Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |#PHARMA 4.0 Pharmaceutical Production: enhance efficiency and prevent machine downtime

Optimize Pharmaceutical Manufacturing, Reduce Downtime and Automate Data Analysis with IMA Sentinel’s AI.

Pharmaceutical production: enhance efficiency and prevent machine downtime

Optimize Pharmaceutical Manufacturing, Reduce Downtime and Automate Data Analysis with IMA Sentinel’s AI.

Optimize your pharmaceutical production processes through data-driven decision-making

Are you looking to maximize the efficiency and product quality of your production while proactively addressing potential malfunctions?

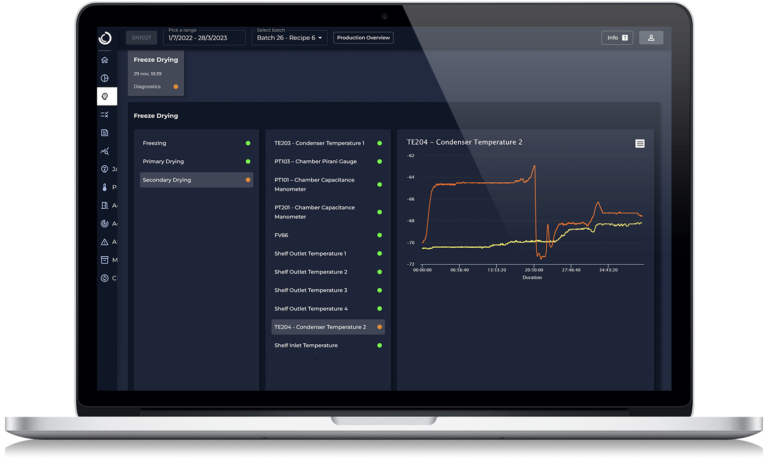

With IMA Sentinel, the digital solution by IMA Group, you can autonomously and in real-time monitor ongoing processes, identify alarms, analyse symptoms of imminent machine downtime and malfunctions, and take prompt corrective actions.

Advanced data management and analysis

View and analyse data from a variety of sources using automated reports in an intuitive environment.

![]()

Key indicators brief

Identify weak points immediately and improve process efficiency through a single interface.

Turnkey efficiency

Compare operational data from plants or retrieve historical data for further analysis.

Advanced data management and analysis

View and analyze data from a variety of sources using automated reports in an intuitive environment.

![]()

Key indicators briefly

Identify weak points immediately and improve process efficiency through a single interface.

Turnkey efficiency

Compare operational data from plants or retrieve historical data for further analysis.

IMA Sentinel: enhance process performance with AI and predictive analytics in pharma 4.0 production

