PACK EXPO LAS VEGAS 2023

- PACK EXPO Las Vegas 2023

- Machines Live Demo

- Pharma

- Medical devices

- Food

- E-Commerce

- End Of Line

- IMA ZERO

- IMA DIGITAL

Array

(

[acf_fc_layout] => welcome_screen

[tab_title] => PACK EXPO Las Vegas 2023

[tab_id] => home

[title] => IMA Group at PACK EXPO Las Vegas 2023

[content] => The IMA Group is glad to announce its participation at PACK EXPO LAS VEGAS 2023.

Discover our processing, assembly and packaging solutions for the Pharmaceutical, Medical Devices, Food and E-Commerce industries.

Discover more:

|

|

|

|

Today sustainability and digital transformation are two sides of the same coin, capable of having a positive impact on business and environment. [stripe_view] => all [single_width] => 100 [single_align] => left [multiple_align] => top [boxes] => Array ( [0] => Array ( [acf_fc_layout] => image [title] => [view] => full [image] => 35662 [lightbox] => [play] => light [image_size] => cover [stuck] => 1 [image_gif] => ) [1] => Array ( [acf_fc_layout] => text [title] => About Sustainability on show [html] => [content] =>

Discover our range of sustainable solutions and let us introduce you to OPENLab: our network of technological laboratories and testing areas.

Let our experts analyse your material, directly on show: bring your sample, and with our tools we will be able to test it in real time.

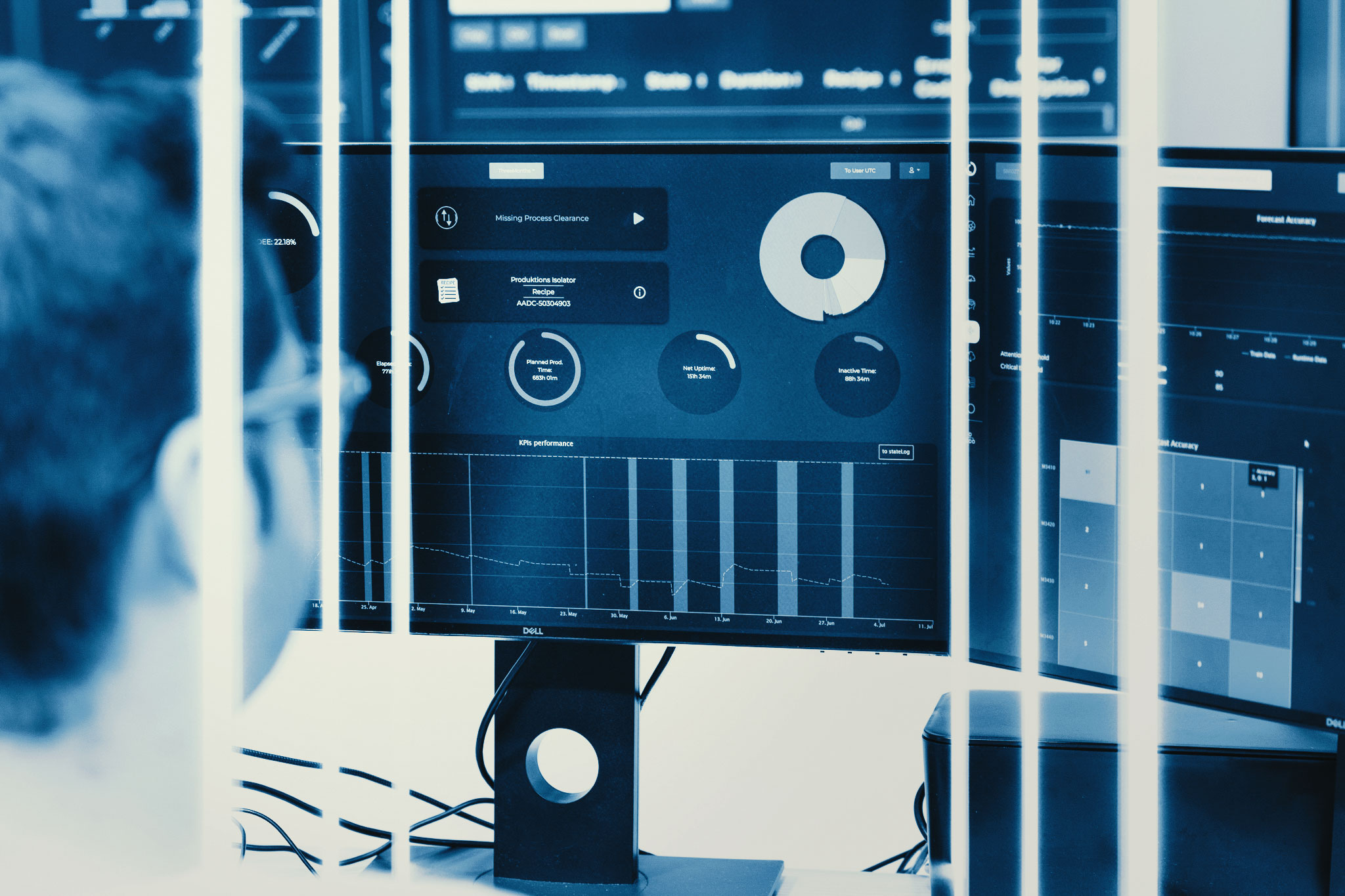

The machines speak Digital and tell of the IMA Smart Factory. Data collected in real time are sent to the IMA Control Room and displayed on dashboards. An actual simulation of what happens during production: data analysis, potential implementations and the increase in production capacity.

[content_html] => [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => link [button_id] => [button_class] => [text] => discover more about IMA DIGITAL [icon] => explore [internal_link] => [link] => https://ima.it/en/exhibition/packexpo-las-vegas/#ima-digital [link_page] => [tab] => 1 ) ) ) ) [stripe_id] => [stripe_class] => [font_color] => dark [background_color] => white [padding_top] => default [padding_bottom] => default [background_image] => [background_image_size] => cover [background_image_position] => center [add_mobile_background] => [background_image_mobile] => ) [1] => Array ( [acf_fc_layout] => stripeContent [main_title] => [stripe_view] => all [single_width] => 100 [single_align] => left [multiple_align] => top [boxes] => Array ( [0] => Array ( [acf_fc_layout] => text [title] => [html] => [content] =>Las Vegas Convention Center

3150 Paradise Rd, Las Vegas, NV 89109, United States

[content_html] => [buttons_on] => [view_default] => [buttons_items] => ) ) [stripe_id] => [stripe_class] => [font_color] => dark [background_color] => white [padding_top] => default [padding_bottom] => default [background_image] => [background_image_size] => cover [background_image_position] => center [add_mobile_background] => [background_image_mobile] => ) ) )IMA Group at PACK EXPO Las Vegas 2023

Details

- Pharma,Food & Dairy,Confectionery,E-Commerce

- Las Vegas, Nevada, USA

- Central Hall, Booth C-3200/3400

- 11/09/2023 to 13/09/2023

Green soul, digital brain.

