IMA Sentinel

The data-driven services platform, enriched by Artificial Intelligence, for continuous and autonomous monitoring of the system’s performance.

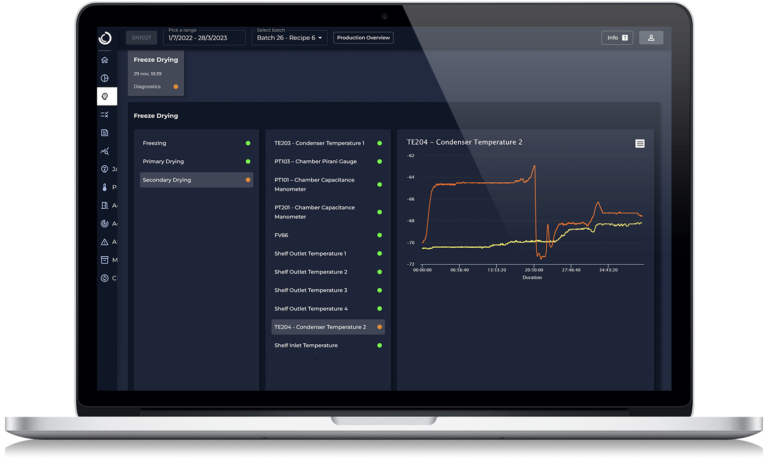

Gain full real-time 24/7 visibility of the performance of every machine and production line, thanks to the highly intuitive interface and real-time data capture. Quickly identify and resolve issues with fact-based analytical support for a wide range of initiatives aimed at continuous efficiency improvement.

IMA Sentinel

The data-driven services platform, enriched by Artificial Intelligence, for continuous and autonomous monitoring of the system’s performance.

Gain full real-time 24/7 visibility of the performance of every machine and production line, thanks to the highly intuitive interface and real-time data capture. Quickly identify and resolve issues with fact-based analytical support for a wide range of initiatives aimed at continuous efficiency improvement.

Connect your installed base.

Monitor it remotely.

Increase your efficiency.

IMA Sentinel contributes to making informed production decisions. The platform monitors OEE and the widest range of parameters to increase efficiency and the quality of the final product.

Sentinel is enriched with Artificial Intelligence algorithms, enabling you to to make your production the most advanced ever.

Connect your installed base. Monitor it remotely. Increase your efficiency.

IMA Sentinel contributes to guide production decision. The platform monitors OEE and the widest range of parameters to increase efficiency and the quality of the final product.

Sentinel is enriched with Artificial Intelligence algorithms, enabling you to make your production the most advanced ever.

![]()