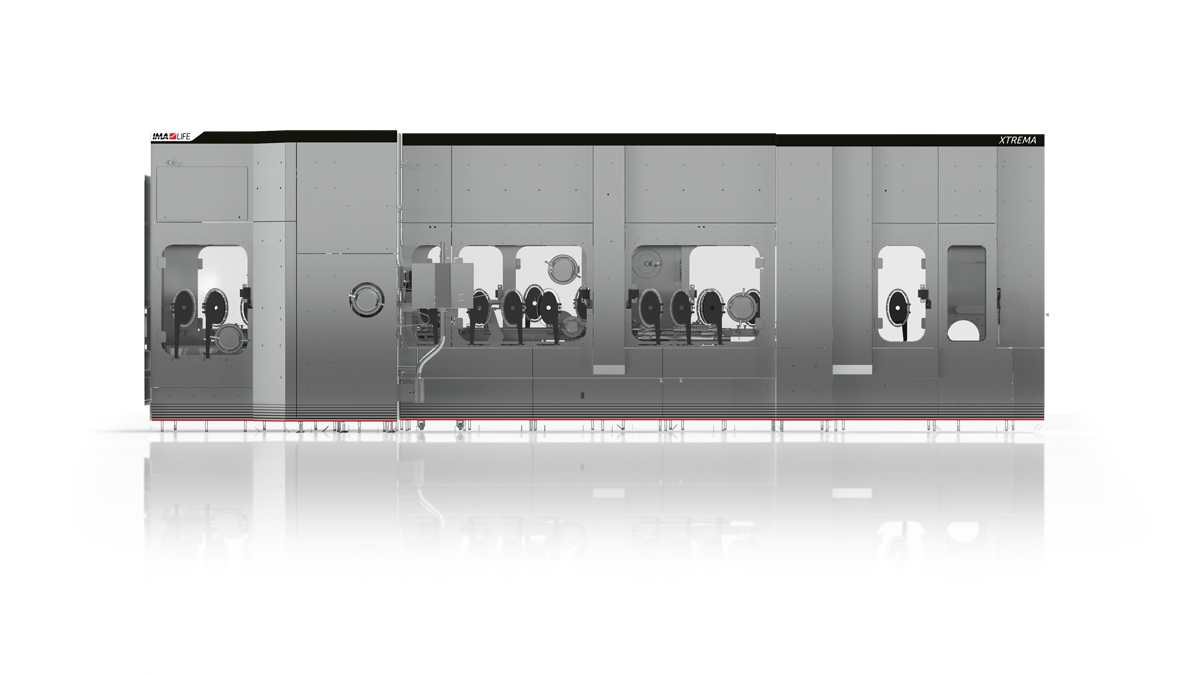

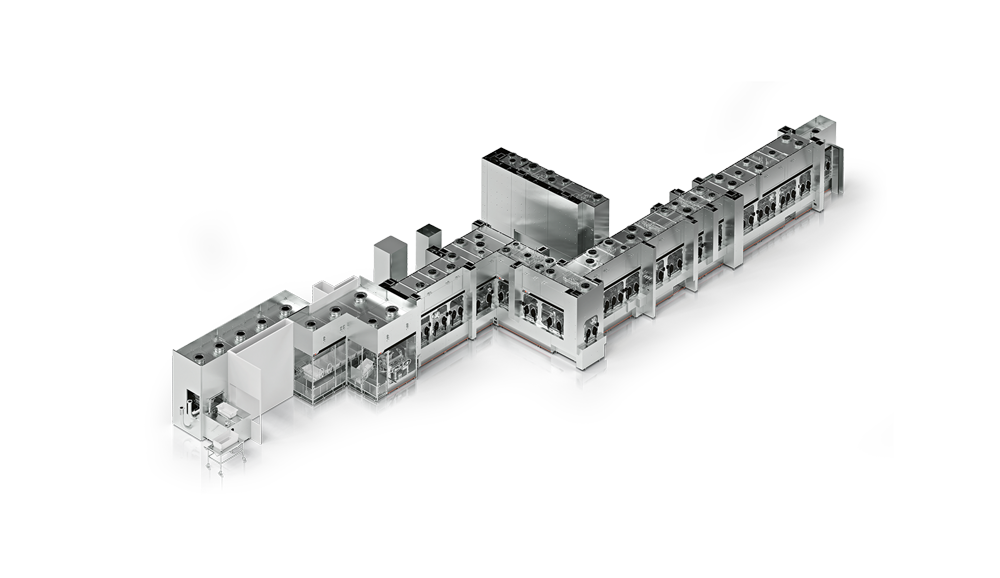

IMA Sentinel is a specialized solution for managing large volumes of data from multiple machines in an aseptic fill-finish line. It applies algorithms to machines, subsystems, and components, offering both Ready-To-Use analytic solutions from equipment suppliers and custom algorithms developed with pharmaceutical company specialists.

Production performance & OEE

IMA Sentinel provides extensive visibility and insights into monitoring plant efficiency, status, and alarms.

- It offers detailed views of current machine status, alarms, recipe parameters, OEE and KPIs;

- It evaluates the quality and reliability of critical processes, providing machine data statistics for intelligent line harmonization;

It facilitates accurate production planning with real average performance.

Advanced Monitoring

IMA Sentinel enables advanced monitoring capabilities through various algorithms, including:

- Hidden anomaly detection in dynamics or components;

- System reliability assessment by comparing critical parameter trends with historical or optimal conditions (golden batch);

- Generation of statistics and reports to monitor efficiency deviations, correlating them with batches, formats, and recipes;

- Support for root cause analysis and evaluation of precision performance degradation.

Predictive Maintenance

IMA Sentinel also offers excellent optimization opportunities through the implementation of anomaly detection and prediction algorithms. By utilizing supervised and unsupervised methods, IMA Sentinel contributes to:

- Reducing the occurrence of failures or unexpected events in specific components, subsystems, or processes.

- Decreasing the frequency of production stoppages that can bring the entire fill-finish plant to a standstill

Unlock the full potential of your pharma 4.0 plant

![]()

FULL POWER IN A FEW CLICKS

Is analysing vast amounts of data taking up too much time, resources, and manual effort? With IMA Sentinel, you can automate the collection of production data, alarms, good products, rejects, causes of rejects, machine downtime, and critical trends.

