Chapter 01 #highcustomizedlines

From concept

Total flexibility

For over 50 years, IMA Safe has been investing in developing its internal know-how to offer solutions capable of satisfying every market need, maturing over time with unparalleled flexibility in the development of totally customized lines. Efficient and innovative solutions allow the realization of packaging of any type of product, even in its most complex configuration.

Thanks to a rigorous study of line layouts conceived on the actual space and on the customer production needs, the connections between the machines are designed to completely adapt to the surrounding area without affecting the performance of the line.

This is why an IMA Safe line is synonymous with flexibility.

To Reality

There’s always a solution

We like to think of a line as a 360° customer-structured project: it communicates to us what it wants to achieve and we work as a team to provide it with a line that exactly fits its request, always adding something else.

For this reason, over the years we have been able to collaborate with some of the most important pharmaceutical companies in managing the most complex projects. Thanks to the consolidated reliability of IMA Safe, numerous customers have chosen brand new technologies and solutions.

Case studies

- Cyndea Pharma

- Farmindustria S.A. (Abbott)

- Ultra Laboratorios

The challenge:

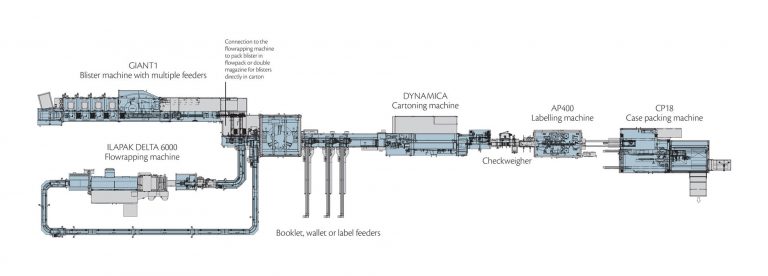

Designing of a packaging line complex in terms of machines, accessories and ancillary equipment. It should be able to handle more than 30 different formats, guaranteeing maximum performance for each machine of the line. Despite this, the layout should be thought to occupy a compact footprint according to the customer’s need.

Product configuration examples

Machines:

The Challenge:

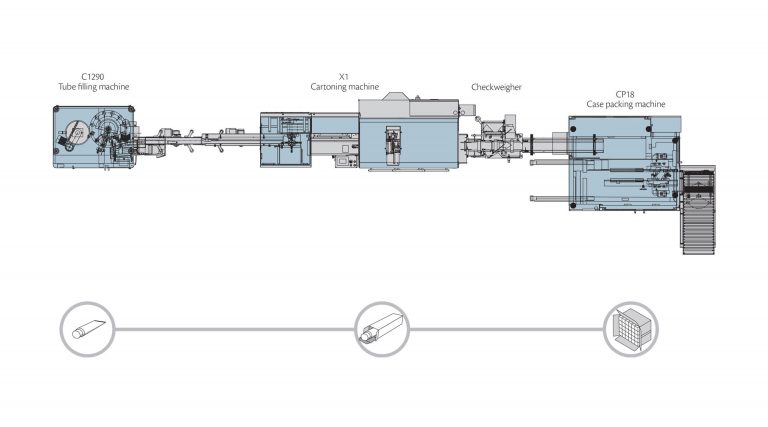

Designing of a performing packaging line, from tube filling to case packing, characterized by flexibility of handle a variety of tube sizes, combined to compactness of footprint.

Machines:

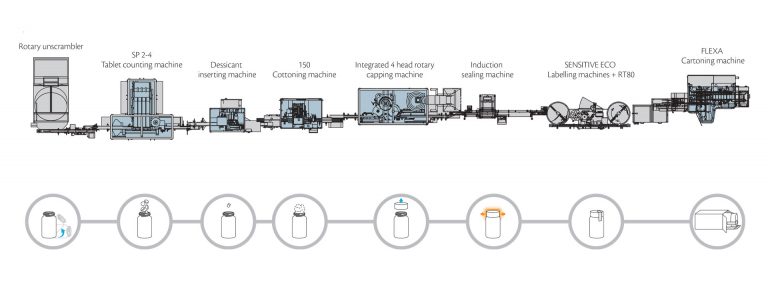

The Challenge:

3 complete counting lines able to manage 70 product presentations each.

High speed production, simple and fast changeover, simplified and safe cleaning procedures thanks to the specifically thought design. These aspects allow the lines to easily adapt to different formats/presentations, cutting downtimes. To get the most out of the line, IMA Safe and Ultra Laboratorios Mexico together have carried out an analysis of packaging materials and their optimization, making production as efficient as possible. The result is super flexible and performing packaging lines.

Machines:

With its essential design and small footprint, the SENSITIVE ECO is the most competitive solution among the linear labelling machines in the IMA Life range. Accurate and easy-to-use, it responds to the needs of standardised labelling.