In the pharmaceutical sector the need to protect the product from contamination due to the presence of personnel or the environment is one of the major drivers for containment. What matters most in aseptic processes is the max. reduction of contamination risk.

In the pharmaceutical sector the need to protect the product from contamination due to the presence of personnel or the environment is one of the major drivers for containment. What matters most in aseptic processes is the max. reduction of contamination risk.

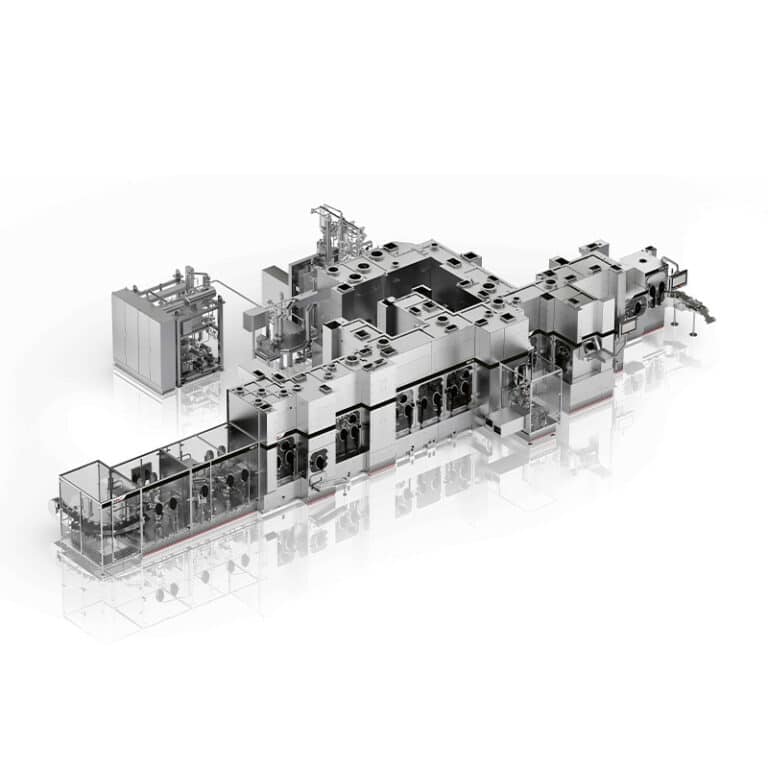

Unique Potential. Integrated Solutions for Processing Excellence.

Combined with automated filling systems for liquids or powders, ISOLATION TECHNOLOGY minimizes the direct human intervention in the processing area and is now a technology that is increasingly and rapidly being implemented by the pharma industry.

Internationally recognized as an expert in advanced aseptic processing applications, IMA Life has gained a wealth of experience in Cross Contamination Control and can offer a solid understanding of the risks associated with the handling of potent and cytotoxic compounds.

Sustainability

IMA has always been committed to reducing the environmental impact of its equipment, addressing the issue of consumption through design choices, high-efficiency components and optimizing the control dynamics on processing machines such as isolators. Several active projects are currently under development to exploit the advantages offered by advanced solutions for data collection and analysis in order to reduce consumption. These functions as part of the project “Sentinel”.

* Specific accelerometric sensors will be installed inside the isolators in order to monitor the ventilation motors and ensure they are functioning correctly.

* In the machines that are part of the fill-finish process (such as filling machines, vial washers, alu-capping machines), specific sensors will be fitted to monitor electrical consumption.

* Additional sets of sensors will be provided for HVAC data collection.

ISOLATION TECHNOLOGY Highlights

Lab Version

The IMA Life range production also includes the ideal solution to perform Sterility Tests, drastically decreasing false positive results.

Designed for QC Labs, pharma production and pharmacies, the IMA Life sterility test isolators are equipped with unidirectional air flow system and guarantee a constant positive pressure gradient between the chambers and the external lab environment.

- Technical Data

TBD

ISOLATION TECHNOLOGY Gallery

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website