At the EOL HUB, we specialize in providing comprehensive solutions for the secondary and end-of-line stages of product packaging across various industries.

EOL stands for Endless Opportunities Like:

ADVANCED TECHNOLOGIES

Provide comprehensive solutions that are on time and on target, expertly handling products of any shape and size with maximum care and efficiency.

INNOVATION

Develop innovative, sustainable stand-alone solutions or complete lines focused on efficiency and flexibility to meet evolving market demands and respond to emerging trends.

BESPOKE SOLUTIONS

Supply tailor-made solutions through close analysis of production scenarios and a clear understanding of objectives.

COMPETENT

From the early stage of a project to production, we offer expert guidance in solving challenges such as line layout, product handling, speed requirements, and space constraints, serving as dedicated consultants and allies.

Explore our solutions for Pharma

Explore our solutions for Food

Explore our solutions for Personal Care

-

Cartoning

-

Multipack & Sleeving

-

Stretch & shrink wrap

-

Over

wrapping

-

Case packing

-

Palletizing

-

Product handling

-

Label application

There’s nothing we can’t do with cardboard.

Our horizontal cartoning machines cover a diverse range of product shapes and sizes, starting from pre-glued blanks.

The forming, loading, and closing systems are capable of performing these functions independently as stand-alone modules or integrated into a unified framework combining multiple operations. They can also integrate seamlessly with a case packing station for a comprehensive all-in-one solution.

Horizontal cartoning

Horizontal cartoning machines, intermittent or continuous, designed for gentle product loading at high, medium, or low speed. Cartons can be closed with hot melt or tuck-in system.

Forming, Loading, and Closing

Stand-alone or integrated systems suitable for handling a variety of cartons and trays. Forming capabilities include single, double, or triple forming heads. Closing options feature hot melt or interlocking systems. Products are efficiently managed by delta robots.

Integrated solutions

Integrated packaging machines combining forming, loading, and closing units for both cartons and cases are available.

These systems guarantee maximum efficiency in handling different products at different speeds.

Smart sleeve for a secure multipack

Our sleeving machines are designed for the efficient packing of various products such as bottles, cups, jars, cans, and thermoformed containers from single or double lanes up to two product layers.

Sleeving

These systems place rigid packages and thermoformed containers of different shapes and sizes into cluster packs and sleeves. Cardboard sleeve closing can be done by means of hot-melt gluing on the bottom or top of the packs.

Integrated solutions

Sleeving machines can be combined with case packers to fit areas with space constraints.These systems guarantee maximum efficiency in handling different products at different speeds.

Wrap It Right: Stretch and Shrink Solutions Tailored for Precision!

Our wide range of machines can cover different speeds, with dedicated solutions for products whose shape tends to vary

widely, including those supplied in containing trays or pucks. Stretch banding and shrink wrapping machines are not only

compact but also flexible and feature a sleek, simple design for efficient and user-friendly operation.

Stretch banding

Engineered to handle high speeds effortlessly, these machines seamlessly wrap bands of film or eco-friendly materials around products, whether they are turned on edge or stacked. Perfect for diverse production environments, our machines ensure precision and reliability.

Shrink wrapping

Our systems are crafted to bundle bottles of any shape or cartoned products and shrink-wrap them using PE film within a compact tunnel. They ensure efficient processing with minimal downtime, emphasizing time-saving efficiency, ergonomic design, ease of use, and high-quality execution.

Accuracy defined: from film to seal

Accuracy is our priority across all stages of film winding, cutting, folding, and sealing.

Our overwrapping machines guarantee geometrically precise cuts and flawless seals, eliminating wrinkles, air bubbles, and imperfections. They offer versatility with options for transverse sealing and lateral sealing for both single items and bundled packaging, and they can run with paper, compostable, biodegradable materials, as well as traditional OPP film.

Side Sealing

In these machines, the film is unwound vertically from a roll. As the product is conveyed forward, it is pushed against the vertically unwound film, which is then wrapped around the entire product. Consequently, the film is then sealed along the side, completing the overwrapping process. The vertical unwinding and side sealing process make these machines particularly effective for high-speed, high-volume packaging operations across various industries, including food, pharmaceuticals, and consumer goods.

Bottom Sealing

On machines where the film is unwound horizontally, the product moves upward from bottom to top, it is pushed against the unwound film, which then wraps around the entire product. The final step in the process involves sealing the film on the bottom. This method effectively protects the product from moisture, dust, and contaminants while providing a clean and professional appearance.

Stand alone or integrated case packers

No matter the type of case packing you require, you can find it with us!

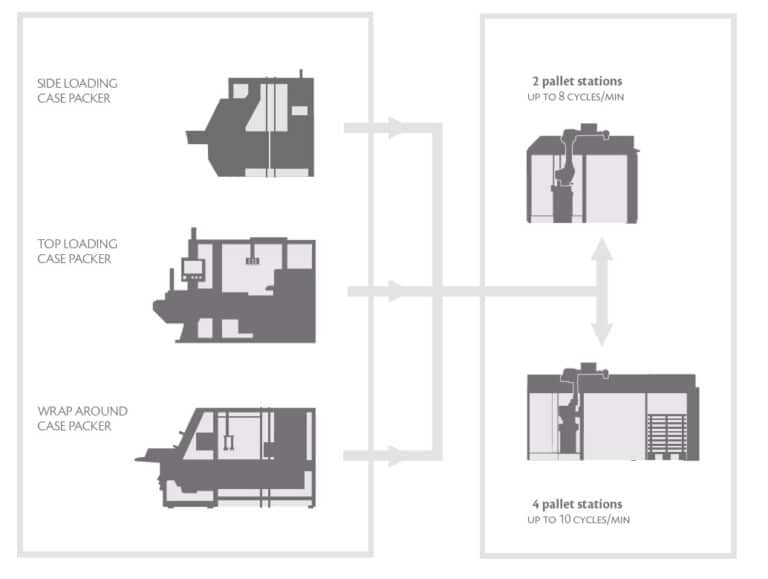

Our offerings cover a wide range of side loading, top loading, and wrap-around machines designed to handle all shapes, sizes, and types of products, starting from RSC pre-glued cases or flat blanks. These solutions accommodate various product combinations, infeed options, and closing types, including hot melt or self-adhesive closures, and can operate at a wide range of speeds. We also provide “All-in-one” solutions that combine carton forming, loading, and closing with top-loading and wrap-around case packing within the same frame. Additionally, our case packing machines can be integrated with a palletizing station within a compact frame.