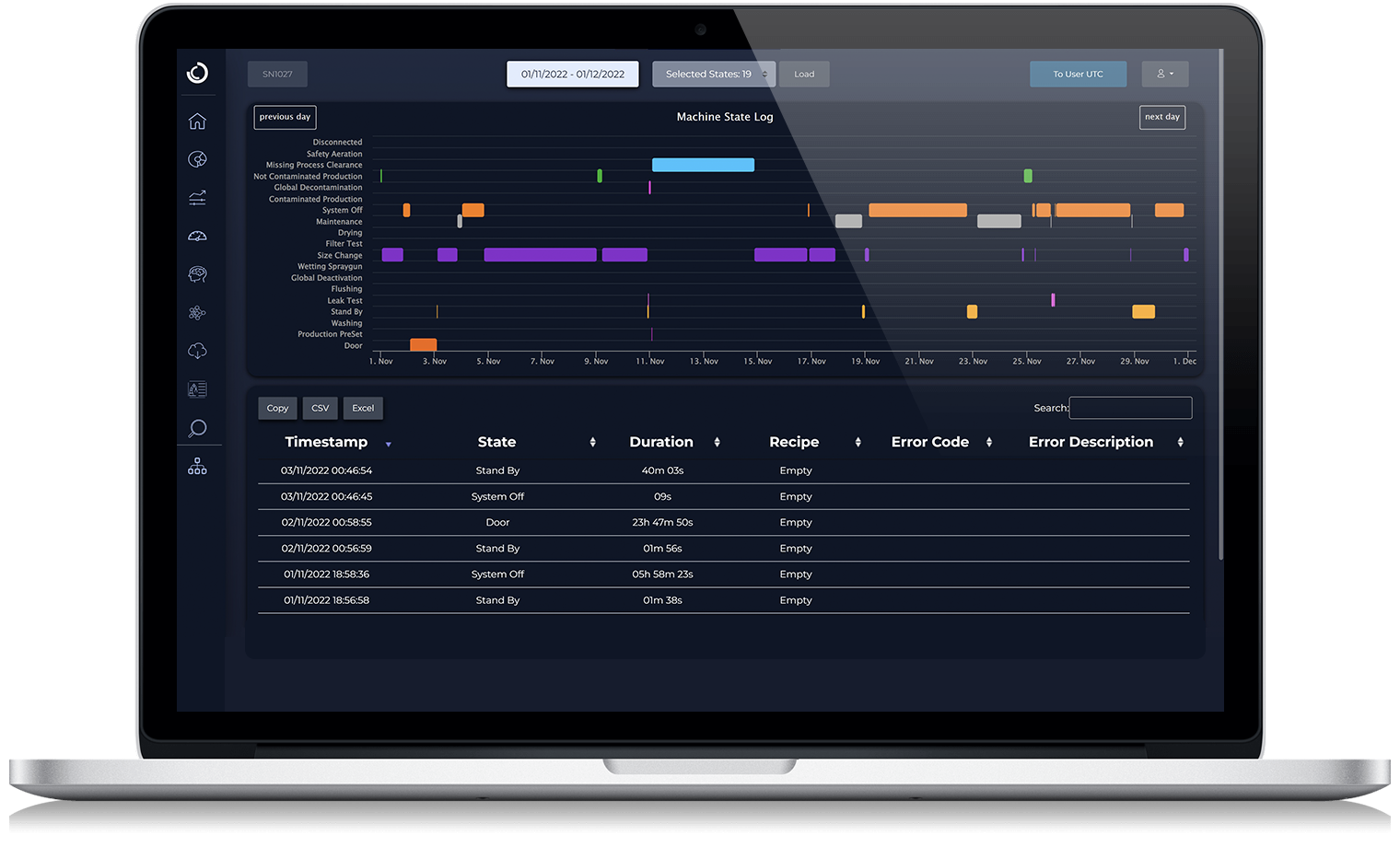

MONITOR IN REAL-TIME

Connect & monitor any piece of equipment, dialogue with all ERP and MES systems, receive and analyse data from all PLCs.

OPTIMISING PROCESSES

Increase your production performance through our list of smart dynamic actions.

DATA-DRIVEN AI OPTIMISATION

Identify and optimise underperforming components to keep your machines running optimally.

THE PROBLEM

LACK OF VISIBILITY AND CONTROL

Modern production facilities often make use of complex and varied equipment and an integration of technologies makes it difficult to really understand what is happening in production, resulting in data sometimes being collected by hand.

This results in limited visibility of production progress, a risk of unplanned downtime occurring, difficulty in having a single tool to monitor the entire installed base. Not to mention poor control over product quality, high production costs and equally high numbers of product rejects, inefficiencies and high energy consumption with sinificant environmental impact.

THE PROBLEM

LACK OF VISIBILITY AND CONTROL

Modern production facilities often make use of complex and varied equipment and an integration of technologies makes it difficult to really understand what is happening in production, resulting in data sometimes being collected by hand.

This results in limited visibility of production progress, a risk of unplanned downtime occurring, difficulty in having a single tool to monitor the entire installed base. Not to mention poor control over product quality, high production costs and equally high numbers of product rejects, inefficiencies and high energy consumption with significant environmental impact.

Continuous improvement in manufacturing begins with the acquisition of data from production facilities. IMA Group has automated and expedited the collection of machine data for 360-degree visibility into what is happening in real-time.

Data acquired from equipment cells are reprocessed and made immediately understandable, thanks to the artificial intelligence algorithms employed, so that quick and more suitable decisions can be made to make manufacturing operations more efficient.

