Syringe, vial and cartridge-based injectables have nowadays evolved into a manageable dosing strategy for a variety of medical conditions. The STERIFILL RS series allows for flexible production methods for injectable pharmaceuticals.

Syringe, vial and cartridge-based injectables have nowadays evolved into a manageable dosing strategy for a variety of medical conditions. The STERIFILL RS series allows for flexible production methods for injectable pharmaceuticals.

Simplifying fill-finish design

As patient safety and dosing accuracy are the main issues concerning injectable administration, IMA Life offers a flexible, reliable small-batch machine for the filling and stoppering of a wide range of Ready-To-Use disposable components. The STERIFILL RS series is specifically designed according to cGMP and FDA regulations and is fit for conventional clean rooms, closed RABS or isolation technology.

STERIFILL RS Highlights

- Technical Data

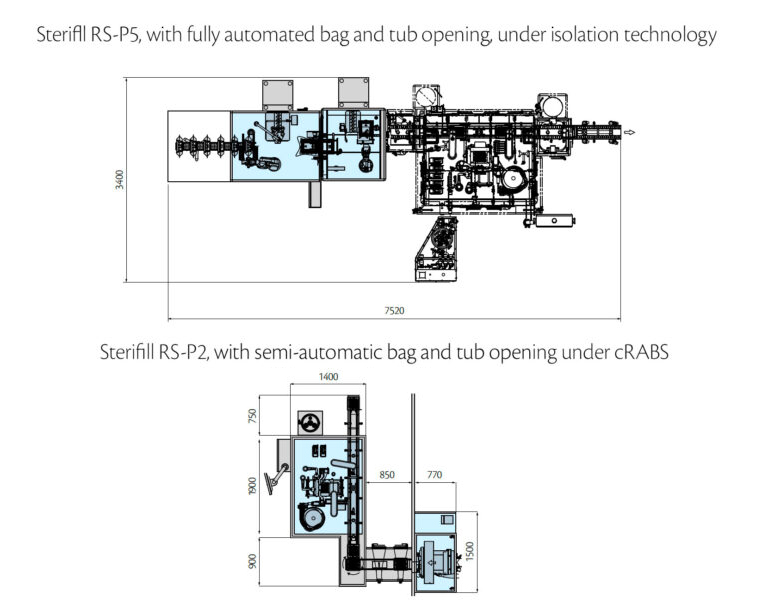

- Machine Layout

| Features | STERIFILL RS | |

| STERIFILL RS P2 | STERIFILL RS P5 | |

| Automation | Fully autometed | Fully autometed |

| Footprint | 2.560 x 1.540 x 2.080 [L x W x H] | 2100 x 1600 x 2.080 [L x W x H] |

| In-process Control | Statistical |

Statistical |

| RTU vial dimensions | Ø 16 – 42,4 mm | Ø 16 – 42,4 mm |

| Output vials | up to 4.400 pcs/h | up to 10.800 pcs/h |

| RTU syringe dimensions | 0.5 – 20 ml | 0.5 – 20 ml |

| Output syringes | up to 4.800 pcs/h | up to 12.000 pcs/h |

| RTU cartridge dimensions | 1 -20 ml | 1 -20 ml |

| Output cartridges | up to 3.100 pcs/h | up to 7.800 pcs/h |

| Suitable for high potent | Yes | Yes |

| Loading from depyrogenration tunnel | No | No |

STERIFILL RS Gallery

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website