Host Milano 2023

- Host Milano 2023

- Machines on show

- IMA ZERO

Array

(

[acf_fc_layout] => welcome_screen

[tab_title] => Host Milano 2023

[tab_id] =>

[title] => The IMA Group on show at Host Milano 2023

[content] => The IMA COFFEE HUB is getting ready for the 2023 edition of Host Milano, starting on October 13th until October 17th.

There is no better place than Host to discover IMA Coffee solutions and get updated on the Coffee Industry.

Come meet IMA experts on our stand!

Get in touch with the latest solutions and innovations developed by the IMA COFFEE HUB.

On show:

- TTA60 Traditional roaster

- TMR25 Modular roaster

- SR4N Capsule filling and sealing machine

- SB1 Lab Capsule filling and sealing machine

Meet our experts from the END OF LINE hub and discover the most complete technological offering of manipulation, cartoning, overwrapping, case packing, stretch banding, shrink wrapping, palletizing, de-palletizing and labelling solutions.

Come join us at Host Milano 2023.

[widget] => [stripes] => Array ( [0] => Array ( [acf_fc_layout] => stripeContent [main_title] => [stripe_view] => all [single_width] => 100 [single_align] => left [multiple_align] => top [boxes] => Array ( [0] => Array ( [acf_fc_layout] => text [title] => [html] => [content] =>Fiera Milano

[content_html] => [buttons_on] => [view_default] => [buttons_items] => ) ) [stripe_id] => [stripe_class] => [font_color] => dark [background_color] => white [padding_top] => default [padding_bottom] => default [background_image] => [background_image_size] => cover [background_image_position] => center [add_mobile_background] => [background_image_mobile] => ) ) )The IMA Group on show at Host Milano 2023

The IMA COFFEE HUB is getting ready for the 2023 edition of Host Milano, starting on October 13th until October 17th.

There is no better place than Host to discover IMA Coffee solutions and get updated on the Coffee Industry.

Come meet IMA experts on our stand!

Get in touch with the latest solutions and innovations developed by the IMA COFFEE HUB.

On show:

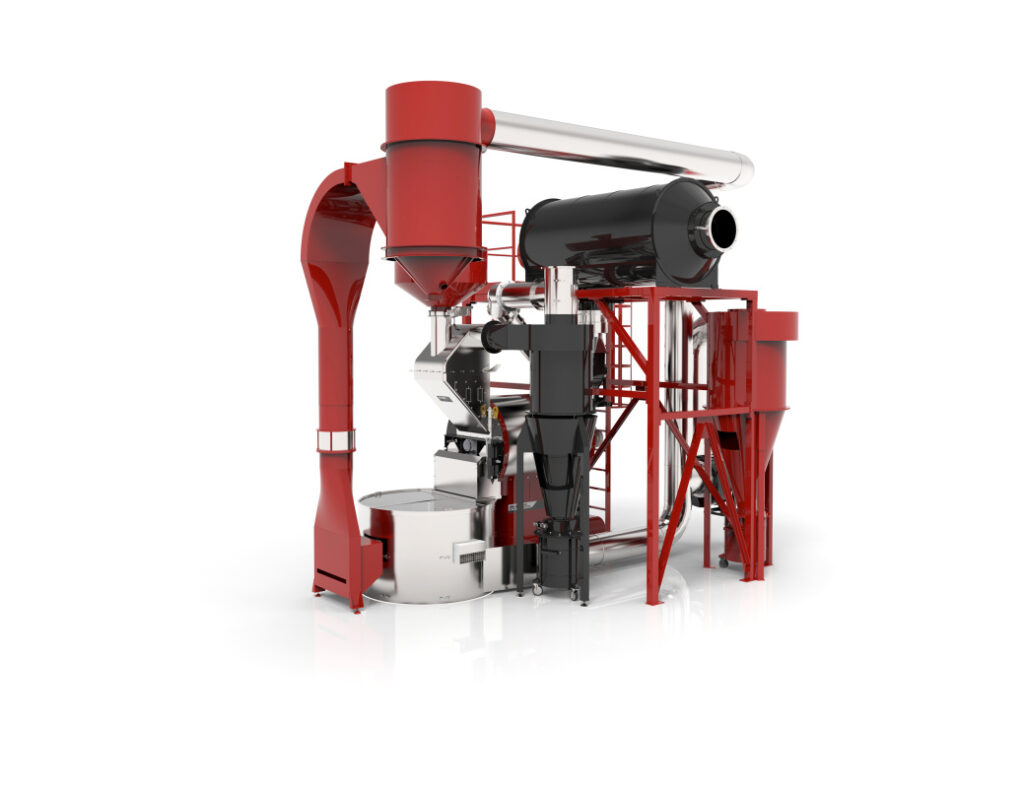

- TTA60 Traditional roaster

- TMR25 Modular roaster

- SR4N Capsule filling and sealing machine

- SB1 Lab Capsule filling and sealing machine

Meet our experts from the END OF LINE hub and discover the most complete technological offering of manipulation, cartoning, overwrapping, case packing, stretch banding, shrink wrapping, palletizing, de-palletizing and labelling solutions.