THE SOLUTION

REAL-TIME VISIBILITY AND PROCESSES IMPROVEMENT

THE SOLUTION

REAL-TIME VISIBILITY AND PROCESSES IMPROVEMENT

Continuous improvement in manufacturing begins with the acquisition of data from production facilities. IMA Group has automated and expedited the collection of machine data for 360-degree visibility into what is happening in real-time.

Data acquired from equipment cells are reprocessed and made immediately understandable, thanks to the artificial intelligence algorithms employed, so that quick and more suitable decisions can be made to make manufacturing operations more efficient.

![]()

IDENTIFY AND PREVENT DOWNTIMES

Monitor remotely and at any time how the production of your machines or lines is going, through simplified and easily understood dashboards.

![]()

INCREASE EFFICIENCY

Uses the list of smart dynamic actions to increase the performance: based on benchmarking algorithms, able to suggest a specific action on a specific cause of efficiency loss.

![]()

REDUCE COSTS AND REJECTS

Through reading alarms and smart tips you are able to increase the yield of your production batches and decrease the number of discarded parts.

![]()

IDENTIFY AND PREVENT DOWNTIMES

Monitor remotely and at any time how the production of your machines or lines is going, through simplified and easily understood dashboards.

![]()

INCREASE EFFICIENCY

Uses the list of smart dynamic actions to increase the performance: based on benchmarking algorithms, able to suggest a specific action on a specific cause of efficiency loss.

![]()

REDUCE COSTS AND REJECTS

Through reading alarms and smart tips you are able to increase the yield of your production batches and decrease the number of discarded parts.

Unleash maximum OEE and performance for your installed base with our Solutions

OEE & Performance Management

Boost OEE and Performance Management with Actionable Insights. Gain access to dedicated dashboards for data efficiency and control, enabling you to enhance overall performance through:

- Smart and dynamic actions empowering operators to improve conditions.

- Machine data statistics for intelligent line harmonisation.

- Real-time average performance for precise production planning.

