Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |PHARMA ASEPTIC PROCESSING AND FREEZE DRYING SOLUTIONS

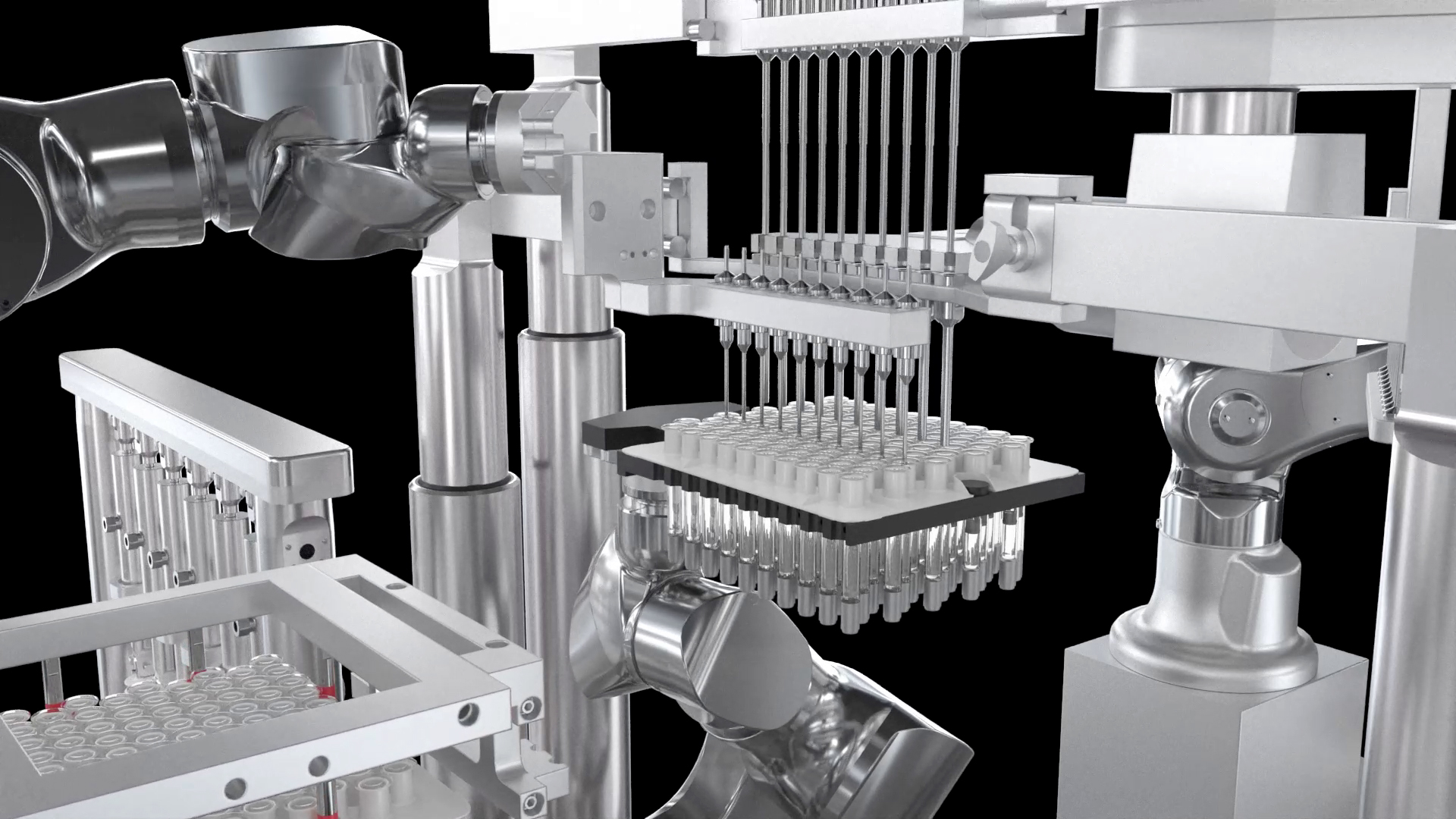

INJECTA 36 - High-speed, Advanced Robotic Processing for Ready-To-Use Components

INJECTA 36 raises the bar for high-speed production of Ready-To-Use Components.