Today sustainability and digital transformation are two sides of the same coin, capable of having a positive impact on business and environment.

About Sustainability on show

Discover our range of sustainable solutions and let us introduce you to OPENLab: our network of technological laboratories and testing areas.

Let our experts analyse your material, directly on show: bring your sample, and with our tools we will be able to test it in real time.

About Digitalization on show

The machines speak Digital and tell of the IMA Smart Factory. Data collected in real time are sent to the IMA Control Room and displayed on dashboards. An actual simulation of what happens during production: data analysis, potential implementations and the increase in production capacity.

Las Vegas Convention Center

3150 Paradise Rd, Las Vegas, NV 89109, United States

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => Machines Live Demo

[tab_id] => demo-agenda

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] =>

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] => Download now the complete agenda of live machines’ demos on show!

[content_html] =>

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => machines' live demo agenda

[icon] => file_download

[link] => 36703

[tab] => 1

)

)

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeAgenda

[main_title] =>

[stripe_view] => all

[intro_text] =>

[days] => Array

(

[0] => Array

(

[title] => September 11th, 2023

[timeline] => Array

(

[0] => Array

(

[title] => VEGATRONIC 6000 DZ - High-speed continuous motion vertical bagging machine

[start_time] => 10.30

[end_time] => 10.45

[description] => The new Vegatronic 6000 DZ is a continuous motion vertical bagging machine featuring quick and fully automatic changeover solutions, great accessibility for easy maintenance and standard components interchangeable with the current Vegatronic 6000. This compact and high-speed VFFS machine is capable of producing a wide range of pack styles – from Doy style with and without zipper, to Quattro and Pillow bags.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

[registration_link] =>

[file_ical] =>

)

[1] => Array

(

[title] => VEGATRONIC 6400 HD - HD ultra hygienic VFFS bagger

[start_time] => 10.45

[end_time] => 11.00

[description] => The machine has been developed and adapted to meet the specific demands of the meat (IQF) and produce (both IQF and fresh) industries in terms of sanitary design, accessibility, fast changeover and OEE. At PackExpo will be equipped with a new PATENTED system engineered to handle leafy products effectively and optimally.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

[registration_link] =>

[file_ical] =>

)

[2] => Array

(

[title] => DELTA OF 360 X - Horizontal Form, Fill & Seal

[start_time] => 11.15

[end_time] => 11.30

[description] => The world’s first variable geometry flow wrapping machine. The Delta OF-360 X is capable of running any packaging films, from paper-based films to complex laminates and recyclable mono-polymer films, with changeovers effected simply by pressing a button on the machine’s HMI. At a time when the future direction of sustainable packaging is fluid and uncertain, this HFFS solution gives manufacturers and packers total flexibility to switch easily between different substrates – whether they already exist or have yet to be developed.

Marco Pocaterra // Technical Sales Support Director – IMA Ilapak HFFS Division

Dimitri Ghinis // Bakery Product Manager – IMA Ilapak HFFS Division

[registration_link] =>

[file_ical] =>

)

[3] => Array

(

[title] => C1290 - Automatic Tubefiller

[start_time] => 15.00

[end_time] => 15.15

[description] => A benchmark model, appreciated worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations, always delivering outstanding performance. Available in different levels of automation along with the widest range of additional devices, in all cases it grants the “state of the art” of single nozzle technology: complete, fast, easy to use.

Andrea Dotti // Marketing Manager – IMA Comadis

[registration_link] =>

[file_ical] =>

)

[4] => Array

(

[title] => E-CO FLEX - E-Commerce and E-Fulfillment Packaging Station

[start_time] => 15.30

[end_time] => 15.45

[description] => E-CO Flex is an innovative automated packaging station designed to streamline the packing process and provide invaluable support to operators. This highly modular solution leverages the customer’s existing case suite, enabling it to intelligently select the most suitable case size for each product to be packed, with the ability to downsize the case height if needed. The result is an optimal case size, leading to reduced dimensional (DIM) weight and significant freight savings.

Capponcelli Simone // Division Coordinator – IMA E-Commerce

[registration_link] =>

[file_ical] =>

)

)

)

[1] => Array

(

[title] => September 12th, 2023

[timeline] => Array

(

[0] => Array

(

[title] => E-CO FLEX - E-Commerce and E-Fulfillment packaging station

[start_time] => 10.30

[end_time] => 10.45

[description] => E-CO Flex is an innovative automated packaging station designed to streamline the packing process and provide invaluable support to operators. This highly modular solution leverages the customer’s existing case suite, enabling it to intelligently select the most suitable case size for each product to be packed, with the ability to downsize the case height if needed. The result is an optimal case size, leading to reduced dimensional (DIM) weight and significant freight savings.

Capponcelli Simone // Division Coordinator – IMA E-Commerce

[registration_link] =>

[file_ical] =>

)

[1] => Array

(

[title] => C1290 - Automatic Tubefiller

[start_time] => 11.00

[end_time] => 11.15

[description] => A benchmark model, appreciated worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations, always delivering outstanding performance. Available in different levels of automation along with the widest range of additional devices, in all cases it grants the “state of the art” of single nozzle technology: complete, fast, easy to use.

Andrea Dotti // Marketing Manager – IMA Comadis

[registration_link] =>

[file_ical] =>

)

[2] => Array

(

[title] => VEGATRONIC 6400 HD - HD ultra hygienic VFFS bagger

[start_time] => 11.15

[end_time] => 11.30

[description] => The machine has been developed and adapted to meet the specific demands of the meat (IQF) and produce (both IQF and fresh) industries in terms of sanitary design, accessibility, fast changeover and OEE. At PackExpo will be equipped with a new PATENTED system engineered to handle leafy products effectively and optimally.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

[registration_link] =>

[file_ical] =>

)

[3] => Array

(

[title] => VEGATRONIC 6000 DZ - High-speed continuous motion vertical bagging machine

[start_time] => 11.30

[end_time] => 11.45

[description] => The new Vegatronic 6000 DZ is a continuous motion vertical bagging machine featuring quick and fully automatic changeover solutions, great accessibility for easy maintenance and standard components interchangeable with the current Vegatronic 6000. This compact and high-speed VFFS machine is capable of producing a wide range of pack styles – from Doy style with and without zipper, to Quattro and Pillow bags.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

[registration_link] =>

[file_ical] =>

)

[4] => Array

(

[title] => DELTA OF 360 X - Horizontal Form, Fill & Seal

[start_time] => 15.00

[end_time] => 15.15

[description] => The world’s first variable geometry flow wrapping machine. The Delta OF-360 X is capable of running any packaging films, from paper-based films to complex laminates and recyclable mono-polymer films, with changeovers effected simply by pressing a button on the machine’s HMI. At a time when the future direction of sustainable packaging is fluid and uncertain, this HFFS solution gives manufacturers and packers total flexibility to switch easily between different substrates – whether they already exist or have yet to be developed.