![]()

LET OTHERS DO THE HEAVY WORK

Are you facing challenges in analysing data and achieving satisfactory results and reports? IMA Sentinel is the ideal tool to support you in efficiently comparing trend curves, conducting golden batch analyses, and swiftly accessing production history.

![]()

GET STRAIGHT TO THE POINT

Are you struggling to investigate individual causes and associated alarms that are impacting productivity? With IMA Sentinel, you can automatically and instantly identify the causes of rejects, generate Pareto charts, and pinpoint the alarms that have had the greatest impact on production performance.

![]()

CONNECT THE RIGHT ELEMENTS

Are you finding it challenging to correlate products, alarms, and rejects to determine where intervention is truly required? With IMA Sentinel, you can effortlessly and automatically correlate formats and products with alarms and rejects, enabling you to quickly identify areas that need intervention.

![]()

LOOK AHEAD TO THE FUTURE

Do you need a comprehensive view of long-term quality in your plant? With IMA Sentinel, you can identify trends and potential plant degradation that extend beyond the short and medium term, providing you with a broader perspective.

![]()

FULL REPORTS IN A MOVE

Are you overwhelmed by large volumes of data that are challenging to interpret and process using traditional tools? With IMA Sentinel, you can automatically generate reports similar to the current ones, while storing them in production databases in a computerized and organized manner.

![]()

OPEN YOUR MIND

Are you facing difficulties in obtaining visibility into machine and line efficiency? With IMA Sentinel, you can gain complete visibility on the calculation of overall equipment efficiency (OEE) for the entire production line, as well as for each individual machine within the plant.

![]()

BREATHE AND TAKE YOUR TIME

Are you interested in a comprehensive system that can instantly alert you to excessive rejects caused by malfunctions? Sentinel seamlessly connects and integrates all machines, PLCs, and HMIs, offering a 360° view of production processes and real-time alarms that can help mitigate efficiency losses.

Detect anomalies and root causes of downtime with AI-powered support. Easily identify issues in a few clicks.

Sentinel simplifies and automates the entire analysis process: from the general efficiency monitoring page, you can delve into the details of each performance through guided navigation, using simple and intuitive dashboards. This allows for the immediate identification of issues that slow down or cause malfunctions in production, as well as for an equally efficient implementation of corrective actions.

Empower your fill-finish plant with dedicated artificial intelligence strategies

Freeze dryers

IMA Sentinel offers a variety of algorithms to detect hidden anomalies.

- It can assess system reliability by comparing critical parameter trends with historical/optimal conditions;

- It optimizes preventive maintenance by analysing medium- and long-term trends;

- It utilizes specially designed mathematical models that incorporate anomaly detection and prediction algorithms.

Fillers

IMA Sentinel enables advanced performance analysis:

- by gathering information from each produced item

- to identify major factors causing rejects and their correlations with product type, format, and production dynamics.

The analysis module:

- provides process statistics and reports to monitor efficiency drops, correlating them with batches, formats, and filling recipes. It evaluates error distribution;

- distinguishes batching and control system effects, supports root cause analysis, and assesses accuracy performance degradation within and across production batches.

Isolators

Sentinel extracts process data and makes advanced monitoring possible by:

- analysing different stages of the production cycle

- evaluating the stability and repeatability of decontamination cycles and the performance of critical machine parameters.

Sentinel implements predictive maintenance algorithms for ventilation systems specifically designed to anticipate any failures and to reduce the occurrence of production downtime.

Empower your fill-finish plant with dedicated artificial intelligence strategies

Freeze dryers

IMA Sentinel offers a variety of algorithms to detect hidden anomalies.

- It can assess system reliability by comparing critical parameter trends with historical/optimal conditions;

- It optimizes preventive maintenance by analyzing medium- and long-term trends;

- It utilizes specially designed mathematical models that incorporate anomaly detection and prediction algorithms.

Fillers

IMA Sentinel enables advanced performance analysis:

- by gathering information from each produced item

- to identify major factors causing rejects and their correlations with product type, format, and production dynamics.

The analysis module:

- provides process statistics and reports to monitor efficiency drops, correlating them with batches, formats, and filling recipes. It evaluates error distribution;

- distinguishes batching and control system effects, supports root cause analysis, and assesses accuracy performance degradation within and across production batches.

Isolators

Sentinel extracts process data and makes advanced monitoring possible by:

- analysing different stages of the production cycle

- evaluating the stability and repeatability of decontamination cycles and the performance of critical machine parameters.

