A flexible range of cappers that can handle both screw or press-on caps with ease on round or irregular shaped containers. Models are available in 3 heads for low speed applications and fully integrated models, in 4, 6, 8 and 10 head versions for high speeds.

A flexible range of cappers that can handle both screw or press-on caps with ease on round or irregular shaped containers. Models are available in 3 heads for low speed applications and fully integrated models, in 4, 6, 8 and 10 head versions for high speeds.

Now more than ever, the capper for you

Rotary cappers offer a fast tool-less change over for the operators with an easy to navigate touchscreen HMI with product recipe system for ease of adjustment.

The Screw Cap application uses magnetic clutch application as standard for reliable and consistent torque on all caps including child resistant (CRC) and induction sealed closures, with the option of servo torque control on all models.

The 4, 6, 8 and 10 head versions offer a fully integrated solution with caps bowl feeder.

Sustainability

Energy consumption is reduced to a minimum.

Rotary Capper Range Highlights

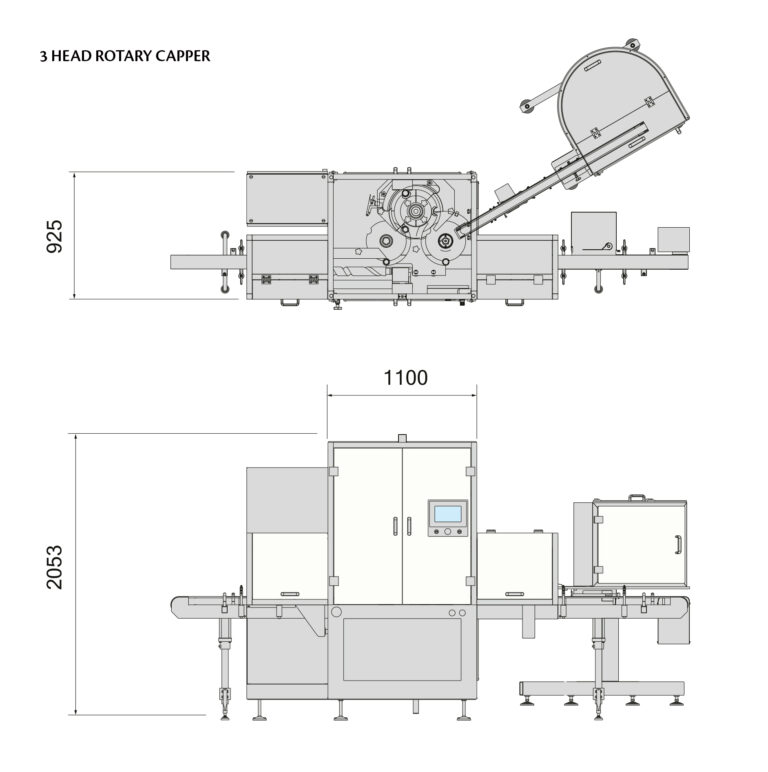

3 Head Rotary Capper

A 3 head rotary capper suitable for speed up to 100 bpm. Machine can handle round or irregular shaped containers, screw or press-on caps.

The cap feeder is mounted on a simple electrically adjusted stand complete with an enclosure around the cap feeder for noise reduction, the capper turret is a powered adjustment to accommodate different height bottles.

Standard screw cap application torque is controlled with magnetic clutches, the machine is available with servo torque control as an option.

- Technical Data

- Machine Layout

| TECHNICAL DATA INTEGRATED ROTARY CAPPER | |

| Production output | Up to 300 bottles/min.* |

| Cap size | 25 mm to 80 mm |

| Bottle diameter range | 25 mm to 120 mm (depending on model) |

| Bottle height range | 40 mm to 240 mm |

*Depending on machine model, container and closure.

| TECHNICAL DATA 3 HEAD ROTARY CAPPER | |||||

| Production output | Up to 100 bottles/min.* | ||||

| Cap size | 25 mm to 80 mm | ||||

| Bottle diameter range | 25 mm to 100 mm (depending on model) | ||||

| Bottle height range | 40 mm to 240 mm | ||||

*Depending on machine model, container and closure.

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website