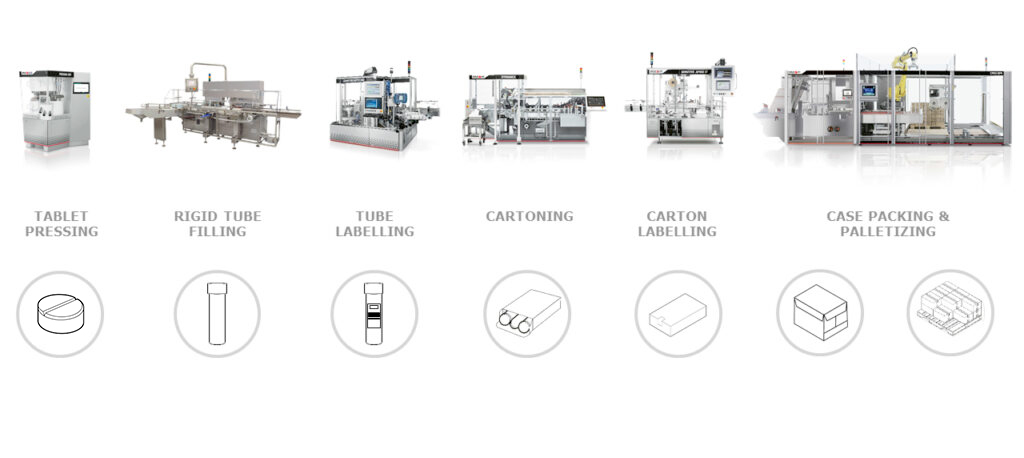

Follow the Effervescent Tablets Applications Line

Discover and customise your complete effervescent tablet processing and packaging line

The synergy between IMA divisions ensures a complete and unprecedented range of machines for the production and packaging of effervescent tablets

Example of an effervescent tablet processing and packaging line

Synergy between the Pharma divisions has created a 360º solution, flexible enough to offer two packaging solutions with the same equipment. This is modularity at its best, where a complete line has a double function: tubes directly in a carton or tubes loaded on a tray. Doesn’t matter about the running function: the end of the line is so flexible, using the same technology, it can pack two completely different types of infed product. These are aspects common to all IMA technologies: versatility and compatibility. We combine these features with standards that characterise us the most: production speed, packaging quality, material waste and rejection.

The layout shows a complete line for packaging effervescent tablets. IMA offers a line managing the process from powder compression up to output of the effervescent tablet, which is then packed in tubes that will be, according to the chosen format, packed in a carton or loaded by an IMA robotic system onto a paper tray. Afterwards, wraparound technology will be able to handle both types of packaging and then move the case to the palletizer, that prepares the product for shipment.

Portfolio for effervescent tablets

Array

(

[cover_macro] => 3933

[cover_name_type] => txt

[cover_name] => PREXIMA

[cover_descriptor] => Tablet press

[cover_focus_on] => 1

[cover_focus_content] => Everything gained in years of experience and expertise in the industry has been carefully channelled into PREXIMA, the new series of tablet press machines. Available in three models, PREXIMA is the best solution to handle all production volumes.

[buttons_on] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the webinar

[icon] => play_circle_outline

[link] => l8ZZ8d8Cn60

[autoplay] => 1

)

)

[cover_focus_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the webinar

[icon] => play_circle_outline

[link] => l8ZZ8d8Cn60

[autoplay] => 1

)

)

)

[news] =>

[thumbnail] => 30008

[tag_line] => All our skills. Compressed.

[overview] => Powered by IMA Active’s knowledge of the sector, designed with unique Italian style, built to deliver top-level performance, PREXIMA drives productivity to a higher level of efficiency. PREXIMA ensures optimal performance even with the most difficult-to-manage powders, keeping the tablet uniform in terms of weight and hardness.

[sustainability] =>

An in-depth evaluation has been carried out on different types of main motorisation to choose the one that provides the best performance, while always keeping an eye on energy saving in order to obtain high efficiency, maximum control, advanced diagnostic and reduction of consumption (elimination of motor cooling system). PREXIMA applies brushless motorisation to ensure energy efficiency while granting high machine performance.

Moreover PREXIMA guarantees waste reduction. Advanced machine learning functions are used for more efficient self-adjustment of process parameters: less waste, better product quality. All this maximises machine functionality, keeping the machine performance on target and allowing the single rejection of products out of specification.

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Isolation of the processing area, thanks to the use of specially designed seals and protections.

)

[1] => Array

(

[highlight] => Excellent accessibility, ensuring straightforward operations, easy inspection and cleaning.

)

[2] => Array

(

[highlight] => Quick turret removal: the HMI guides the operator step by step.

)

[3] => Array

(

[highlight] => Sturdy structure guarantees both pre-compression and main compression forces up to 100 kN.

)

[4] => Array

(

[highlight] => Optimised lubrication: no oil dripping from upper punches and no black spots on tablets.

)

[5] => Array

(

[highlight] => Low noise level: sound-proof panels and anti-vibration feet keep the noise level below 75 dB.

)

[6] => Array

(

[highlight] => MAX new corporate HMI plays a strategic role in improving operator efficiency, while ensuring prompt responsiveness, enhanced predictability and easy learning.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 22134

[content] => Tested at the anechoic chamber at the University of Ferrara (Italy) to select the best technical solution and sound-proof materials, PREXIMA minimises vibrations.

[buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => Watch the webinar

[icon] => play_circle_outline

[link] => l8ZZ8d8Cn60

[autoplay] => 1

)

)

)

)

[technical_data] => | TECHNICAL DATA PREXIMA 80 | ||||

| Die type | B+D | D | B | BB |

| Tool type | B+D | D | B | B |

| Number of press stations | 4+4 | 13 | 16 | 19 |

| Maximum tablet diameter (mm) | 16+25 | 25 | 16 | 13 |

| Maximum die filling (mm) | 18 | |||

| Maximum output (tablets/hour) | 20,400 | 66,300 | 81,600 | 96,900 |

| Revolution per minute (min -1) | 85 | |||

| Maximum pre-compression force (kN) | 10 | |||

| Maximum compaction force (kN) | 60 | |||

| Maximum installed power (kW) | 75 | |||

| Standard voltage | 400V (+/- 10%) 50-60 Hz | |||

| Pitch circle diameter (mm) | 180 | |||

| TECHNICAL DATA PREXIMA 300 | |||||

| Die type | IMA 32 | D | B | BB | IMA 8 |

| Tool type (EU and TSM) | IMA 32 | D | B | IMA 8 | |

| Number of press stations | 18 | 27 | 33 | 41 | 55 |

| Maximum tablet diameter (mm) | 39 | 25 | 16 | 13 | 10 |

| Maximum die filling (mm) | 24 | 20 | 19 | ||

| Maximum output (tablets/hour) monolayer | 97,200 | 194,400 | 237,600 | 295,200 | 396,000 |

| Revolution per minute (-1) | 120 | ||||

| Maximum pre-compression force (kN) | 100 | ||||

| Maximum compaction force (kN) | 100 | ||||

| Electrical power requirement (kW) | 14 | ||||

| Standard voltage | 400V (+/- 10%) 50-60 Hz | ||||

| Pitch circle diameter (mm) | 380 | ||||

| TECHNICAL DATA PREXIMA 800 | ||||

| Die type | D | B | BB | IMA 8 |

| Tool type (EU and TMS) | D | B | IMA 8 | |

| Number of press stations | 53 | 65 | 81 | 105 |

| Maximum tablet diameter (mm) | 25 | 16 | 13 | 10 |

| Maximum die filling (mm) | 20 | 19 | ||

| Maximum output (tablets/hour) monolayer | 572,400 | 702,000 | 874,800 | 1,260,000 |

| Revolution per minute (-1) | 90 | 100 | ||

| Maximum pre-compression force (kN) | 100 | |||

| Maximum compaction force (kN) | 100 | |||

| Electrical power requirement (kW) | 27 | |||

| Standard voltage | 400V (+/- 10%) 50-60 Hz | |||

| Pitch circle diameter (mm) | 745 | |||

PREXIMA 80 tablet press is designed for R&D applications and small scale production. In R&D configuration the machine offers wide range of tools to characterize the tablet; it furthermore offers flexibility on any tablet dimension, as the MIX turret fits four stations B and four station D. Mating this machine with IMAGO R&D software, available as an option, makes the ideal choice for R&D departments.

An equivalent machine model is available also for high containment installation in OEB 5 configuration.

PREXIMA 300 is the single side tablet press for medium production. Beside excellent accessibility, its clever design makes the turret removal quick thanks to the rotating arm completely housed inside the mechanical compartment, while the built-in electrical cabinet enables for an easier installation. Sturdy, efficient and flexible, it is available also for the production of big tablets up to 39 mm diameter.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => Download brochure [icon] => file_download [link] => 26691 [tab] => ) ) ) ) [2] => Array ( [version_label] => PREXIMA 800 [version_title] => PREXIMA 800 [version_thumbnail] => 26694 [version_overview] =>PREXIMA 800 is the double sided tablet press for high production and is suitable also for bilayer tableting. The excellent accessibility which characterizes the PREXIMA series ensures a complete access to the process area all-around the machine. The construction of the machine is based on four columns linked together by two strong cast iron structures which directly support the four compression rollers from both sides. This ensures all the forces are transferred to the product to achieve the highest tablet compression and stability at maximal speed.

[version_overview_buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => Download brochure [icon] => file_download [link] => 26691 [tab] => ) ) ) ) ) [view_default] => 1 )

Everything gained in years of experience and expertise in the industry has been carefully channelled into PREXIMA, the new series of tablet press machines. Available in three models, PREXIMA is the best solution to handle all production volumes.

Array

(

[rel_market] => Array

(

[0] => 7

)

[clone_list] => Array

(

)

[contact] => marketing.life.it@ima.it

[no_index] =>

[tile_description] =>

[tile_speed] => Up to 600 pcs/minute

[cover_macro] => 29047

[cover_name_type] => txt

[cover_name] => SENSITIVE ROTO

[cover_descriptor] => Labelling machine for vials and bottles

[cover_focus_on] => 1

[news] =>

[thumbnail] => 29048

[tag_line] => Perfection is all-around.

[overview] => The Sensitive Roto includes four machine models suitable for applying self-adhesive labels to both sides of oval, square or rectangular bottles, vials and cylindrical containers with unusual shapes.

The modular design and range of groups that can be installed on these machines make them the most flexible solution for high-speed labelling.

The machine can be equipped with up to four labelling heads and can also apply outserts, booklets and hanging labels. Additionally it boasts brushless motors which move each holding platform to ensure precise container positioning during the labelling phase.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[versions_on] =>

[addon_on] =>

[technical_data] => | SENSITIVE ROTO Technical data | ||||

| Model | Sensitive Roto 400 | Sensitive Roto 540 | Sensitive Roto 720 | Sensitive Roto 960 |