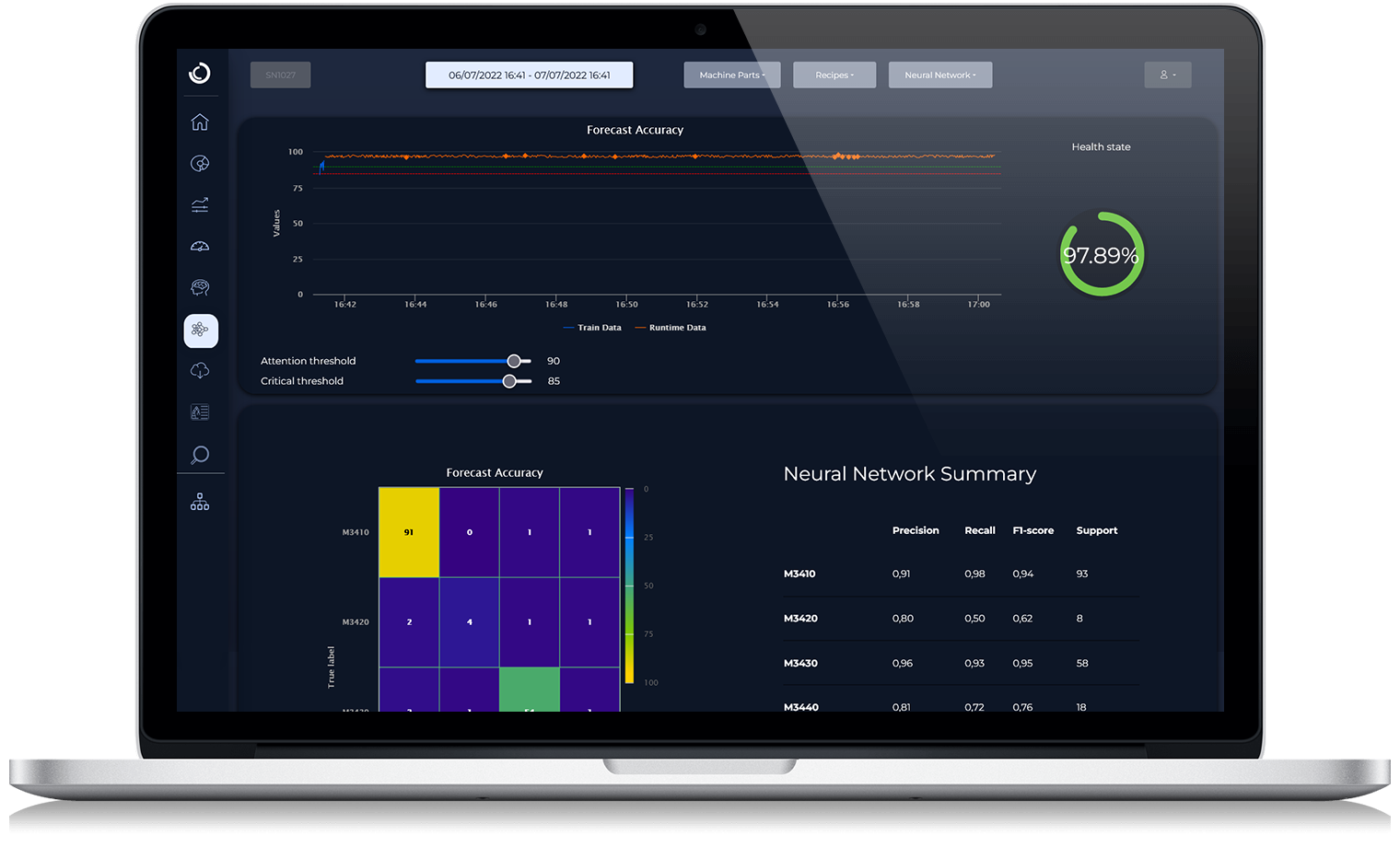

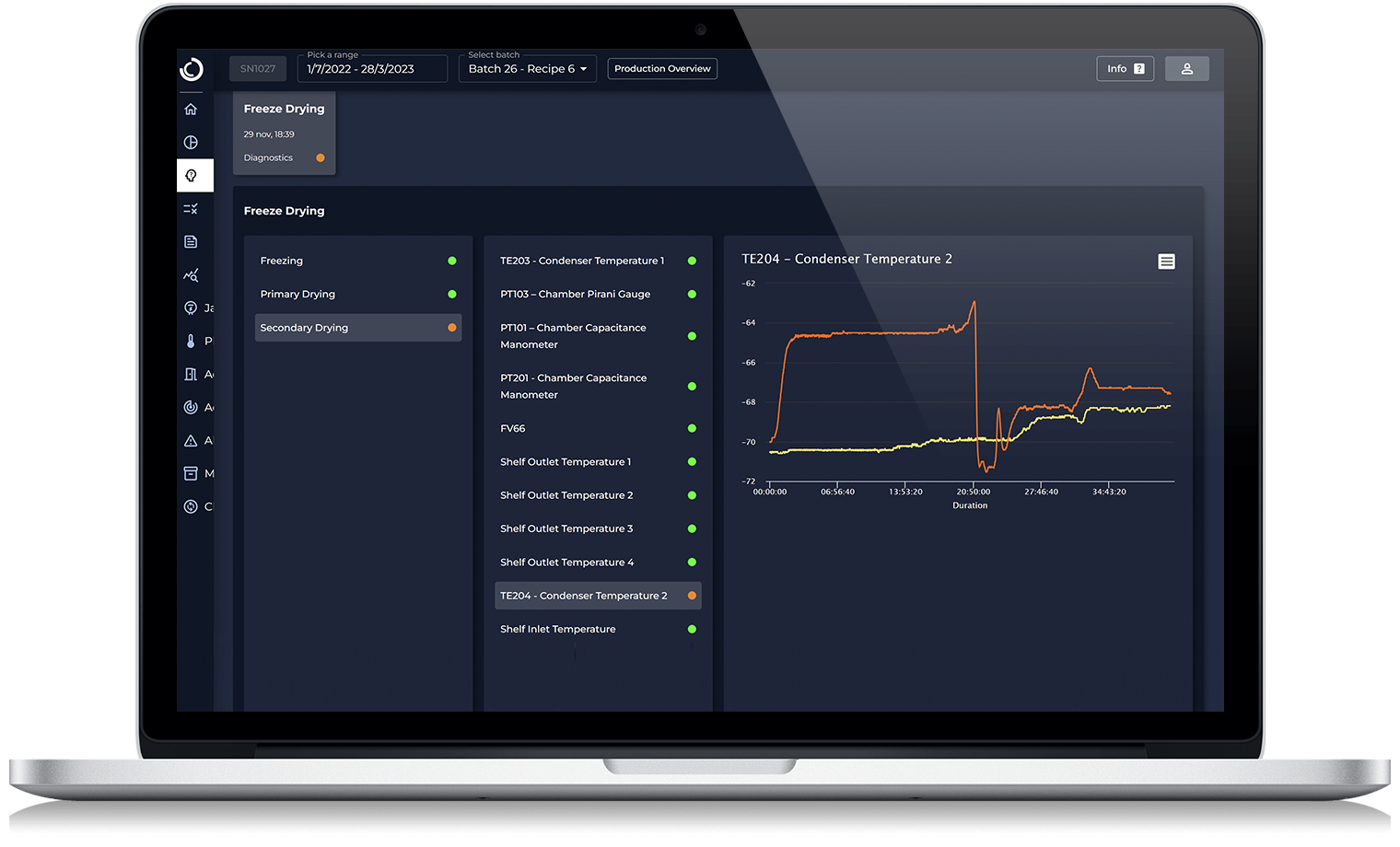

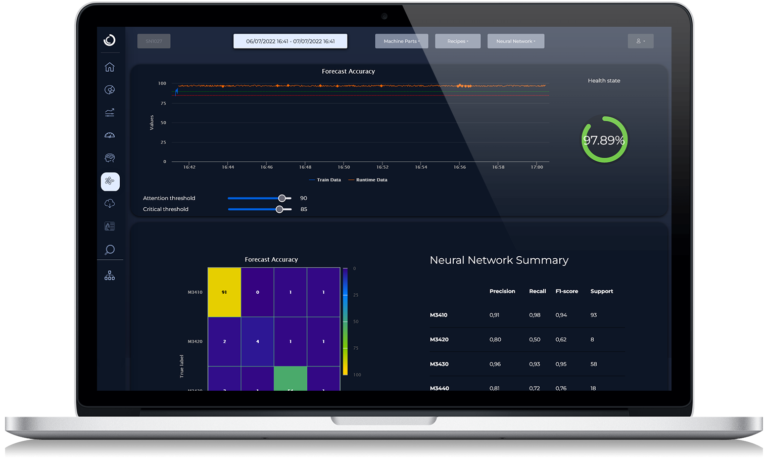

Advanced Monitoring

Unlock the Power of Advanced Algorithms to Uncover Hidden Anomalies:

- Assess system reliability by comparing critical parameter trends;

- Optimise preventive maintenance while ensuring reliability;

- Evaluate the stability and repeatability of specific process cycles, and monitor the performance of critical parameters.

Predictive Maintenance

Empower Predictive Maintenance with Advanced Anomaly Detection Algorithms.

- Utilise Custom Mathematical Models for Accurate Anomaly Detection and Prediction;

- Extract Patterns to Predict Anomalous Conditions and Identify Potential Future Failures;

- Detect Temperature Fluctuations and Uncover Critical Oscillating Patterns;

- Predict Component Failures for Proactive Maintenance Strategies.

Descriptive & Diagnostic Analytics

Drive Continuous Process Control with Sentinel, Monitoring System Variables and Indicators. Leverage Smart Analytics to Investigate Root Causes:

- Identify Where and Why Problems Occur in the Process.

- Gain Insights to Restore Processes to Normal Activity.

