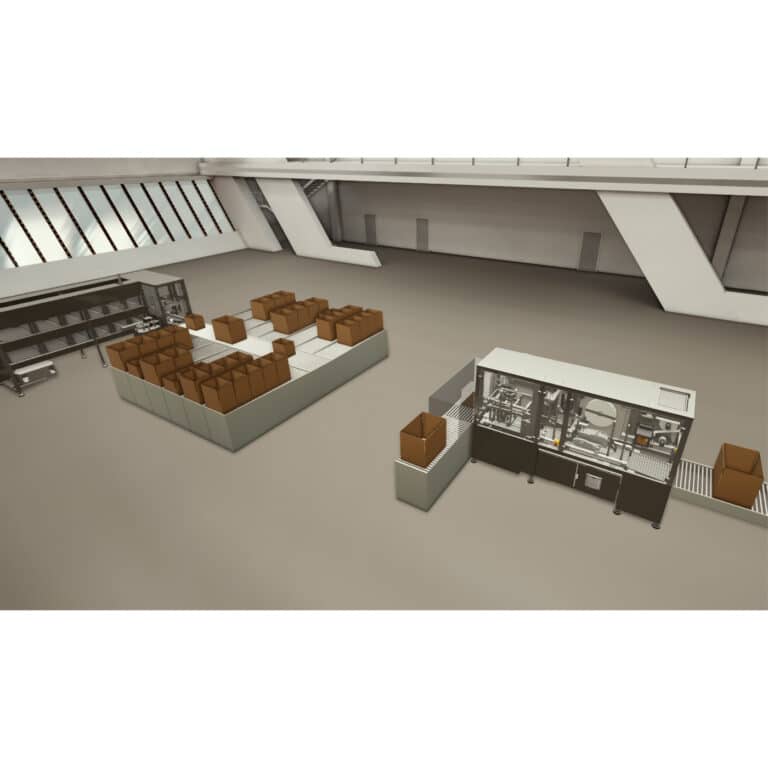

CASE ERECTING FOR PICK-TO-BOX CONFIGURATION

The E-CO Flex Forming case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

CASE ERECTING FOR RIGHT-SIZE BOX SELECTION BY OPERATOR

If the customer’s WMS does not have precise product cubing data or if the process requires operator involvement in selecting the right-size box, the E-CO Flex proves highly beneficial. Utilizing the carton magazine, various box sizes are pre-assembled and directed onto separate slipways. Each slipway corresponds to a different box size, allowing operators to visually select the most appropriate case for each incoming order.

- Technical Data

- Machine Layout

| E-CO FLEX TECHNICAL DATA | |

| Throughput speed (cases per minute) | Up to 10 CPM |

| Bench Height | 33.5” (85 cm) |

| Boxes size range | from 7″ x 6″ x 3″ (178 x 152 x 76 mm) to 21″ x 15″ x 13″ (533 x 38 1x 330 mm) |

| Box Type |

Standard or multi – depth box – RSC – 0201 |

| Adhesive Technology | Water-activated (or gummed) tape |

| Tape Width | 3” core width max roll diameter 20” |

| Corrugated Box Layout | Right hand or left hand |

| Installed power | 480V (±10%), 3 Phase + 1 Ground, 60Hz, 10A Air |