The rising demand for operator safety in aseptic processing, when handling high-potent powdered substances, has boosted the research and the adoption of innovative aseptic dosing technologies replacing the traditional methods.

The rising demand for operator safety in aseptic processing, when handling high-potent powdered substances, has boosted the research and the adoption of innovative aseptic dosing technologies replacing the traditional methods.

Performance enhanced through innovation.

The increasing initiatives taken by the Pharmaceutical regulatory authorities to encourage safe, secure and restricted human intervention in aseptic environments are expected to boost the adoption of new powder-filling technologies over the next few years.

As safety, cleanliness and high containment requirements are the key issues to be addressed when facing such a technological challenge, at IMA Life we have developed and implemented an innovative powder-processing concept.

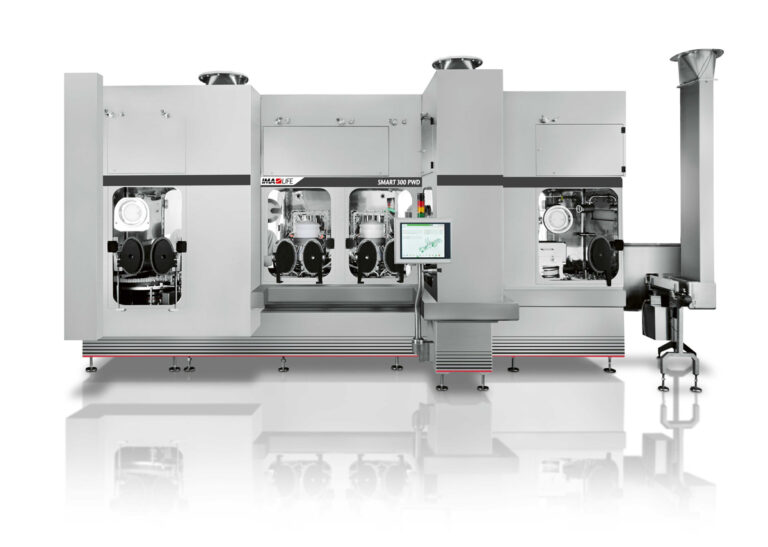

The new SMART 300 PWD AUGER rises to the challenge in high-potent drug processing and ensures accurate decontamination control to avoid risk of residual toxicity and cross-contamination between batches. The machine processes at superior speeds of up to 300 pcs/minute and simultaneously doses two different types of pharmaceutical powders inside the same vial with single 100% check-weighing.

Sustainability

Drug manufacturers are primarily focused on safety, secondly on sustainability. Nevertheless, these two goals need not be mutually exclusive. IMA has therefore taken action to develop several projects to this regard.

IMA powder auger dosing systems are prearranged to perform Cleaning-In-Place (CIP) and Sterilisation-In-Place (SIP) procedures. This enables a reduction in the number of operating procedures for system commissioning and can also reduce the Single-Use packaging usually required for handling parts normally sterilised in autoclaves. In addition to the reduction in disposable materials, the process is more energy efficient than a traditional Cleaning “out of place” (COP) and consequent autoclave sterilisation.

Working aseptically, the system allows for the dosing of powder drugs, thus avoiding the use of Single-Use packaging. Auger technology is the main principle to have inspired the existing development of the new IMA Life powder dosing machine, SMART 300 PWD AUGER, performing at up to 300 pcs/min. This helps minimise the use of plastic, disposable components.

Application

For the Sterile Pharma market, for the aseptic powder dosing sector, including high potent drugs, this technology is applied to the SMART PWD AUGER series.

SMART 300 PWD AUGER Highlights

SMART PWD AUGER VERSION

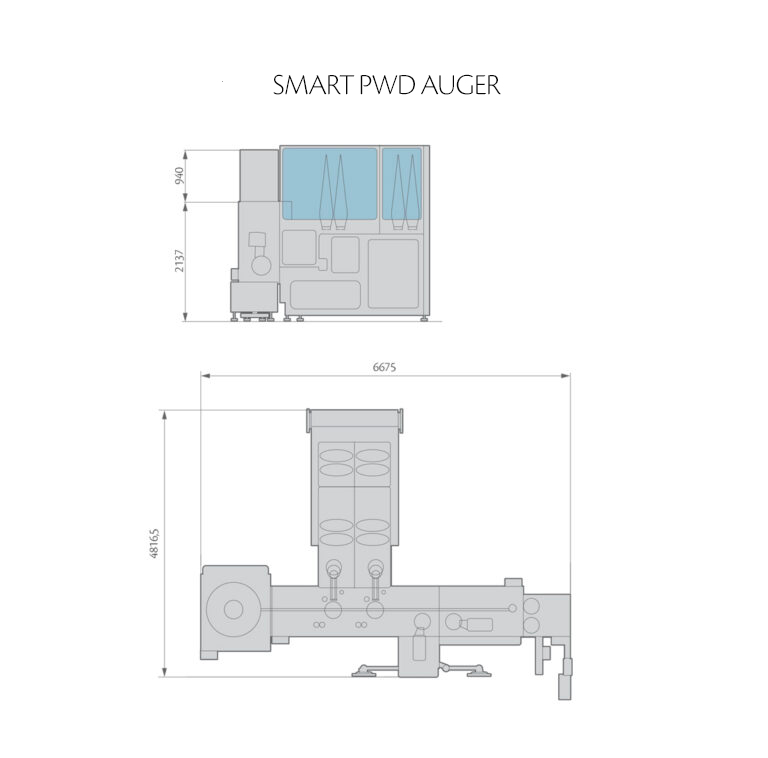

Smart PWD Auger

SMART PWD AUGER is designed for medium-to-small-scale production, for the dosage of a single blend of powder (version with single/double dosing unit/s) or two different powders into the same vial. In this case, the machine is configured with two single or double auger dosing units, each dedicated to one product.

Stoppering and capping functions included as well.

Suitable to be installed under oRABS or cRABS or isolation technology.

Machine performance of up to 90 pcs/min with 100% check-weighing.

- Technical Data

- Machine Layout

| SMART 300 PWD AUGER TECHNICAL DATA | ||

| Min. | Max. | |

| Vial diameter | 22 | 54 |

| Vial height | 35 | 115 |

| Stopper diameter | 20 | 33 |

| Filling volume | From 50 mg | |

| Output with 100% IPC * |

Up to 300 ppm (with 6 auger dosing units) Up to 150 ppm (with 3 auger dosing units) Up to 150 ppm (split-fill configuration) |

|

| Transport system | Intermittent motion | |

| Standard voltage | 400 V, 50 Hz, 3ph + N + G | |

| Installed power | 19 kW | |

| SMART PWD AUGER SERIES DATA | ||

| Min. | Max. | |

| Vial diameter | 22 | 54 |

| Vial height | 35 | 115 |

| Stopper diameter | 20 | 33 |

| Filling volume | From 50 mg | |

| Output with 100% IPC * |

Up to 90 vpm (double index) Up to 50 vpm (single index) |

|

| Transport system | Intermittent motion | |

| Standard voltage | 400 V, 50 Hz, 3ph + N + G | |

| Installed power | 19 kW | |

*According to filling volume and product type.

SMART 300 PWD AUGER Gallery

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website