| Maximum output (pieces/minute) | 400 | 600 | 600 | 600 |

| Installed power (kW) | 3 | |||

| Standard voltage | 400 V – 50 Hz | |||

| Bottle maximum height (mm) | 220 | |||

| Bottle diameter (mm) | 16-86 | |||

| Label height (mm) | 10-100 | |||

| Label length (mm) | 15-250 | |||

| Label reel diameter (mm) | 400 | |||

| Label accuracy (mm) | ±1 | |||

[layouts] => Array ( [0] => Array ( [image] => 16888 ) [1] => Array ( [image] => 16887 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 28974 [id] => 28974 [title] => SENSITIVE SERIES FOR VIALS AND BOTTLES_EN [filename] => SENSITIVE-SERIES-FOR-VIALS-AND-BOTTLES_EN.pdf [filesize] => 2015932 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2024/04/SENSITIVE-SERIES-FOR-VIALS-AND-BOTTLES_EN.pdf [link] => https://ima.it/pharma/machine/sensitive-200/sensitive-series-for-vials-and-bottles_en/ [alt] => [author] => 16 [description] => [caption] => [name] => sensitive-series-for-vials-and-bottles_en [status] => inherit [uploaded_to] => 2379 [date] => 2024-04-24 07:36:40 [modified] => 2024-04-24 07:37:26 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => MvVDXJEayCI [gallery] => Array ( [0] => Array ( [image] => 16688 [description] => Vial infeed ) [1] => Array ( [image] => 16687 [description] => Label application ) [2] => Array ( [image] => 16689 [description] => Label check with camera ) [3] => Array ( [image] => 16690 [description] => Vial outfeed ) [4] => Array ( [image] => 16691 [description] => Bottle outfeed ) ) [related] => no [line_step] => Array ( [0] => 11 ) [aseptic] => non_aseptic [market_products] => Array ( [0] => 15 [1] => 618 [2] => 627 [3] => 625 [4] => 617 [5] => 624 [6] => 626 [7] => 619 [8] => 623 ) [market_packs] => Array ( [0] => 3945 [1] => 2171 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [technologies] => Array ( [0] => 119 [1] => 120 [2] => 122 [3] => 121 ) [thread_tag] => [market_packs_specs] => Array ( ) [output_on] => [focus] => Array ( [image] => 16687 [content] => Continuous infeed of new label reels without machine interruption is possible thanks to a double Easy Splice reel carrier which can be easily moved and positioned parallel to or perpendicular to the conveyor belt. [buttons] => Array ( [buttons_on] => [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => link [button_id] => [button_class] => [text] => Watch the webinar series [icon] => play_circle_outline [internal_link] => 1 [link] => [link_page] => https://ima.it/pharma/brands/ima-life/sensitive-roto-400-webinar-series/ [tab] => ) ) ) ) [embed_iframe] => [form_price] => [cover_focus_content] =>

Where great performance and high-speed labelling of vials and bottles are required, Sensitive Roto comes into play. Versatile and reliable, it ensures an extremely precise application of labels providing information related to the content of the containers.

[buttons_on] => 1 [cover_focus_buttons] => Array ( [buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => link [button_id] => [button_class] => [text] => Watch the webinar series [icon] => play_circle_outline [internal_link] => 1 [link] => [link_page] => https://ima.it/pharma/brands/ima-life/sensitive-roto-400-webinar-series/ [tab] => ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Compact and ergonomic design with stainless steel finish. ) [1] => Array ( [highlight] => Can be supplied in stand-alone version or integrated in complete processing and packaging lines. ) [2] => Array ( [highlight] => Positive transport of the containers for precise label application ) [3] => Array ( [highlight] => Full servomotor technology for maximum precision during the labelling process. ) [4] => Array ( [highlight] => Rejection unit for containers with missing labels and/or incorrectly printed data which are driven onto a parallel belt or collected in a box. ) [5] => Array ( [highlight] => Easy installation of overprinting devices and camera vision systems to read and check data. ) [6] => Array ( [highlight] => Straightforward access over the entire labelling process, quick clearance and cleaning. ) ) [body_class] => [no_follow] => [seo_image] => 17242 [seo_title] => [seo_description] => Where great performance and high-speed labelling of vials and bottles are required, Sensitive Roto comes into play. Versatile and reliable, it ensures [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => link [button_id] => [button_class] => [text] => Watch the webinar series [icon] => play_circle_outline [internal_link] => 1 [link] => [link_page] => https://ima.it/pharma/brands/ima-life/sensitive-roto-400-webinar-series/ [tab] => ) ) )

Where great performance and high-speed labelling of vials and bottles are required, Sensitive Roto comes into play. Versatile and reliable, it ensures an extremely precise application of labels providing information related to the content of the containers.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

[0] => 4

)

[contact] => mktg.packaging@ima.it

[no_index] =>

[cover_macro] => 2719

[cover_name_type] => txt

[cover_name] => DYNAMICA

[cover_descriptor] => Continuous motion cartoner

[cover_focus_on] => 1

[cover_focus_content] => DYNAMICA Series multipurpose continuous motion cartoner is available in different versions, according to the product specifications, carton dimension sizes and speed. It grants the maximum versatility in terms of applications, infeed systems and carton sizes

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 3043

[tab] =>

)

)

)

[news] =>

[thumbnail] => 2474

[tag_line] => Beyond the limit of the maximum flexibility

[overview] => Flexibility as key feature: this Series offers the widest range of products to be packed, carton dimension range and applications. Moreover, DYNAMICA S version is able to combine both the continuous and the intermittent motion depending on the product fed.

The ergonomics, in terms of carton magazine, product flow and leaflet folding unit heights, is maximum. Last but not least, DYNAMICA is also compact but at the same time easy to manage and intuitive to set up.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 3043

[tab] =>

)

)

)

[sustainability] =>

This system allows the use of recycled cardboards.

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Multi-purpose.

)

[1] => Array

(

[highlight] => Feeding systems: wide range of solutions to pack different products.

)

[2] => Array

(

[highlight] => Very wide cartons sizes range.

)

[3] => Array

(

[highlight] => IMA Safe Roll-One, leaflet folding unit.

)

[4] => Array

(

[highlight] => Ergonomic design.

)

[5] => Array

(

[highlight] => Very easy to manage and intuitive.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 2475

[content] => Cost effective and flexible feeding systems are available at IMA Safe, which offer a wide range of solutions for both pharma and extra pharma fields.

[buttons] => Array

(

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 21536

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => Watch and discover our feeding systems

[icon] => play_circle_outline

[link] => zWyrR5uTcDg

[autoplay] => 1

)

)

)

)

[versions_on] =>

[addon_on] => 1

[addon_items] => Array

(

[0] => Array

(

[image] => 5099

[description] => Roll-One - The IMA patented leaflet folding unit is designed to fold flat sheets using a simple but innovative technology indipendent from the leaflet thickness. To change the leaflet size is just a matter of one simple and fast part replacement.

)

[1] => Array

(

[image] => 2298

[description] => Track & Trace - The integrated module to the cartoner, to apply camera and ink-jet system, is the ideal solution for cartoning serialization having a shorter line and higher efficiency.

