Vial filling machines and processing solutions

One of the major challenges for IMA Life is to implement the latest technologies in aseptic vial filling, whilst ensuring compliance with the highest cGMP’s standards in filling accuracy.

From the decontamination of containers, through depyrogenation, up to liquid vial filling or powder vial filling, closing and capping operations, all our efforts are targeted to avoid any possible contamination risk while delivering the highest performance.

The very compact and versatile design of IMA Life injectable vial filling machines, allows for suitable integration under isolator or different containment solutions without changing the basic machine configuration and minimising human intervention in the processing area.

The external washers complete the range of vial filling line and fit the market’s increasing demand for decontamination solutions to remove product particles from the outside of vials.

Our expertise

1. Washing and Depyrogenating

The decontamination technology is a crucial path in drug processing lines, that is why container washing before and after the filling phase is so important.

Over 50 years of experience in the production of equipment for vial washing combined with constant commitment to innovation, make IMA Life a world leader in the field. The equipment range comes complete with the external vial washers which respond to the increasing demand of filled and capped vial decontamination.

The depyrogenating tunnels installed after the vial washing machines are designed to satisfy any production requirement and are suitable for any kind of application: they come both in the standard and in the dry heat sterilisation version, and can be easily integrated into lines designed to handle high-toxic compounds and/or in lines with isolators.

2. Aseptic Filling and Stoppering

IMA Life machines for aseptic filling are distinguished by their rigorous detail design and are the result of careful research in fluid dynamics, to guarantee maximum product protection of all aseptic filling environments (such as traditional clean rooms, isolation technology or other containment solutions).

Compact and ergonomic design ensures great flexibility for all types of layout. Statistical and 100% IPC control of filled weight along with very advanced CIP/SIP units allow the machines to reach a very high standard in product quality. Aseptic processing of vials is certainly one of the most critical activities in primary drug packaging.

3. Capping

The primary purpose of vial capping is to secure the closure in place, ensuring the integrity of the pharmaceutical product. Capping also serves to provide a tamper-evident seal, assuring end-users that the product has not been opened or compromised. This process can be performed under controlled and sterile conditions, either downstream or by direct integration in the machine frame as a module.

IMA Life vial capping machines feature a broad range of application capabilities: from traditional aluminium caps, with or without flip-off, to the most sophisticated caps such as add-vantage, bio-set and monovial closures.

4. Labelling

The IMA Life production range includes a vast array of vial labelling machines, which can be supplied in stand-alone version or as an integral part of complete packaging lines.

The Sensitive and Sensitive Roto series of vial labellers can apply any kind of self-adhesive labels (wrap-around, front, rear or both sides) and, thanks to the configuration flexibility of the operative groups, can fit overprinting devices and camera vision systems to read and check data.

These machines feature different solutions to align the packaging of pharmaceutical products to emerging requirements in terms of Track & Trace of the final products.

Our Machines Portfolio

Array

(

[cover_macro] => 29005

[cover_name_type] => txt

[cover_name] => VEGA

[cover_descriptor] => Rotary Vial Washers

[cover_focus_on] => 1

[news] =>

[thumbnail] => 29006

[tag_line] => Small Volume Injectable’s star

[overview] => Being the majority of SVIs aseptically processed (i.e. end containers not sterilized), essential becomes to rigorously adhere to cGMP standards as far as sterility assurance is concerned – FDA and EMA guidelines.

VEGA washing flow follows said directions in terms of structural design, connections, and adaptability of the decontamination process.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => download brochure

[icon] => description

[link] => 330

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

)

[sustainability] =>

The use of a recycled water loop in our Vega series rotary washing machines allows for an important WFI consumption saving for customers, while granting high cleaning performance and, when requested, pyrogen reductions.

[highlights_on] => 1

[focus_on] => 1

[technical_data] => | TECHNICAL DATA VEGA SERIES | ||||

| Model | VEGA 2 | VEGA 4 | VEGA 6 | VEGA 8 |

| Version with 12/24 gripper units with 4/6 pincers | ||||

| Gripper units |

12 gripper units with 4 pincers (total 48 pincers) |

12 Gripper units with 4 pincers (total 48 pincers) | 12 Gripper units with 6 pincers (total 72 pincers) | 24 Gripper units with 4 pincers (total 96 pincers) |

| Ampoules diameter (mm) |

– |

Min. 10.75 Max. 22.50 |

Min. 10.75 Max. 17.75 |

Min. 10.75 Max. 17.75 |

| Cartridges | – | All sizes | All sizes | All sizes |

| Vials max. external diameter (mm) | 32 | 42.5 | 32 | 32 |

| Vials max. height (mm) | 58 | 75 | 60 | 60 |

| Production max. pcs/hour | 9,000 | 12,000 | 18,000 | 24,000 |

| Version with 12/24 gripper units with 2/3 pincers | ||||

| Gripper units | 12 Gripper units with 2 pincers (total 24 pincers) | 12 Gripper units with 2 pincers (total 24 pincers) | 12 Gripper units with 3 pincers (tatal 36 pincers) | 24 Gripper units with 2 pincers (tatal 48 pincers) |

| Ampoules diameter (mm) |

– |

Min. 10.75

Max. 22.50 |

Min. 10.75

Max. 22.50 |

Min. 10.75

Max. 22.50 |

| Cartridges | – | All sizes | All sizes | All sizes |

| Vials max. external diameter (mm) | 52 | 52 | 52 | 52 |

| Vials max. height (mm) | 105 | 95 | 95 | 95 |

| Output up to (pcs/hour) | 4,500 | 6,000 | 9,000 | 12,000 |

Containers coming in contact with parenteral preparations must be rendered sterile and non-pyrogenic, process resulting particularly successful with the VEGA Series, where the easy configurable washing sequence enhances the efficiency of the cleaning procedure

[buttons_on] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 330 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 330 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Low maintenance impact ) [1] => Array ( [highlight] => Ultrasonic pre-wash connection with de-packing machines or turntables ) [2] => Array ( [highlight] => Completely drainable washing circuit ) [3] => Array ( [highlight] => Steaming in place of washing circuit ) [4] => Array ( [highlight] => Easy and full access to the machine from both sides, no hidden areas ) [5] => Array ( [highlight] => Washing process completely validatable ) [6] => Array ( [highlight] => Possibility to handle a wide range of containers (ampoules, vials, cartridges) ) [7] => Array ( [highlight] => Compact version for low speed production lines, with upstream integrated rotary table ) ) [focus] => Array ( [image] => 29007 [content] => The decontamination cycle varies with the condition of the containers to be cleaned, therefore, besides the integration of additional media, the VEGA washer is suitable to include siliconizing stations and SIP process. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 330 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) ) [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => marketing.life.it@ima.it [no_index] => [versions_on] => [addon_on] => [technologies] => Array ( [0] => 35 [1] => 70 ) [tile_description] => [tile_speed] => Up to 400 vials/minute [line_step] => Array ( [0] => 9 ) [aseptic] => aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 617 [9] => 621 [10] => 620 [11] => 619 [12] => 2624 ) [market_packs] => Array ( [0] => 3945 [1] => 2005 ) [market_packs_specs] => Array ( ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [thread_tag] => [output_on] => [seo_image] => [seo_title] => VEGA: Rotary Vial Washers [seo_description] => The easy configurable washing sequence of the VEGA Series enhances the efficiency of the cleaning procedure. VEGA: Rotary Vial Washers. [embed_iframe] => [form_price] => [body_class] => [no_follow] => )

Containers coming in contact with parenteral preparations must be rendered sterile and non-pyrogenic, process resulting particularly successful with the VEGA Series, where the easy configurable washing sequence enhances the efficiency of the cleaning procedure

Array

(

[cover_macro] => 28996

[cover_name_type] => txt

[cover_name] => HYDRA

[cover_descriptor] => Linear vial washer

[cover_focus_on] => 1

[news] =>

[thumbnail] => 28997

[tag_line] => The imperative for effective washing.

[overview] => HYDRA is a linear washing machine for vials and bottles of all sizes, and is suitable for plastic and oval containers upon request.

Containers for sterile preparation are processed in a different way according to the material they are made of and the product to be filled. Tailored according to the nature of containers, HYDRA performs thousands of customised washing cycles.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => download brochure

[icon] => description

[link] => 321

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

)

[sustainability] =>

The use of a recycled water loop in our Hydra series linear washing machines allows for an important WFI consumption saving for customers, while granting high cleaning performance and, when requested, pyrogen reductions.

