Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |Ilapak Delta OF 360X - variable geometry concepts

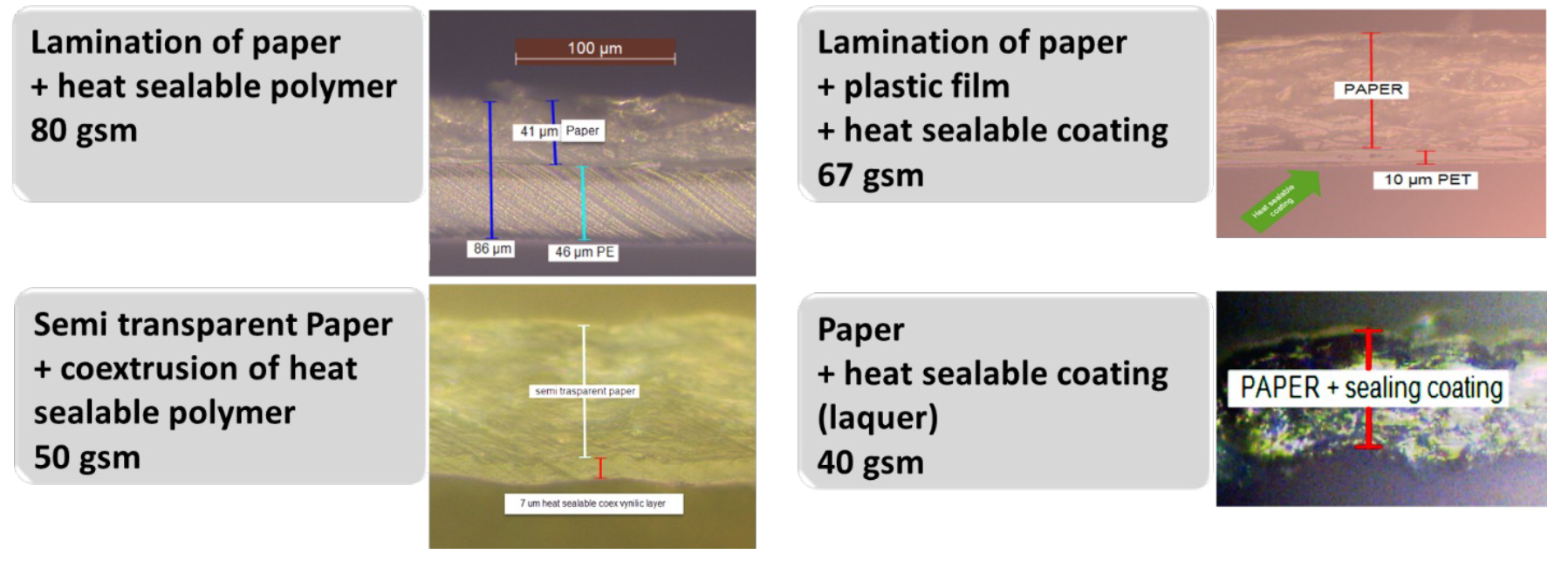

Currently on the market it is possible to find many kinds of heat sealable Paper packaging materials which can very much differ one to the other in term of composition and processability on a HFFS machines:

Some of them are easily processable (under the unwinding, folding and forming point of view) with a standard machine configuration.