Sentinel implements predictive maintenance algorithms for ventilation systems specifically designed to anticipate any failures and to reduce the occurrence of production downtime.

IsoTech Lab

The IMA Life IsoTech Lab is an in-house Isolator Research & Development Laboratory where we design and develop tailored containment solutions to process liquid, powder and lyo products in an aseptic environment.

The solutions developed within the IsoTech Lab operate in highly advanced and sophisticated technological environments. To achieve top-notch standards and ensure the best qualitative and quantitative performance, we employ real-time monitoring solutions based on machine learning algorithms and artificial intelligence. Sentinel, the platform developed within the IMA Digital program, enables us to pursue our goals through integrated management of vast amounts of data from various machines within an aseptic filling and finishing line.

Discover new solutions to support your growth

Unlocking New Opportunities in Pharma: IMA’s Data Processing, AI, and ML Algorithms for Enhanced Production Performance with IMA Algomarket and IMA Sandbox.

IMA Algomarket

Accessible algorithm-driven solutions for enhanced data collection and digital applications

Discover the power of choice with IMA Algomarket. Our platform offers a predefined menu or virtual shelf of algorithm-driven use cases, making advanced algorithms easily accessible to all. Experience efficient data collection and enjoy the benefits of an out-of-the-box solution, with advanced algorithms available as a service. With user-friendly digital applications, customization is kept to a minimum, requiring only patience as the algorithms learn and train. Embrace the possibilities and optimize your processes effortlessly.

IMA Sandbox

Collaborative platform for algorithm co-development and partnership

Step into the IMA Sandbox, a collaborative architecture that brings together centralized data collection and management in a cloud-based “playground.” In the sandbox, IMA builds real partnerships with customers, combining our expertise as machine builders with their in-house production process knowledge. Our collaboration begins with a seamless brainstorming phase, working hand in hand with their teams to navigate the complexities of different IT architectures.

By joining the sandbox, you become part of a larger community, benefiting from collective insights and experiences. Embrace the power of collaboration and unlock the potential for innovative solutions tailored to your specific needs. Together, we can drive continuous improvement and achieve manufacturing excellence.

IMA Algomarket

Accessible algorithm-driven solutions for enhanced data collection and digital applications

Discover the power of choice with IMA Algomarket. Our platform offers a predefined menu or virtual shelf of algorithm-driven use cases, making advanced algorithms easily accessible to all. Experience efficient data collection and enjoy the benefits of an out-of-the-box solution, with advanced algorithms available as a service. With user-friendly digital applications, customization is kept to a minimum, requiring only patience as the algorithms learn and train. Embrace the possibilities and optimize your processes effortlessly.

IMA Sandbox

Collaborative platform for algorithm co-development and partnership

Step into the IMA Sandbox, a collaborative architecture that brings together centralized data collection and management in a cloud-based “playground.” In the sandbox, IMA builds real partnerships with customers, combining our expertise as machine builders with their in-house production process knowledge. Our collaboration begins with a seamless brainstorming phase, working hand in hand with their teams to navigate the complexities of different IT architectures.

By joining the sandbox, you become part of a larger community, benefiting from collective insights and experiences. Embrace the power of collaboration and unlock the potential for innovative solutions tailored to your specific needs. Together, we can drive continuous improvement and achieve manufacturing excellence.

Discover more empowering solutions for your production

A4Gate

![]()

An integrated hardware and software solution that ensures cyber security, safeguarding data confidentiality, system operations, and operator safety.

IMA Data Room

![]()

A virtual space powered by IIoT technologies to collect and store information, while housing advanced data analysis software programs.

IMA Control Room

![]()

A comprehensive service designed to enhance plant efficiency, providing detailed reports, specific alerts, and 24/7 general support.

IMA Sentinel

![]()

A data-driven services platform, empowered by Artificial Intelligence, offering continuous and autonomous monitoring of system performance.

IMA Artificial Intelligence

![]()

Cutting-edge technologies that leverage production data to drive increased efficiency and performance.

Discover more empowering solutions for your production

IMA Sentinel

![]()

A data-driven services platform, empowered by Artificial Intelligence, offering continuous and autonomous monitoring of system performance.

A4Gate

![]()

An integrated hardware and software solution that ensures cyber security, safeguarding data confidentiality, system operations, and operator safety.

IMA Data Room

![]()

A virtual space powered by IIoT technologies to collect and store information, while housing advanced data analysis software programs.

IMA Control Room

![]()

A comprehensive service designed to enhance plant efficiency, providing detailed reports, specific alerts, and 24/7 general support.