[highlights_on] => 1

[focus_on] => 1

[technical_data] => | TECHNICAL DATA HYDRA | ||||||

| Machine Model | Production pcs/hour | Number of baskets per row | Typical basket | Size range | ||

| Minimum mouth diameter (mm) | Maximum height (mm) | External diameter (mm) | ||||

| HYDRA 1000 9 A | 10,800 | 9 | A | 7 | 110 | 14-25 |

| HYDRA 1300 17 A | 20,400 | 17 | ||||

| HYDRA 1500 21 A | 25,200 | 21 | ||||

| HYDRA 1800 29 A | 34,800 | 29 | ||||

| HYDRA 2000 33 A | 39,600 | 33 | ||||

| HYDRA 1000 7 B | 8,400 | 7 | B | 7 | 110 | 16-36 |

| HYDRA 1300 13 B | 15,600 | 13 | ||||

| HYDRA 1500 17 B | 20,400 | 17 | ||||

| HYDRA 1800 23 B | 27,600 | 23 | ||||

| HYDRA 1000 6 C | 7,200 | 6 | C | 10 | 110 | 20-52 |

| HYDRA 1300 10 C | 12,000 | 10 | ||||

| HYDRA 1500 13 C | 15,600 | 13 | ||||

| HYDRA 1800 18 C | 21,600 | 18 | ||||

| HYDRA 2000 21 C | 25,200 | 21 | ||||

| HYDRA 2000 21 C-S | 25,200 | 21 | ||||

| HYDRA 1000 5 D | 4,500 | 5 | D | 10 | 180 | 32-66 |

| HYDRA 1300 8 D | 7,200 | 8 | ||||

| HYDRA 1500 10 D | 9,000 | 10 | ||||

| HYDRA 1800 14 D | 12,600 | 14 | ||||

| HYDRA 1000 4 I | 3,600 | 4 | I | 10 | 180 | 50-80 |

| HYDRA 1300 7 I | 6,300 | 7 | ||||

| HYDRA 1500 9 I | 8,100 | 9 | ||||

| HYDRA 1800 11 I | 9,900 | 11 | ||||

| Production data and size ranges refer to standard machines with a single size of washing baskets. Additional container sizes can be processed by replacing the baskets. | ||||||

HYDRA was created after many years of research and development focusing on container decontamination for injectable drugs. Designed according to the cGMP guidelines, the machine features the highest quality standards required by the pharmaceutical industry.

[buttons_on] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 321 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 321 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Special upper guide rail for containers allowing for washing at high pressure without vibration or movement. ) [1] => Array ( [highlight] => Complete segregation between process, circuit and mechanical areas to avoid cross contamination. ) [2] => Array ( [highlight] => No vial breakages thanks to a system of levers, incorporating spring-loaded telescopic overload, driving machine movements, including raising of the washing needles. ) [3] => Array ( [highlight] => No dripping of contaminated water from the baskets onto the vials thanks to the positive discharge of containers from the basket. ) [4] => Array ( [highlight] => Vacuum-assisted positive unloading for unstable containers or in case of high speed. ) [5] => Array ( [highlight] => Possible direct connection to automatic container feeding systems (depacking of inspection machine) or to feeding conveyors. ) [6] => Array ( [highlight] => Ultrasonic bath unit for containers available. ) ) [focus] => Array ( [image] => 28998 [content] => Injectable products are sterile when free of any living microorganism, pathogenic or not, which are capable of reproduction. HYDRA can achieve a 3-log endotoxin reduction for terminal sterilisation applications. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 321 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) ) [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => marketing.life.it@ima.it [no_index] => [versions_on] => [addon_on] => [technologies] => Array ( [0] => 35 [1] => 70 ) [tile_description] => [tile_speed] => Up to 660 vials/minute [line_step] => Array ( [0] => 9 ) [aseptic] => both [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 617 [9] => 621 [10] => 620 [11] => 619 [12] => 2624 ) [market_packs] => Array ( [0] => 3945 [1] => 2171 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [market_packs_specs] => Array ( ) [thread_tag] => [output_on] => [seo_image] => [seo_title] => HYDRA: Linear Vial Washers [seo_description] => HYDRA was created after many years of research and development focusing on container decontamination for injectable drugs. HYDRA: Linear Vial Washers [embed_iframe] => [form_price] => [no_follow] => [body_class] => )

HYDRA was created after many years of research and development focusing on container decontamination for injectable drugs. Designed according to the cGMP guidelines, the machine features the highest quality standards required by the pharmaceutical industry.

Array

(

[cover_macro] => 15908

[cover_name_type] => txt

[cover_name] => HYDRA 100/300/400

[cover_descriptor] => Vial external washer

[cover_focus_on] => 1

[cover_focus_content] => Conceived for outer surface decontamination of pharmaceutical containers after the filling process, Hydra 100/300/400 minimizes the legal risk of long-term exposure for packaging operators and medical personnel handling cytotoxic products or potent compounds.

[buttons_on] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Watch the webinars series

[icon] => play_circle_outline

[internal_link] => 1

[link] =>

[link_page] => https://ima.it/pharma/brands/ima-life/hydra400-webinar-series/

[tab] =>

)

)

[cover_focus_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Watch the webinars series

[icon] => play_circle_outline

[internal_link] => 1

[link] =>

[link_page] => https://ima.it/pharma/brands/ima-life/hydra400-webinar-series/

[tab] =>

)

)

)

[news] =>

[thumbnail] => 29022

[tag_line] => A step forward in decontamination technology

[overview] => The rotary external washers Hydra 100/300/400 have been designed to perform the decontamination of external surfaces of glass or plastic cylindrical containers (bottles, vials, etc.) potentially contaminated by the product during the filling process.

The decontamination process can be carried out using water or by adding to the water a dedicated washing media in case of toxic products, in order to avoid any risk of contamination.

Ideal for completion of aseptic processing lines, Hydra 100/300/400 are the perfect solution for any output.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => download brochure

[icon] => description

[link] => 367

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

)

[sustainability] =>

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Rounded corners inside the processing area improving water drainage and machine cleanability.

)

[1] => Array

(

[highlight] => Complete separation between process and mechanical areas by means of special seals.

)

[2] => Array

(

[highlight] => Segregated washing circuits.

)

[3] => Array

(

[highlight] => Reduced machine footprint to save space in the production area: drives and washing circuit housed in the machine frame.

)

[4] => Array

(

[highlight] => Easy access to all machine areas.

)

[5] => Array

(

[highlight] => Simple mechanical drives with low maintenance time impact.

)

[6] => Array

(

[highlight] => Machines can be pre-arranged with RABS (Restricted Access Barrier System) or installed within an isolator enclosure.

)

[7] => Array

(

[highlight] => Siemens PLC and HMI ensuring repeatability and safety of the whole process.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 15911

[content] => The water supply system has been designed to avoid cross contamination between containers and machine. The steady water flow ensures the separation of the contamination agent and its dragging towards the drainage point.

[buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[technical_data] => | TECHNICAL DATA | |||

| HYDRA 100 | HYDRA 300 | HYDRA 400 | |

| Washing stations (up to) | 4 | 6 | 8 |

| Vial range Ø (mm) | 14.75 – 52 | 14.75 – 66 | 14 – 54 |

| Vial height (mm) | 34.5 – 110 | 34.5 – 136 | 34 – 110 |

| Output (vials minute) | 60 with vials Ø 52 mm 150 with max. vial Ø 24 mm | 150 with vials Ø 32-60 mm 300 with vial Ø 32 mm | 200 with vials Ø 33-54 mm 400 with vial Ø 32 mm |

| Water consumption (litres/hour) | 400 – 600 | 600 – 900 | 900 – 1200 |

| Water pressure (bar) | 2.5 – 4 | ||

| Compressed air consumption (litres/minute) | 3000 | 3100 | 3200 |

| Compressed air pressure (bar) | 6 | ||

| Standard voltage | 400 V – 50 Hz | ||

| Installed power (kW) | 5 | ||

| Weight (kg) | 1200 | 1600 | 2000 |

[layouts] => Array ( [0] => Array ( [image] => 15943 ) [1] => Array ( [image] => 15944 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 28966 [id] => 28966 [title] => DECONTAMINATION TECHNOLOGY_EN [filename] => DECONTAMINATION-TECHNOLOGY_EN.pdf [filesize] => 1781214 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2024/04/DECONTAMINATION-TECHNOLOGY_EN.pdf [link] => https://ima.it/pharma/machine/decontamination-technology/decontamination-technology_en/ [alt] => [author] => 16 [description] => [caption] => [name] => decontamination-technology_en [status] => inherit [uploaded_to] => 366 [date] => 2024-04-24 07:23:17 [modified] => 2024-04-24 07:23:33 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => 6LOGIMG7h9E [gallery] => Array ( [0] => Array ( [image] => 15912 [description] => HYDRA 100 work area ) [1] => Array ( [image] => 15913 [description] => Gripper detail ) [2] => Array ( [image] => 15914 [description] => Vial washing ) [3] => Array ( [image] => 15915 [description] => Vial washing ) [4] => Array ( [image] => 15918 [description] => Drying blade detail ) [5] => Array ( [image] => 15919 [description] => Shaped drying blade ) [6] => Array ( [image] => 15920 [description] => Hydra 400 washing carrousel ) ) [related] => no [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => marketing.life.it@ima.it [no_index] => [versions_on] => [addon_on] => [technologies] => Array ( [0] => 35 [1] => 71 ) [tile_description] => [tile_speed] => Up to 600 vials/minute [line_step] => Array ( [0] => 9 ) [aseptic] => aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 617 [9] => 621 [10] => 620 [11] => 619 [12] => 2624 ) [market_packs] => Array ( [0] => 3945 [1] => 2171 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [thread_tag] => [market_packs_specs] => Array ( ) [output_on] => [no_follow] => [seo_image] => 16963 [seo_title] => HYDRA 100/300/400 • Vial External Washers [seo_description] => Conceived for outer surface decontamination of pharmaceutical containers after the filling process, Hydra 100/300/400 minimizes the legal risk of long [embed_iframe] => [form_price] => [body_class] => [view_default] => 1 )

Conceived for outer surface decontamination of pharmaceutical containers after the filling process, Hydra 100/300/400 minimizes the legal risk of long-term exposure for packaging operators and medical personnel handling cytotoxic products or potent compounds.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[contact] => marketing.life.it@ima.it

[no_index] =>

[tile_description] =>

[tile_speed] =>

[cover_macro] => 29015

[cover_name_type] => txt

[cover_name] => BLUE GALAXY

[cover_descriptor] => Depyrogenating Tunnels

[cover_focus_on] => 1

[news] =>

[thumbnail] => 29016

[tag_line] => High technology for the safety of sterilization process

[overview] => BLUE GALAXY is a series of de-pyrogenating tunnels designed to be incorporated in production lines that require continuous de-pyrogenation by means of dry heat.

The wide range available responds adequately to any production requirement; top-level design technology allows use in any kind of application; easily integrated intolines handling highly toxic compounds or equipped with isolators.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

The use of thyristors TRIAC to drive and regulate the current absorption to the heating batteries is the preferred application in IMA Blue Galaxy sterilisation tunnels to keep the process under control, thus reducing electrical energy consumption.

The air recirculation in heating and cooling zones encourages the heat exchange between the system and the glass containers, reducing energy consumption.

Night mode with reduced fan speed and temperature in hot zone.

All tunnels are equipped with delayed start up/run modes to empty functions in the hot and cooling zones in order to get the required temperatures during start/end batch.

By the automatic air velocity control in heating zones, the fan speed is automatically increased when air temperature increases, to compensate for the reduced air density.

[highlights_on] => 1

[focus_on] => 1

[versions_on] =>

[addon_on] =>

[technical_data] => | BLUE GALAXY SERIES TECHNICAL DATA | |||||||||

| Model | 550 FL | 870 FL | 870 FLS | 1.250 FL | 1.250 FLS | 1.250 2 FLS | 1.250 3 FLS | ||

| X (mm) | 550 | 870 | 870 | 1.250 | 1.250 | 1.250 | 1.250 | ||

| W (mm) | 1.705 | 2.025 | 2.025 | 2.410 | 2.410 | 2.410 | 2.410 | ||

| L (mm) | 2.980 | 2.980 | 3.810 | 4.410 | 7.025 | 8.245 | 9.940 | ||

| H (mm) | 2.980 | 2.980 | 3.075 | 3.175 | 3.175 | 3.175 | 3.175 | ||

| Upon request reduced height (mm) | 2.700 | 2.700 | 2.760 | 2.760 | 2.760 | 2.760 | 2.760 | ||

| Power (kW) | 39 | 50 | 60 | 70 | 145 | 149 | 214 | ||

| DRY-HEAT VERSION (APPLICABLE ON ALL A.M. MODELS) | |||||||

| Model | 550 FL | 870 FL | 870 FLS | 1.250 FL | 1.250 FLS | 1.250 2 FLS | 1.250 3 FLS |

| Power (kW) | 63 | 74 | 90 | 110 | 225 | 229 | 334 |

| L (mm) | LENGHT =+70 mm | ||||||

| Reduced height (mm) | NOT AVAILABLE | ||||||

The above mentioned heights are referred to a vial working flow eight of 950 mm.

As far as the production capacities of the different vials sizes are concerned, ask for the thermic cycles simulation.

All pharmacopoeia indicate Escherichia Coli type 5 as the endotoxin to be used for checking that a de-pyrogenation process is accomplished correctly. A de-pyrogenation process has to initially guarantee at least a log 3 reduction of endotoxins.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [highlights] => Array ( [0] => Array ( [highlight] => Completely automatic unloading procedure. ) [1] => Array ( [highlight] => The system for air balancing, pressurisation and heating/cooling enables effective thermal treatment of glass containers. ) [2] => Array ( [highlight] => Control and automation system set-up with different PLC or PC types. ) [3] => Array ( [highlight] => Dry-heat/VHP sterilisation of cooling zone (IMA Life patent pending). ) [4] => Array ( [highlight] => Reduction of endotoxins >log 3. ) ) [focus] => Array ( [image] => 29014 [content] => PROCESS REPEATABILITY: by keeping the hot zone in overpressure, we guarantee the exposure time and lethality parameters to be exactly the same. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [seo_image] => [seo_title] => BLUE GALAXY: Depyrogenating Tunnels [seo_description] => BLUE GALAXY is a series of de-pyrogenating tunnels designed to be incorporated in production lines with continuous de-pyrogenation by dry heat. [embed_iframe] => [form_price] => [no_follow] => [body_class] => )

All pharmacopoeia indicate Escherichia Coli type 5 as the endotoxin to be used for checking that a de-pyrogenation process is accomplished correctly. A de-pyrogenation process has to initially guarantee at least a log 3 reduction of endotoxins.

Array

(

[cover_macro] => 2652

[cover_name_type] => txt

[cover_name] => ALU

[cover_descriptor] => Capping machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 29025

[tag_line] => Caps the best, caps the rest!

[overview] => ALU is a rotary capping machine reaching medium-high speeds and is particularly suited to sealing aseptic products. Its design criteria, such as limited dimensions, ergonomics, reduced particle generation and the geometry facilitating unidirectional laminar flow all allow the machine to be installed in classified areas, in conventional sterile rooms or under isolation technology.

Depending on customer requirements, the machine is available in two different models and features a broad range of application capabilities: from traditional aluminium caps, with or without flip-off, to the most sophisticated caps such as add-vantage, bio-set and monovial closures.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] =>

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[technical_data] => | TECHNICAL DATA ALU SERIES | ||

| Machine model |

ALU 400 |

ALU 600 |

| Capping heads | 8 | 12 |

| Output (vials/minute) | 400 | 600 |

| Standard voltage | 400 V – 50 Hz | |

| Installed power (kW) | 12 | |

| Weight (kg) | 1800 | 1900 |

| Vial diameter (mm)* | 14-52 | |

| Vial height (mm) | 35-110 | |

| * 85 mm in case of large volume configuration | ||

The longstanding experience in the development and production of capping machines for vials has been channelled into ALU. Unique in style and built to deliver top-level performance, this machine will drive your productivity to a higher degree of efficiency.

