Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |TRAINING

Improve your knowledge: train your employees through theory and on-the-job activities.

IMA Life Training enhances the learning process to teach procedures, concepts and competences on machines and lines through dedicated training contents created in e-learning mode.

It offers a structured Virtual Training Portfolio, in which each Course/Product is designed for specific targets based on different customer profiles and skills.

Thanks to this approach, everyone can learn independently, check and monitor comprehension, with or without the physical presence of machinery and trainers.

Furthermore, with immersive technologies such as virtual and augmented reality, gamification can be created to allow the trainee to interact and learn through intuitive processes.

All digital material is provided in the Customer’s language. Furthermore, an interpreting service can be provided to support face-to-face training.

Digital Academy Lab

IMA’s Digital Lab environments are specially designed to enable learning through the use of the latest digital technologies.

Interactive multimedia formats and Virtual Reality enrich the experience.

Take a tour, in person or remotely of our IMA digital academy lab to experience our digital solutions and discover all the opportunities.

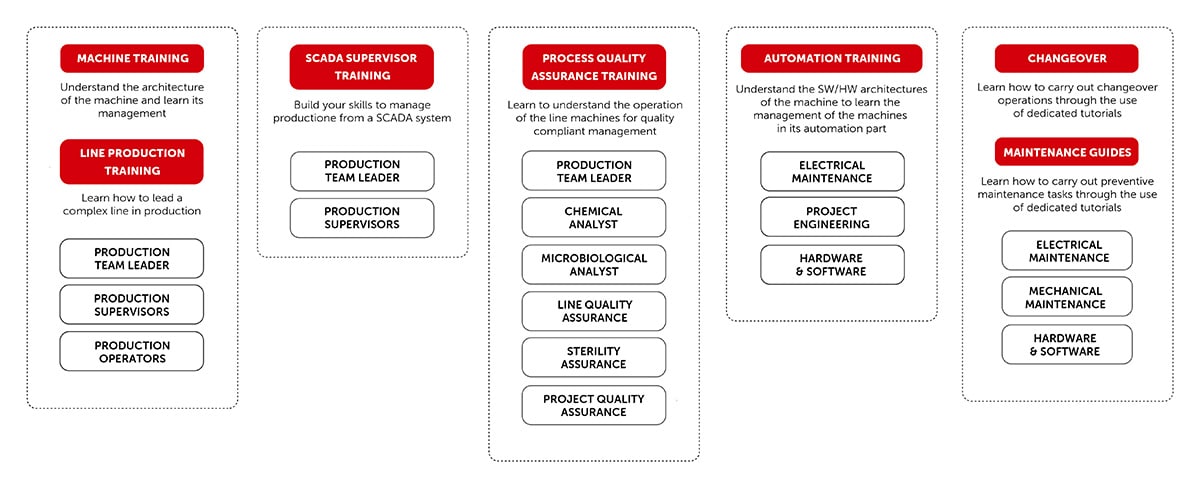

Training Portfolio

Each course is purpose-driven, designed to support specific professional roles, and tailored to the customer’s machines or production line. Every course is available as a standalone product or as part of a training package.

KEY FEATURES

Empower your team with targeted, effective e-learning solutions that drive productivity and operational excellence.

- Incremental Learning Path: Courses are developed within a step-by-step learning framework, addressing the individual competencies and the collective needs of the entire workforce.

- Role-Specific Training: Each course is tailored to meet the specific needs of various professional roles, ensuring both relevance and effectiveness.

- Tailored Content: Training materials are customized to align with the specific machines and production lines used by our customers, enhancing practical application and efficiency.

- Portable and Structured: E-learning serves as a structured foundation, always accessible and with information available at any time.

Unlock the full potential of your team with our tailored digital solutions. Click on each product HERE to explore detailed information and find the perfect fit for your training needs.

Learning Methods

Module 1 | e-Learning

Explore our courses on IMA SkillGate, designed to meet both individual and collective workforce needs through incremental learning. With your personal account, access your tailored learning path anytime, anywhere, both online and offline. Enjoy unlimited activations for comprehensive training at your own pace. You can also integrate the same content into your own LMS if you have one.

Module 2 | On field

Combine classroom sessions with on-the-job training, guided by expert trainers who will deepen your understanding and provide hands-on support. Optimize the training of new resources, enhance performance, and practice with experienced trainers. Access e-learning content designed to support your daily work, always available and reusable according to your time, space, and needs.

Module 2 | in remote

Dive deeper into your e-learning experience with dedicated remote sessions led by expert trainers who can answer all your questions. Enjoy the benefits of distance learning: professional guidance, cost savings, unlimited participants, and flexible access from any location or device. Record sessions and request interpretation services as needed.