OEE & Performance Management

Boost OEE and performance management with actionable insights. Gain access to dedicated dashboards for data efficiency and control, enabling you to enhance overall performance through:

- Smart and dynamic actions empowering operators to improve conditions.

- Machine data statistics for intelligent line harmonisation.

- Real-time average performance for precise production planning.

Advanced Monitoring

Unlock the power of advanced algorithms to uncover hidden anomalies:

- Assess system reliability by comparing critical parameter trends;

- Optimise preventive maintenance while ensuring reliability;

- Evaluate the stability and repeatability of specific process cycles, and monitor the performance of critical parameters.

Predictive Maintenance

Empower predictive maintenance with advanced anomaly detection algorithms.

- Utilise custom mathematical models for accurate anomaly detection and prediction;

- extract patterns to predict anomalous conditions and identify potential future failures;

- Detect temperature fluctuations and uncover critical oscillating patterns;

- Predict component failures for proactive maintenance strategies.

Descriptive & Diagnostic Analytics

Drive continuous process control with Sentinel, monitoring system variables and indicators. Leverage smart analytics to investigate root causes:

- Identify where and why problems occur in the process.

- Gain insights to restore processes to normal activity.

Empower various aspects of manufacturing processes with multiple features

![]()

KNOWLEDGE IS POWER

Do you lack sufficient knowledge about the underlying processes that drive production?

Sentinel provides all the tools, levers, and information to understand how to act and improve the production process.

![]()

SEEK THE INFINITE

Are you concerned about the possibility of an unplanned machine downtime?

Sentinel helps reduce downtime by providing all the instructions and alerts to understand where to act and prevent sudden machine stoppages.

![]()

SIMPLIFY YOUR PROCESSES

Do you struggle with using different software to manage different machines?

Sentinel can connect and integrate all machines, PLCs, and HMIs to provide a 360° view of production processes.

![]()

MAKE DATA-DRIVEN DECISIONS

Do operators find it challenging to manage complex systems?

Sentinel provides numerous smart suggestions on where to focus to recover efficiency more quickly.

![]()

LOOK TO THE NEXT STEP

Do you lack visibility on when the production batch will finish?

Sentinel provides real-time visibility of batch progress with a forecast of when production will end, offering real-time data based on machine OEE.

![]()

LOOK BEYOND YOUR BOUNDARIES

Do you lack benchmarks to understand how well your production is performing?

Sentinel provides a constantly updated benchmark for each individual cause of lost efficiency, enabling you to understand how production is performing and where to intervene for improvement.

![]()

STAY INFORMED

Outside the production context, do you lack visibility of plant performance?

Sentinel offers remote and real-time control of production processes, ensuring complete visibility and control over production processes whether you are in the office, at home, or traveling.

![]()

RAISE YOUR EXPECTATIONS

Do you have limited control over product quality, high production costs, and a high number of product rejects?

Sentinel supports production strategies with the goal of increasing final product quality, reducing costs, and minimising product rejects.

![]()

SAVE THE PAST TO OPTIMISE THE FUTURE

Do you have limited data or struggle to retrieve information on past performance?

Sentinel not only provides real-time information you need but also allows you to download all relevant data, opening a window into the past.

![]()

DIGITALISATION IS SUSTAINABILITY

Does your production have excessive energy consumption and high environmental impact?

Sentinel provides indicators and strategies to adjust parameters and enable your production to have a green footprint and be more sustainable.

How IMA Artificial Intelligence enhances production management

Efficiently monitor single equipment or entire plants with coordinated machines, using a comprehensive set of KPIs for monitoring overall efficiency.

- Calculate overall plant/line efficiency;

- Identify bottleneck assets;

- Improve operating procedures to optimise the production process;

- Track production goals and compare results with historical data.

How IMA Artificial Intelligence enhances production management

Effectively monitor single equipment or entire plants with coordinated machines, utilising a comprehensive set of KPIs for monitoring overall efficiency.

- Calculate overall plant/line efficiency;

- Identify bottleneck assets;

- Improve operating procedures to optimise the production process;

- Track production goals and compare results with historical data.

