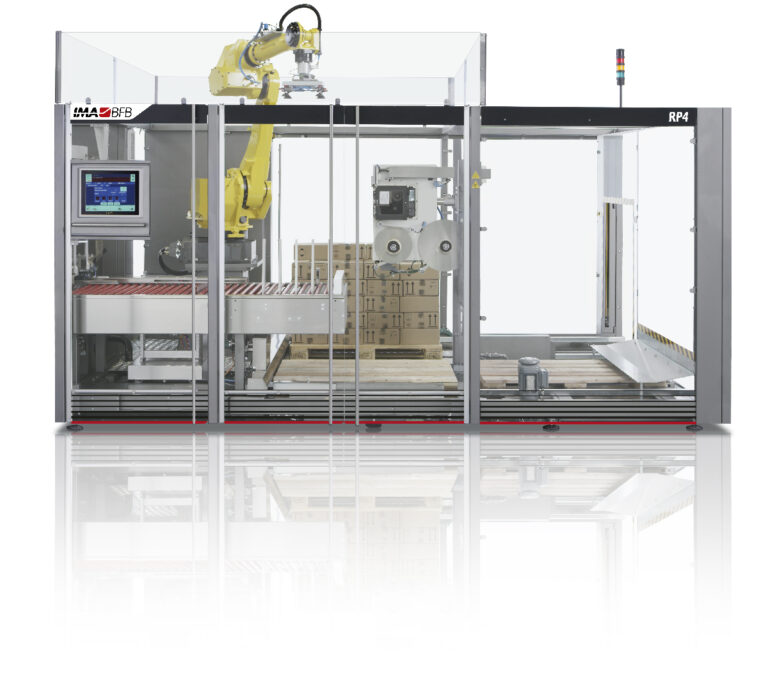

Reduced dimensions of the palletizing section and flexible palletizing options, in line with real market needs; these aspects characterize the RP2/RP4 palletizers, equipped with a 6-axis robot capable of absorbing and working at high speed.

Reduced dimensions of the palletizing section and flexible palletizing options, in line with real market needs; these aspects characterize the RP2/RP4 palletizers, equipped with a 6-axis robot capable of absorbing and working at high speed.

Smart technology for different products and tasks.

Built to deliver maximum productivity and efficiency, these latest-generation palletizing solutions offer exceptional flexibility. Based around a 6-axis robot which picks up incoming cases, ink-jet printing and labelling or weighing them, everything is carried out efficiently.

Cases are then placed on the pallet according to pre-set patterns memorised by the operator. Modular design allows for customization of the palletizing section, whose dimensions are kept to a minimum.

RP2/RP4 palletizers are conceived to be stand alone or easily integrated with case packers thanks to their quick plug-in connection.

RP2/RP4 Highlights

Case Packer - Palletizer integrated versions

RP2/RP4 palletizers are available in different case packer-palletizer integrated versions, tailored to fit any space constraints and autonomy needs seamlessly.

Different palletizing solutions according to the layout space requests

RP2

Automatic palletizer with single palletization station suitable for handling RSC cases or naked bundles, picked up by means of a six axes manipulator. When pallet is complete, the robot places the cases on the buffer area, giving the operator time to unload the full pallet while the machine is working.

RP4

Automatic and extremely flexible palletizer with double palletization stations suitable for handling RSC cases or naked bundles, loaded by means of a six axes manipulator. When the pallet is complete, the automatic pallet transport moves the complete pallet to the waiting area on exit and replaces it with a new one, ready to be loaded. Operator removes the full pallet and the machine keeps on working at the same time.

- Technical Data

- Machine Layout

| TECHNICAL DATA | |||

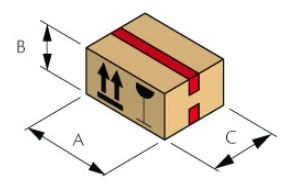

| Product dimensions | A | B | C |

| Min. | 800 | 1200 | 1400 |

| Max. | 1000 | 1200 | 1400 |

| Max. speed | up to 10 cycles/min. | ||

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website