The COTTONER Series utilizes an inverted “U” technique of inserting cushioning material into containers maintaining the product integrity for a cleaner packing process which eliminates stray wisps of cotton.

The COTTONER Series utilizes an inverted “U” technique of inserting cushioning material into containers maintaining the product integrity for a cleaner packing process which eliminates stray wisps of cotton.

The perfect handling for your cotton

The COTTONER Series is fully automatic cGMP and user friendly machine. It is equipped with specially angled shears that cut coil cleanly and uniformly each time to remove any potential for tails or wisps.

Moreover, cotton inspection systems are available to detect high or missing cotton, either as an integrated add-on to an existing machine, or as a separate stand-alone inspection station.

Sustainability

Energy consumption is reduced to a minimum.

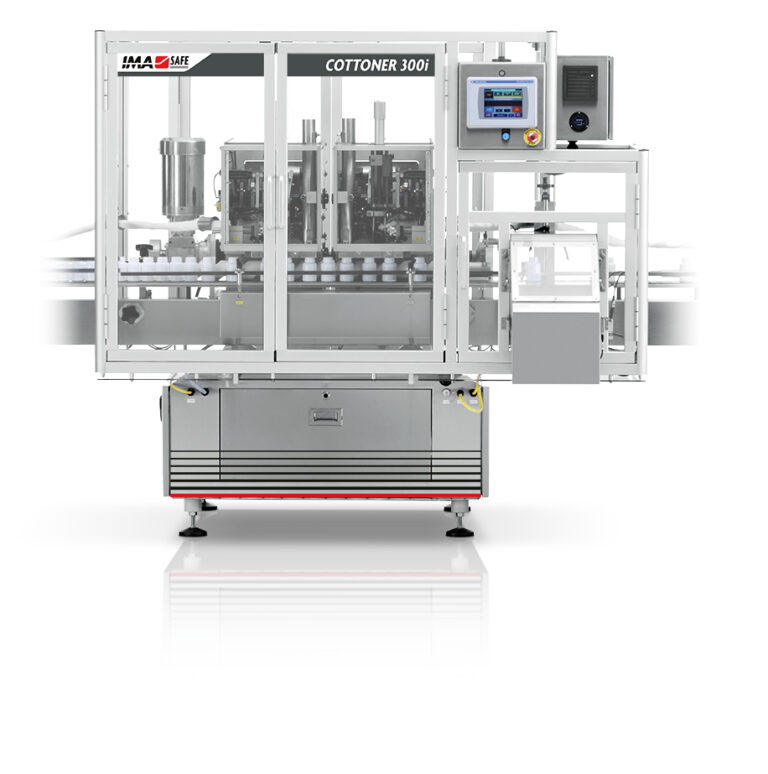

COTTONER Highlights

- Technical Data

- Machine Layout

| TECHNICAL DATA COTTONER | ||

| COTTONER 150 | COTTONER 300 | |

| Production output | Up to 150 bottles/min. | Up to 300 bottles/min. |

| Bottle diameter | 38-115 mm | 38-115 mm |

| Bottle height | 41-228 mm | 41-228 mm |