Enhancing the performance of advanced robotics, the INJECTA 36 raises the bar for high-speed production of Ready-To-Use components. The same cutting-edge robotic technologies assure accurate no-touch-transfer component processing with minimal operator access to the working area. Introducing an innovative solution for 100% In-Process Control and check-weighing, INJECTA 36 consolidates IMA Life as a key player in the Ready-To-Use segment for automatic filling & closing machines to maximise production performance.

|

NEBULA - High-speed Decontamination Tunnel

Adopting an unprecedented approach to ensuring 100% sterility of RTU material as it enters and transits isolated production lines, NEBULA is a high-speed decontamination tunnel which integrates seamlessly with IMA Life aseptic fill-finish lines. Responding to the recently published GMP Annex 1 notes whereby risks linked with sterility assurance must be minimised during material transfer and must be supported by high capability transfer technology, Nebula accomplishes what no other solution has done before, especially in terms of speed. 6-log decontamination is achieved over the entire packaging using aerodynamic containment of highly concentrated vapour phase hydrogen peroxide (HC-VPHP), while material crosses the tunnel in a matter of seconds. This allows for continuous, high-speed tub introduction, up to six per minute. NEBULA is a system which can be connected to aseptic fill-finish plants to enhance their performance. Moreover, in face of the increasingly stringent regulations defined in Annex 1, Nebula provides a valid means of guaranteeing excellent sterility assurance.

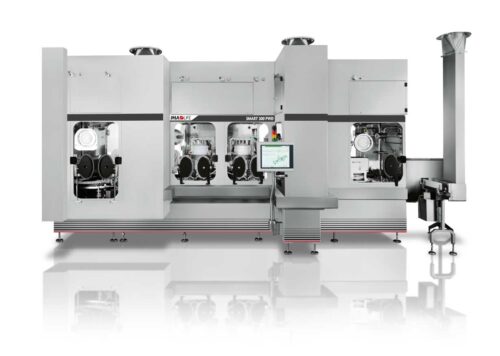

SMART 300 PWD AUGER - High-Speed Powder Dosing & Stoppering Machine

IMA Life has researched and developed a new powder-processing concept which addresses issues such as safety, cleanliness and high containment requirements with innovative technologies. Processing at a rate of 300 pcs/minute, the new SMART 300 PWD AUGER handles high-potent drugs providing accurate decontamination control to avoid risk of residual toxicity and cross-contamination between batches. Capable of dosing two different pharmaceutical powder types inside the same vial at the same time, the machine also performs single 100% check-weighing. The in-place cleaning and sterilisation of the auger dosing unit helps to avoid cross contamination and guarantee the sterility assurance level.

![]()