Marco Pocaterra // Technical Sales Support Director – IMA Ilapak HFFS Division

Dimitri Ghinis // Bakery Product Manager – IMA Ilapak HFFS Division

[registration_link] =>

[file_ical] =>

)

)

)

[2] => Array

(

[title] => September 13th, 2023

[timeline] => Array

(

[0] => Array

(

[title] => DELTA OF 360 X - Horizontal Form, Fill & Seal

[start_time] => 10.30

[end_time] => 10.45

[description] => The world’s first variable geometry flow wrapping machine. The Delta OF-360 X is capable of running any packaging films, from paper-based films to complex laminates and recyclable mono-polymer films, with changeovers effected simply by pressing a button on the machine’s HMI. At a time when the future direction of sustainable packaging is fluid and uncertain, this HFFS solution gives manufacturers and packers total flexibility to switch easily between different substrates – whether they already exist or have yet to be developed.

Marco Pocaterra // Technical Sales Support Director – IMA Ilapak HFFS Division

Dimitri Ghinis // Bakery Product Manager – IMA Ilapak HFFS Division

[registration_link] =>

[file_ical] =>

)

[1] => Array

(

[title] => C1290 - Automatic Tubefiller

[start_time] => 10.45

[end_time] => 11.00

[description] => A benchmark model, appreciated worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations, always delivering outstanding performance. Available in different levels of automation along with the widest range of additional devices, in all cases it grants the “state of the art” of single nozzle technology: complete, fast, easy to use.

Andrea Dotti // Marketing Manager – IMA Comadis

[registration_link] =>

[file_ical] =>

)

[2] => Array

(

[title] => VEGATRONIC 6400 HD - HD ultra hygienic VFFS bagger

[start_time] => 11.00

[end_time] => 11.15

[description] => The machine has been developed and adapted to meet the specific demands of the meat (IQF) and produce (both IQF and fresh) industries in terms of sanitary design, accessibility, fast changeover and OEE. At PackExpo will be equipped with a new PATENTED system engineered to handle leafy products effectively and optimally.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

[registration_link] =>

[file_ical] =>

)

[3] => Array

(

[title] => VEGATRONIC 6000 DZ - High-speed continuous motion vertical bagging machine

[start_time] => 11.15

[end_time] => 11.30

[description] => The new Vegatronic 6000 DZ is a continuous motion vertical bagging machine featuring quick and fully automatic changeover solutions, great accessibility for easy maintenance and standard components interchangeable with the current Vegatronic 6000. This compact and high-speed VFFS machine is capable of producing a wide range of pack styles – from Doy style with and without zipper, to Quattro and Pillow bags.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

[registration_link] =>

[file_ical] =>

)

[4] => Array

(

[title] => E-CO FLEX - E-Commerce and E-Fulfillment packaging station

[start_time] => 11.30

[end_time] => 11.45

[description] => E-CO Flex is an innovative automated packaging station designed to streamline the packing process and provide invaluable support to operators. This highly modular solution leverages the customer’s existing case suite, enabling it to intelligently select the most suitable case size for each product to be packed, with the ability to downsize the case height if needed. The result is an optimal case size, leading to reduced dimensional (DIM) weight and significant freight savings.

Capponcelli Simone // Division Coordinator – IMA E-Commerce

[registration_link] =>

[file_ical] =>

)

)

)

)

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => min

[padding_bottom] => default

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

)

)

Download now the complete agenda of live machines’ demos on show!

VEGATRONIC 6000 DZ - High-speed continuous motion vertical bagging machine

The new Vegatronic 6000 DZ is a continuous motion vertical bagging machine featuring quick and fully automatic changeover solutions, great accessibility for easy maintenance and standard components interchangeable with the current Vegatronic 6000. This compact and high-speed VFFS machine is capable of producing a wide range of pack styles – from Doy style with and without zipper, to Quattro and Pillow bags.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

VEGATRONIC 6400 HD - HD ultra hygienic VFFS bagger

The machine has been developed and adapted to meet the specific demands of the meat (IQF) and produce (both IQF and fresh) industries in terms of sanitary design, accessibility, fast changeover and OEE. At PackExpo will be equipped with a new PATENTED system engineered to handle leafy products effectively and optimally.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

DELTA OF 360 X - Horizontal Form, Fill & Seal

The world’s first variable geometry flow wrapping machine. The Delta OF-360 X is capable of running any packaging films, from paper-based films to complex laminates and recyclable mono-polymer films, with changeovers effected simply by pressing a button on the machine’s HMI. At a time when the future direction of sustainable packaging is fluid and uncertain, this HFFS solution gives manufacturers and packers total flexibility to switch easily between different substrates – whether they already exist or have yet to be developed.

Marco Pocaterra // Technical Sales Support Director – IMA Ilapak HFFS Division

Dimitri Ghinis // Bakery Product Manager – IMA Ilapak HFFS Division

C1290 - Automatic Tubefiller

A benchmark model, appreciated worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations, always delivering outstanding performance. Available in different levels of automation along with the widest range of additional devices, in all cases it grants the “state of the art” of single nozzle technology: complete, fast, easy to use.

Andrea Dotti // Marketing Manager – IMA Comadis

E-CO FLEX - E-Commerce and E-Fulfillment Packaging Station

E-CO Flex is an innovative automated packaging station designed to streamline the packing process and provide invaluable support to operators. This highly modular solution leverages the customer’s existing case suite, enabling it to intelligently select the most suitable case size for each product to be packed, with the ability to downsize the case height if needed. The result is an optimal case size, leading to reduced dimensional (DIM) weight and significant freight savings.

Capponcelli Simone // Division Coordinator – IMA E-Commerce

E-CO FLEX - E-Commerce and E-Fulfillment packaging station

E-CO Flex is an innovative automated packaging station designed to streamline the packing process and provide invaluable support to operators. This highly modular solution leverages the customer’s existing case suite, enabling it to intelligently select the most suitable case size for each product to be packed, with the ability to downsize the case height if needed. The result is an optimal case size, leading to reduced dimensional (DIM) weight and significant freight savings.

Capponcelli Simone // Division Coordinator – IMA E-Commerce

C1290 - Automatic Tubefiller

A benchmark model, appreciated worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations, always delivering outstanding performance. Available in different levels of automation along with the widest range of additional devices, in all cases it grants the “state of the art” of single nozzle technology: complete, fast, easy to use.

