Open RABS represent the first solution available in the barrier technology scenario, introducing the concept of product protection.

Closed RABS provide minimal protection during manipulation of mildly potent products.

Open RABS represent the first solution available in the barrier technology scenario, introducing the concept of product protection.

Closed RABS provide minimal protection during manipulation of mildly potent products.

Safety first, for both product and operator.

Open RABS is a simple solution, used extensively in the pharmaceutical sector, to separate the production area from the operator and the external environment. Product protection is only effective if the airflow is active, whereas no protection is offered to the operator when potent compounds are being processed. Easy to install and a cost-effective solution, it is the minimum barrier solution to be used in case of aseptic production environments.

Closed RABS is an evolution of the “Open” solution, providing a minimal degree of operator protection when potent compounds are being processed.

Sustainability

IMA has always been committed to reducing the environmental impact of its equipment, addressing the issue of consumption through design choices, high-efficiency components and optimizing the control dynamics on processing machines such as barrier technologies (Open RABS and Closed RABS).

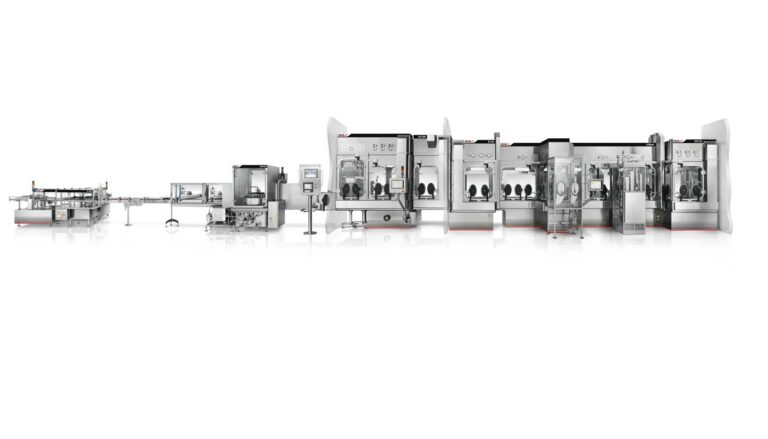

BARRIER TECHNOLOGY: OPEN & CLOSED RABS Highlights

- Machine Layout

BARRIER TECHNOLOGY: OPEN & CLOSED RABS Gallery

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website