Case Packer - Palletizer integrated versions

Minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Side loading Case packing

Horizontal loading case packing is the ideal solution for applications requiring reliability and compactness. Our side-loading case packers efficiently handle both individual and bundled cartons into RSC cases, providing a wide range of options to accommodate various speeds and production requirements.

Top loading Case packing

Our top loading case packers efficiently handle even unstable products while maintaining high speeds. These systems are versatile, capable of forming, loading, and closing pre-glued cases and flat blanks to meet diverse packaging needs.

Wrap around case packing

These machines are designed for the efficiently handling of all shapes and sizes, even if they are unstable or critical to run at high speeds. Our wrap-around case packers are designed to pack individual or bundled products into cases, display boxes or trays with internal or external hoods starting from flat blanks or RSC cases.

The Final Touch to Your Packaging Line: Palletizing and De-Palletizing

Palletizing and de-palletizing solutions with single or multiple pallet stations for RSC cases, wraparound cases, trays and bundles, ready for line integration.

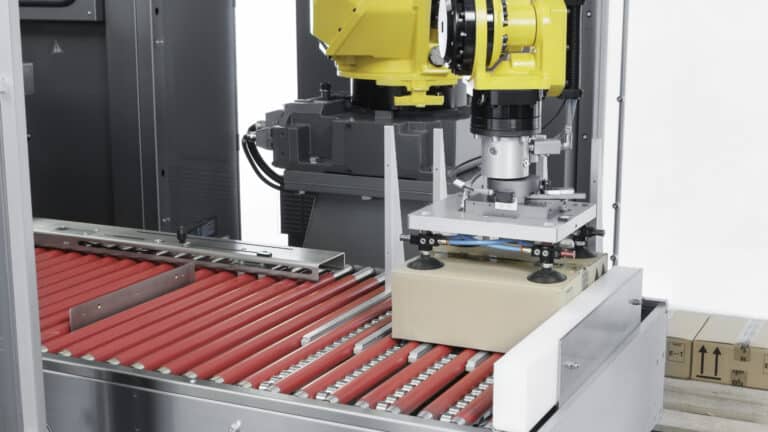

Available in several versions ranging from basic applications such as manual pallet loading up to more sophisticated solutions such as automatic feeding of empty pallets and unloading of full pallets, our palletizers and de-palletizers use precise, rapid multi-axis robotized systems for accurate positioning of products.

Palletizing

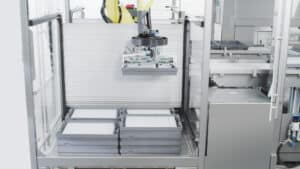

Our palletizing machines are highly versatile, enabling automatic palletization of RSCs, trays, containers with special flaps, or pre-assembled display cases. They can be supplied as stand-alone units or integrated with case packers, capable of precisely palletizing individual items, multiple cases in specified patterns, or entire layers of cases. Additionally, we offer centralized solutions for palletizing different products from various production lines.

De-palletizing

Our robotized de-palletization systems are designed to efficiently unload products such as trays, bundles, and cases from pallets. The de-palletization is managed by an integrated vision system able to recognize the trays’ position and the overlapping/direction of trays. The machine can also be equipped with a re-palletizing function. These de-palletizing machines can be configured with 2, 4, or 6 pallet stations and integrated with product handling systems.

Efficient Handling Solutions: Precision from Start to Finish

Product handling machines are specifically engineered to handle a wide array of items such as medical devices, BFS products, pens, jars, caps, pouches, bottles, and more.

These systems rely on robotic technology at their core, enabling flexible product handling at any stage of the production line—whether at the beginning, middle, or end. They seamlessly integrate with cartoners, flow wrappers, case packers, and de-palletizers ensuring reliable operations throughout the packaging or storage process.

Produc Handling

Robotic systems designed to load/unload products from/to transport trays and insert them or take them from the line. They can be integrated with de-palletizers for greater autonomy.

Tray Loading

Robotized tray loading systems which fix for different products like tubes and bottles. The products are picked-up from pucks by a robot and carefully placed into display trays.

Flexible Labelling Solutions for Every Package Type.

Print & apply or apply-alone labelling equipment for a wide range of package types, including cases, trays, flowpacks, doypacks, bags, jars, bottles, pallets, as well as any applications in logistics and e-commerce. With a genuinely modular design, our solutions offer flexibility in configuration and application.

Print & Apply

Industry-oriented reliable and safe Print&Apply solutions designed to meet the most demanding application needs. Future proof systems, easily reconfigurable, that grows together with your needs.

Label applicators

Labeling systems developed for OEMs and integrators offering high-performance in a compact form-factor. Easy and flexible installation and several opportunities for HMI integration.

Pallet labeling

End-of-line 3 side Print&Apply out of the box with multi-axis, fully programmable, electric movements for a freely configurable and precise label positioning. With advanced, built-in safety features, it can be installed without safety barriers.