[buttons_on] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 320 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 320 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Very low particle generation system to avoid product contamination. ) [1] => Array ( [highlight] => Pneumatic circuit to keep constant applied vertical force. ) [2] => Array ( [highlight] => 100% measurement and control of vertical compression force. ) [3] => Array ( [highlight] => Various types of controls available to check crimp quality and flip-off cap colour. ) [4] => Array ( [highlight] => Coding unit and camera vision system for data reading and check. ) [5] => Array ( [highlight] => Low size changeover and set-up time. ) [6] => Array ( [highlight] => Little maintenance required. ) [7] => Array ( [highlight] => Equipped with Siemens PLC and with a user-friendly control panel. ) ) [focus] => Array ( [image] => 2654 [content] => Crimping is performed by rotating the vial against an idle roller. The advantage of this system over traditional methods is to guarantee maximum sealing precision and minimise particle generation on the vial mouth. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 320 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) ) [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => marketing.life.it@ima.it [no_index] => [versions_on] => [addon_on] => [technologies] => Array ( [0] => 73 [1] => 75 ) [tile_description] => [tile_speed] => Up to 600 vials/minute [line_step] => Array ( [0] => 10 ) [aseptic] => aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 603 [4] => 615 [5] => 616 [6] => 617 [7] => 621 [8] => 620 [9] => 619 [10] => 2624 ) [market_packs] => Array ( [0] => 3945 [1] => 2171 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [market_packs_specs] => Array ( ) [thread_tag] => [output_on] => [seo_image] => [seo_title] => ALU SERIES: Alu-Capping Machines for Aseptic Environments [seo_description] => ALU cappers meticulously check the compliance with the production parameters. ALU SERIES: Alu-Capping Machines for Aseptic Environments. [embed_iframe] => [form_price] => [no_follow] => [body_class] => )

The longstanding experience in the development and production of capping machines for vials has been channelled into ALU. Unique in style and built to deliver top-level performance, this machine will drive your productivity to a higher degree of efficiency.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[contact] => marketing.life.it@ima.it

[no_index] =>

[cover_macro] => 15294

[cover_name_type] => txt

[cover_name] => STERICAP

[cover_descriptor] => Capping machine

[cover_focus_on] => 1

[cover_focus_content] => Conceived to provide high capping precision, STERICAP ensures the most remarkable performance. Compact and with a simple and essential design, it is a competitive solution in terms of speed, flexibility and ease of use.

[buttons_on] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => download brochure

[icon] => description

[link] =>

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => download brochure

[icon] => description

[link] =>

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

)

[news] =>

[thumbnail] => 29026

[tag_line] => Capping essentials

[overview] => STERICAP is a rotary capping machine for low-medium speed requirements and is particularly suited to sealing aseptic products. Its compact design ensures air turbulence minimisation and offers the best conditions for H2O2 exposure and barrier system operations.

Available as one model, STERICAP can be fitted with 3 or 6 capping heads depending on customer requirements and features a broad range of application capabilities: from traditional aluminium caps, with or without flip-off, to the most sophisticated caps such as add-vantage, bio-set and monovial closures.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Very low particle generation system to avoid product contamination.

)

[1] => Array

(

[highlight] => Pneumatic circuit to keep constant applied vertical force.

)

[2] => Array

(

[highlight] => 100% measurement and control of vertical compression force.

)

[3] => Array

(

[highlight] => Various types of controls available to check crimp quality and flip-off cap colour.

)

[4] => Array

(

[highlight] => Coding unit and camera vision system for data reading and check.

)

[5] => Array

(

[highlight] => Low size changeover and set-up time.

)

[6] => Array

(

[highlight] => Little maintenance required.

)

[7] => Array

(

[highlight] => Equipped with Siemens PLC and with a user-friendly control panel.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 2700

[content] => Crimping is performed by rotating the vial against a single idle blade fitted at the centre of the carrousel. This system guarantees maximum sealing precision and minimises particle generation on the vial mouth.

[buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[versions_on] =>

[addon_on] =>

[technical_data] => | TECHNICAL DATA STERICAP | ||

| Capping heads | 3 | 6 |

| Output (vials/minute) | 125 | 300 |

| Standard voltage | 400 V – 50 Hz | |

| Installed power (kW) | 6 | |

| Weight (kg) | 1500 | |

| Vial diameter (mm)* | 14-52 | |

| Vial height (mm) | 35-110 | |

| * 85 mm in case of large volume configuration | ||

[layouts] => Array ( [0] => Array ( [image] => 15295 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 28960 [id] => 28960 [title] => ALU AND STERICAP_EN [filename] => ALU-AND-STERICAP_EN.pdf [filesize] => 1420427 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2024/04/ALU-AND-STERICAP_EN.pdf [link] => https://ima.it/pharma/machine/alu-series/alu-and-stericap_en/ [alt] => [author] => 16 [description] => [caption] => [name] => alu-and-stericap_en [status] => inherit [uploaded_to] => 309 [date] => 2024-04-24 07:09:33 [modified] => 2024-04-24 07:09:56 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => [gallery] => Array ( [0] => Array ( [image] => 15296 [description] => Alu-cap pre-feeding hopper ) [1] => Array ( [image] => 15297 [description] => Vibrating bowl for alu-cap feeding ) [2] => Array ( [image] => 15300 [description] => Alu-cap feeding unit ) [3] => Array ( [image] => 15299 [description] => Alu-cap release ) [4] => Array ( [image] => 15301 [description] => Capping unit ) [5] => Array ( [image] => 15302 [description] => Vial rejection ) ) [related] => no [technologies] => Array ( [0] => 73 [1] => 75 ) [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 603 [4] => 615 [5] => 616 [6] => 617 [7] => 621 [8] => 620 [9] => 619 [10] => 2624 ) [market_packs] => Array ( [0] => 2171 [1] => 3945 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [line_step] => Array ( [0] => 10 ) [tile_description] => [tile_speed] => Up to 300 vials/minute [aseptic] => aseptic [market_packs_specs] => Array ( ) [thread_tag] => [output_on] => [seo_image] => [seo_title] => STERICAP: Alu-Capping Machine [seo_description] => STERICAP couples the pioneering IMA Life sealing system with a new upgraded system to guarantee the best possible capping quality. [embed_iframe] => [form_price] => [no_follow] => [body_class] => )

Conceived to provide high capping precision, STERICAP ensures the most remarkable performance. Compact and with a simple and essential design, it is a competitive solution in terms of speed, flexibility and ease of use.

Array

(

[cover_macro] => 2693

[cover_name_type] => txt

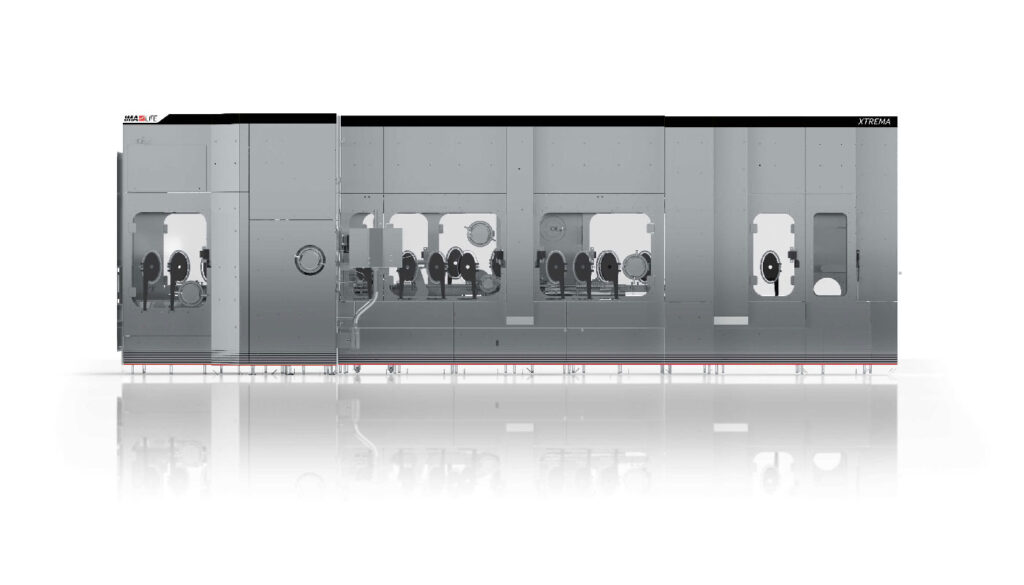

[cover_name] => XTREMA

[cover_descriptor] => High Speed Filling & Stoppering Machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 26195

[tag_line] => eXperience the eXtreme

[overview] => During the aseptic filling of dose containers with a drug, essential is preventing its contamination, thus minimising its exposure to environment, equipment, manipulation from operators, etc., until its sealing.

