Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |The secondary packaging of parenteral products in tray is a process that requires high quality production standards: a careful handling of the product, high productivity and maximum flexibility in both product feeding and machine configuration.

That’s why the IMA Safe series of deep draw thermoforming machines, C260 and C360, is exactly the solution you need.

![]()

Deep draw thermoforming for parenteral products

C260 for small and medium production batches, C360 for large batches: discover and find your made-to-measure solution.

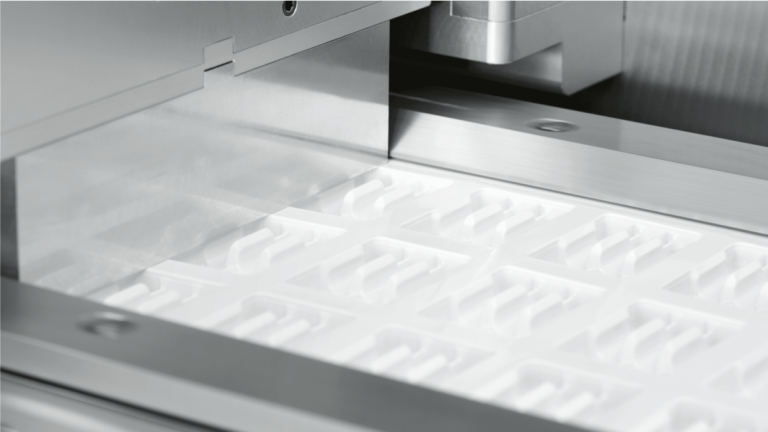

Make the most of being able to handle any type of forming material. Combining an advanced preheating system with the forming process provides uniform film thickness.

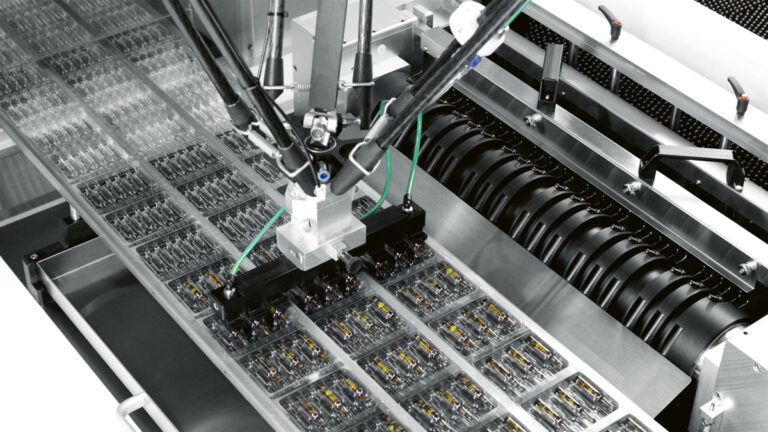

IMA Safe has developed robot-controlled solutions capable of feeding any parenteral product and accessory. The feeding area enables maximum layout flexibility: product can be loaded at the front or rear of the machine.

If tray sealing is required, a sealing unit can be installed that guarantees uniform sealing pressure and offsets any irregular thickness in the materials. The cutter area is extremely accessible and the unit is easily removable for size changeovers.

The connection with the cartoning machine enables maximum layout flexibility. Inline or 90° configurations are possible.

Thanks to a flexible robotised feeder, it is possible to feed a wide range of products, in any configuration inside the tray

