Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |E-MOB

More power, less CO2.

Is our commitment to investing in the search for new solutions and technologies for sustainable mobility.

IMA, with the creation of the new IMA AUTOMATION HUB, plans to continue its path of global development, which focuses on expanding its international customer base and on further strengthening its core competencies of assembly technologies, as well as on investing in research and development aimed at introducing continuous innovations in the field of sustainable mobility.

Electric and hybrid vehicles can lead to emissions reduction and to the conservation of the environment. The Company’s biggest investment ever is the acquisition of IMA AUTOMATION ATOP, an Italian excellence in manufacturing lines for the production of e-traction engines, supported by the latest acquisition of IMA AUTOMATION FASP that will complement the portfolio of high-tech solutions provided by IMA.

Thanks to its own long-standing know-how, combined with a continuous search for innovative technological solutions, IMA AUTOMATION operates in the field of electric drives for sustainable mobility (e-mobility) with hybrid and plug-in electric drive motors. IMA AUTOMATION has the opportunity to become not only one of the leading international providers of EV motors solutions, but also a key supplier of technological solutions to the overall electric motor markets. With this new organisation IMA takes an active step forward in the E-Mob program within IMA ZERO project that represents our commitment to investing in the search for new solutions and technologies for sustainable mobility.

Bike To Work & E-charging stations

Hairpin Technology

Inserting Coil Winding Technology

Magnet Assembly Technology

Wounded Rotor Technology

Bike To Work & E-charging stations

Bike To Work

Bike To Work is a local project that aims at fostering the use of bike through kilometric incentives for home to work transfers, pushing workers to choose public over private means of transportation for daily trips.

Through this project IMA wants to increase awareness in citizens, encouraging them to make more responsible mobility choices.

E-charging stations

In order to foster and promote a more sustainable mobility, IMA installed e-charging stations for electric and hybrid cars in its Italian plants. Each e-charging station has two charging points, which allow the management of two cars at the same time.

After a promotion and incentive period that saw employees being able to recharge for free, from April 2025 recharging can be carried out at a capped price equal to the average cost incurred by the Company in the last year.

Charging time provides a maximum of two hours per session to allow daily rotation among users who will register for the service operated by external provider.

This enables the employees to keep on charging their cars while they are at work, optimising both waiting times for the car’s charging and the employee’s time itself.

In this way, the Group commits to encouraging its workers to use electric and hybrid transport means, and to adopting the philosophy of sustainable mobility.

This contributes to pollution and emission reduction. E-charging stations represent a further step forward for IMA, which is more and more oriented towards a more “electric” future that not only brings to a more eco-friendly re “electric” future that not only brings to a more eco-friendly life approach, but also supports the fight against climate change.

