Time and ease of use are of the essence with small to medium batch production, but with SMART, IMA expertise has gone even further, combining proven technology with high quality standards and the reliability required for all aseptic filling needs.

Time and ease of use are of the essence with small to medium batch production, but with SMART, IMA expertise has gone even further, combining proven technology with high quality standards and the reliability required for all aseptic filling needs.

Inspired by excellence

SMART is part of the IMA LIFE range of liquid filling, stoppering and capping machines for aseptic environments. Particularly suited to small to medium batch production, configured to handle glass and plastic vials within the SVP (small volume parenterals) filling range. The machine is completely servo-driven and can reach up to 120vpm and contemporarily offer 100% IPC of all vials filled. All types of dosing systems can be installed on the machine. Configuration for LVP (large volume parenterals) available as well.

SMART Highlights

Smart 300 version

SMART 300 is the answer to the increasing demand for even more flexible and versatile liquid processing solutions. Short start-up times, easy changeovers and a high degree of automation are key considerations. Particularly suited to medium to high batch production, configured to handle glass and plastic vials within the SVP (small volume parenterals) filling range, the machine is completely servo-driven and can reach up to 300vpm and contemporarily offer 100% IPC of all vials filled.

SMART 300 can be equipped with all types of dosing systems typical of aseptic operations, and is suitable for installation in cleanrooms, isolators, or other containment solutions, as all materials are compatible with sanitizing agents and suitable for VPHP exposure.

- Technical Data

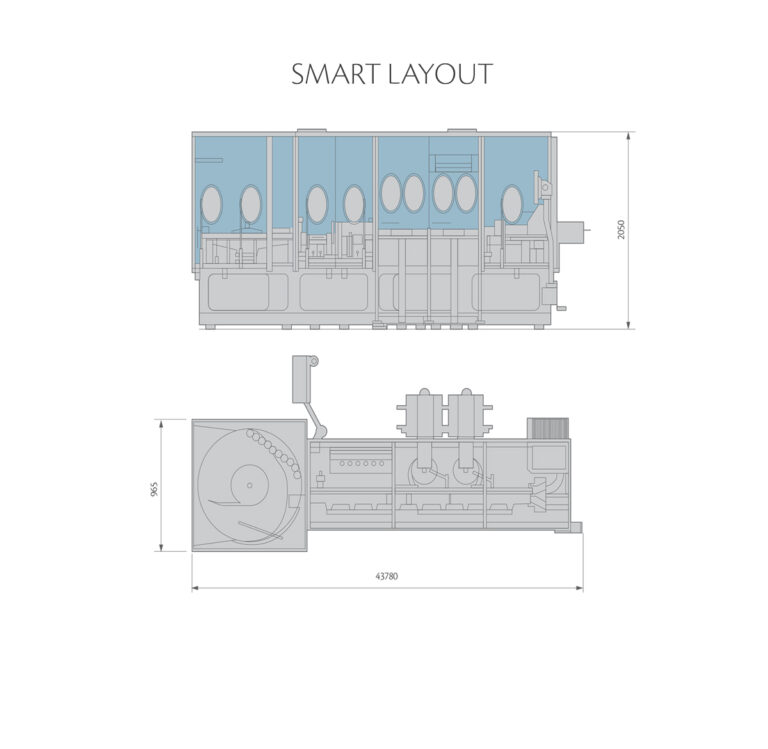

- Machine Layout

| TECHNICAL DATA SMART | ||||

| Model | SVP version | LVP version | ||

| Min. | Max. | Min. | Max. | |

| Vial diameter (mm) | 16* | 54 (up to 36 with double index) | 16* | 88 |

| Vial height (mm) | 35 | 91.4 | 35 | 150 |

| Stopper diameter (mm) | 13 | 20 | 13 | 33 |

| Stopper height (mm) | – | 25 | – | 25 |

| Filling volume | 0.25 | 100 | 0.25 | 500 |

| Filling accuracy with volumetrics pumps |

± 0,5% on nom. dosing volume based on a water based product |

|||

| Output |

Up to 120 vpm with double index configuration |

Up to 75 vpm | ||

| Output with 100% IPC | Max. 120 vpm (double index) | Up to 75 vpm | ||

| Vial transport system | Intermittent motion | |||

| * Diameter smaller than 16 mm (up to 14.75 mm) can also be handled with dedicated size parts | ||||

| TECHNICAL DATA SMART 300 |

||

| Min. | Max. | |

| Vial diameter (mm) | 16* | 54 |

| Vial height (mm) | 35 | 91.4 |

| Stopper diameter (mm) | 13 | 20 |

| Stopper height (mm) | – | 25 |

| Filling Volume | 0.25 | 100 |

| Filling accuracy with volumetric pumps | ±0.5% on nom. dosing volume based on a water based product | |

| Output with 100% IPC | Up to 300 vpm | |

| Vial transport system | Intermittent motion | |

|

*Diameter smaller than 16 mm (up to 14.75 mm) can also be handled with dedicated size parts |

||

SMART Gallery

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website