XTREMA fundamental characteristics respond to the industry’s stringent technical requirements of vial filling, and with its flexible and ergonomic design it assures the most complete possibility to integrate modular equipment, and, why not, even to install multiple filling systems (liquids & powders) to be used alternatively within the same machine frame.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => download brochure

[icon] => description

[link] => 331

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[technical_data] => | TECHNICAL DATA XTREMA | ||

| Min. | Max. | |

| Vial diameter | 14 mm | 54 mm |

| Vial height | 30 mm | 110 mm |

| Stopper diameter | 13 mm | 33 mm |

| Filling dosing unit | up to 15 | |

| Filling volume | 0.10 – 100 mL | |

| Output | Up to 600 vpm | |

| Output with 100% IPC | Max. 600 vpm | |

| Transport system |

Intermittent motion Continuous motion Intermittent/Continuous motion |

|

The main concern of the pharmaceutical packaging market has always been the integrity of the drug, and, in the case of parenteral dosage forms, its sterility. XTREMA indeed embodies the latest technological breakthrough in aseptic filling.

[buttons_on] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 331 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 331 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Ergonomic displacement of operating groups ) [1] => Array ( [highlight] => Geometry facilitating the unidirectional air flow (UAF) ) [2] => Array ( [highlight] => Ideal for Vapour Phase Hydrogen Peroxide exposure. ) [3] => Array ( [highlight] => Machine completely sealed and no tools required for size changeover. ) [4] => Array ( [highlight] => Output up to 600 vpm ) [5] => Array ( [highlight] => Machine with continuous/intermittent motion selectable from HMI ) [6] => Array ( [highlight] => 100% check-weighing system at 600 vpm and anthropomorphic robotized nozzle carrier ) [7] => Array ( [highlight] => New liquid dispensing pumps with revolutionary assembly technique ) ) [focus] => Array ( [image] => 2692 [content] => XTREMA is your filler for product loss minimisation at high speed -100% IPC (check-weighing sampling)- up to 600 vpm. And, with the “Quick Fit” feature of the filling pumps -CIP/SIP ready-, no tools are needed nor to get in touch with product contact parts. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 331 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) ) [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => marketing.life.it@ima.it [no_index] => [versions_on] => [addon_on] => [technologies] => Array ( [0] => 73 [1] => 74 [2] => 136 [3] => 135 [4] => 77 [5] => 78 [6] => 132 ) [tile_description] => [tile_speed] => Up to 600 vials/minute [line_step] => Array ( [0] => 10 ) [aseptic] => aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 615 [6] => 616 [7] => 617 [8] => 621 [9] => 620 [10] => 619 [11] => 2624 ) [market_packs] => Array ( [0] => 3945 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [market_packs_specs] => Array ( ) [thread_tag] => [output_on] => [seo_image] => [seo_title] => XTREMA: High Speed Filling & Stoppering Machine [seo_description] => XTREMA indeed embodies the latest technological breakthrough in aseptic filling of the pharmaceutical packaging. [embed_iframe] => [form_price] => [no_follow] => [body_class] => )

The main concern of the pharmaceutical packaging market has always been the integrity of the drug, and, in the case of parenteral dosage forms, its sterility. XTREMA indeed embodies the latest technological breakthrough in aseptic filling.

Array

(

[cover_macro] => 2690

[cover_name_type] => txt

[cover_name] => XTREMA PWD

[cover_descriptor] => High Speed Powder Dosing & Stoppering Machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 28861

[tag_line] => Cutting-edge powder microdosing

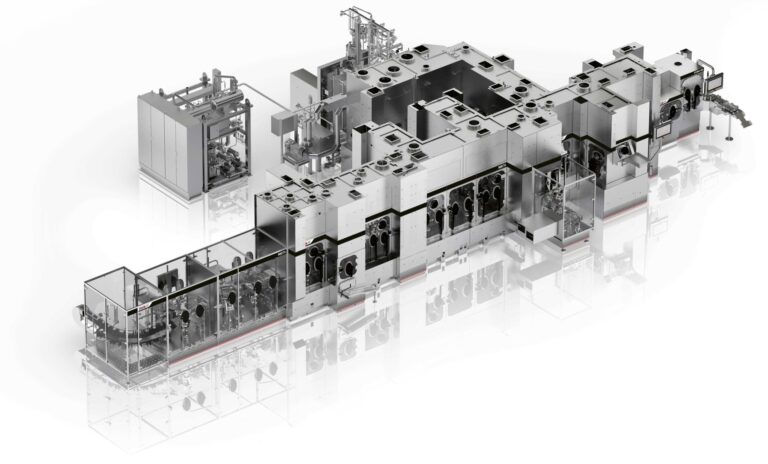

[overview] => The threat of a so-called “post-antibiotic” era – a time when there are no longer any effective antibiotic treatments – could become a reality without a concerted and comprehensive effort to fight this global threat.

Today large pharmaceutical companies and biotech firms are again highly engaged in antibiotic development.

IMA Life contribution to face this emerging criticality is a new generation of filling machines capable of dosing 2 different broad spectrum powders in the same vial with separate 100% check weighing (SPLIT-FILL).

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[technical_data] => | TECHNICAL DATA XTREMA PWD SERIES | ||

| Min. | Max. | |

| Vial diameter | 22 | 56 |

| Vial height | 30 | 136 |

| Stopper diameter | 20 | 33 |

| Stopper height | – | 25 |

| Powder dosing unit | Up to 3 dosing units | |

| Filling volume | From 10 mg | |

| Output with 100% IPC | Up to 400 vpm | |

| Transport system | Intermittent motion | |

The continued emergence of multi-drug resistance bacteria is a global issue.

The development of new antibiotics, especially those with new modes of action, is imperative to help treat new infections. This is the scenario where XTREMA PWD has been designed.

The continued emergence of multi-drug resistance bacteria is a global issue.

The development of new antibiotics, especially those with new modes of action, is imperative to help treat new infections. This is the scenario where XTREMA PWD has been designed.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[contact] => marketing.life.it@ima.it

[no_index] =>

[tile_description] =>

[tile_speed] => Up to 300 vials/minute

[cover_macro] => 22316

[cover_name_type] => txt

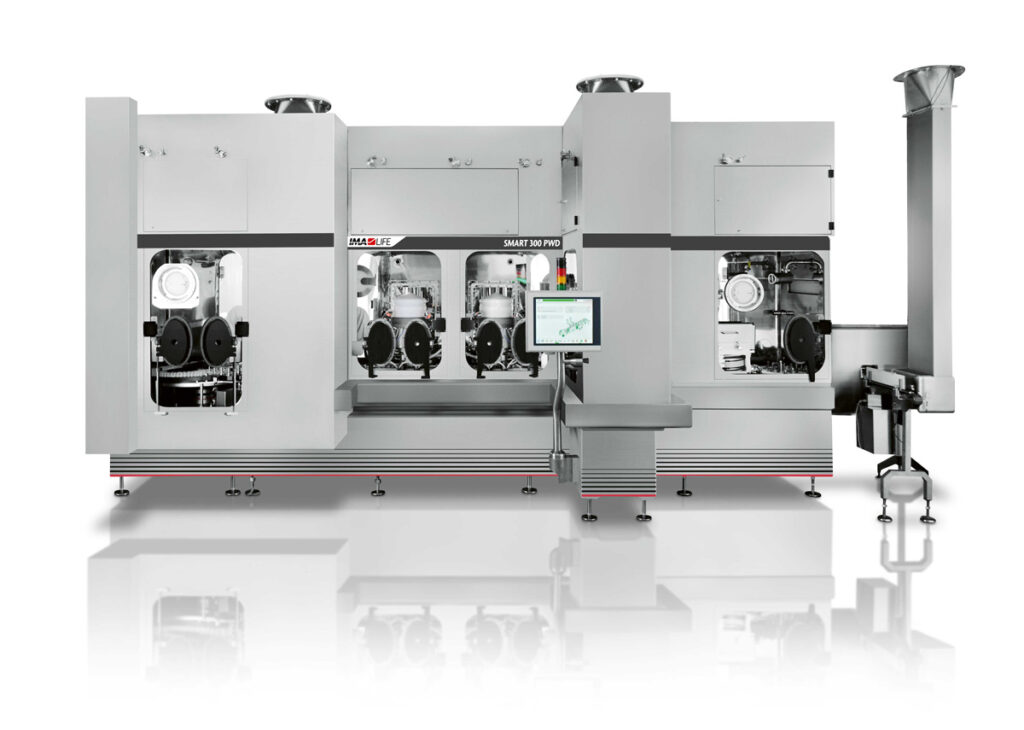

[cover_name] => SMART 300 PWD AUGER

[cover_descriptor] => High-Speed Powder Dosing & Stoppering Machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 28215

[tag_line] => Performance enhanced through innovation.