Andrea Dotti // Marketing Manager – IMA Comadis

VEGATRONIC 6400 HD - HD ultra hygienic VFFS bagger

The machine has been developed and adapted to meet the specific demands of the meat (IQF) and produce (both IQF and fresh) industries in terms of sanitary design, accessibility, fast changeover and OEE. At PackExpo will be equipped with a new PATENTED system engineered to handle leafy products effectively and optimally.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

VEGATRONIC 6000 DZ - High-speed continuous motion vertical bagging machine

The new Vegatronic 6000 DZ is a continuous motion vertical bagging machine featuring quick and fully automatic changeover solutions, great accessibility for easy maintenance and standard components interchangeable with the current Vegatronic 6000. This compact and high-speed VFFS machine is capable of producing a wide range of pack styles – from Doy style with and without zipper, to Quattro and Pillow bags.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

DELTA OF 360 X - Horizontal Form, Fill & Seal

The world’s first variable geometry flow wrapping machine. The Delta OF-360 X is capable of running any packaging films, from paper-based films to complex laminates and recyclable mono-polymer films, with changeovers effected simply by pressing a button on the machine’s HMI. At a time when the future direction of sustainable packaging is fluid and uncertain, this HFFS solution gives manufacturers and packers total flexibility to switch easily between different substrates – whether they already exist or have yet to be developed.

Marco Pocaterra // Technical Sales Support Director – IMA Ilapak HFFS Division

Dimitri Ghinis // Bakery Product Manager – IMA Ilapak HFFS Division

DELTA OF 360 X - Horizontal Form, Fill & Seal

The world’s first variable geometry flow wrapping machine. The Delta OF-360 X is capable of running any packaging films, from paper-based films to complex laminates and recyclable mono-polymer films, with changeovers effected simply by pressing a button on the machine’s HMI. At a time when the future direction of sustainable packaging is fluid and uncertain, this HFFS solution gives manufacturers and packers total flexibility to switch easily between different substrates – whether they already exist or have yet to be developed.

Marco Pocaterra // Technical Sales Support Director – IMA Ilapak HFFS Division

Dimitri Ghinis // Bakery Product Manager – IMA Ilapak HFFS Division

C1290 - Automatic Tubefiller

A benchmark model, appreciated worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations, always delivering outstanding performance. Available in different levels of automation along with the widest range of additional devices, in all cases it grants the “state of the art” of single nozzle technology: complete, fast, easy to use.

Andrea Dotti // Marketing Manager – IMA Comadis

VEGATRONIC 6400 HD - HD ultra hygienic VFFS bagger

The machine has been developed and adapted to meet the specific demands of the meat (IQF) and produce (both IQF and fresh) industries in terms of sanitary design, accessibility, fast changeover and OEE. At PackExpo will be equipped with a new PATENTED system engineered to handle leafy products effectively and optimally.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

VEGATRONIC 6000 DZ - High-speed continuous motion vertical bagging machine

The new Vegatronic 6000 DZ is a continuous motion vertical bagging machine featuring quick and fully automatic changeover solutions, great accessibility for easy maintenance and standard components interchangeable with the current Vegatronic 6000. This compact and high-speed VFFS machine is capable of producing a wide range of pack styles – from Doy style with and without zipper, to Quattro and Pillow bags.

Francesco Mariottini // Business Developer – IMA Ilapak VFFS Division

Andrea Boccolini // Technical Sales Support Manager – IMA Ilapak VFFS Division

E-CO FLEX - E-Commerce and E-Fulfillment packaging station

E-CO Flex is an innovative automated packaging station designed to streamline the packing process and provide invaluable support to operators. This highly modular solution leverages the customer’s existing case suite, enabling it to intelligently select the most suitable case size for each product to be packed, with the ability to downsize the case height if needed. The result is an optimal case size, leading to reduced dimensional (DIM) weight and significant freight savings.

Capponcelli Simone // Division Coordinator – IMA E-Commerce

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => Pharma

[tab_id] => pharma

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] =>

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] => ONE VISION, ONE FUTURE, ONE SUPPLIER: The All-In-One PHARMA

[html] =>

[content] => Meet the complexities of today’s world with a single supplier who can provide everything you need to shape the future of pharma together.

Take a look at our machines displayed on show!

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] => pharma

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => default

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => SENSITIVE AV - Labelling machine for ampoules and vials

[stripe_view] => all

[full_width] =>

[content] => The SENSITIVE AV is designed to apply labels on small or unstable containers such as ampoules, cartridges and small vials. The machine guarantees excellent reliability and features a positive transport system for precise label application.

Compact and ergonomic, it can be equipped with many types of overprinting devices and camera vision systems to read and check data.

Available in stand-alone version or integrated in complete processing and packaging lines.

[image] =>

[image_left] => 36381

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

[2] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => C1290 - Automatic tubefiller

[stripe_view] => all

[full_width] =>

[content] => Comadis C1290 is the ultimate proposal coming from many years experience in tube filling industry: complete, fast, easy to use.

Co.Ma.Di.S. C1290 is a major update of the successful “C1090”, the benchmark model sold worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations.

Improved in a number of details, it is now performing tube cleaning by dedicated station, batch data collection via USB port and continuous monitoring – on request – of tube folding and tube crimping areas.

[image] =>

[image_left] => 36609

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

[3] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Solid dose processing solutions

[stripe_view] => all

[full_width] =>

[content] => IMA Active offers a complete range of machines for the processing of oral solid dosage forms: granulation equipment, tableting machines, capsule filling machines with a wide range of filling and control systems, capsule and tablet coating machines in perforated pan and solid wall, capsule and tablet weighing machines, product handling and washing systems.

[image] => 32482

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

)

)

ONE VISION, ONE FUTURE, ONE SUPPLIER: The All-In-One PHARMA

Meet the complexities of today’s world with a single supplier who can provide everything you need to shape the future of pharma together.

Take a look at our machines displayed on show!

SENSITIVE AV - Labelling machine for ampoules and vials

The SENSITIVE AV is designed to apply labels on small or unstable containers such as ampoules, cartridges and small vials. The machine guarantees excellent reliability and features a positive transport system for precise label application.

Compact and ergonomic, it can be equipped with many types of overprinting devices and camera vision systems to read and check data.

Available in stand-alone version or integrated in complete processing and packaging lines.

C1290 - Automatic tubefiller

Comadis C1290 is the ultimate proposal coming from many years experience in tube filling industry: complete, fast, easy to use.

Co.Ma.Di.S. C1290 is a major update of the successful “C1090”, the benchmark model sold worldwide in many different applications, which has proved to offer enough flexibility to be used in various configurations.

Improved in a number of details, it is now performing tube cleaning by dedicated station, batch data collection via USB port and continuous monitoring – on request – of tube folding and tube crimping areas.

![]()

Solid dose processing solutions

IMA Active offers a complete range of machines for the processing of oral solid dosage forms: granulation equipment, tableting machines, capsule filling machines with a wide range of filling and control systems, capsule and tablet coating machines in perforated pan and solid wall, capsule and tablet weighing machines, product handling and washing systems.

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => Medical devices

[tab_id] => medical-devices

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => IMA AUTOMATION develops flexible and reliable medical devices assembly solutions.

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] => The AUTOMATION Hub has many years of experience in the medical industry, specifically for the assembly of Drug Delivery, Wearables, Diagnostics, Tubing Sets and Surgical Instruments.