Hairpin Technology

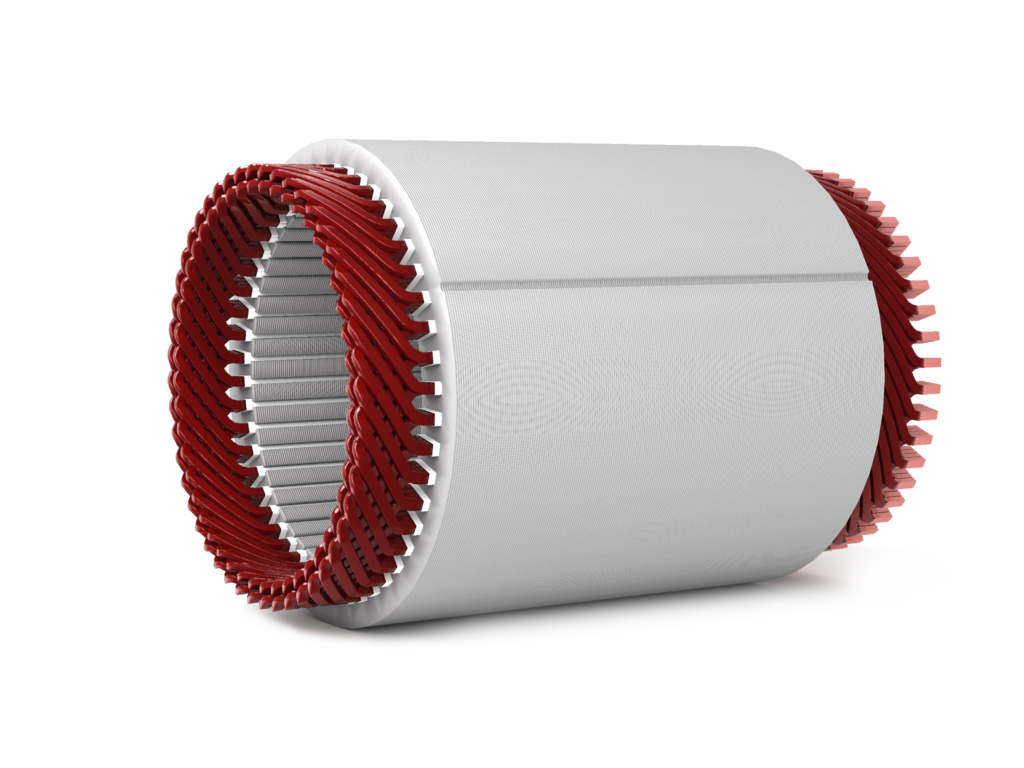

The hairpin technology

The hairpin technology is an innovative solution for the electric traction due to its very high flexibility and wire forming quality.

This technology enables the maximisation of the stator cavity filling to obtain a higher power with a more compact motor.

Hairpin stator

IMA AUTOMATION ATOP is a state-of-the-art player in hairpin, the reference technology for large scale production of hairpin stators for traction electric motors. With a consolidated know-how in manufacturing special machines, IMA AUTOMATION ATOP has achieved considerable results in a relatively short time, accomplishing the design and manufacture of innovative machines and automatic lines for the assembly of hairpin motors.

High speed and accurate hairpin design are ensured to manufacture hybrid stators. Machines are capable to perform all hairpin, pitches lengths and product specifications.

Inserting Coil Winding Technology

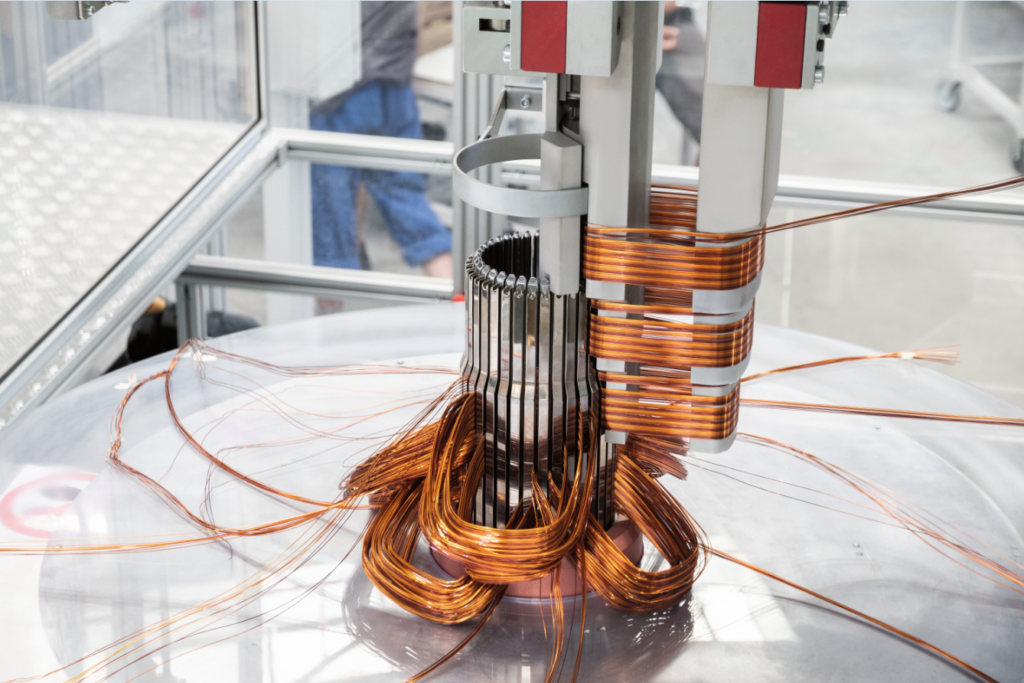

Coil winding and inserting technology

This is an innovative winding technology that includes flyer technology, applied in high performance processes with winding bow, and rotating shapes technology (no twist), which eliminates the twist effect in case of windings with many in parallel wires.