[overview] => The increasing initiatives taken by the Pharmaceutical regulatory authorities to encourage safe, secure and restricted human intervention in aseptic environments are expected to boost the adoption of new powder-filling technologies over the next few years.

As safety, cleanliness and high containment requirements are the key issues to be addressed when facing such a technological challenge, at IMA Life we have developed and implemented an innovative powder-processing concept.

The new SMART 300 PWD AUGER rises to the challenge in high-potent drug processing and ensures accurate decontamination control to avoid risk of residual toxicity and cross-contamination between batches. The machine processes at superior speeds of up to 300 pcs/minute and simultaneously doses two different types of pharmaceutical powders inside the same vial with single 100% check-weighing.

[overview_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => Contact us

[icon] => mail

[form_email] => mktg.life@ima.it

[type] => product

[private_product] => 2-22161

[private_exhibition] =>

[form_type] =>

[form_id] =>

)

)

)

[sustainability] =>

Drug manufacturers are primarily focused on safety, secondly on sustainability. Nevertheless, these two goals need not be mutually exclusive. IMA has therefore taken action to develop several projects to this regard.

IMA powder auger dosing systems are prearranged to perform Cleaning-In-Place (CIP) and Sterilisation-In-Place (SIP) procedures. This enables a reduction in the number of operating procedures for system commissioning and can also reduce the Single-Use packaging usually required for handling parts normally sterilised in autoclaves. In addition to the reduction in disposable materials, the process is more energy efficient than a traditional Cleaning “out of place” (COP) and consequent autoclave sterilisation.

Working aseptically, the system allows for the dosing of powder drugs, thus avoiding the use of Single-Use packaging. Auger technology is the main principle to have inspired the existing development of the new IMA Life powder dosing machine, SMART 300 PWD AUGER, performing at up to 300 pcs/min. This helps minimise the use of plastic, disposable components.

Application

For the Sterile Pharma market, for the aseptic powder dosing sector, including high potent drugs, this technology is applied to the SMART PWD AUGER series.

[highlights_on] => 1

[focus_on] => 1

[versions_on] => 1

[addon_on] =>

[technical_data] => | SMART 300 PWD AUGER TECHNICAL DATA | ||

| Min. | Max. | |

| Vial diameter | 22 | 54 |

| Vial height | 35 | 115 |

| Stopper diameter | 20 | 33 |

| Filling volume | From 50 mg | |

| Output with 100% IPC * |

Up to 300 ppm (with 6 auger dosing units) Up to 150 ppm (with 3 auger dosing units) Up to 150 ppm (split-fill configuration) |

|

| Transport system | Intermittent motion | |

| Standard voltage | 400 V, 50 Hz, 3ph + N + G | |

| Installed power | 19 kW | |

| SMART PWD AUGER SERIES DATA | ||

| Min. | Max. | |

| Vial diameter | 22 | 54 |

| Vial height | 35 | 115 |

| Stopper diameter | 20 | 33 |

| Filling volume | From 50 mg | |

| Output with 100% IPC * |

Up to 90 vpm (double index) Up to 50 vpm (single index) |

|

| Transport system | Intermittent motion | |

| Standard voltage | 400 V, 50 Hz, 3ph + N + G | |

| Installed power | 19 kW | |

*According to filling volume and product type.

[layouts] => Array ( [0] => Array ( [image] => 22817 ) [1] => Array ( [image] => 24865 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 28371 [id] => 28371 [title] => Smart 300 PWD Auger_EN_Launch brochure [filename] => Smart-300-PWD-Auger_EN_Launch-brochure-1.pdf [filesize] => 1699532 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2022/04/Smart-300-PWD-Auger_EN_Launch-brochure-1.pdf [link] => https://ima.it/pharma/machine/smart-300-pwd-auger/smart-300-pwd-auger_en_launch-brochure-2/ [alt] => [author] => 24 [description] => [caption] => [name] => smart-300-pwd-auger_en_launch-brochure-2 [status] => inherit [uploaded_to] => 22161 [date] => 2024-02-22 08:16:47 [modified] => 2024-02-22 08:16:47 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => h04rNqNthN8 [gallery] => Array ( [0] => Array ( [image] => 22317 [description] => Vial inlet ) [1] => Array ( [image] => 22326 [description] => Powder feeding duct ) [2] => Array ( [image] => 22319 [description] => IPC tare check-weighing ) [3] => Array ( [image] => 22320 [description] => IPC first gross check-weighing ) [4] => Array ( [image] => 22321 [description] => Dosing with nozzle cleaning device ) [5] => Array ( [image] => 22323 [description] => 100% Gross check-weighing ) [6] => Array ( [image] => 22324 [description] => Filling area overview ) [7] => Array ( [image] => 22325 [description] => Powder bag loading by MTI ) [8] => Array ( [image] => 22327 [description] => CIP SIP system ) [9] => Array ( [image] => 22333 [description] => Auger dosing with three powder screws ) [10] => Array ( [image] => 22334 [description] => Auger dosing unit side view ) ) [related] => no [line_step] => Array ( [0] => 10 ) [aseptic] => aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 603 [3] => 615 [4] => 616 [5] => 617 [6] => 621 [7] => 620 [8] => 2624 ) [market_packs] => Array ( [0] => 3945 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [technologies] => Array ( [0] => 73 [1] => 74 [2] => 134 [3] => 136 [4] => 27 [5] => 48 [6] => 79 [7] => 132 ) [thread_tag] => [market_packs_specs] => Array ( ) [output_on] => [cover_focus_content] =>The rising demand for operator safety in aseptic processing, when handling high-potent powdered substances, has boosted the research and the adoption of innovative aseptic dosing technologies replacing the traditional methods.

[buttons_on] => 1 [cover_focus_buttons] => Array ( [buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => Contact us [icon] => mail [form_email] => mktg.life@ima.it [type] => product [private_product] => 2-22161 [private_exhibition] => [form_type] => [form_id] => ) ) ) [focus] => Array ( [image] => 23728 [content] => Star-wheel system for vial transfer to the stoppering station. The vials are transferred by the transport system onto the lifting platform which elevates the vials in order to allow stopper insertion. Automatic clamping of the vibratory bowl in order to minimise interventions during changeover. [buttons] => Array ( [buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => Contact us [icon] => mail [form_email] => mktg.life@ima.it [type] => product [private_product] => 2-22161 [private_exhibition] => [form_type] => [form_id] => ) ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Auger powder dosing technology. ) [1] => Array ( [highlight] => Multiple dosing of two different pharmaceutical powders in the same vial. ) [2] => Array ( [highlight] => Advanced 100% IPC with speeds of up to 300 pcs/min. ) [3] => Array ( [highlight] => CIP/SIP of the auger dosing system. ) [4] => Array ( [highlight] => Continuous stoppering unit with adjustable stoppering head by servomotor. ) [5] => Array ( [highlight] => Perfect for isolation technology with possibility of wetting in place. ) [6] => Array ( [highlight] => cRABS for powder containment. ) ) [seo_image] => [seo_title] => SMART PWD: Powder Filling & Stoppering Machine [seo_description] => The rising demand for operator safety in aseptic processing, when handling high-potent powdered substances, has boosted the research and the adoption [embed_iframe] => [form_price] => [no_follow] => [body_class] => [versions_title] => SMART PWD AUGER VERSION [versions] => Array ( [0] => Array ( [version_label] => Smart PWD Auger [version_title] => Smart PWD Auger [version_thumbnail] => 22332 [version_overview] =>SMART PWD AUGER is designed for medium-to-small-scale production, for the dosage of a single blend of powder (version with single/double dosing unit/s) or two different powders into the same vial. In this case, the machine is configured with two single or double auger dosing units, each dedicated to one product.