- Machine Training

- Line Production

- Changeover

- SCADA

- Process Quality Assurance

- Automation

- Maintenance Training

- Coaching

Machine Training

TARGET REFERENCE

The training addresses the production team leaders, production supervisors and production operators and is suggested to chemical and microbiological analysts and line quality assurance as well as electrical, mechanical, hardware and software maintenance operators.

GOALS

On completion of the course, the participants shall be able to:

- Discover all safety aspect linked to the machine

- Identify the machine sub-assemblies and their functions

- Learn the structure of the control panel

- Discover how to execute the pre-production phases

- Properly manage the production follow up

- Perform a good post production

- Use the command and control panel

- Identify size parts for changeover

- React properly when faced with main machine faults

ADVANTAGES

- Run the machine efficiently, reducing the number of breaks in production and lowering reaction time.

- Improve overall knowledge of the machine sub-assemblies and their functions.

- Improve operator autonomy and efficiency.

Line Production

TARGET REFERENCE

The training addresses the production team leaders, production supervisors and production operators and is suggested to line quality assurance and project quality assurance.

GOALS

On completion of the course, the participants shall be able to:

- Discover how to synchronise all the equipment in order to properly set the whole line in production.

- Understand and control equipment conditions and function relations in all production phases.

- React properly when faced with main line faults.

ADVANTAGES

- Manage the line efficiently, reducing the number of breaks in production and lowering reaction time.

- Improve overall knowledge of line behaviour during all phases of production time.

- Improve autonomy and efficiency to manage all-round line production.

Changeover

TARGET REFERENCE

The training addresses the electrical, mechanical, hardware and software maintenance operators.

GOALS

On completion of the course, the participants shall be able to:

- Understand and use IMA vocabulary.

- Understand correct procedure of size changeover.

- Understand possible recalibration of machine settings.

ADVANTAGES

- Reduce size-changeover time.

- Reduce the risk of wrong settings.

Reduce the risk of machine faults/damages due to wrong installation.

Scada Supervisor

TARGET REFERENCE

The training addresses the production team leaders and production supervisors and is suggested to electrical, hardware and software maintenance operators.

GOALS

On completion of the course, the participants shall be able to:

- Use the Scada Supervisor processes in terms of production and trouble shooting.

- Report management.

ADVANTAGES

- Real-time monitoring for a detailed view and quick interventions.

- Optimise efficiency and reduce operating costs.

- Early detection of problems to avoid disruption.

- Advanced diagnostics to identify the root cause of problems.

- Improved security through constant monitoring.

- Greater transparency and traceability of operations.

- Evidence-based decision support.

Process Quality Assurance

TARGET REFERENCE

The training addresses production team leaders, chemical and microbiological analysts, line quality assurance, project quality assurance and sterility assurance and is suggested to production supervisors.

GOALS

On completion of the course, the participants shall be able to:

- GMP Management.

- Equipment cycles and processes.

- Create and handle new recipes.

- Critical control parameter analysis and management to ensure the sterility quality of the line processes.

ADVANTAGES

Gain confidence with all the sterility control aspects of the production phase processes.

Automation Training

TARGET REFERENCE

The training addresses the electrical, hardware and software maintenance operators and the project engineering.

GOALS

- Ability to identify the main reasons behind malfunctions.

- Support IMA in diagnosis and troubleshooting.

- Efficiently carry out machine maintenance, reducing the number of breaks in production and lowering reaction time.

ADVANTAGES

- Run the machine efficiently, reducing the number of breaks in production and lowering reaction time.

- Improve technician autonomy and efficiency.

Maintenance Training

TARGET REFERENCE

The training addresses the electrical, mechanical, hardware and software maintenance operators.

GOALS

On completion of the course, the participants shall be able to:

- Understand and use IMA vocabulary.

- Understand and use the maintenance plan and the maintenance manual.

- Understand main adjustments.

- Understand complete machine synchronization.

ADVANTAGES

Efficiently carry out machine maintenance, reducing the number of breaks in production and lowering reaction time.

Coaching

TARGET REFERENCE

The coaching addresses the production operators having already a basic familiarity of the equipment and its main processes, and who are willing to improve their knowledge of the equipment and its components as well as practice operating the machine on the job.

GOALS

- Encourage employee development and improved performance.

- Address specific problem areas with specific employees (vs. a group).

- Less about “how to” and more about “how well”.

ADVANTAGES

- Bottom-up approach built on the employee’s needs and questions.

- Encourage employee to examine and reflect on his/her own development and take constructive criticism.

- Deliberate focus on specific areas of improvement, with benchmarks and goals for measuring progress.