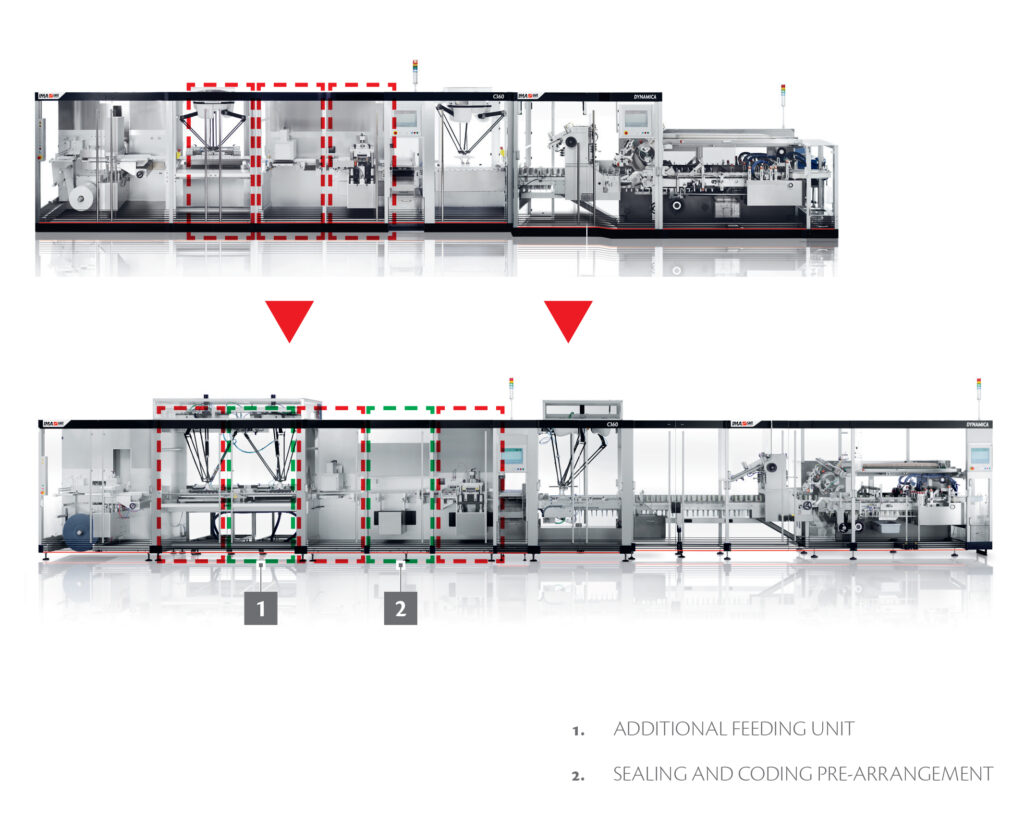

Compact and modular line concept

IMa Safe’s solutions is based on a modular concept. The line can be completely customised in terms of product feeders and machine units installed. The footprint is extremely compact also in case of complex configurations.

C260 and C360 can be coupled to all IMA Safe cartoning machines according to customer requirements

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

[0] => 4

)

[contact] => marketing.safe@ima.it

[no_index] =>

[cover_macro] => 2719

[cover_name_type] => txt

[cover_name] => DYNAMICA

[cover_descriptor] => Continuous motion cartoner

[cover_focus_on] => 1

[cover_focus_content] => DYNAMICA Series multipurpose continuous motion cartoner is available in different versions, according to the product specifications, carton dimension sizes and speed. It grants the maximum versatility in terms of applications, infeed systems and carton sizes

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 3043

[tab] =>

)

)

)

[news] =>

[thumbnail] => 2474

[tag_line] => Beyond the limit of the maximum flexibility

[overview] => Flexibility as key feature: this Series offers the widest range of products to be packed, carton dimension range and applications. Moreover, DYNAMICA S version is able to combine both the continuous and the intermittent motion depending on the product fed.

The ergonomics, in terms of carton magazine, product flow and leaflet folding unit heights, is maximum. Last but not least, DYNAMICA is also compact but at the same time easy to manage and intuitive to set up.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 3043

[tab] =>

)

)

)

[sustainability] =>

This system allows the use of recycled cardboards.

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Multi-purpose.

)

[1] => Array

(

[highlight] => Feeding systems: wide range of solutions to pack different products.

)

[2] => Array

(

[highlight] => Very wide cartons sizes range.

)

[3] => Array

(

[highlight] => IMA Safe Roll-One, leaflet folding unit.

)

[4] => Array

(

[highlight] => Ergonomic design.

)

[5] => Array

(

[highlight] => Very easy to manage and intuitive.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 2475

[content] => Cost effective and flexible feeding systems are available at IMA Safe, which offer a wide range of solutions for both pharma and extra pharma fields.

[buttons] => Array

(

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 21536

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => Watch and discover our feeding systems

[icon] => play_circle_outline

[link] => zWyrR5uTcDg

[autoplay] => 1

)

)

)

)

[versions_on] =>

[addon_on] => 1

[addon_items] => Array

(

[0] => Array

(

[image] => 5099

[description] => Roll-One - The IMA patented leaflet folding unit is designed to fold flat sheets using a simple but innovative technology indipendent from the leaflet thickness. To change the leaflet size is just a matter of one simple and fast part replacement.

)

[1] => Array

(

[image] => 2298

[description] => Track & Trace - The integrated module to the cartoner, to apply camera and ink-jet system, is the ideal solution for cartoning serialization having a shorter line and higher efficiency.