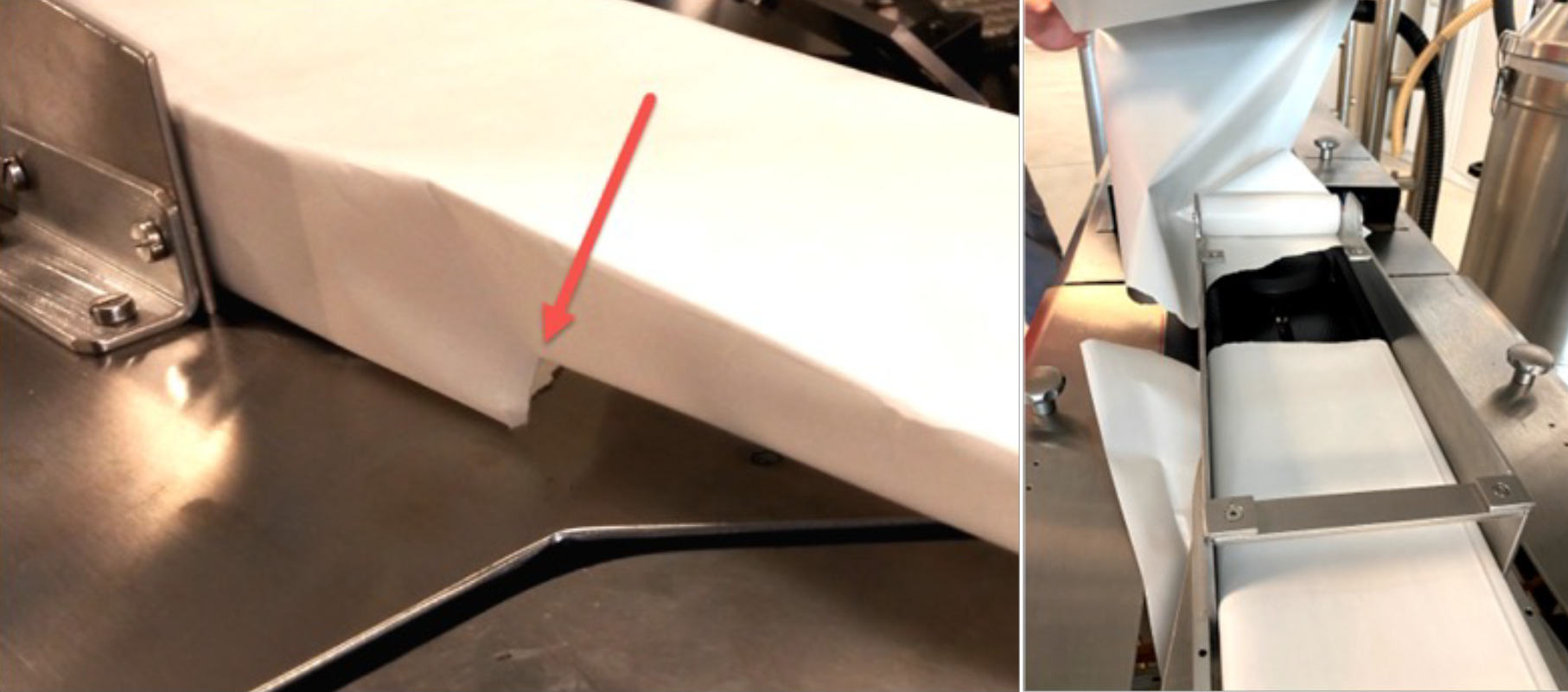

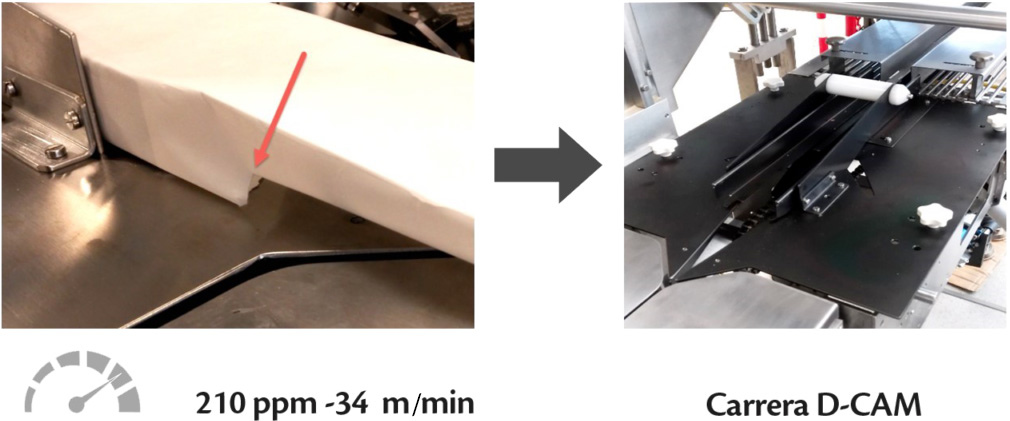

Many others show big troubles during the run and are often subjected to breakages during forming/unwinding operations:

OPENLab’s study on the possible causes:

- Coefficient Of Friction – COF – packaging/packaging or packaging/machine parts

- Packaging Mechanical properties

- Contact surface area between packaging and machine parts

- Geometry of forming box

- Packaging feeding inclination to folding/forming box

- Position of pulling rollers with respect to folding/forming box

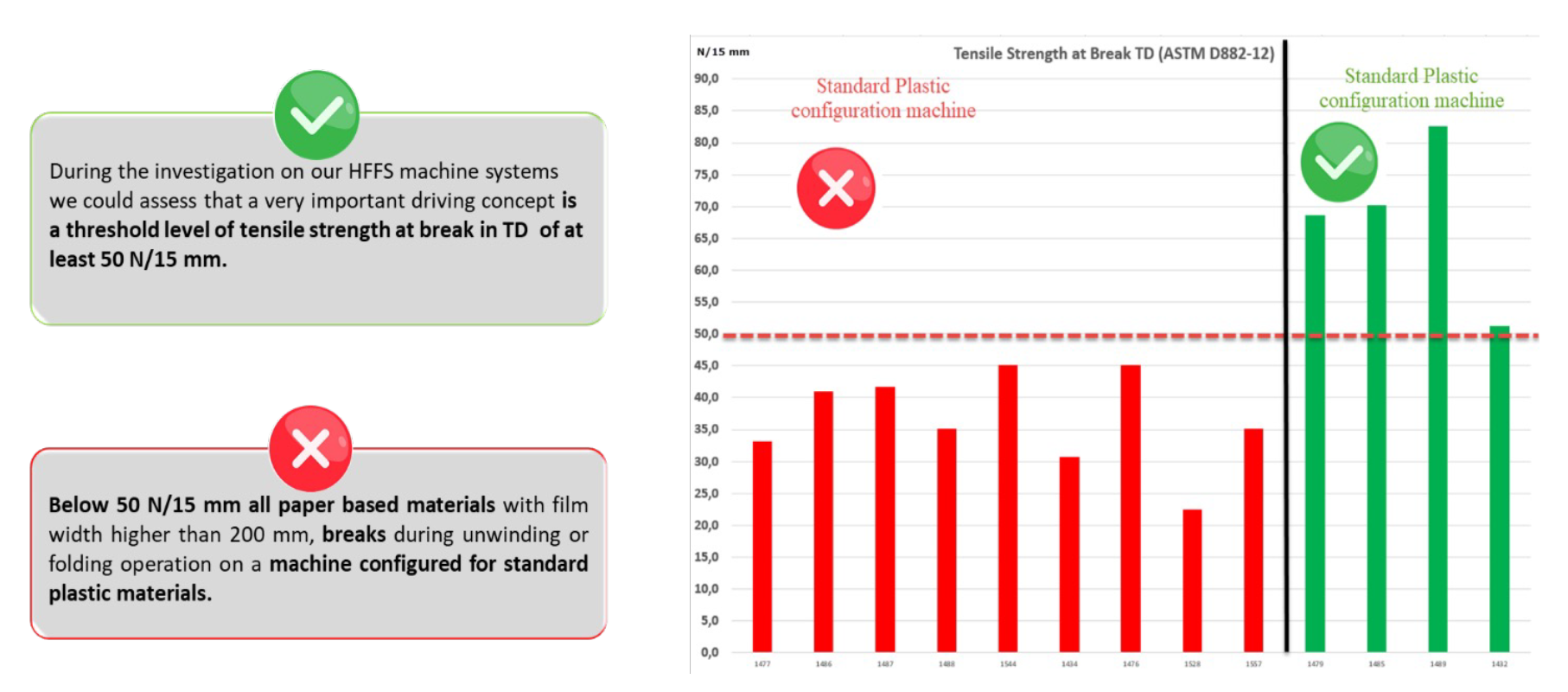

Outcome: Correlation between the value of tensile strength at break CD, Paper breakage and machine configuration