Make sure to stop by our booth 3200-3400 in Central Hall: our experts will be at our visitors’ disposal to discover all about our gamma of highly technolgical assembly solutions for the medical devices sector.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => X-PEN - Pen and autoinjector assembly system

[stripe_view] => all

[full_width] =>

[content] => At Pack Expo Las Vegas 2023 X-Pen will be under the spotlight! Let our experts introduce you to our new technology.

X-PEN is the standard modular platform for pen and autoinjector final assembly systems.

With robust latest technologies, labelling as standard, quick time-to-market, compact design, standard machine bases and a fast ROI, our X-PEN systems use state-of-the-art technology: at your fingertips.

[image] => 36642

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

)

)

IMA AUTOMATION develops flexible and reliable medical devices assembly solutions.

The AUTOMATION Hub has many years of experience in the medical industry, specifically for the assembly of Drug Delivery, Wearables, Diagnostics, Tubing Sets and Surgical Instruments.

Make sure to stop by our booth 3200-3400 in Central Hall: our experts will be at our visitors’ disposal to discover all about our gamma of highly technolgical assembly solutions for the medical devices sector.

X-PEN - Pen and autoinjector assembly system

At Pack Expo Las Vegas 2023 X-Pen will be under the spotlight! Let our experts introduce you to our new technology.

X-PEN is the standard modular platform for pen and autoinjector final assembly systems.

With robust latest technologies, labelling as standard, quick time-to-market, compact design, standard machine bases and a fast ROI, our X-PEN systems use state-of-the-art technology: at your fingertips.

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => Food

[tab_id] => food

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] =>

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] => IMA serves the international Food Industry with the best platforms and machines

[html] =>

[content] => Available to satisfy any need, consistently providing tailored technologies for the processing and packaging of tea & herbs, coffee, confectionery & snacks, stock cubes and savoury, dairy and baby food, bakery, protein, produce and more.

Take a look at our machines displayed on show!

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] => food

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Vegatronic 6400 HD - VFFS hygienic machine

[stripe_view] => all

[full_width] =>

[content] => The Vegatronic 6400 HD is an evolution of IMA Ilapak’s top performing Vegatronic 6000 bagger, which has been developed and adapted to meet the specific demands of the meat (IQF) and produce (both IQF and fresh) industries in terms of sanitary design, accessibility, fast changeover and OEE.

Open frame design, IP66 rated electrical components, easily removable forming tube and a cantilever film reel shaft are among the features that combine to make the Vegatronic 6400 HD the most efficient and hygienic bagger on the market today.

At Pack Expo, this solution will be on display with a new PATENTED system engineered to handle leafy products effectively and optimally. Come and visit us to find out more.

[image] =>

[image_left] => 32368

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Discover more about IMA OPENLab

[icon] => explore

[internal_link] =>

[link] => https://ima.it/en/open-lab/

[link_page] =>

[tab] => 1

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

[2] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Vegatronic 6000 DZ - Continuous motion vertical bagging machine

[stripe_view] => all

[full_width] =>

[content] => The IMA Ilapak Vegatronic 6000 DZ, unveiled for the first time ever at Interpack 2023, is a high speed VFFS continuous film motion (CFM) bagging machine capable of running a wide range of pack styles such as pillow, block bottom, 3 side seal, Quad seal, Doy Shark with and without inline zipper and pyramid bags. Solution equipped with a fully automatic format changeover system and characterized by a compact design and great accessibility for easy maintenance.

[image] =>

[image_left] => 36368

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

[3] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => DELTA OF-360 X - Horizontal Form, Fill & Seal

[stripe_view] => all

[full_width] =>

[content] => IMA Ilapak has made an industry breakthrough, launching the world’s first variable geometry flow wrapper.

The revolutionary Delta OF-360X is capable of running any packaging films, from paper-based films to complex laminates and recyclable mono-polymer films, with changeovers effected simply by pressing a button on the machine’s HMI. At a time when the future direction of sustainable packaging is fluid and uncertain, this HFFS solution gives manufacturers and packers total flexibility to switch easily between different substrates – whether they already exist or have yet to be developed.

As well as future-proofing factories to keep pace with packaging material changes, the Delta OF-360X insulates manufacturers against energy price rises. The machine is built on IMA Ilapak’s new full-electric flow wrapping platform, which uses on average 37% less power than a conventional flow wrapper. IMA Ilapak’s engineers have achieved these efficiency gains by replacing energy-intensive pneumatic applications with highly efficient linear actuators.

[image] =>

[image_left] => 35093

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

[4] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Eagle – Horizontal Form, Fill & Seal

[stripe_view] => all

[full_width] =>

[content] => The IMA Delta Systems Eagle flow wrapper is a versatile platform and is commonly integrated into a wide variety of automated packaging systems.

Capable of speeds in excess of 1200 ppm, this USA-made flow wrapper is designed for 24/7 production environments and includes standard features such as automatic splicing and expanded touchscreen diagnostics to allow efficient operation and overall efficiency excellence.

The Eagle is fitted with industry leading controls and servo technology such as Allen Bradley and comes with industry leading diagnostic software that allows maintenance personnel real time access to on board preventative maintenance tools including oscilloscopes, ladder logic PLC, input analyzers, and audit logs of all operator changes with time and date stamp.

[image] =>

[image_left] => 36382

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

[5] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => Meet our experts in our dedicated corners on show

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[6] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Confectionery & Snacks

[stripe_view] => all

[full_width] =>

[content] => Make the Most in the Chocolate and Confectionery market.

IMA supports the Confectionery international industry responding to the most diverse processing and packaging requirements with machines and platforms conceived to handle gums, candies, coated sweets and bars, from powder dosing to palletizing.

[image] => 33040

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

[7] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Dairy, Baby Food & Beverages

[stripe_view] => all

[full_width] =>

[content] => Make the most in the Dairy market.

IMA serves the international Dairy market with the best platforms and machines available to satisfy all the industry needs about the processing and packaging of processed cheese, butter & margarine, yoghurt, beverages & baby food.

[image] => 30663

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

)

)

IMA serves the international Food Industry with the best platforms and machines

Available to satisfy any need, consistently providing tailored technologies for the processing and packaging of tea & herbs, coffee, confectionery & snacks, stock cubes and savoury, dairy and baby food, bakery, protein, produce and more.

Take a look at our machines displayed on show!

Vegatronic 6400 HD - VFFS hygienic machine

The Vegatronic 6400 HD is an evolution of IMA Ilapak’s top performing Vegatronic 6000 bagger, which has been developed and adapted to meet the specific demands of the meat (IQF) and produce (both IQF and fresh) industries in terms of sanitary design, accessibility, fast changeover and OEE.

Open frame design, IP66 rated electrical components, easily removable forming tube and a cantilever film reel shaft are among the features that combine to make the Vegatronic 6400 HD the most efficient and hygienic bagger on the market today.

