Designed with an extremely compact layout to save space in the production area, PRECISA combines very high production speeds with an outstanding weighing system in terms of precision.

Designed with an extremely compact layout to save space in the production area, PRECISA combines very high production speeds with an outstanding weighing system in terms of precision.

Inborn precision.

Conceived for 100% weight control and selection of pharmaceutical products packed in hard gelatine and HPMC capsules, PRECISA uses an extremely reliable product transfer system to the weighing cell that minimises vibrations. After weighing, any out-of-weight products are rejected into a specific container.

PRECISA Highlights

- Technical Data

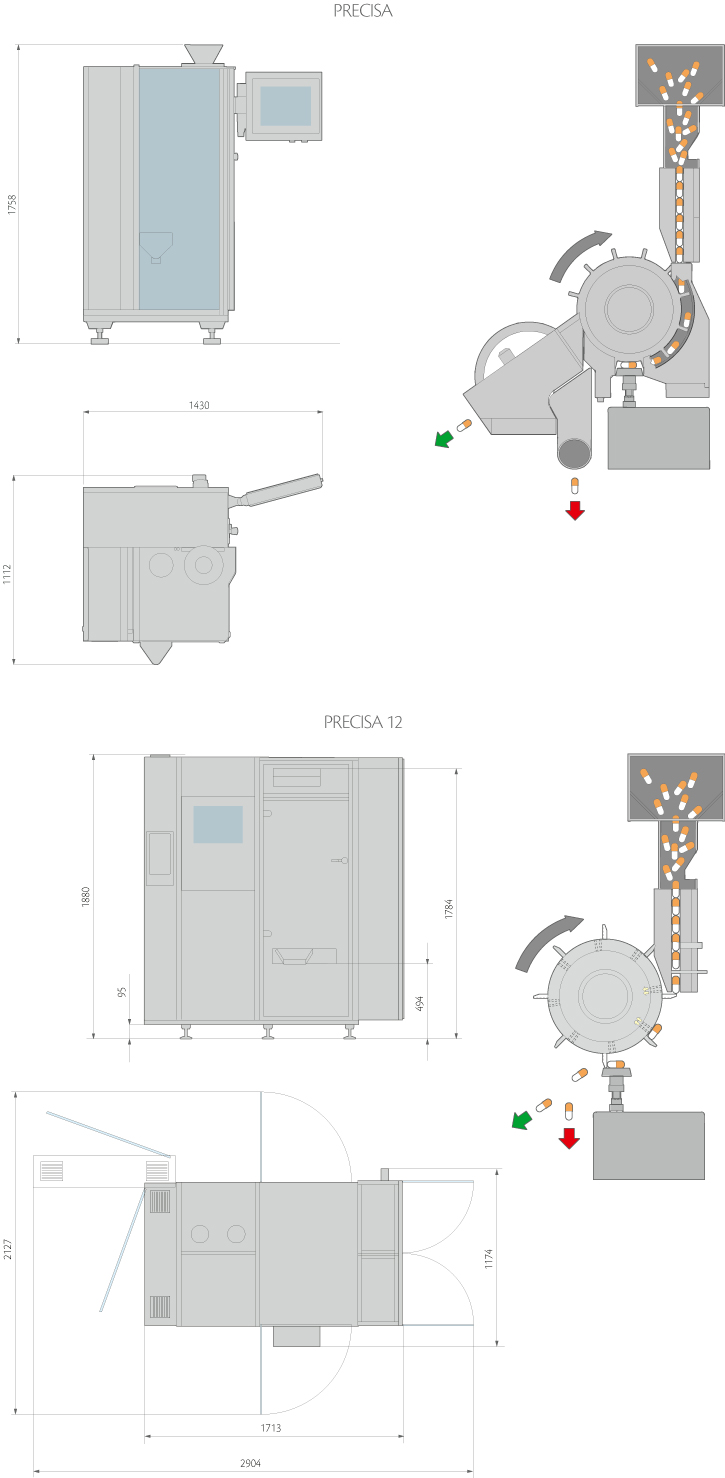

- Machine Layout

| TECHNICAL DATA PRECISA | |||

| Model | 70 | 150 | 230 |

| Maximum output (units/hour) | 70,000 | 150,000 | 230,000 |

| Power supply | AC three phase without neutral | ||

| Installed power (kW) | 2.5 | ||

| Compressed air | 60 dm3/min – 6 Bar | 80 dm3/min – 6 Bar | 100 dm3/min – 6 Bar |

| Weight (kg) | 730 | 750 | 770 |

| Weighing range (mg) | 1 ÷ 2,000 | ||

| Scale accuracy – Standard deviation (mg) | ± 1 | ||

| Feeding hopper capacity (l) | 15 | 20 | 25 |

| Product | 000-5, Supro A-E, DB, DB.AA – Vegicaps: vegetable capsules | ||

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website