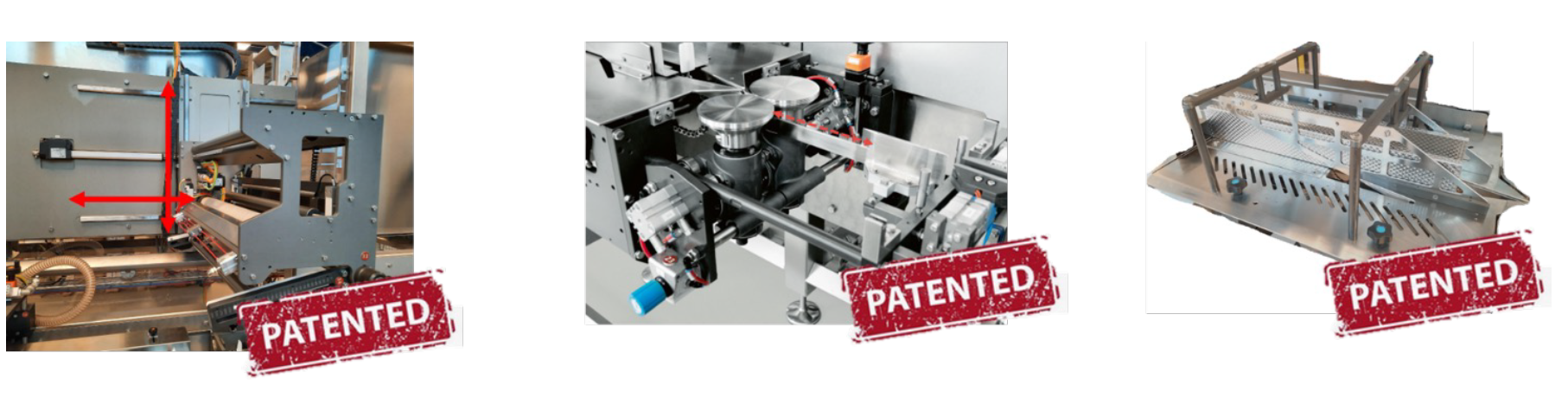

These observations along with team-work with Technical Mechanical Office led to variable geometry concept patenting (adjustable packaging feeding inclination and position of pulling roller, folding box special geometry).

All mounted as modules of Ilapak Delta OF 360X:

Other case Studies

Array

(

[in_evidence] =>

[thread_type] => case

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[firewall_close] =>

[firewall_cookie] =>

[minisite] => 244

[hide_minisite_header] =>

[minisite_cover] =>

[minisite_link] =>

[copy_thread_to_other_site] =>

[not_listed] =>

[cover] => none

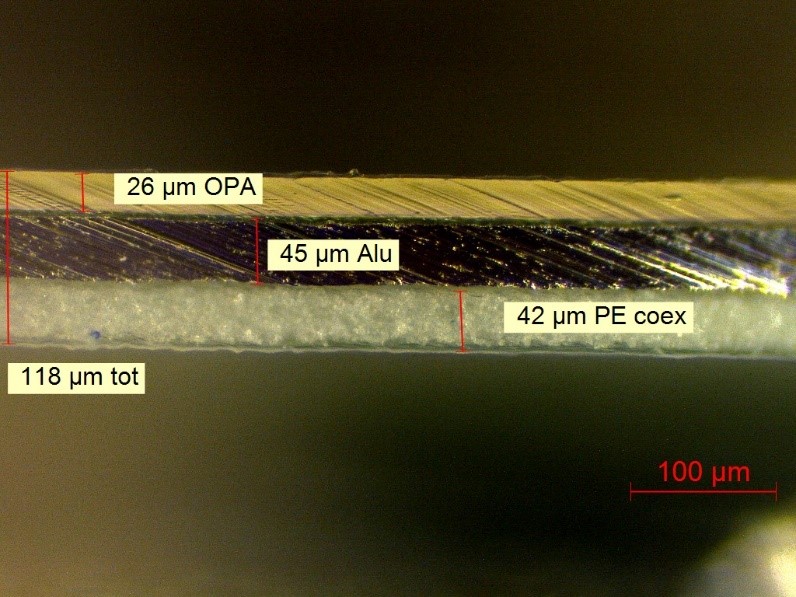

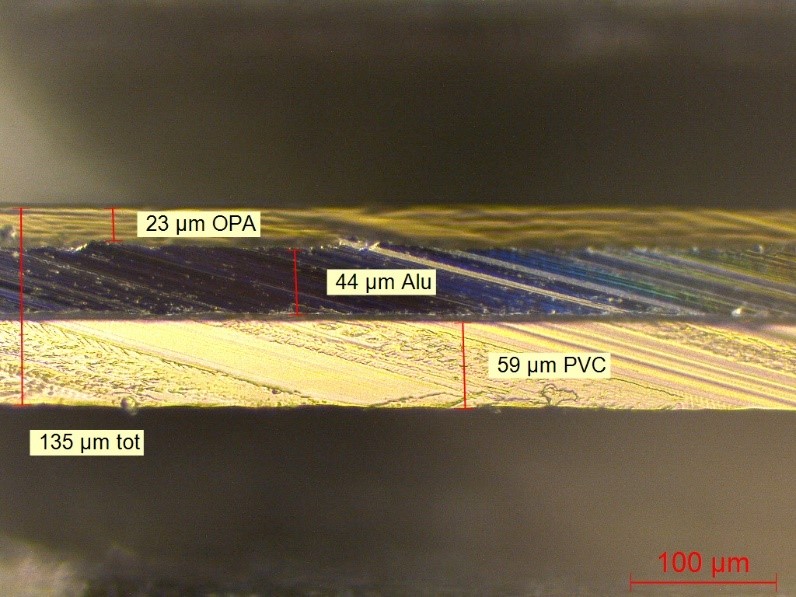

[content] => Stratigraphy @20x.

|

|

Overall and single layers thicknesses of PE-based material (left) and PVC-based material (right).

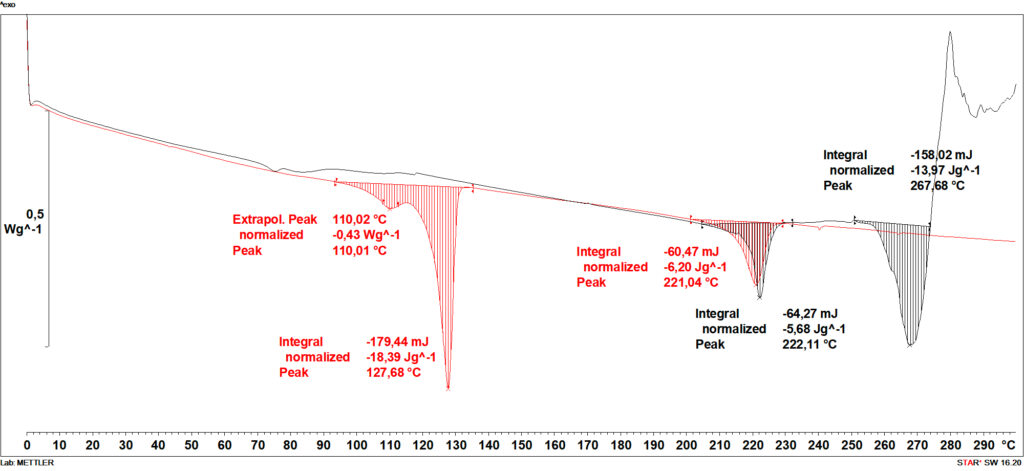

DSC analysis

Melting peaks of different layers (LDPE-HDPE@110-128 °C, PA@221-222 °C, PVC@268°C) useful for defining sealing conditions and polymer types.

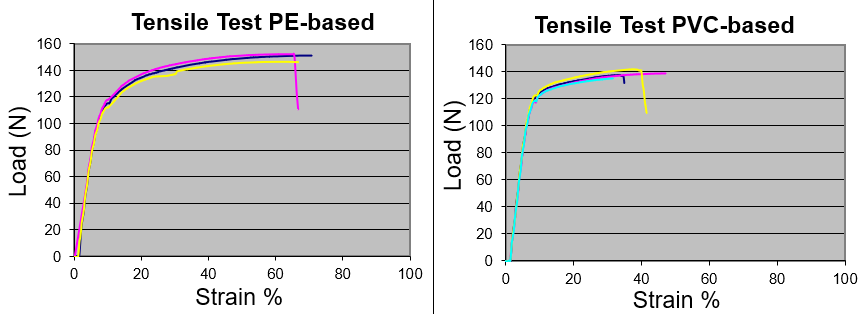

Tensile properties

Tensile mechanical behaviour: the PE-based sample appear to be “softer” (less rigid, with higher elongation at break) than the PVC one. This may lead to different mechanical response on forming step.

