Nowadays drug production requires top flexibility, samely does its processing equipment. Even with large-batch manufacturing, improved automation, broader product handling capabilities and quick changeovers are a must. Here the MULTIFILL F800 comes into play.

Nowadays drug production requires top flexibility, samely does its processing equipment. Even with large-batch manufacturing, improved automation, broader product handling capabilities and quick changeovers are a must. Here the MULTIFILL F800 comes into play.

Scale-up filling perspective

The MULTIFILL F800 Series is our upgrading for big batch production yet keeping the typical all-round features necessary when handling infusions, ophthalmic, oral products, solutions, lotions or nasal sprays.

Its plus is the possibility of being equipped with the latest generation of completely automated CIP/SIP systems.

The series comprises the version as stand-alone filler or that with the closing and/or capping stations as well as the version as stand-alone capper.

MULTIFILL F800 Highlights

- Technical Data

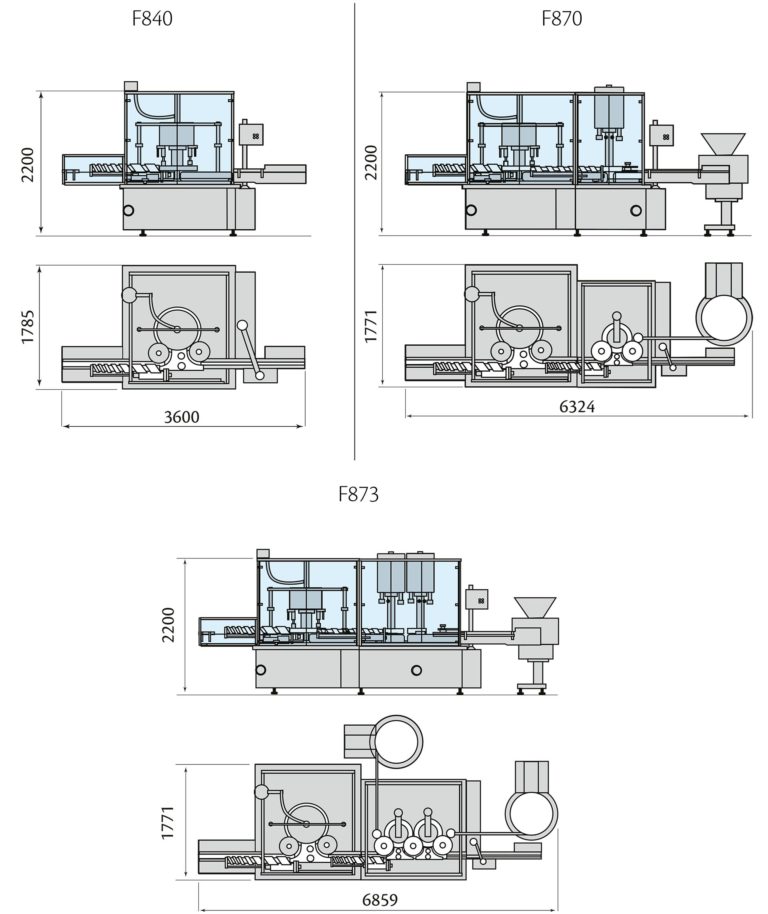

- Machine Layout

| TECHNICAL DATA MULTIFILL F840 | ||

| Model | F840 | |

| Min. | Max. | |

| Bottle diameter (mm) | 16 | 80/95* |

| Bottle height (mm) | 40 | 200 |

| Max. closure diameter (mm) | – | |

| Filling heads | 12/18/24 | |

| Closing heads | – | |

| Out-put (Bottles/h) | Up to 27,000 | |

| Installed power | 5 kW | |

| Voltage | 400 V – 50 Hz | |

| (*) Depending on number of closing heads | ||

| TECHNICAL DATA MULTIFILL F870-873 | ||||

| MODEL | F870 | F873 | ||

| Min. | Max. | Min. | Max. | |

| Bottle diameter (mm) | 16 | 80/95* | 16 | 80/95* |

| Bottle height (mm) | 40 | 200 | 40 | 200 |

| Max. closure diameter (mm) | 60 | 60 | ||

| Filling heads | 12/18/24 | 12/18/24 | ||

| Closing heads | 6/8/10 | 6/8/10 | ||

| Out-put (Bottles/h) | Up to 27,000 | Up to 27,000 | ||

| Installed power | 7 kW | 8 kW | ||

| Voltage | 400 V – 50 Hz | 400 V – 50 Hz | ||

| (*) Depending on number of closing heads | ||||

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website