)

)

[technical_data] => | TECHNICAL DATA DYNAMICA | ||||

| Width (A) | Height (B) | Lenght (H) | Production output | |

| DYNAMICA L | min 25 – 130 max | min 12 – 90 max | min 65 – 200 max | Up to 250 cartons/min. |

| DYNAMICA E | min 30 – 90 max | min 15 – 65 max | min 100 – 250 max | Up to 300 cartons/min. |

| DYNAMICA SLEEVE* | min 48 – 90 max | min 8 – 15 max | min 65 – 106 max | Up to 350 cartons/min. |

| DYNAMICA S | min 25 – 95 max | min 12 – 90 max | min 65 – 200 max | Up to 350 cartons/min. |

| DYNAMICA V | min 25 – 95 max | min 12 – 90 max | min 65 – 150 max | Up to 400 cartons/min. |

*Version for carton sleeve style

[layouts] => Array ( [0] => Array ( [image] => 5467 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 21536 [id] => 21536 [title] => DYNAMICA SERIES_EN [filename] => DYNAMICA-SERIES_EN.pdf [filesize] => 2764700 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2017/02/DYNAMICA-SERIES_EN.pdf [link] => https://ima.it/pharma/machine/dynamica/dynamica-series_en/ [alt] => [author] => 18 [description] => [caption] => [name] => dynamica-series_en [status] => inherit [uploaded_to] => 2296 [date] => 2022-01-17 14:02:54 [modified] => 2022-01-17 14:03:01 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => 5nsKhNDldAI [gallery] => Array ( [0] => Array ( [image] => 2480 [description] => Product transport ) [1] => Array ( [image] => 2476 [description] => Carton magazine ) [2] => Array ( [image] => 2477 [description] => Carton pick-up and opening ) [3] => Array ( [image] => 2478 [description] => IMA Safe Roll-One ) [4] => Array ( [image] => 2479 [description] => Product insertion into the carton ) ) [related] => no [technologies] => Array ( [0] => 96 [1] => 104 [2] => 87 [3] => 120 [4] => 121 ) [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2176 [1] => 2177 ) [market_brands] => Array ( [0] => 3861 ) [market_plants] => Array ( [0] => 3861 ) [line_step] => Array ( [0] => 11 ) [tile_description] => Continuous motion cartoner. DYNAMICA Series multipurpose continuous motion cartoner is available in different versions, according to the product specifications, carton dimension sizes and speed. It grants the maximum versatility in terms of applications, infeed systems and carton sizes. [tile_speed] => Up to 400 cartons/min [aseptic] => both [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 3043 [tab] => ) ) [thread_tag] => [market_packs_specs] => Array ( ) [output_on] => [addon_title] => Good To Know [embed_iframe] => [form_price] => [no_follow] => [seo_image] => [seo_title] => DYNAMICA: Continuous motion cartoner [seo_description] => DYNAMICA Series multipurpose continuous motion cartoner grants the maximum versatility in terms of applications, infeed systems and carton size range. [body_class] => )

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

[0] => 3

[1] => 4

)

[contact] => mktg.packaging@ima.it

[no_index] =>

[cover_macro] => 2721

[cover_name_type] => txt

[cover_name] => FLEXA

[cover_descriptor] => Intermittent or continuous motion cartoner

[cover_focus_on] => 1

[cover_focus_content] => FLEXA Series includes intermittent and continuous motion versions to better satisfy your demands according to the product to be packed. With FLEXA you choose the maximum flexibility and ergonomics in the most compact machine.

[buttons_on] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 2186

[tab] =>

)

)

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 2186

[tab] =>

)

)

)

[news] =>

[thumbnail] => 17840

[tag_line] => Space-saving design for whatever product to be packed

[overview] => FLEXA, besides being very flexible in terms of carton configurations and dimensions is also extremely versatile in packing the widest range of products thanks to the intermittent motion (single pusher) or the continuous motion (double pusher).

Moreover, FLEXA is one of the most compact machine in its range with a ergonomic design that assures a facility of packaging materials loading.

The changeover is very simple, fast and toolless thanks to the servomotor technology applied.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

This system allows the use of recycled cardboards.

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Feeding systems for a wide range of solutions.

)

[1] => Array

(

[highlight] => Wide range of carton dimensions.

)

[2] => Array

(

[highlight] => Very compact cartoning machine available in either intermittent or continuous motion.

)

[3] => Array

(

[highlight] => Operator friendly.

)

[4] => Array

(

[highlight] => Very easy to clean.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 2723

[content] => Cost effective and flexible feeding systems are available at IMA Safe, which offer a wide range of solutions for both pharma and extra pharma fields.

[buttons] => Array

(

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 2186

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => WATCH AND DISCOVER OUR FEEDING SYSTEMS

[icon] => play_circle_outline

[link] => zWyrR5uTcDg

[autoplay] => 1

)

)

)

)

[versions_on] =>

[addon_on] => 1

[technical_data] => | TECHNICAL DATA FLEXA | ||||

| CONTINUOUS MOTION | INTERMITTENT MOTION | |||

| MODEL | FLEXA CLD | FLEXA CLDB | FLEXA ASB | FLEXA ALB |

| Max Speed | 180 cycles/min. | 160 cycles/min. | 120 cycles/min. | 120 cycles/min. |

| Carton dimensions |

||||

| Width (A) | min 15-90 max | min 15-140 max | min 15-140 max | min 15-140 max |

| Height (B) | min 12-90 max | min 12-90 max | min 12-65 max | min 12-90 max |

| Length (C/H) | min 55-220 max | min 55-220 max | min 55-190 max | min 55-220 max |

Array

(

[cover_macro] => 2181

[cover_name_type] => txt

[cover_name] => X

[cover_descriptor] => Intermittent motion cartoner

[cover_focus_on] => 1

[cover_focus_content] => X Series multipurpose intermittent motion cartoner, is the best price/performance ratio solution in its product range. Thanks to the use of both mechanical and robotized feeding systems, it can handle the widest product variety in the market.

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 28705

[tag_line] => X, love at first sight

[overview] => X Series is available in four versions:

- X1 and XL1

- X2 and XL2, servo-driven versions

The maximum versatility, in terms of products to be packed and carton dimension sizes, is a key feature of this Series. Moreover, with its compact footprint and balcony design, X offers to you also a huge flexibility in the organizing of lines. The compactness of the machine is also demonstrated with the integrated T&T solution inside the frame, keeping the same standard length.

X is also very intuitive: no special training are needed for the operators. It has very low maintenance costs, central issue in the current marketing strategies of pharmaceutical companies, and a fast changeover thanks to a number of size parts reduced to the minimum.

[overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [sustainability] =>

This system allows the use of recycled cardboards.

[highlights_on] => 1 [highlights] => Array ( [0] => Array ( [highlight] => Multi-purpose. ) [1] => Array ( [highlight] => Best performance price ratio in its class. ) [2] => Array ( [highlight] => Compact foot print. ) [3] => Array ( [highlight] => Feeding systems for a wide range of solutions. ) [4] => Array ( [highlight] => IMA Safe Roll-One, leaflet folding unit. ) [5] => Array ( [highlight] => Easy to handle. ) [6] => Array ( [highlight] => Low maintenance costs. ) ) [focus_on] => 1 [focus] => Array ( [image] => 1101 [content] => Cost effective and flexible feeding systems are available at IMA Safe, which offer a wide range of solutions for both pharma and extra pharma fields. [buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 21537 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => Watch and Discover our feeding systems [icon] => play_circle_outline [link] => zWyrR5uTcDg [autoplay] => 1 ) ) ) ) [technical_data] =>| X SERIES – TECHNICAL DATA | ||

| MODEL | X1 – X2* | XL1 – XL2* |

| Production output | Up to 90 cartons/min. | Up to 60 cartons/min. |

| Carton dimensions | ||

| Width (A) | min. 15-105 max. | min. 15-165 max. |

| Height (B) | min. 12-90 max. | min. 12-100 max. |

| Length (H) | min. 65-220 max. | min. 65-220 max. |

| A+B | 195 max. | 240 max. |

*Servo-driven version

[layouts] => Array ( [0] => Array ( [image] => 17856 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 28483 [id] => 28483 [title] => X SERIES_EN [filename] => X-SERIES_EN-1.pdf [filesize] => 2433291 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2016/12/X-SERIES_EN-1.pdf [link] => https://ima.it/pharma/machine/x1/x-series_en-2/ [alt] => [author] => 19 [description] => [caption] => [name] => x-series_en-2 [status] => inherit [uploaded_to] => 371 [date] => 2024-02-28 09:29:29 [modified] => 2024-02-28 09:29:36 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => JMCrbpE0xtc [gallery] => Array ( [0] => Array ( [image] => 1105 [description] => Carton magazine ) [1] => Array ( [image] => 1106 [description] => Carton pick-up and opening ) [2] => Array ( [image] => 1110 [description] => Product insertion into the carton ) [3] => Array ( [image] => 1107 [description] => Coding unit ) [4] => Array ( [image] => 1103 [description] => Carton closing ) [5] => Array ( [image] => 1104 [description] => Carton outfeed and rejection ) ) [related] => no [versions_on] => [addon_on] => 1 [technologies] => Array ( [0] => 96 [1] => 104 [2] => 87 [3] => 88 [4] => 120 [5] => 121 ) [rel_market] => Array ( ) [clone_list] => Array ( [0] => 4 ) [contact] => [no_index] => [tile_description] => Intermittent motion cartoner. X Series multipurpose intermittent motion cartoner, is the best price/performance ratio solution in its product range. Thanks to the use of both mechanical and robotized feeding systems, it can handle the widest product variants range in the market. [tile_speed] => Up to 90 cartons/min [line_step] => Array ( [0] => 11 ) [aseptic] => both [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2176 [1] => 2177 ) [market_brands] => Array ( [0] => 3861 ) [market_plants] => Array ( [0] => 3861 ) [thread_tag] => [market_packs_specs] => Array ( ) [addon_items] => Array ( [0] => Array ( [image] => 2478 [description] => Roll-One - The IMA patented leaflet folding unit is designed to fold flat sheets using a simple but innovative technology indipendent from the leaflet thickness. To change the leaflet size is just a matter of one simple and fast part replacement. ) [1] => Array ( [image] => 3806 [description] => Track & Trace - X Series allows a perfect integration inside the frame of the machine, without any extension, with: printing system, camera and gluing system (tamper evident closure) ) ) [output_on] => [addon_title] => Good To Know [embed_iframe] => [seo_title] => X1: Intermittent motion cartoner [seo_description] => X1 Series multipurpose intermittent motion cartoner, is the best price/performance ratio solution in its product range. [no_follow] => [seo_image] => 11893 [form_price] => [body_class] => )

Array

(

[cover_macro] => 2675

[cover_name_type] => txt

[cover_name] => SENSITIVE AP400 3T

[cover_descriptor] => Labelling machine for cartons

[cover_focus_on] => 1

[news] =>

[thumbnail] => 29060

[tag_line] => Sensitive to serialisation

[overview] => Versatile by design, the SENSITIVE AP400 3T can be supplied in many different configurations according to customer requirements: one labelling head for vignette application, two for tamper-evident sealing or three for both vignette and tamper-evident implementation.

User-friendliness is a hallmark of this machine. Easy operation and quick maintenance are guaranteed.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => download brochure

[icon] => description

[link] => 325

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => watch the video

[icon] => play_arrow

[link] =>

[autoplay] => 1

)

)

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[technical_data] => | TECHNICAL DATA SENSITIVE AP400 3T | |

| Maximum output (cartons/minute) | 400 |

| Installed power (kW) | 3.5 (depending on machine configuration) |

| Standard voltage | 400 V – 50 Hz – 3PH + PE |

| A (mm)* | 400 – 600 – 800 – 1100 |

| Weight (kg) – approximate value | 1,000 |

| Vignette label size (mm) |

Length 15 – 60 |

| Vignette reel diameter (mm) | Up to 400 |

| Tamper-evident label size (mm) |

Length 15-35 |

| Tamper-evident reel diameter (mm) | Up to 400 |

| Labelling accuracy (mm) | ± 1 |

| * Depending on carton size | |

| CARTON DIMENSIONS | |

| A (mm) | 20 to 130* |

| B (mm) | 12 to 100 |

| C (mm) | 50 to 210 |

| * Larger dimension will be managed by customer configurations | |

When product protection from damage and tampering is mandatory, the carton labels play a fundamental role. Conceived with this “must” in mind, the SENSITIVE AP400 3T ensures accurate and precise label application while reaching a high production speed.