Come join us at Host Milano 2023.

Details

- Coffee

- Milan, Italy

- Hall 22P - Stand K47 K57 L48 L58

- 13/10/2023 to 17/10/2023

Fiera Milano

Array

(

[acf_fc_layout] => products

[tab_title] => Machines on show

[tab_id] => machines-on-show

[products_loops] => Array

(

[0] => Array

(

[title] =>

[content] => Take a closer look at our machines on show!

[products] => Array

(

[0] => 10_1798

[1] => 10_1363

[2] => 10_4049

[3] => 10_1774

)

)

)

)

Take a closer look at our machines on show!

From 25 up to 400 kg per batch, TT Roasters have a compact and reliable design. The air convection technologies allow a perfect coffee roasting control, optimizing the thermal efficiency and the flavour development.

Designed for medium production volumes, the SR Series machines are a reliable and cost effective solution, which ensures high technological standards and high dosing accuracy in a compact footprint.

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => IMA ZERO

[tab_id] => ima-zero

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] =>

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] => Stop by our stand to discover more about OPENLab!

[html] =>

[content] => IMA is bringing a part of its OPENLab on show – a small laboratory on the stand that illustrates the analysis and research of packaging materials carried out in the Group’s network of laboratories.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Come visit us to deep dive into our IMA ZERO’s No-Plastic Program (NOP).

[stripe_view] => all

[full_width] =>

[content] => In the OPENLab corner, you will have the opportunity to see up close our sustainable samples related to different markets covered by the Group, which were analysed and tested in our laboratories to deliver eco-friendly packaging solutions to our customers.

Our experts will be there to give you all the support and information you need.

[image] => 36752

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

[2] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => Take a closer look at our NOP and LOW programs, part of the IMA ZERO Corporate Project

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => min

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[3] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => NOP

[stripe_view] => all

[full_width] =>

[content] => NOP means we promote eco-friendly plastic substitutes for the packages manufactured on IMA machines.

After the recent green light in Strasbourg by the European Parliament, the directive limiting the use of various disposable plastic items requires new automatic machines capable of lowering the use of plastic in packaging. Together with our partners, we foster plastic-free, compostable or biodegradable materials, recyclable and/or more sustainable plastic-based materials, through the research and testing of alternative processes.

[image] => 36753

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

[4] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => LOW

[stripe_view] => all

[full_width] =>

[content] => LOW is our commitment to increasing IMA’s sustainable practices to preserve resources.

Over the years, we have been incorporating this concept both in our organisation and development policies, for constant adoption and conception of innovative low impact technologies:

• We have started setting water and electric consumption standards for all our new machines, developing innovative production methods.

• New IMA plants are designed to use renewable energy resources and to minimise waste and consumption.

[image] => 36754

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

)

)

Stop by our stand to discover more about OPENLab!

IMA is bringing a part of its OPENLab on show – a small laboratory on the stand that illustrates the analysis and research of packaging materials carried out in the Group’s network of laboratories.

Come visit us to deep dive into our IMA ZERO’s No-Plastic Program (NOP).

In the OPENLab corner, you will have the opportunity to see up close our sustainable samples related to different markets covered by the Group, which were analysed and tested in our laboratories to deliver eco-friendly packaging solutions to our customers.

Our experts will be there to give you all the support and information you need.

Take a closer look at our NOP and LOW programs, part of the IMA ZERO Corporate Project

NOP

NOP means we promote eco-friendly plastic substitutes for the packages manufactured on IMA machines.

After the recent green light in Strasbourg by the European Parliament, the directive limiting the use of various disposable plastic items requires new automatic machines capable of lowering the use of plastic in packaging. Together with our partners, we foster plastic-free, compostable or biodegradable materials, recyclable and/or more sustainable plastic-based materials, through the research and testing of alternative processes.

LOW

LOW is our commitment to increasing IMA’s sustainable practices to preserve resources.

Over the years, we have been incorporating this concept both in our organisation and development policies, for constant adoption and conception of innovative low impact technologies:

• We have started setting water and electric consumption standards for all our new machines, developing innovative production methods.

• New IMA plants are designed to use renewable energy resources and to minimise waste and consumption.