At Pack Expo, this solution will be on display with a new PATENTED system engineered to handle leafy products effectively and optimally. Come and visit us to find out more.

![]()

Vegatronic 6000 DZ - Continuous motion vertical bagging machine

The IMA Ilapak Vegatronic 6000 DZ, unveiled for the first time ever at Interpack 2023, is a high speed VFFS continuous film motion (CFM) bagging machine capable of running a wide range of pack styles such as pillow, block bottom, 3 side seal, Quad seal, Doy Shark with and without inline zipper and pyramid bags. Solution equipped with a fully automatic format changeover system and characterized by a compact design and great accessibility for easy maintenance.

![]()

DELTA OF-360 X - Horizontal Form, Fill & Seal

IMA Ilapak has made an industry breakthrough, launching the world’s first variable geometry flow wrapper.

The revolutionary Delta OF-360X is capable of running any packaging films, from paper-based films to complex laminates and recyclable mono-polymer films, with changeovers effected simply by pressing a button on the machine’s HMI. At a time when the future direction of sustainable packaging is fluid and uncertain, this HFFS solution gives manufacturers and packers total flexibility to switch easily between different substrates – whether they already exist or have yet to be developed.

As well as future-proofing factories to keep pace with packaging material changes, the Delta OF-360X insulates manufacturers against energy price rises. The machine is built on IMA Ilapak’s new full-electric flow wrapping platform, which uses on average 37% less power than a conventional flow wrapper. IMA Ilapak’s engineers have achieved these efficiency gains by replacing energy-intensive pneumatic applications with highly efficient linear actuators.

![]()

![]()

Eagle – Horizontal Form, Fill & Seal

The IMA Delta Systems Eagle flow wrapper is a versatile platform and is commonly integrated into a wide variety of automated packaging systems.

Capable of speeds in excess of 1200 ppm, this USA-made flow wrapper is designed for 24/7 production environments and includes standard features such as automatic splicing and expanded touchscreen diagnostics to allow efficient operation and overall efficiency excellence.

The Eagle is fitted with industry leading controls and servo technology such as Allen Bradley and comes with industry leading diagnostic software that allows maintenance personnel real time access to on board preventative maintenance tools including oscilloscopes, ladder logic PLC, input analyzers, and audit logs of all operator changes with time and date stamp.

Meet our experts in our dedicated corners on show

Confectionery & Snacks

Make the Most in the Chocolate and Confectionery market.

IMA supports the Confectionery international industry responding to the most diverse processing and packaging requirements with machines and platforms conceived to handle gums, candies, coated sweets and bars, from powder dosing to palletizing.

Dairy, Baby Food & Beverages

Make the most in the Dairy market.

IMA serves the international Dairy market with the best platforms and machines available to satisfy all the industry needs about the processing and packaging of processed cheese, butter & margarine, yoghurt, beverages & baby food.

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => E-Commerce

[tab_id] => ecommerce

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => IMA E-COMMERCE: THE ROOTS OF A NEW PACKAGING ERA.

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] => E-commerce has become a vital part of the retail industry and it is projected to continue its growth in the coming years. With over 60 years of experience in automated packaging solutions, IMA has established strong technological roots to usher in a new era of packaging.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] => e-commerce

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => E-CO Flex - E-fulfillment packaging station

[stripe_view] => all

[full_width] =>

[content] => E-CO Flex consolidates multiple stations into a single unit, improving productivity, efficiency, and profitability while also supporting green initiatives and reducing plant space needs compared to current multi-pack station setups.

The E-CO Flex selects the best-fit box size for the product and connecting to the customer’s WMS system. It erects and tapes the bottom of the box, using traditional or water-activated tape, and adds any necessary identification stickers. The result is a pre-assembled box presented to the operator, who simply inserts the items to be shipped and secures them with the required amount of cushioning material. The operator reinserts the open-faced box back into the machine where the remaining void is measured: if necessary, the E-CO Flex will automatically reduce the height of the box and then close it.

The E-CO Flex developed in partnership with Intertape Polymer Group Inc. (“IPG”).

[image] =>

[image_left] => 35753

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

)

)

IMA E-COMMERCE: THE ROOTS OF A NEW PACKAGING ERA.

E-commerce has become a vital part of the retail industry and it is projected to continue its growth in the coming years. With over 60 years of experience in automated packaging solutions, IMA has established strong technological roots to usher in a new era of packaging.

E-CO Flex - E-fulfillment packaging station

E-CO Flex consolidates multiple stations into a single unit, improving productivity, efficiency, and profitability while also supporting green initiatives and reducing plant space needs compared to current multi-pack station setups.

The E-CO Flex selects the best-fit box size for the product and connecting to the customer’s WMS system. It erects and tapes the bottom of the box, using traditional or water-activated tape, and adds any necessary identification stickers. The result is a pre-assembled box presented to the operator, who simply inserts the items to be shipped and secures them with the required amount of cushioning material. The operator reinserts the open-faced box back into the machine where the remaining void is measured: if necessary, the E-CO Flex will automatically reduce the height of the box and then close it.

The E-CO Flex developed in partnership with Intertape Polymer Group Inc. (“IPG”).

![]()

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => End Of Line

[tab_id] => end-of-line

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => Come and discover the range of solutions developed by the Group for this specific sector!

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] => Whether the product being processed is food, cosmetics, pharmaceutical, home care, mechanical componentry or simply a hardware item, that product needs to be manipulated in different ways and the END OF LINE hub brings a specific expertise to provide comprehensive solutions.

The companies within the hub develop a variety of technologies that enter into play along all packaging lines. Each company contributes with specific expertise to deliver the most complete technological offering of manipulation, cartoning, overwrapping, case packing, stretch banding, shrink wrapping, palletizing, de-palletizing and labelling solutions.

These following represent the companies within the hub, providing a comprehensive answer:

IMA BFBA leading brand for secondary packaging solutions, ranging from overwrapping machines to case packing and palletizing equipment. |

IMA CIEMMEExperts in carton packaging machinery, closing and forming machines and automatic loading systems for different market sectors. |

IMA MESPICDesigners and developers of tailor-made machines, from conveyors to wrapping, from case packers to palletizers, and complete turn-key systems for the end-of-line. |

IMA PHOENIXA leading manufacturer of print & apply and modular labellers for self-adhesive labels, delivering labelling solutions to distributors, system integrators and OEMs. |

This degree of versatility is what makes IMA END OF LINE unique and appealing to diverse industries. In particular, those who share the group’s strong focus of sustainable packaging solutions. IMA pioneers research into new materials and has already successfully developed eco-friendly materials and packaging technologies. Furthermore, the hub’s designers and engineers take pride in their ability to customise each line with bespoke solutions to suit the specific needs and goals of the customer.

|

|

|

[content_html] => [buttons_on] => [view_default] => [buttons_items] => ) ) [stripe_id] => end-of-line [stripe_class] => [font_color] => dark [background_color] => white [padding_top] => default [padding_bottom] => default [background_image] => [background_image_size] => cover [background_image_position] => center [add_mobile_background] => [background_image_mobile] => ) [1] => Array ( [acf_fc_layout] => stripeContent [main_title] => IMA End of Line HUB [stripe_view] => all [single_width] => 100 [single_align] => left [multiple_align] => top [boxes] => Array ( [0] => Array ( [acf_fc_layout] => video [title] => [play] => light [image] => 36742 [video] => dWituKUh9AU [content] => ) ) [stripe_id] => [stripe_class] => stripeContentCenter [font_color] => dark [background_color] => white [padding_top] => min [padding_bottom] => min [background_image] => [background_image_size] => cover [background_image_position] => center [add_mobile_background] => [background_image_mobile] => ) ) )

Come and discover the range of solutions developed by the Group for this specific sector!