Conclusions

When a new material is being tested on machines, different behaviours than classical materials could be explained by physico-chemical and mechanical lab analysis. Some results may give some hints on the counter-measures to take in order to efficiently process those new materials.

[sidebar_on] => [label] => [rel_market] => Array ( [0] => 2 ) [view_correlate] => )Array

(

[in_evidence] =>

[thread_type] => case

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[firewall_close] =>

[minisite] => 244

[hide_minisite_header] =>

[minisite_cover] =>

[minisite_link] =>

[not_listed] =>

[cover] => none

[content] => CUSTOMER’S REQUEST

Adopt a compostable material and improve shelf life of chocolate without compromising its quality.

IMA-ILAPAK

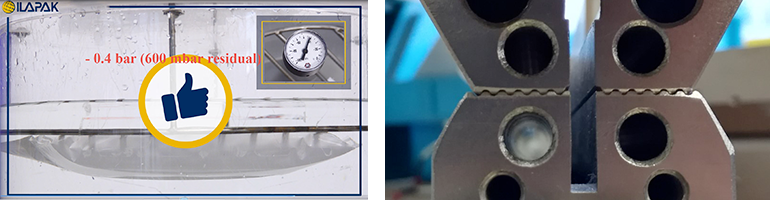

Machine engineering to process the film at comparable speed with respect to standard materials with the possibility to use modified atmosphere packaging.

FILM MANUFACTURER- SACCHITAL- SAES GROUP

Design of a paper-based high gas/moisture barrier industrial compostable film

Problem 1: Paper-based materials have higher coefficient of friction and rigidity due to fibers packing -> Parts consumption and material breaks.

Solution: folding box re-thinking both in shape and surface treatment to reduce friction effects and smoothen the bending forces.

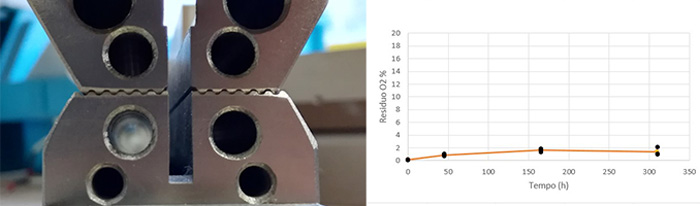

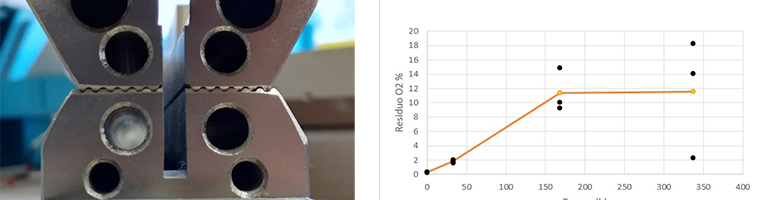

Problem 2: standard sealing jaws micro-punctured the material.

Micro-fractures could not be detected at first. Only monitoring the O2 content over time revealed that the gas was slowly entering.

Solution: re-thinking of jaws profile (smoother) avoided puncturing, while maintaining good sealing properties.

The O2 content over time remained low, showing the disappearance of micro-holes.

Problem 3: hot sealing bars could partially melt the product inside.

Solution: ultrasonic sealing to avoid the consequences of heat application on the product.

[sidebar_on] => 1

[view_correlate] => 1

[widgets] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] => Get in touch

[content] => For further information

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => Contact us

[icon] => mail

[form_email] => openlab@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

)

[sidebar] => Array

(

[widgets] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] => Get in touch

[content] => For further information

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => Contact us

[icon] => mail

[form_email] => openlab@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

)

)

[rel_market] => Array

(

[0] => 3

)

[main_title] => Other Case History

[stripe_view] => all

[type] => openlabCase

[threads] => Array

(

[0] => case

)

[count] =>

[terms] =>

[stream_thread] => Array

(

[main_title] => Other Case History

[stripe_view] => all

[type] => openlabCase

[threads] => Array

(

[0] => case

)

[count] =>

[terms] =>

)

[stream_bt] => Array

(

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => View all OpenLab Case Histories

[icon] => list

[internal_link] =>

[link] =>

[link_page] =>

[tab] =>

)

)

)

[firewall_cookie] =>

[copy_thread_to_other_site] =>

[label] =>

)