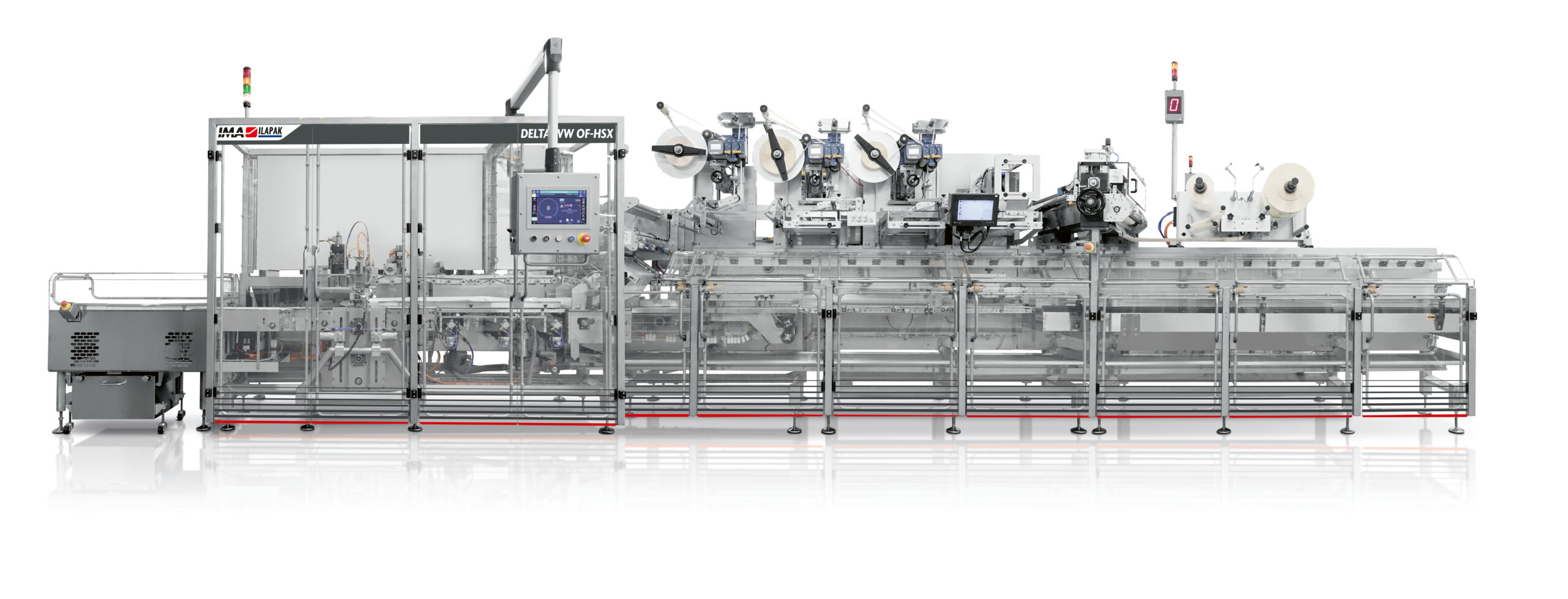

IMA ILAPAK’S full electric machine DELTA WW OF-HSX won the Sustainable Packaging News Awards 2022 for the Sustainable Packaging Machinery category.

- IMA ILAPAK’S FULL ELECTRIC MACHINE DELTA WW OF-HSX is the winner for the Sustainable Packaging Machinery category of the Sustainable Packaging News Awards.

- The Full Electric machine strongly contributes to pursuing the IMA ZERO’s goal, namely to reduce environmental impact, collocating into the Low-Impact Program (LOW).

- The DELTA WW OF-HSX machine leads to less energy consumption, less environmental impact and less business costs, while guaranteeing a better final product compared to pneutimatic, thanks to a greater precision of servo-actuated controls.

Thanks to all its sustainable features that do not compromise performance, IMA Ilapak’s Full Electric DELTA WW OF-HSX was announced as a winner in the Sustainable Packaging Machinery category of the Sustainable Packaging News Awards. The contest rewards the most innovative sustainable solutions in the field of packaging from the past year, and IMA’s win further highlights the commitment and the major importance given to sustainability.

The Full Electric machine DELTA WW OF-HSX is, in fact, an eco-friendly solution that falls under the IMA ZERO’s Low-Impact Program (LOW) that is one of the four categories in which IMA ZERO is declined, together with NOP (No-Plastic Program), E-MOB (Sustainable Mobility Program) and YOU (Human-Centric Program).

The main aim of such program is to reduce environmental impact and Ilapak’s machine perfectly embraces this goal, as it is a flow wrapper that drastically reduces energy consumption the faster the machine operates.

IMA Ilapak’s Full Electric machines are equipped with a compressor, which only serves to manage pneumatic applications that do not work in cyclic. Non-cyclic pneumatic, in fact, is characterized by a lower consumption, because it is only used for some specific actions; on the contrary, unlike cyclic pneumatic where energy is used for every cycle, so in this case the faster the machine, the higher energy consumption.

Comparing the DELTA WW OF-HSX to a standard flow wrapper and considering the same operating hours and speed – 170ppm – in one year, the DELTA consumes 1.500 kWh, whereas a standard machine 27.400 kWh (including air network losses). This project leads to less energy consumption, less environmental impact and less business costs, while at the same time gaining a better performance and a greater efficiency.

Watch the official video of the Full Electric to understand more deeply why it is the perfect choice that combines innovation, sustainability and quality.

About IMA ILAPAK

For over 50 years, IMA Ilapak, with its wide range of flexible packaging solutions, has satisfied every form, fill and seal packaging requirement of the food, pharma, medical devices and wet wipes industries.

Besides flow wrap machines HFFS (Horizontal Form Fill and Seal) and vertical baggers VFFS (Vertical Form Fill and seal), the Company’s portfolio includes packaging machinery for modified atmosphere applications (MAP – Modified Atmosphere Packaging), product handling solutions, counting and weighing machines and complete, fully automated packaging lines.

Represented in more than 50 countries in the world by its own network of sales and service subsidiaries and a number of qualified agents, IMA Ilapak is the point of reference in the packaging market.

About IMA ZERO

IMA ZERO is the evolution of IMA’s commitment to Sustainable Development: its ultimate goal is to minimise environmental impact in industrial manufacturing, while promoting and creating a working and living habitat that always puts people and biodiversity at the centre.

The project is declined into 4 main programs:

- LOW (Low-Impact Program) refers to the pledge to lower the Group’s impact on the environment, reducing emissions, waste, as well as water and energy consumption, and preserving natural resources.

- NOP (No-Plastic Program) fosters the employment of eco-friendly materials for the gradual reduction of plastic in packaging produced by IMA machines. To this purpose, IMA OPENLab plays a fundamental role: the Group’s network of technological laboratories and testing areas is dedicated to the research of sustainable materials, technologies and production optimisation processes.

- E-MOB (Sustainable Mobility Program) includes the Group’s projects about sustainable and electric mobility, for example the implementation of e-charging stations at IMA’s plants to charge hybrid and electric cars during working time. The Company’s biggest investment was the acquisition of IMA AUTOMATION ATOP, an Italian excellence in manufacturing lines for the production of e-traction engines, and the acquisition of IMA AUTOMATION FASP.

- YOU (Human-Centric Program) concerns the Group’s commitment to putting people at the centre, promoting different projects related to equal opportunities, inclusion, integration, professional development, and anything that can improve working and living conditions.

IMA Ilapak’s Full Electric DELTA WW OF-HSX was announced as a winner in the Sustainable Packaging Machinery category of the Sustainable Packaging News Awards.