Coil winding stator

Applicable to

IMA AUTOMATION FASP designs and manufactures various types of machines and systems for the insertion of the stators slot windings, able to manage both basic and manual processes, and completely automated processes through the application of the technology developed by IMA AUTOMATION FASP, called HPCIS (High Performance Coil Insertion System), which allows a high fill factor of the processed stators.

Magnet Assembly Technology

Magnet assembly technology

IMA AUTOMATION has a long experience with all the main types of magnetic materials. We are able to manage different product assembly configurations and positions.

Permanent magnet rotor

A consolidated know-how in rotor assembly solutions to meet specific customer requests, even the most complex. The assembly of these rotors requires maximum accuracy, guaranteed by an excellent control of each phase of the process.

Wounded Rotor Technology

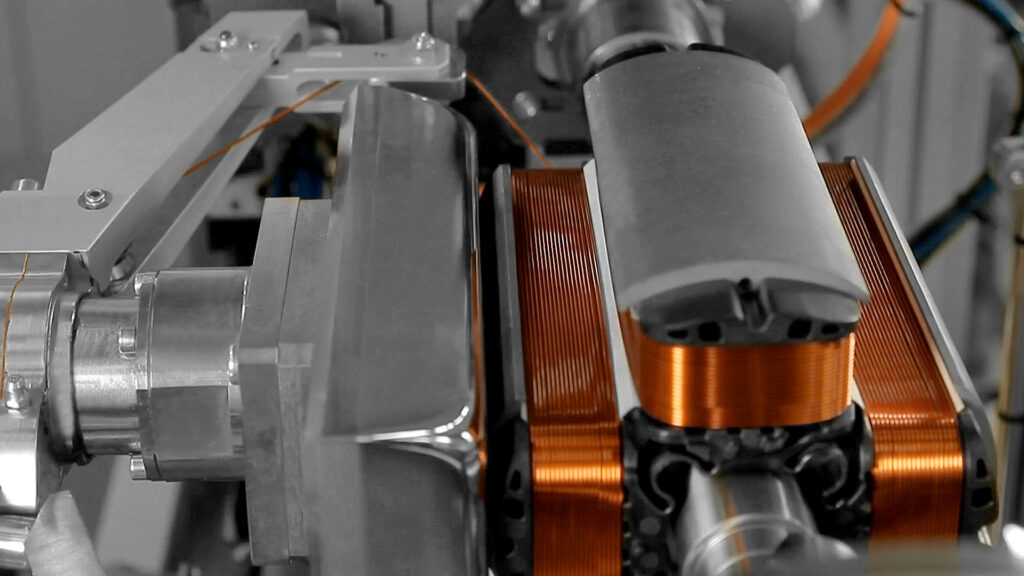

Flyer winding technology

The flyer technology is the starting point of our technological know-how. IMA AUTOMATION designs and manufactures fully programmable wire stratification process with flyer winding technology for high slot fill and accurate coil wire positioning.

Needle winding Technology

This technology is extremely flexible and dynamic. The head of the needle has the characteristic of rotating the head for wire routing on the upper and bottom part of the product. This solution defines an automatic system to increase the productivity and the wire stratification.

Applicable to

Coil winding rotor

The production of such rotors requires complex assembly processes combined with a strong design capability. These features are constantly offered by IMA AUTOMATION ATOP with complete line solutions. Multi-station and speed winding machines able to reach maximum productivity and reduce operating space.

Single pole stator assembly

Lines for fully automatic single pole stratification winding, assembly, fusing and testing. Brushless single pole stators are conceived to meet the growing demand for energy-efficient, compact and best performing motors.