Stoppering and capping functions included as well.

Suitable to be installed under oRABS or cRABS or isolation technology.

Machine performance of up to 90 pcs/min with 100% check-weighing.

[version_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) ) [versions_thumbnail] => [versions_tag_line] => Smart PWD Auger [versions_overview] =>Smart PWD Auger is designed for medium-to-small-scale production, for the dosage of a single blend of powder (version with single/double dosing unit/s) or two different powders into the same vial. In this case, the machine is configured with two single or double auger dosing units, each dedicated to one product.

Machine performance of up to 120 pcs/min.

Stoppering and capping functions included as well.

Suitable to be installed under oRABS or cRABS or isolation technology.

The rising demand for operator safety in aseptic processing, when handling high-potent powdered substances, has boosted the research and the adoption of innovative aseptic dosing technologies replacing the traditional methods.

Array

(

[cover_macro] => 28855

[cover_name_type] => txt

[cover_name] => SMART

[cover_descriptor] => Filling, Stoppering and Capping Machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 28856

[tag_line] => Inspired by excellence

[overview] => SMART is part of the IMA LIFE range of liquid filling, stoppering and capping machines for aseptic environments. Particularly suited to small to medium batch production, configured to handle glass and plastic vials within the SVP (small volume parenterals) filling range. The machine is completely servo-driven and can reach up to 120vpm and contemporarily offer 100% IPC of all vials filled. All types of dosing systems can be installed on the machine. Configuration for LVP (large volume parenterals) available as well.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => download brochure

[icon] => description

[link] => 326

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[technical_data] => | TECHNICAL DATA SMART | ||||

| Model | SVP version | LVP version | ||

| Min. | Max. | Min. | Max. | |

| Vial diameter (mm) | 16* | 54 (up to 36 with double index) | 16* | 88 |

| Vial height (mm) | 35 | 91.4 | 35 | 150 |

| Stopper diameter (mm) | 13 | 20 | 13 | 33 |

| Stopper height (mm) | – | 25 | – | 25 |

| Filling volume | 0.25 | 100 | 0.25 | 500 |

| Filling accuracy with volumetrics pumps |

± 0,5% on nom. dosing volume based on a water based product |

|||

| Output |

Up to 120 vpm with double index configuration |

Up to 75 vpm | ||

| Output with 100% IPC | Max. 120 vpm (double index) | Up to 75 vpm | ||

| Vial transport system | Intermittent motion | |||

| * Diameter smaller than 16 mm (up to 14.75 mm) can also be handled with dedicated size parts | ||||

| TECHNICAL DATA SMART 300 |

||

| Min. | Max. | |

| Vial diameter (mm) | 16* | 54 |

| Vial height (mm) | 35 | 91.4 |

| Stopper diameter (mm) | 13 | 20 |

| Stopper height (mm) | – | 25 |

| Filling Volume | 0.25 | 100 |

| Filling accuracy with volumetric pumps | ±0.5% on nom. dosing volume based on a water based product | |

| Output with 100% IPC | Up to 300 vpm | |

| Vial transport system | Intermittent motion | |

|

*Diameter smaller than 16 mm (up to 14.75 mm) can also be handled with dedicated size parts |

||

Time and ease of use are of the essence with small to medium batch production, but with SMART, IMA expertise has gone even further, combining proven technology with high quality standards and the reliability required for all aseptic filling needs.

[buttons_on] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 326 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 326 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Suitable for small to medium batch production with output up to 120/vpm or medium to high with output up to 300/vpm (Smart 300 series) ) [1] => Array ( [highlight] => Slim andsmart pharma design, fit for each type of layout, even when space constraints are an issue ) [2] => Array ( [highlight] => 100% check-weighing of all filled vials ) [3] => Array ( [highlight] => Integrated capping operations in grade A environment available ) [4] => Array ( [highlight] => Easy and fast size changeover through quick snap release ) [5] => Array ( [highlight] => Suitable for installation under isolator, cRABS or other containment solutions ) ) [focus] => Array ( [image] => 2679 [content] => Whichever your filling layout requirement is, SMART’s compact and flexible design fits well. From wall installation to right-to-left or left-to-right execution, space constraints are no longer a limit. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => marketing.life.it@ima.it [no_index] => [versions_on] => 1 [addon_on] => [technologies] => Array ( [0] => 73 [1] => 75 [2] => 74 [3] => 134 [4] => 136 [5] => 135 [6] => 77 [7] => 78 [8] => 132 ) [tile_description] => [tile_speed] => Up to 120 vials/minute (Smart); up to 300 vials/minute (Smart 300) [line_step] => Array ( [0] => 10 ) [aseptic] => aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 615 [6] => 616 [7] => 617 [8] => 621 [9] => 620 [10] => 619 [11] => 2624 [12] => 623 ) [market_packs] => Array ( [0] => 3945 [1] => 2171 [2] => 2250 [3] => 2249 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [market_packs_specs] => Array ( ) [thread_tag] => [output_on] => [seo_image] => [seo_title] => SMART: Filling, Stoppering and Capping Machine [seo_description] => SMART combines proven simple technology with high standards of quality and reliability suitable to any aseptic filling need. [embed_iframe] => [form_price] => [no_follow] => [body_class] => [versions_title] => [versions] => [versions_thumbnail] => 26722 [versions_tag_line] => Smart 300 version[versions_overview] =>

SMART 300 is the answer to the increasing demand for even more flexible and versatile liquid processing solutions. Short start-up times, easy changeovers and a high degree of automation are key considerations. Particularly suited to medium to high batch production, configured to handle glass and plastic vials within the SVP (small volume parenterals) filling range, the machine is completely servo-driven and can reach up to 300vpm and contemporarily offer 100% IPC of all vials filled.

SMART 300 can be equipped with all types of dosing systems typical of aseptic operations, and is suitable for installation in cleanrooms, isolators, or other containment solutions, as all materials are compatible with sanitizing agents and suitable for VPHP exposure.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) )

Time and ease of use are of the essence with small to medium batch production, but with SMART, IMA expertise has gone even further, combining proven technology with high quality standards and the reliability required for all aseptic filling needs.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[contact] => marketing.life.it@ima.it

[no_index] =>

[tile_description] =>

[tile_speed] => Up to 120 vials/minute

[cover_macro] => 6056

[cover_name_type] => txt

[cover_name] => SMART PWD

[cover_descriptor] => Powder Dosing & Stoppering Machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 28860

[tag_line] => Breaking new ground in powder processing

[overview] => Antibiotic-resistant bacteria are bacteria that are not controlled or killed by antibiotics. They are able to survive and even multiply in the presence of an antibiotic.

In order to address this public health concern, the research, development and handing of a “new generation” of antibiotic powders are key topics within the Pharmaceutical Industry.