)

)

[technical_data] => | TECHNICAL DATA DYNAMICA | ||||

| Width (A) | Height (B) | Lenght (H) | Production output | |

| DYNAMICA L | min 25 – 130 max | min 12 – 90 max | min 65 – 200 max | Up to 250 cartons/min. |

| DYNAMICA E | min 30 – 90 max | min 15 – 65 max | min 100 – 250 max | Up to 300 cartons/min. |

| DYNAMICA SLEEVE* | min 48 – 90 max | min 8 – 15 max | min 65 – 106 max | Up to 350 cartons/min. |

| DYNAMICA S | min 25 – 95 max | min 12 – 90 max | min 65 – 200 max | Up to 350 cartons/min. |

| DYNAMICA V | min 25 – 95 max | min 12 – 90 max | min 65 – 150 max | Up to 400 cartons/min. |

*Version for carton sleeve style

[layouts] => Array ( [0] => Array ( [image] => 5467 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 21536 [id] => 21536 [title] => DYNAMICA SERIES_EN [filename] => DYNAMICA-SERIES_EN.pdf [filesize] => 2764700 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2017/02/DYNAMICA-SERIES_EN.pdf [link] => https://ima.it/pharma/machine/dynamica/dynamica-series_en/ [alt] => [author] => 18 [description] => [caption] => [name] => dynamica-series_en [status] => inherit [uploaded_to] => 2296 [date] => 2022-01-17 14:02:54 [modified] => 2022-01-17 14:03:01 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => 5nsKhNDldAI [gallery] => Array ( [0] => Array ( [image] => 2480 [description] => Product transport ) [1] => Array ( [image] => 2476 [description] => Carton magazine ) [2] => Array ( [image] => 2477 [description] => Carton pick-up and opening ) [3] => Array ( [image] => 2478 [description] => IMA Safe Roll-One ) [4] => Array ( [image] => 2479 [description] => Product insertion into the carton ) ) [related] => no [technologies] => Array ( [0] => 96 [1] => 87 [2] => 120 [3] => 121 ) [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2176 [1] => 2177 ) [market_brands] => Array ( [0] => 3861 ) [market_plants] => Array ( [0] => 3861 ) [line_step] => Array ( [0] => 11 ) [tile_description] => Continuous motion cartoner. DYNAMICA Series multipurpose continuous motion cartoner is available in different versions, according to the product specifications, carton dimension sizes and speed. It grants the maximum versatility in terms of applications, infeed systems and carton sizes. [tile_speed] => Up to 400 cartons/min [aseptic] => both [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 3043 [tab] => ) ) [thread_tag] => [market_packs_specs] => Array ( ) [output_on] => [addon_title] => Good To Know [embed_iframe] => [form_price] => [no_follow] => [seo_image] => [seo_title] => DYNAMICA: Continuous motion cartoner [seo_description] => DYNAMICA Series multipurpose continuous motion cartoner grants the maximum versatility in terms of applications, infeed systems and carton size range. [body_class] => [canonical_url] => )

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

[0] => 3

[1] => 4

)

