Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |BEVERAGES & BABY FOOD PROCESSING AND PACKAGING SOLUTIONS

MODULA - Unspouted Pouch Filling Machine

MODULA is a continuous rotary machine that fills and ultrasonically seals pre-made pouches using a patented “double pick-up” system. Ideal for liquid and high-viscous products, Modula is very versatile and offers high-speed changeover procedures.

Suitable for different filling applications such as food, pet food and beverages, where high hygienic standards, huge flexibility, and rapid changeover procedures are key factors on a competitive market, MODULA ensures ultimate filling accuracy and sealing reliability, especially for retortable products, and boasts an extremely low rejection rate.

![]()

![]()

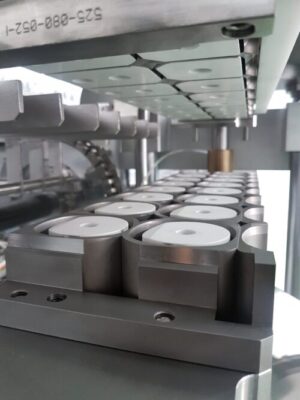

EFS-L - New Indexing Platform for Pre-formed Cups

Modular in design with stainless steel construction and servo-operations the machine allows for flexibility with filling stations, pre-fill and post fill for wet or dry ingredients.

The chainless solution for the cup transportation enables format flexibility and precision index positioning throughout the machine.

Capable of filling cups up to a diameter of 130 mm, the filling and sealing machine is suitable for a broad variety of products. Key benefits of the EFS-L are the format flexibility, the chainless drive, the recipe functionality, and its’ improved hygiene options.

At the show you can have a look on the machine running paper cups with paper lids, PP cups with PP lids.

On May 8th at 4.30 pm a machine demo will be held on EFS-L by our experts: take a look at the agenda >>

![]()

Cutting Tool

IMA ERCA, IMA HASSIA, and IMA INTECMA offer a complete range of thermoforming (form-fill-seal) machines from low to high speed for cups.

All companies continuously developed innovative solutions with a precise aim to meet goals that would combine technology and efficiency to achieve more sustainable packagings and processes.

The patented solutions for a range of tools from IMA INTECMA can be applied to all tools contained in a form, fill and seal machine. By using the tools from ZERO Technology, a quick changeover from PS (Polystyrene) to more recyclable materials such as PET, PP and PLA can be realised. With the innovative cutting tool, end users can handle PET multipacks as easy as PS multipacks and simply break them into individual cups.

On May 5th at 4.30 pm a machine demo will be held on the Cutting Toolby our experts: take a look at the agenda >>

![]()