IMA Life’s SMART PWD is the straightforward solution to comply with this crucial issue, able not only to process difficult powders accurately, but also to simultaneously dose, by vacuum-pressure, two different types of pharmaceutical products inside the same vial with single 100% check-weighing.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[versions_on] =>

[addon_on] =>

[technical_data] => | SMART PWD SERIES TECHNICAL DATA | ||

| Min. | Max. | |

| Vial diameter | 22 | 54 |

| Vial height | 35 | 115 |

| Stopper diameter | 20 | 33 |

| Filling volume | From 10 mg | |

| Output with 100% IPC * | Up to 150 vpm (double index) Up to 80 vpm (single index) |

|

| Transport system | Intermittent motion | |

| Standard voltage | 400 V, 50 Hz, 3ph + N + G | |

| Installed power | 19 kW | |

Today certain bacteria have developed resistance to antibiotics that were once commonly used to treat them. The implementation of more powerful antibiotics, and new aseptic technologie, like SMART PWD contribute to solving this serious public health issue.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [focus] => Array ( [image] => 6060 [content] => Stoppers are picked up by a quick-release pick & place vacuum assisted arm, and placed onto the vial’s mouth. The pick & place system is controlled by brushless motors and configured for each vial size. Stoppering and (possible) integrated capping operations are performed at a full operating speed. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [highlights] => Array ( [0] => Array ( [highlight] => Vacuum-pressure powder filling system. ) [1] => Array ( [highlight] => Possibility of dosing up to 2 different pharmaceutical powders in the same vial. ) [2] => Array ( [highlight] => Advanced 100% IPC with speeds of up to 120 pcs/min. ) [3] => Array ( [highlight] => Pick & place stoppering system. ) [4] => Array ( [highlight] => Possible integration of a capping station. ) [5] => Array ( [highlight] => Fit for isolation technology with possibility of wetting in place. ) [6] => Array ( [highlight] => cRABS for powder containment. ) ) [seo_image] => [seo_title] => SMART PWD: Powder Filling & Stoppering Machine [seo_description] => SMART PWD is the straightforward solution to simultaneously dose two different types of pharmaceutical products inside the same vial. [embed_iframe] => [form_price] => [no_follow] => [body_class] => )

Today certain bacteria have developed resistance to antibiotics that were once commonly used to treat them. The implementation of more powerful antibiotics, and new aseptic technologie, like SMART PWD contribute to solving this serious public health issue.

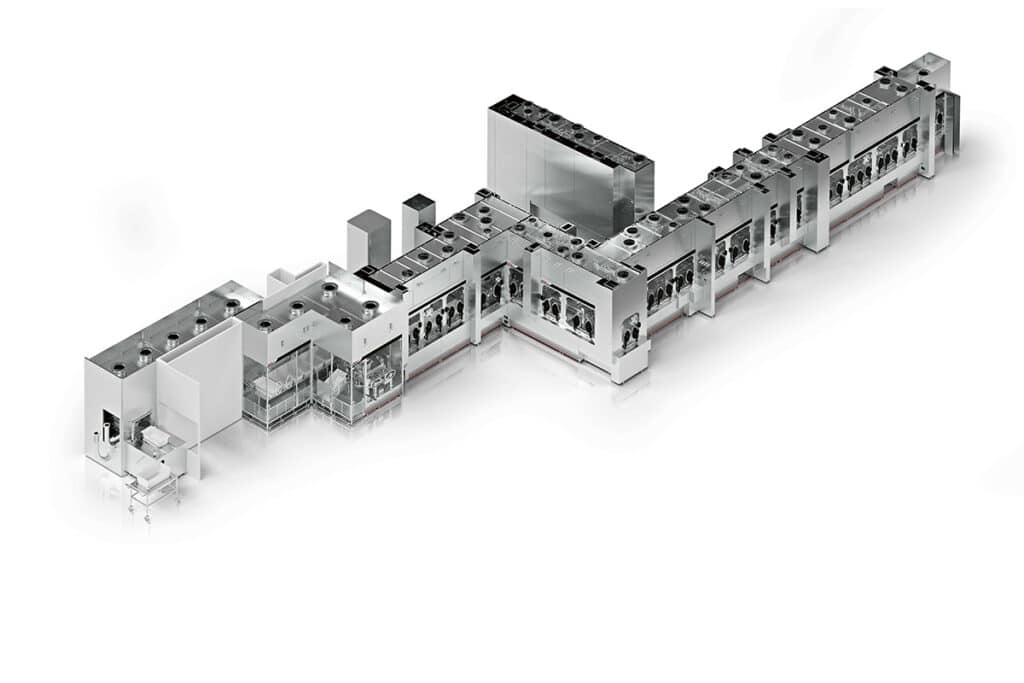

Array

(

[cover_macro] => 26778

[cover_name_type] => txt

[cover_name] => SMART DB2

[cover_descriptor] => Sterile Bag Filling and Closing Machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 28859

[tag_line] => Multipurpose bag-filling made smart.

[overview] => Working with flexible materials used in sterile bags does not contribute to making an aseptic filling process perfectly repeatable. Along the DB2 processing line, groups feature special technical solutions to overcome the non-repeatability issue, and Smart DB2 accomplishes the liquid and powder filling operations of the multi-chamber, Ready-To-Use sterile bags. The first filling process is made with powder drugs by means of dosing disks. The second filling process is made with liquid products, by means of mass-flow technology.

The integrated CIP SIP system allows cleaning and sterilisation-in-place procedures of both liquid and powder products, according to authority’s guidelines, minimising the need to remove and autoclave parts, and granting the SAL (Sterilisation Assurance Level).

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => download brochure

[icon] => description

[link] => 331

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[technical_data] => Sterile bags have many applications in the pharma market and IMA LIFE can provide high-speed turnkey solutions starting from the automatic loading and decontamination of the sterile empty bags up to their final collection.

[buttons_on] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 331 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 331 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Suitable for high batch production with output up to 42 bags per minute with a filling volume of 50ml for the liquid section and 3.5 grams for the powder section. Bag size to be defined in accordance with customer requirements at an early stage of the project. ) [1] => Array ( [highlight] => Minimum human intervention is required: major activities/issues are solved through robot interactions. ) [2] => Array ( [highlight] => Automatic 100% liquid and powder tare and gross check-weighing of the bags. ) [3] => Array ( [highlight] => Whole line contained under isolation technology to avoid any contamination risk and maintain the sterility class. ) [4] => Array ( [highlight] => Both powder filling and liquid filling systems are cleaned and sterilised by integrated CIP SIP (Cleaning In Place - Sterilisation In Place) technology. ) ) [focus] => Array ( [image] => 26927 [content] => Automated devices, robotic technologies and physical barriers are implemented to minimise operator intervention and maintain aseptic conditions. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 331 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) ) [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => marketing.life.it@ima.it [no_index] => [versions_on] => [addon_on] => [technologies] => Array ( [0] => 73 [1] => 74 [2] => 134 [3] => 136 [4] => 27 [5] => 48 [6] => 77 [7] => 78 [8] => 79 [9] => 132 [10] => 247 ) [tile_description] => [tile_speed] => Up to 42 bags/minute [line_step] => Array ( [0] => 10 ) [aseptic] => aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 615 [6] => 616 [7] => 617 [8] => 621 [9] => 620 [10] => 619 [11] => 2624 ) [market_packs] => Array ( [0] => 2056 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [market_packs_specs] => Array ( ) [thread_tag] => [output_on] => [seo_image] => [seo_title] => SMART DB2: Sterile Bag Filling and Closing Machine [seo_description] => Working with flexible materials used in sterile bags does not contribute to making an aseptic filling process perfectly repeatable. [embed_iframe] => [form_price] => [no_follow] => [body_class] => [versions_title] => SMART DB1 VERSION [versions] => [versions_thumbnail] => [versions_tag_line] => SMART DB1 [versions_overview] => [versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) )

Sterile bags have many applications in the pharma market and IMA LIFE can provide high-speed turnkey solutions starting from the automatic loading and decontamination of the sterile empty bags up to their final collection.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[embed_iframe] =>

[form_price] =>

[contact] => marketing.life@ima.it

[thread_tag] =>

[tile_description] =>

[tile_speed] =>

[cover_macro] => 27163

[cover_name_type] => txt

[cover_name] => EASYFILL PWD

[cover_descriptor] => Powder dosing and stoppering machine

[cover_focus_on] => 1

[cover_focus_content] => Delivering powder dosing excellence with ease, EASYFILL PWD boasts our consolidated technology within easy reach of pharma companies, with a guarantee that only IMA Life can give as an undisputed leader in powder microdosing.

[buttons_on] => 1

[cover_focus_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => Contact us

[icon] => mail

[form_email] => marketing.life@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

[news] =>

[thumbnail] => 27165

[tag_line] => Delivering powder dosing excellence.

[overview] => Easyfill PWD is a powder dosing and stoppering machine for vials, with an intermittent-motion, in-line positive transport system. Available in two models, it covers low and medium-speed requirements.

The dosing system with vacuum pressure technology offers extreme precision and versatility during the process where accuracy and low particle generation levels are required. The use of servomotors ensures the vacuum can be easily adjusted for correct slug creation, holding, ejection and chamber cleaning.

Able to perform multiple dosing, Easyfill PWD can be fitted with one or two dosing groups and can be equipped with 100% IPC without affecting machine speed.

[overview_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => Contact us

[icon] => mail

[form_email] => marketing.life@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>