[contact] => marketing.safe@ima.it

[no_index] =>

[cover_macro] => 2721

[cover_name_type] => txt

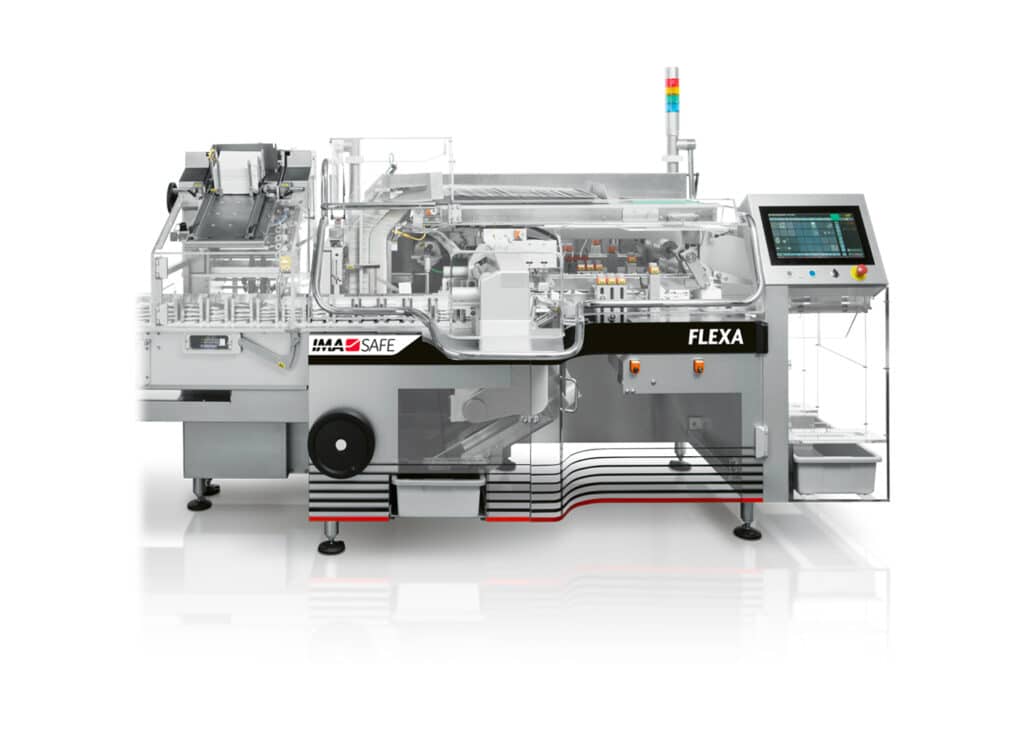

[cover_name] => FLEXA

[cover_descriptor] => Intermittent or continuous motion cartoner

[cover_focus_on] => 1

[cover_focus_content] => FLEXA Series includes intermittent and continuous motion versions to better satisfy your demands according to the product to be packed. With FLEXA you choose the maximum flexibility and ergonomics in the most compact machine.

[buttons_on] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 2186

[tab] =>

)

)

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 2186

[tab] =>

)

)

)

[news] =>

[thumbnail] => 32925

[tag_line] => Space-saving design for whatever product to be packed

[overview] => FLEXA, besides being very flexible in terms of carton configurations and dimensions is also extremely versatile in packing the widest range of products thanks to the intermittent motion (single pusher) or the continuous motion (double pusher).

Moreover, FLEXA is one of the most compact machine in its range with a ergonomic design that assures a facility of packaging materials loading.

The changeover is very simple, fast and toolless thanks to the servomotor technology applied.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

This system allows the use of recycled cardboards.

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Feeding systems for a wide range of solutions.

)

[1] => Array

(

[highlight] => Wide range of carton dimensions.

)

[2] => Array

(

[highlight] => Very compact cartoning machine available in either intermittent or continuous motion.

)

[3] => Array

(

[highlight] => Operator friendly.

)

[4] => Array

(

[highlight] => Very easy to clean.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 2723

[content] => Cost effective and flexible feeding systems are available at IMA Safe, which offer a wide range of solutions for both pharma and extra pharma fields.

[buttons] => Array

(

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 2186

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => WATCH AND DISCOVER OUR FEEDING SYSTEMS

[icon] => play_circle_outline

[link] => zWyrR5uTcDg

[autoplay] => 1

)

)

)

)

[versions_on] =>

[addon_on] => 1

[technical_data] => | TECHNICAL DATA FLEXA | ||||

| CONTINUOUS MOTION | INTERMITTENT MOTION | |||

| MODEL | FLEXA CLD | FLEXA CLDB | FLEXA ASB | FLEXA ALB |

| Max Speed | 180 cycles/min. | 160 cycles/min. | 120 cycles/min. | 120 cycles/min. |

| Carton dimensions |

||||

| Width (A) | min 15-90 max | min 15-140 max | min 15-140 max | min 15-140 max |

| Height (B) | min 12-90 max | min 12-90 max | min 12-65 max | min 12-90 max |

| Length (C/H) | min 55-220 max | min 55-220 max | min 55-190 max | min 55-220 max |

Array

(

[cover_macro] => 32930

[cover_name_type] => txt

[cover_name] => X

[cover_descriptor] => Intermittent motion cartoner

[cover_focus_on] => 1

[cover_focus_content] => X Series multipurpose intermittent motion cartoner, is the best price/performance ratio solution in its product range. Thanks to the use of both mechanical and robotized feeding systems, it can handle the widest product variety in the market.

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 28705

[tag_line] => X, love at first sight

[overview] => X Series is available in four versions:

- X1 and XL1

- X2 and XL2, servo-driven versions

The maximum versatility, in terms of products to be packed and carton dimension sizes, is a key feature of this Series. Moreover, with its compact footprint and balcony design, X offers to you also a huge flexibility in the organizing of lines. The compactness of the machine is also demonstrated with the integrated T&T solution inside the frame, keeping the same standard length.

X is also very intuitive: no special training are needed for the operators. It has very low maintenance costs, central issue in the current marketing strategies of pharmaceutical companies, and a fast changeover thanks to a number of size parts reduced to the minimum.

[overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [sustainability] =>

This system allows the use of recycled cardboards.