[buttons_on] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 325 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => download brochure [icon] => description [link] => 325 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => watch the video [icon] => play_arrow [link] => [autoplay] => 1 ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Positive carton transport system ensuring smooth transfer throughout the working area. ) [1] => Array ( [highlight] => Brushless technology offering maximum labelling precision. ) [2] => Array ( [highlight] => Easy access to the working area. ) [3] => Array ( [highlight] => Automatic rejection of cartons with non-conforming labels or faultily printed data. ) [4] => Array ( [highlight] => No need to change parts even when handling different carton sizes. ) [5] => Array ( [highlight] => Inkjet or laser printers can be fitted to print Data Matrix code and human readable data on the carton. ) [6] => Array ( [highlight] => Intuitive HMI for machine monitoring and supervision of data collection. ) ) [focus] => Array ( [image] => 2677 [content] => Track & Trace already starts inside the SENSITIVE AP400 3T where the label dispensing and application unit works perfectly in sync with the carton transport system and with the optical fibre positive rejection system. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [rel_market] => Array ( [0] => 7 ) [clone_list] => Array ( ) [contact] => marketing.life.it@ima.it [no_index] => [versions_on] => [addon_on] => [technologies] => Array ( [0] => 119 [1] => 120 [2] => 122 [3] => 121 ) [tile_description] => When product protection from damage and tampering is mandatory, the carton labels play a fundamental role. Conceived with this “must” in mind, the SENSITIVE AP400 TE 3T ensures accurate and precise label application while reaching a high production speed. [tile_speed] => Up to 400 cartons/minute [line_step] => Array ( [0] => 11 ) [aseptic] => non_aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2176 [1] => 2177 [2] => 2178 ) [market_brands] => Array ( [0] => 3860 ) [market_plants] => Array ( [0] => 3860 ) [thread_tag] => [market_packs_specs] => Array ( ) [output_on] => [seo_image] => [seo_title] => SENSITIVE AP400 TE 3T: Labelling Machine for Cartons [seo_description] => SENSITIVE AP400 TE 3T ensures accurate and precise label application when product protection from damage and tampering is mandatory. [embed_iframe] => [form_price] => [no_follow] => [body_class] => )

Array

(

[embed_iframe] =>

[form_price] =>

[contact] => imaeol@ima.it

[no_index] =>

[thread_tag] =>

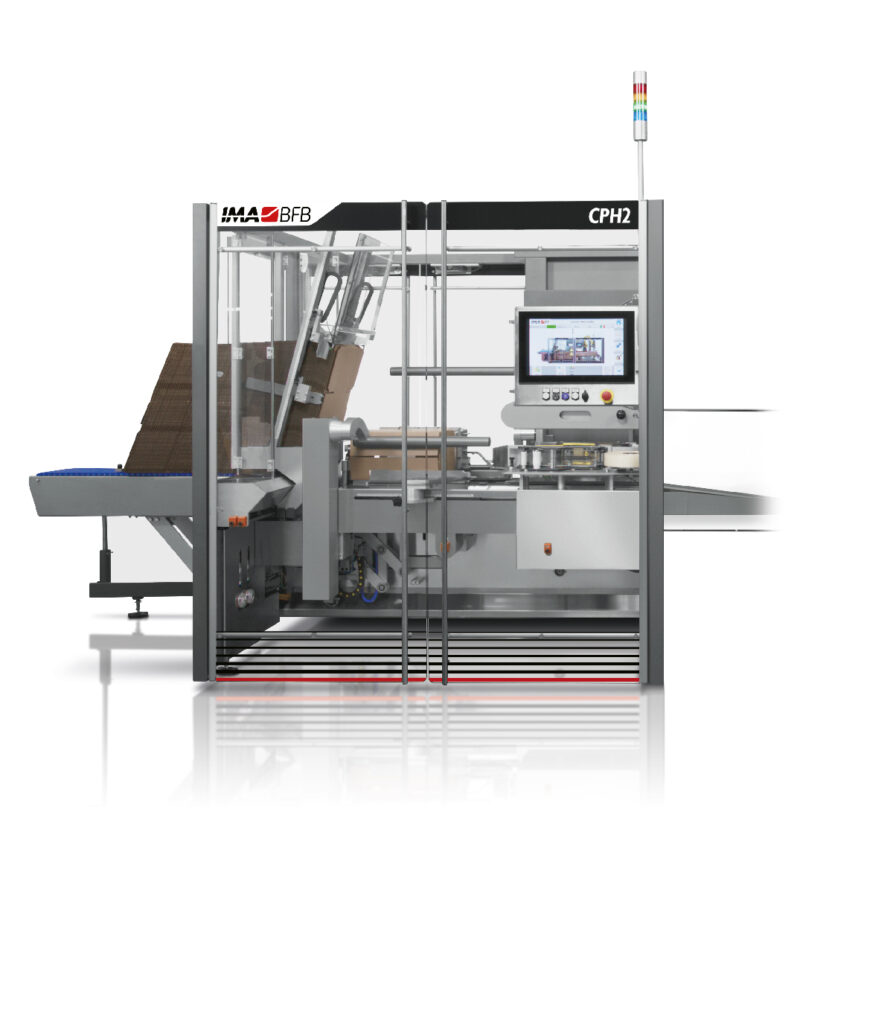

[tile_description] => SIDE LOADING CASE PACKING MACHINE. Medium speed case packer designed to handle the widest range of products and materials used in the pharmaceutical industry.

[tile_speed] => 10 cycles/min.

[cover_macro] => 14803

[cover_name_type] => txt

[cover_name] => CPH2

[cover_descriptor] => Side loading case packing machine

[cover_focus_on] => 1

[cover_focus_content] => Medium speed case packer designed to handle the widest range of products and materials used in pharmaceutical, with maximum ease of use and total control of the packaging process

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 27927

[tag_line] => Fit for the future

[overview] => Fully automatic side loading case packer designed to satisfy all of your current and future case packing requirements.

The machine has been built to maximize efficiency and ease of use in an ever increasingly demanding work place, to guarantee complete line clearance and to ensure total access to all modules.

The CPH2 is designed to ensure total control throughout all stages of the serialization process.

Flexibility, maximum efficiency, total access and total control make the CPH2 a casepacker of new generation.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => The new 830 mm high case magazine ensures easy loading of cases. Correct case feeding to the

picking area is guaranteed by a bottom driven belt.

