HYDRA was created after many years of research and development focusing on container decontamination for injectable drugs. Designed according to the cGMP guidelines, the machine features the highest quality standards required by the pharmaceutical industry.

HYDRA was created after many years of research and development focusing on container decontamination for injectable drugs. Designed according to the cGMP guidelines, the machine features the highest quality standards required by the pharmaceutical industry.

The imperative for effective washing.

HYDRA is a linear washing machine for vials and bottles of all sizes, and is suitable for plastic and oval containers upon request.

Containers for sterile preparation are processed in a different way according to the material they are made of and the product to be filled. Tailored according to the nature of containers, HYDRA performs thousands of customised washing cycles.

Sustainability

The use of a recycled water loop in our Hydra series linear washing machines allows for an important WFI consumption saving for customers, while granting high cleaning performance and, when requested, pyrogen reductions.

HYDRA Highlights

- Technical Data

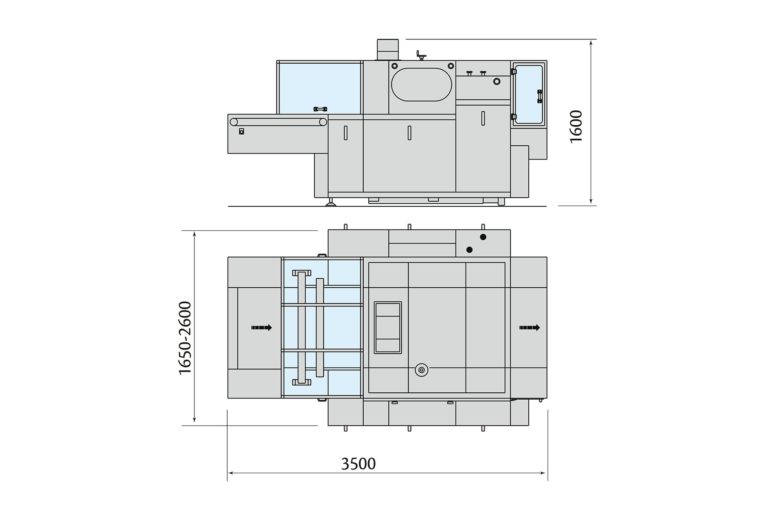

- Machine Layout

| TECHNICAL DATA HYDRA | ||||||

| Machine Model | Production pcs/hour | Number of baskets per row | Typical basket | Size range | ||

| Minimum mouth diameter (mm) | Maximum height (mm) | External diameter (mm) | ||||

| HYDRA 1000 9 A | 10,800 | 9 | A | 7 | 110 | 14-25 |

| HYDRA 1300 17 A | 20,400 | 17 | ||||

| HYDRA 1500 21 A | 25,200 | 21 | ||||

| HYDRA 1800 29 A | 34,800 | 29 | ||||

| HYDRA 2000 33 A | 39,600 | 33 | ||||

| HYDRA 1000 7 B | 8,400 | 7 | B | 7 | 110 | 16-36 |

| HYDRA 1300 13 B | 15,600 | 13 | ||||

| HYDRA 1500 17 B | 20,400 | 17 | ||||

| HYDRA 1800 23 B | 27,600 | 23 | ||||

| HYDRA 1000 6 C | 7,200 | 6 | C | 10 | 110 | 20-52 |

| HYDRA 1300 10 C | 12,000 | 10 | ||||

| HYDRA 1500 13 C | 15,600 | 13 | ||||

| HYDRA 1800 18 C | 21,600 | 18 | ||||

| HYDRA 2000 21 C | 25,200 | 21 | ||||

| HYDRA 2000 21 C-S | 25,200 | 21 | ||||

| HYDRA 1000 5 D | 4,500 | 5 | D | 10 | 180 | 32-66 |

| HYDRA 1300 8 D | 7,200 | 8 | ||||

| HYDRA 1500 10 D | 9,000 | 10 | ||||

| HYDRA 1800 14 D | 12,600 | 14 | ||||

| HYDRA 1000 4 I | 3,600 | 4 | I | 10 | 180 | 50-80 |

| HYDRA 1300 7 I | 6,300 | 7 | ||||

| HYDRA 1500 9 I | 8,100 | 9 | ||||

| HYDRA 1800 11 I | 9,900 | 11 | ||||

| Production data and size ranges refer to standard machines with a single size of washing baskets. Additional container sizes can be processed by replacing the baskets. | ||||||

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website