No system can obtain the maximum Occupational Exposure Level without washing its valves. TWINVALVE combines IMA Active’s experience in powder handling and washing systems to ensure high containment.

No system can obtain the maximum Occupational Exposure Level without washing its valves. TWINVALVE combines IMA Active’s experience in powder handling and washing systems to ensure high containment.

Safety in containment.

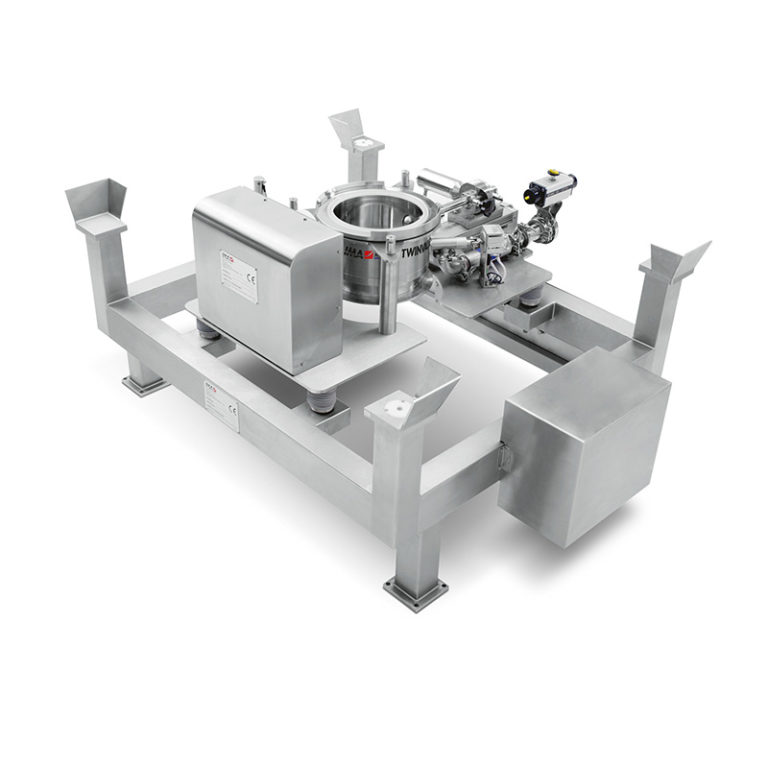

TWINVALVE is a reliable solution to handle powders, granules, tablets and capsules in high containment.

This patented system can be used as a standard butterfly valve on bins and can be easily retrofitted on existing powder handling plants allowing containment during powder transfer.

TWINVALVE Highlights

- Technical Data

| TECHNICAL DATA TWINVALVE | ||||

| Active and passive TwinValve diameter | DN100 | DN150 | DN200 | DN250 |

| Power supply | 400 V – 50 Hz – 3 phase AC (± 10%) | |||

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website