Effectively monitor machine and line efficiency

Monitor the efficiency of individual equipment or entire plants comprising multiple coordinated machines, utilising a comprehensive set of KPIs to gauge overall efficiency.

- Calculate overall plant and line efficiency.

- Identify bottleneck assets.

- Improve operating procedures to optimise the production process.

- Track production goal achievement and compare results with historical data.

Effectively monitor machine and line efficiency

Monitor the efficiency of individual equipment or entire plants comprising multiple coordinated machines, utilising a comprehensive set of KPIs to gauge overall efficiency.

- Calculate overall plant and line efficiency.

- Identify bottleneck assets.

- Improve operating procedures to optimise the production process.

- Track production goal achievement and compare results with historical data.

Driving sustainability with digital solutions

Sentinel offers diverse dashboards to facilitate advanced analysis of energy consumption and assess the impact of various machine types, aiding in the implementation of energy-saving strategies.

- Analyse the energy impact of products, production stages, and machine configurations.

- Compare consumption with historical or optimal operating conditions.

- Identify machine stops or components that contribute to a loss in energy efficiency.

- Support strategies for reducing the CO2 footprint and achieving energy savings.

Driving sustainability with digital solutions

Sentinel offers diverse dashboards to facilitate advanced analysis of energy consumption and assess the impact of various machine types, aiding in the implementation of energy-saving strategies.

- Analyse the energy impact of products, production stages, and machine configurations.

- Compare consumption with historical or optimal operating conditions.

- Identify machine stops or components that contribute to a loss in energy efficiency.

- Support strategies for reducing the CO2 footprint and achieving energy savings.

Preserving data and information

Streamline your data collection process and safeguard against external threats with A4Gate, the advanced hardware and software solution developed by IMA Group in collaboration with our Israeli partner, Terafance.

A4Gate enables seamless connectivity with any machine or production line, ensuring secure data transmission while protecting against potential external breaches. By adopting A4Gate, you can effortlessly collect production data and transmit it through a one-way flow to either the IMA cloud or your own cloud infrastructure.

Once in the cloud, the data can be efficiently processed and optimised, making it readily available for immediate utilisation. With A4Gate, you can leverage the power of data analytics and streamline your operations with ease.

Preserving data and information

Streamline your data collection process and safeguard against external threats with A4Gate, the advanced hardware and software solution developed by IMA Group in collaboration with our Israeli partner, Terafance.

A4Gate enables seamless connectivity with any machine or production line, ensuring secure data transmission while protecting against potential external breaches. By adopting A4Gate, you can effortlessly collect production data and transmit it through a one-way flow to either the IMA cloud or your own cloud infrastructure.

Once in the cloud, the data can be efficiently processed and optimised, making it readily available for immediate utilisation. With A4Gate, you can leverage the power of data analytics and streamline your operations with ease.

IMA Sentinel supports

20+

Customer Leaders

300+

Pieces of machines and lines connected

1000+

Activated Users

Find out more about the other solutions

to empower your production

A4Gate

![]()

An integrated hardware and software solution that ensures cyber security, safeguarding data confidentiality, system operations, and operator safety.

IMA Data Room

![]()

A virtual space powered by IIoT technologies to collect and store information, while housing advanced data analysis software programs.

IMA Control Room

![]()

A comprehensive service designed to enhance plant efficiency, providing detailed reports, specific alerts, and 24/7 general support.

IMA Artificial Intelligence

![]()

Cutting-edge technologies that leverage production data to drive increased efficiency and performance.

A4Gate

![]()

An integrated hardware and software solution that ensures cyber security, safeguarding data confidentiality, system operations, and operator safety.

IMA Data Room

![]()

A virtual space powered by IIoT technologies to collect and store information, while housing advanced data analysis software programs.

IMA Control Room

![]()

A comprehensive service designed to enhance plant efficiency, providing detailed reports, specific alerts, and 24/7 general support.

IMA Artificial Intelligence

![]()

Cutting-edge technologies that leverage production data to drive increased efficiency and performance.