Whether the product being processed is food, cosmetics, pharmaceutical, home care, mechanical componentry or simply a hardware item, that product needs to be manipulated in different ways and the END OF LINE hub brings a specific expertise to provide comprehensive solutions.

The companies within the hub develop a variety of technologies that enter into play along all packaging lines. Each company contributes with specific expertise to deliver the most complete technological offering of manipulation, cartoning, overwrapping, case packing, stretch banding, shrink wrapping, palletizing, de-palletizing and labelling solutions.

These following represent the companies within the hub, providing a comprehensive answer:

IMA BFBA leading brand for secondary packaging solutions, ranging from overwrapping machines to case packing and palletizing equipment. |

IMA CIEMMEExperts in carton packaging machinery, closing and forming machines and automatic loading systems for different market sectors. |

IMA MESPICDesigners and developers of tailor-made machines, from conveyors to wrapping, from case packers to palletizers, and complete turn-key systems for the end-of-line. |

IMA PHOENIXA leading manufacturer of print & apply and modular labellers for self-adhesive labels, delivering labelling solutions to distributors, system integrators and OEMs. |

This degree of versatility is what makes IMA END OF LINE unique and appealing to diverse industries. In particular, those who share the group’s strong focus of sustainable packaging solutions. IMA pioneers research into new materials and has already successfully developed eco-friendly materials and packaging technologies. Furthermore, the hub’s designers and engineers take pride in their ability to customise each line with bespoke solutions to suit the specific needs and goals of the customer.

|

|

|

IMA End of Line HUB

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => IMA ZERO

[tab_id] => ima-zero

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] =>

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] => IMA ZERO at PACK EXPO Las Vegas 2023

[html] =>

[content] => The green element comes to life with the IMA ZERO program: the promise that IMA renews to all its stakeholders; the promise of a constant, virtuous and sustainable approach to the future, in which the Group highlights its awareness that today’s commitment will make the difference in tomorrow’s world

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] => ima-zero

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeTile

[main_title] =>

[stripe_view] => all

[full_width] =>

[content] => IMA is bringing a part of its OPENLab on show!

A small laboratory on the stand that illustrates the analysis and research of packaging materials carried out in the Group’s network of laboratories.

In the OPENLab corner, you will have the opportunity to run some test on your material sample and pack,

Bring them with you!

[image] => 34871

[image_left] =>

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Discover more about IMA OPENLab

[icon] => explore

[internal_link] =>

[link] => https://ima.it/en/open-lab/

[link_page] =>

[tab] => 1

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

[2] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => Discover the tools available on our stand to analyse your material sample in real time

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] => Perkin Elmer Infrared Spectrometer

[html] =>

[content] => It allows to identify the material’s chemical nature (at our OPENLab corner, it will be possible to analyse only materials’ outer surfaces).

The combination of this tool and the Leica Optical Microscopy should give an idea of how many and which layers the material consists of. A few cm2 are enough to carry out such analysis.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[1] => Array

(

[acf_fc_layout] => text

[title] => Leica Optical Microscopy

[html] =>

[content] => It counts and measures the material’s layers, it analyses the material’s surface and it carries out defects’ analysis with potential measurement of elements of interest. Objectives 5x – 10x – 20x – 50x.

The combination of this tool and the Perkin Elmer Infrared Spectrometer should give an idea of how many and which layers the material consists of. A few cm2 are enough to carry out such analysis.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => default

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[3] => Array

(

[acf_fc_layout] => stripeTile

[main_title] =>

[stripe_view] => all

[full_width] =>

[content] =>

Machines belonging to the NOP project integrate the latest solutions developed in terms of eco-friendly and recyclable materials, where OPENLab plays a central role.

NOP means we promote eco-friendly plastic substitutes for the packages manufactured on IMA machines.

After the recent green light in Strasbourg by the European Parliament, the directive limiting the use of various disposable plastic items requires new automatic machines capable of lowering the use of plastic in packaging. Together with our partners, we foster plastic-free, compostable or biodegradable materials, recyclable and/or more sustainable plastic-based materials, through the research and testing of alternative processes.

[image] => 28711

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Book an appointment

[icon] => mail

[internal_link] =>

[link] => #digital-form

[link_page] =>

[tab] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

[4] => Array

(

[acf_fc_layout] => stripeTile

[main_title] =>

[stripe_view] => all

[full_width] =>

[content] =>

Machines belonging to the LOW project are designed to reduce energy consumption and minimise production waste.

LOW is our commitment to increasing IMA’s sustainable practices to preserve resources.

Over the years, we have been incorporating this concept both in our organisation and development policies, for constant adoption and conception of innovative low impact technologies:

• We have started setting water and electric consumption standards for all our new machines, developing innovative production methods.

• New IMA plants are designed to use renewable energy resources and to minimise waste and consumption.

[image] => 29671

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Book an appointment

[icon] => mail

[internal_link] =>

[link] => #digital-form

[link_page] =>

[tab] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

)

)

IMA ZERO at PACK EXPO Las Vegas 2023

The green element comes to life with the IMA ZERO program: the promise that IMA renews to all its stakeholders; the promise of a constant, virtuous and sustainable approach to the future, in which the Group highlights its awareness that today’s commitment will make the difference in tomorrow’s world

IMA is bringing a part of its OPENLab on show!

A small laboratory on the stand that illustrates the analysis and research of packaging materials carried out in the Group’s network of laboratories.

In the OPENLab corner, you will have the opportunity to run some test on your material sample and pack,

Bring them with you!

Discover the tools available on our stand to analyse your material sample in real time

Perkin Elmer Infrared Spectrometer

It allows to identify the material’s chemical nature (at our OPENLab corner, it will be possible to analyse only materials’ outer surfaces).

The combination of this tool and the Leica Optical Microscopy should give an idea of how many and which layers the material consists of. A few cm2 are enough to carry out such analysis.

Leica Optical Microscopy

It counts and measures the material’s layers, it analyses the material’s surface and it carries out defects’ analysis with potential measurement of elements of interest. Objectives 5x – 10x – 20x – 50x.