)

[1] => Array

(

[highlight] => Designed to ensure total access to all machine modules: all parts of the machines can be reached from the operator’s side.

)

[2] => Array

(

[highlight] => Forced opening of the case through two arms allows reliable operations even in case of square shippers or low quality material.

)

[3] => Array

(

[highlight] => Simple design servo driven stacking unit with easy access to cartons collating area. Stacking operation is carried out right in front of the erected case.

)

[4] => Array

(

[highlight] => A servo driven movable hopper follows the cartons collation up into the case and guarantees security of case content.

)

[5] => Array

(

[highlight] => Quick tool-free size changeover with limited amount of adjustments. Fast release system by means of clip switches (on/off): no parts need to be unscrewed with keys.

)

)

[focus_on] => 1

[versions_on] => 1

[addon_on] =>

[output_on] => 1

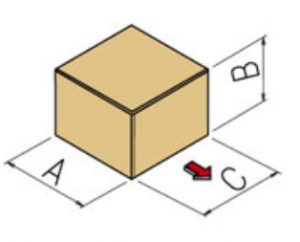

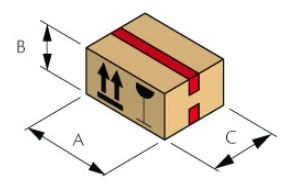

[technical_data] => | CPH2 TECHNICAL DATA | |||

| Case dimensions | A | B | C |

| Min. | 220 | 100 | 90 |

| Max. | 600 | 400 | 400 |

| Product dimensions | a | b | c |

| Min. | 25 | 22 | 60 |

| Max. | 590 | 70/150 | 220 |

| Speed | 10 cases/min. | ||

[layouts] => Array ( [0] => Array ( [image] => 28738 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 28561 [id] => 28561 [title] => CPH2_EN [filename] => CPH2_EN-1.pdf [filesize] => 1854235 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2019/03/CPH2_EN-1.pdf [link] => https://ima.it/pharma/machine/cph2/cph2_en-2/ [alt] => [author] => 29 [description] => [caption] => [name] => cph2_en-2 [status] => inherit [uploaded_to] => 14719 [date] => 2024-03-05 21:56:21 [modified] => 2024-03-05 21:56:38 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => TP2JLN5I_rY [gallery] => Array ( [0] => Array ( [image] => 14732 [description] => Case magazine ) [1] => Array ( [image] => 28562 [description] => Case opening and folding ) [2] => Array ( [image] => 28563 [description] => Carton stacking ) [3] => Array ( [image] => 14730 [description] => Main pusher ) [4] => Array ( [image] => 28564 [description] => Case closing ) [5] => Array ( [image] => 28565 [description] => Camera read with liftable pusher ) ) [line_step] => Array ( [0] => 7 ) [aseptic] => non_aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2180 ) [market_packs_specs] => Array ( ) [market_brands] => Array ( [0] => 3869 ) [market_plants] => Array ( [0] => 3869 ) [rel_market] => Array ( [0] => 3 [1] => 4 [2] => 6 [3] => 7 ) [clone_list] => Array ( [0] => 12 ) [no_follow] => [seo_image] => [seo_title] => [seo_description] => [output_items] => [related] => no [technologies] => Array ( [0] => 105 [1] => 106 [2] => 120 [3] => 122 ) [versions_thumbnail] => 28741 [versions_tag_line] => Case Packer - Palletizer integrated versions [versions_overview] =>

CPH2 is available in different palletizer-integrated versions, according to the output required:

CPH2-RP2

With automatic replacement of the full pallet and case buffering during pallet replacement or with two pallet stations; once one pallet is complete, the robot starts loading the second pallet

CPH2-RP4

With 4 pallet stations for greater autonomy. When the pallet is complete, the automatic transport moves the pallet to the exit area and replaces it with an empty one.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [focus] => Array ( [image] => 14735 [content] => AGGREGATION MODULE. The overall minimal footprint and the cantilever design for improved accessibility ensure total control throughout all stages of the serialization process. The machine can be equipped with a compact module housing labelling units and cameras for aggregation purposes. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [versions_title] => [versions] => [body_class] => [output_items_stripes] => )

Array

(

[embed_iframe] =>

[form_price] =>

[contact] =>

[no_index] =>

[thread_tag] =>

[tile_description] => WRAP AROUND CASE PACKING MACHINE. Electronically driven, high-performance wrap around case packer, the MMP400 benefits from astute ergonomic design features enabling user-friendly operation and optimum productivity, with a flat blanks magazine positioned to allow easy case loading.

[tile_speed] => 30 cycles/min.

[cover_macro] => 14629

[cover_name_type] => txt

[cover_name] => MMP400

[cover_descriptor] => Wrap around case packing machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 14614

[tag_line] => Smart solutions for speed and simplicity.

[overview] => Built to pack individual or bundled products into cases, display boxes or trays starting from flat blanks, the MMP400 wrap around case packer features servo technology enabling speeds of up to 30 cases/minute and extremely smooth handling.

Ergonomically positioned components help to significantly improve operator intervention and thanks to a newly designed case erection mechanism, the horizontal case magazine is as low as possible to achieve increased autonomy. Cases are erected and held in position on two sides during loading.

This system is so effective, it allows for problem-free handling of lower quality corrugated cardboard.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] => 1