[highlights_on] => 1 [highlights] => Array ( [0] => Array ( [highlight] => Multi-purpose. ) [1] => Array ( [highlight] => Best performance price ratio in its class. ) [2] => Array ( [highlight] => Compact foot print. ) [3] => Array ( [highlight] => Feeding systems for a wide range of solutions. ) [4] => Array ( [highlight] => IMA Safe Roll-One, leaflet folding unit. ) [5] => Array ( [highlight] => Easy to handle. ) [6] => Array ( [highlight] => Low maintenance costs. ) ) [focus_on] => 1 [focus] => Array ( [image] => 1101 [content] => Cost effective and flexible feeding systems are available at IMA Safe, which offer a wide range of solutions for both pharma and extra pharma fields. [buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 21537 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => Watch and Discover our feeding systems [icon] => play_circle_outline [link] => zWyrR5uTcDg [autoplay] => 1 ) ) ) ) [technical_data] =>| X SERIES – TECHNICAL DATA | ||

| MODEL | X1 – X2* | XL1 – XL2* |

| Production output | Up to 90 cartons/min. | Up to 60 cartons/min. |

| Carton dimensions | ||

| Width (A) | min. 15-105 max. | min. 15-165 max. |

| Height (B) | min. 12-90 max. | min. 12-100 max. |

| Length (H) | min. 65-220 max. | min. 65-220 max. |

| A+B | 195 max. | 240 max. |

*Servo-driven version

[layouts] => Array ( [0] => Array ( [image] => 17856 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 28483 [id] => 28483 [title] => X SERIES_EN [filename] => X-SERIES_EN-1.pdf [filesize] => 2433291 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2016/12/X-SERIES_EN-1.pdf [link] => https://ima.it/pharma/machine/x1/x-series_en-2/ [alt] => [author] => 19 [description] => [caption] => [name] => x-series_en-2 [status] => inherit [uploaded_to] => 371 [date] => 2024-02-28 09:29:29 [modified] => 2024-02-28 09:29:36 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => JMCrbpE0xtc [gallery] => Array ( [0] => Array ( [image] => 1105 [description] => Carton magazine ) [1] => Array ( [image] => 1106 [description] => Carton pick-up and opening ) [2] => Array ( [image] => 1110 [description] => Product insertion into the carton ) [3] => Array ( [image] => 1107 [description] => Coding unit ) [4] => Array ( [image] => 1103 [description] => Carton closing ) [5] => Array ( [image] => 1104 [description] => Carton outfeed and rejection ) ) [related] => no [versions_on] => [addon_on] => 1 [technologies] => Array ( [0] => 96 [1] => 87 [2] => 88 [3] => 120 [4] => 121 ) [rel_market] => Array ( ) [clone_list] => Array ( [0] => 4 ) [contact] => marketing.safe@ima.it [no_index] => [tile_description] => Intermittent motion cartoner. X Series multipurpose intermittent motion cartoner, is the best price/performance ratio solution in its product range. Thanks to the use of both mechanical and robotized feeding systems, it can handle the widest product variants range in the market. [tile_speed] => Up to 90 cartons/min [line_step] => Array ( [0] => 11 ) [aseptic] => both [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2176 [1] => 2177 ) [market_brands] => Array ( [0] => 3861 ) [market_plants] => Array ( [0] => 3861 ) [thread_tag] => [market_packs_specs] => Array ( ) [addon_items] => Array ( [0] => Array ( [image] => 2478 [description] => Roll-One - The IMA patented leaflet folding unit is designed to fold flat sheets using a simple but innovative technology indipendent from the leaflet thickness. To change the leaflet size is just a matter of one simple and fast part replacement. ) [1] => Array ( [image] => 3806 [description] => Track & Trace - X Series allows a perfect integration inside the frame of the machine, without any extension, with: printing system, camera and gluing system (tamper evident closure) ) ) [output_on] => [addon_title] => Good To Know [embed_iframe] => [seo_title] => X1: Intermittent motion cartoner [seo_description] => X1 Series multipurpose intermittent motion cartoner, is the best price/performance ratio solution in its product range. [no_follow] => [seo_image] => 11893 [form_price] => [body_class] => [canonical_url] => )

Discover a new sustainable solution: the bio-degradable tray

Our well established technologies have been thought once again for the best handling of new generation materials such as the bio-degradable PLA. We keep the same performance, the same quality, with a new purposes: our Planet.

No one is forgotten: new applications are suitable for retrofitting on existing C260 and C360 with just small adjustments in the forming area.