The combination of this tool and the Perkin Elmer Infrared Spectrometer should give an idea of how many and which layers the material consists of. A few cm2 are enough to carry out such analysis.

Machines belonging to the NOP project integrate the latest solutions developed in terms of eco-friendly and recyclable materials, where OPENLab plays a central role.

NOP means we promote eco-friendly plastic substitutes for the packages manufactured on IMA machines.

After the recent green light in Strasbourg by the European Parliament, the directive limiting the use of various disposable plastic items requires new automatic machines capable of lowering the use of plastic in packaging. Together with our partners, we foster plastic-free, compostable or biodegradable materials, recyclable and/or more sustainable plastic-based materials, through the research and testing of alternative processes.

Machines belonging to the LOW project are designed to reduce energy consumption and minimise production waste.

LOW is our commitment to increasing IMA’s sustainable practices to preserve resources.

Over the years, we have been incorporating this concept both in our organisation and development policies, for constant adoption and conception of innovative low impact technologies:

• We have started setting water and electric consumption standards for all our new machines, developing innovative production methods.

• New IMA plants are designed to use renewable energy resources and to minimise waste and consumption.

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => IMA DIGITAL

[tab_id] => ima-digital

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => GREEN SOUL, DIGITAL BRAIN.

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] => Discover IMA Digital solutions, virtual tools and smart services, designed to make production increasingly efficient and geared towards concrete sustainability. Discover the real advantages of a digital approach.

Turn on your Smart Factory at PACK EXPO 2023!

Do you already know which digital solution best suits your needs to increase the efficiency of your plants, better support your maintenance activities, equip your operators with the best skills to manage your installed base?

Come and visit our Booth C-3200/3400, and immerse yourself in our range of digital solutions for manufacturing.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => ARTIFICIAL INTELLIGENCE, COME AND SEE HOW WE APPLY IT

[stripe_view] => all

[full_width] =>

[content] => Artificial intelligence is now a concrete part of the manufacturing reality, which can be applied and used to improve plant performance and enhance production.

Schedule an appointment with our artificial intelligence experts to see how the Artificial Intelligence and Machine Learning applications we have developed help in achieving production goals.

What are you waiting for?

[image] => 35177

[image_left] =>

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Book an appointment

[icon] => mail

[internal_link] =>

[link] => #digital-form

[link_page] =>

[tab] =>

)

)

[stripe_id] => artificial-intelligence

[stripe_class] => imaDigitalBlue

[font_color] => light

[background_opacity] => dark

)

[2] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => OUR CONTROL ROOM ON SHOW!

[stripe_view] => all

[full_width] =>

[content] => At PackExpo we will be present with a real Control Room, a space dedicated to the monitoring services and remote control of the installed base.

Make an appointment to discover how our experts are able to support customers by guiding them in more efficient and effective management of their equipment.

Come to our booth and immerse yourself in the future of Digital Manufacturing.

[image] => 34290

[image_left] =>

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Book an appointment

[icon] => mail

[internal_link] =>

[link] => #digital-form

[link_page] =>

[tab] =>

)

)

[stripe_id] =>

[stripe_class] => imaDigitalBlue

[font_color] => light

[background_opacity] => dark

)

[3] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => DIGITAL TRAINING, THE BEST KNOWLEDGE TRANSFER

[stripe_view] => all

[full_width] =>

[content] => Effective training is the most powerful means of providing the right skills to your operators, so they can better manage your production lines.

At IMA, we have structured specific training modes, without necessarily relying on the presence of a machine. The technologies we use, including immersive technologies, can enhance learning beyond classic training experiences to deliver new skills to your operators through faster, tracked and safer ways.

Come and talk about it with our expert trainers.

[image] => 34292

[image_left] =>

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Book an appointment

[icon] => mail

[internal_link] =>

[link] => #digital-form

[link_page] =>

[tab] =>

)

)

[stripe_id] =>

[stripe_class] => imaDigitalBlue

[font_color] => light

[background_opacity] => dark

)

[4] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => THE NEW FRONTIER OF DIGITAL TWIN. TOWARDS THE IMA INDUSTRIAL METAVERSE.

[stripe_view] => all

[full_width] =>

[content] => Thanks to the experience gained in recent years in the use of virtual commissioning and digital twin technologies, IMA explore the new dimension of an industrial metaverse.

An environment designed to converge in parallel activities such as systems design, development and control, but also IoT connection of machines for preventive production monitoring and verification.

[image] => 35511

[image_left] =>

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Book an appointment

[icon] => mail

[internal_link] =>

[link] => #digital-form

[link_page] =>

[tab] =>

)

)

[stripe_id] =>

[stripe_class] => imaDigitalBlue

[font_color] => light

[background_opacity] => dark

)

[5] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => Improve your processes. Talk with our digital experts at Pack Expo.

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[6] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Do you know how to receive your machines sooner?

[stripe_view] => all

[full_width] =>

[content] => That’s right, thanks to the most advanced technologies we are able to design the machines your production needs, already testing the same systems in dedicated virtual environments.

This allows us to optimise and shorten design timelines, ensuring faster delivery of machines to you. This also allows us to actively collaborate with our customers during the design process.

Learn more about this topic with our experts.

[image] =>

[image_left] => 35027

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => Book an appointment

[icon] => mail

[internal_link] =>

[link] => #digital-form

[link_page] =>

[tab] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

[7] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Do you know how to train your operators without the use of a machine?

[stripe_view] => all

[full_width] =>

[content] => Equipping operators with the right skills is certainly one of the most important steps if you want to keep your production in balance and good health. But how to do it best, without interfering with ongoing activities and using tools that can help contain costs and times? IMA Digital has created a wide range of solutions designed to be efficient:

- without using equipment, but based on the skills that distinguish us, in turn enhanced by digital tools such as interactive platforms

- on board the machine, using tools able to continue training the operator even when he is busy with daily activities.

The training sessions can also be guided by expert trainers, creating digital classes in person or remotely, guaranteeing 360° support.

[image] => [image_left] => 35028 [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => link [button_id] => [button_class] => [text] => Book an appointment [icon] => mail [internal_link] => [link] => #digital-form [link_page] => [tab] => ) ) [stripe_id] => [stripe_class] => [font_color] => dark [background_opacity] => none ) [8] => Array ( [acf_fc_layout] => stripeTile [main_title] => Do you know how to remotely monitor your machines, with the support of AI? [stripe_view] => all [full_width] => [content] =>Production is the beating heart of any company. And as such it must be managed to the best of the company’s ability, with strategies and tools capable of ensuring maximum efficiency.

Our platforms will allow you to monitor your installed base in real time and remotely, and the Artificial Intelligence Algorithms we have developed will allow you to receive guidance and get a glimpse into the future, seeing what is about to happen.

With comprehensive and in-depth monitoring, we are also able to provide you with 24/7 immediate first support in managing your plant problems and ticketing and alerting services to help keep your installed base monitored.

What are you waiting for?