[versions_on] => 1

[addon_on] =>

[output_on] =>

[technical_data] => | TECHNICAL DATA MMP400 |

| MMP400 | A | B | C |

| Case dimensions (MIN) | 80 | 80 | 140 |

| Case dimensions (MAX) | 420 | 325 | 420 |

| MMP600 | A | B | C |

| Case dimensions (MIN) | 80 | 80 | 250 |

| Case dimensions (MAX) | 420 | 325 | 600 |

| Speed: up to 30 cases/min |

The MMP400 is a modular multi-packer built to pack individual or bundled products into cases, display boxes or trays. The machine has been designed for the efficient handling of all shapes and sizes, even if they are unstable or critical to run at high speed.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [highlights] => Array ( [0] => Array ( [highlight] => Cantilever design for optimum accessibility and easy cleaning. ) [1] => Array ( [highlight] => New 830 mm height case magazine for easy loading of cases. ) [2] => Array ( [highlight] => Machine fully servo equipped. ) [3] => Array ( [highlight] => Independent modules on infeed to allow for the efficient handling of all kinds of products: jars, bottles, caps, bags, flowpacks, pillows, soft products (cheese, butter), cartons. ) [4] => Array ( [highlight] => Can be equipped either with a 6 axes robot or with a 2 axes loading system (pusher or pick&place), allowing for handling of any products at high speed. ) [5] => Array ( [highlight] => Internal or external lid unit available. ) [6] => Array ( [highlight] => Flexible machine capable to handle flat blank, RSC, tray and tray/hood with simple changeover. ) ) [body_class] => [no_follow] => [seo_image] => [seo_title] => [seo_description] => [versions_thumbnail] => 21214 [versions_tag_line] => Wrap around case packer - palletizer integrated versions [versions_overview] =>MMP400 is available in different palletizer-integrated versions, according to the output speed required.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [focus] => Array ( [image] => 14832 [content] => At IMA BFB we understand the key to success is the infeed of the machine. We have combined our knowledge and experience in handling different shaped products and developed different and independent modules on infeed. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [versions_title] => [versions] => )

Array

(

[rel_market] => Array

(

[0] => 3

[1] => 4

[2] => 6

[3] => 7

[4] => 10

)

[clone_list] => Array

(

)

[contact] => imaeol@ima.it

[no_index] =>

[cover_macro] => 28747

[cover_name_type] => txt

[cover_name] => RP2/RP4

[cover_descriptor] => Stand alone or integrated palletizing

[cover_focus_on] => 1

[cover_focus_content] => Reduced dimensions of the palletizing section and flexible palletizing options, in line with real market needs; these aspects characterize the RP2/RP4 palletizers, equipped with a 6-axis robot capable of absorbing and working at high speed.

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 27926

[tag_line] => Smart technology for different products and tasks.

[overview] => Built to deliver maximum productivity and efficiency, these latest-generation palletizing solutions offer exceptional flexibility. Based around a 6-axis robot which picks up incoming cases, ink-jet printing and labelling or weighing them, everything is carried out efficiently.

Cases are then placed on the pallet according to pre-set patterns memorised by the operator. Modular design allows for customization of the palletizing section, whose dimensions are kept to a minimum.

RP2/RP4 palletizers are conceived to be stand alone or easily integrated with case packers thanks to their quick plug-in connection.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Modular design for efficient use of available space. The modules can be installed in a way that overcomes restrictions presented by existing facility layout. and design.

)

[1] => Array

(

[highlight] => Equipped with their own electrical cabinet they can be easily integrated with any case packing solution.

)

[2] => Array

(

[highlight] => Flexibility in terms of handling various sizes, shapes and weights: these systems can treat single or multiple cases, trays, bags and groups of bottles even at high speed.

)

[3] => Array

(

[highlight] => Enhanced performance thank to fast and simple format changeovers and reduced maintenance operations.

)

[4] => Array

(

[highlight] => Flexible palletizing options: from 1 to 4 stations for pallet transport and palletization.

)

[5] => Array

(

[highlight] => Many options available: slip-sheet magazine, labelling module, rejection station, T&T groups, pre-arrangement for AGV.

)

)

[focus_on] =>

[versions_on] => 1

[addon_on] =>

[technical_data] => | TECHNICAL DATA | |||

| Product dimensions | A | B | C |

| Min. | 800 | 1200 | 1400 |

| Max. | 1000 | 1200 | 1400 |

| Max. speed | up to 10 cycles/min. | ||

RP2

Automatic palletizer with single palletization station suitable for handling RSC cases or naked bundles, picked up by means of a six axes manipulator. When pallet is complete, the robot places the cases on the buffer area, giving the operator time to unload the full pallet while the machine is working.

RP7

Automatic and extremely flexible palletizer with double palletization stations suitable for handling RSC cases or naked bundles, loaded by means of a six axes manipulator. When the pallet is complete, the automatic pallet transport moves the complete pallet to the waiting area on exit and replaces it with a new one, ready to be loaded. Operator removes the full pallet and the machine keeps on working at the same time.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2212 ) [market_brands] => Array ( [0] => 3869 ) [market_plants] => Array ( [0] => 3869 ) [line_step] => Array ( [0] => 7 ) [tile_description] => PALLETIZER. Speed, reduced dimensions of the palletizing area and flexible palletizing options, in line with real market needs: these aspects characterize the RP2/RP4 palletizers, equipped with a 6-axis robot capable of absorbing and working at high speeds. [tile_speed] => 10 cycles/min. [aseptic] => non_aseptic [thread_tag] => [output_on] => [market_packs_specs] => Array ( ) [related] => no [technologies] => Array ( [0] => 112 [1] => 120 [2] => 122 ) [body_class] => [no_follow] => [seo_image] => [seo_title] => RP2/RP4 [seo_description] => Reduced dimensions of the palletizing section and flexible palletizing options, in line with real market needs [embed_iframe] => [form_price] => [versions_title] => [versions] => Array ( [0] => Array ( [version_label] => [version_title] => Case Packer - Palletizer integrated versions [version_thumbnail] => 28404 [version_overview] =>RP2/RP4 palletizers are available in different case packer-palletizer integrated versions, tailored to fit any space constraints and autonomy needs seamlessly.

[version_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [1] => Array ( [version_label] => [version_title] => Different palletizing solutions according to the layout space requests [version_thumbnail] => 28740 [version_overview] =>RP2

Automatic palletizer with single palletization station suitable for handling RSC cases or naked bundles, picked up by means of a six axes manipulator. When pallet is complete, the robot places the cases on the buffer area, giving the operator time to unload the full pallet while the machine is working.

RP4

Automatic and extremely flexible palletizer with double palletization stations suitable for handling RSC cases or naked bundles, loaded by means of a six axes manipulator. When the pallet is complete, the automatic pallet transport moves the complete pallet to the waiting area on exit and replaces it with a new one, ready to be loaded. Operator removes the full pallet and the machine keeps on working at the same time.

[version_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) ) )

Read our case studies

Relive

Achema

The exclusive tech videos shot during Achema 2024 are now available on our dedicated website