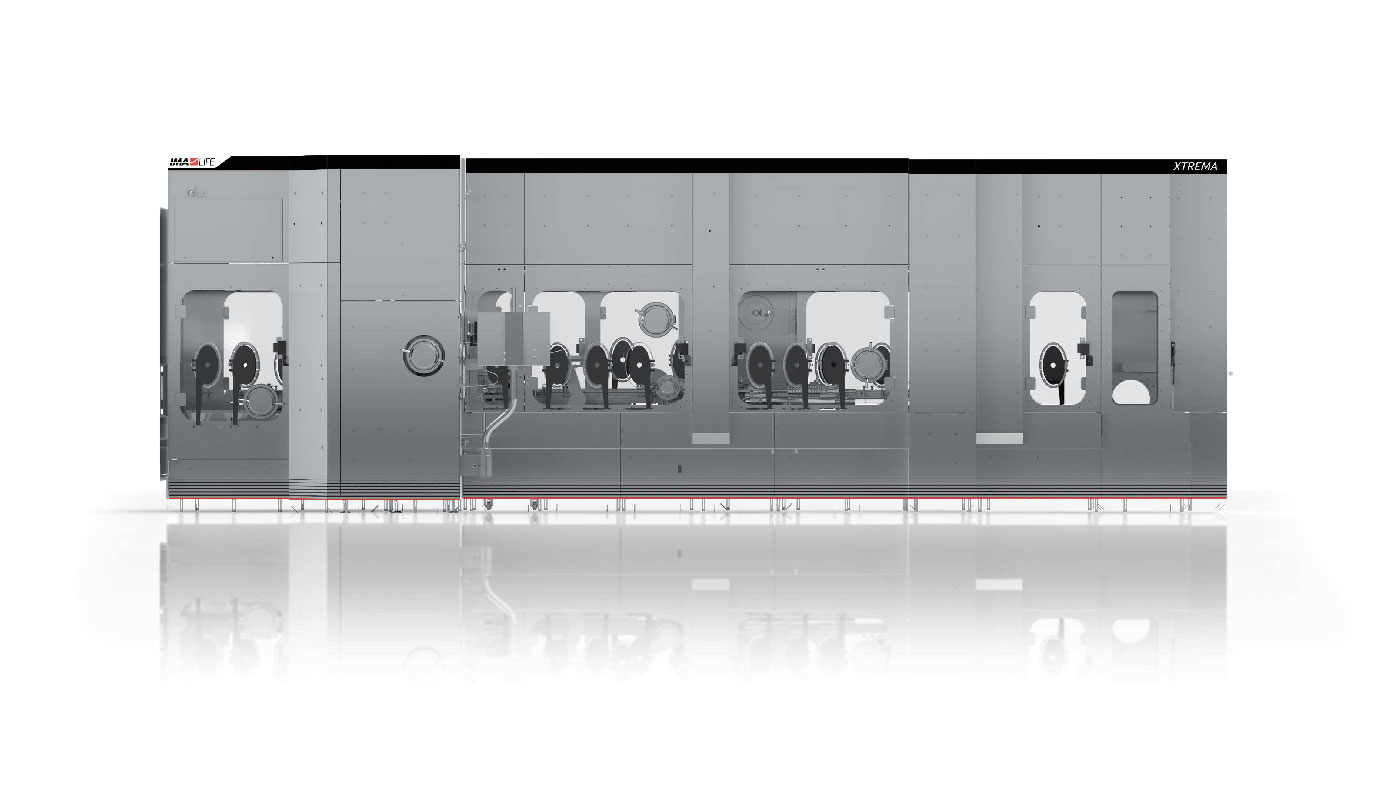

XTREMA, High-Speed Filling and Stoppering Machine for Aseptic Environments

The fundamental characteristics of XTREMA respond to the industry’s stringent technical requirements of vial filling, and with its flexible and ergonomic design it assures the most complete possibility to integrate modular equipment, and, why not, even to install multiple filling systems (liquids & powders) to be used alternatively within the same machine frame. Processing all vial sizes in the SVP and LVP range and changing from continuous to alternate vial transport motion by HMI, XTREMA is your filler for product loss minimisation and refilling at high speed, up to 600 vpm with 100% IPC. And, with the “Quick Fit” feature of the filling pumps – CIP/SIP ready – no tools are needed to get in touch with product contact parts. Ideal for exposure to VPHP, XTREMA is suitable for integration with isolation technology or other containment solutions.

MODULA 50 - Syringe assembly machine

Recently developed by IMA Life, MODULA is the converging element between aseptic filling and secondary packaging.

Conceived to assembly pre-filled glass syringes, it is capable of performing several operations: plunger rod insertion, labelling, backstop assembly and it ensures your syringes flow smoothly through the process, protecting your pharmaceutical products from any potential damage.

MODULA is available in four models to cover low-medium output requirements and provides a high level of automation. It can be easily integrated in complete syringe production lines, with upstream denester or inspection machine and with downstream equipment for secondary packaging up to end-of-line.

The Lab4life Development Lyo Laboratory corner

The Lab4life Development Lyo Laboratory located at IMA Life North America (NY) manufacturing facility includes a number of highly skilled professionals with extensive experience gained in the field of parenteral product and process development technical support including computational modeling, scale-up, equipment characterization and tech transfer and R&D in emerging technologies, providing assistance to our customers worldwide in bridging the requirements between product, process and equipment.

KRYOAIR - Eco-fiendly, Air-based Refrigeration System

During the last 20 years, the gases used in refrigeration systems have been subject to restrictive regulatory measures at a European level in order to limit their impact on the environment. That is why IMA now enables its freeze dryers to be equipped with a new 100% green refrigeration technology using the ultimate natural refrigerant: air. The system is based on a series of compression/cooling/expansion steps made by air, which can be cooled to a temperature as low as -100° C. KRYOAIR is the first high-efficiency power system to generate and accumulate a new green, clean and air-based energy for a low impact on the environment and a high impact on the future of our planet.

![]()

IMA Life's TOUCH Customer Service corner

IMA Life puts the spotlight on an innovative customer relationship experience.

Your experience with IMA Life deserves much more, so get in touch and discover our new customer service approach and the wide range of services we offer to enhance your performance.

From today we can provide you with a wider portfolio of additional training, support and coaching services to improve the effectiveness and yield of your production process and the skills level of your technicians. Choose a support tailored to your needs and cross new boundaries with IMA Life TOUCH.