Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |The aim of recent IMA and Clariant co-operation was to maximise the production output of catalyst tablets made from two different FAMAX®-based blends with two different lubricants.

Clariant and IMA Active: partners in excellence for catalyst tablet manufacturing.

Abstract

As one of the world’s leading specialty chemical companies, Clariant creates value and innovative solutions for customers from many industries. The Group focuses on three key business areas – Care Chemicals, Catalysts, Natural Resources – and recently faced restructuring to allow its high-value specialty businesses to operate in an even more focused and agile manner.

Building on the capability of predecessor company, Süd-Chemie, the Catalysts business unit is a leading global supplier with a long history of innovation and expertise.

Clariant’s Novara site in Italy has, for the last 2 years, undergone a complete restructure to puruse the company’s goals of operational excellence and support some of their key products. Although the catalyst business is a relatively small part of Clariant’s sales revenue, it’s highgly profitable and demonstrates significant growth rates. As part of the restructure, two new capital investments were planned: a tablet press and coating equipment were to be implemented to increase the overall manufacturing capacity and introduce Industry 4.0 and IoT capabilities.

Attributes such as production output and an insolated processing area led Clariant to select the Prexima tablet press: in addition, the Pellegrini pan in GS Coating Equipment offers the best compromise between mixing efficiency and gentle product handling. Both technologies facilitate the automation of production processes and, at the Novara plant, paved the way for future development opportunities and new commercial scenarios.

Clariant is a leading global and independent manufacturer of high-performance catalysts for use in the chemicals, plastics, and oil and gas industries. Customised catalyst solutions for specific requirements can also be developed in collaboration with customers. Clariant’s innovative catalysts and adsorbents deliver significant and sustainable customer value by driving higher production throughput, lowering energy consumption, and reducing hazardous emissions from industrial processes and combustion engines. FAMAX® 200, produced by Clariant, is a next-generation, iron-molybdenum-based catalyst, for methanol to formaldehyde oxidation that is optimised to enhance plant efficiency.

The catalyst’s advanced composition and design achieve higher specific formaldehyde production at lower cooling medium temperatures, thus increasing overall plant economy.

Formulating formalin

Formaldehyde is a colourless, poisonous gas used as an antiseptic, disinfectant, histologic fixative, and general-purpose chemical reagent for laboratory applications. It’s well known as a preservative in medical facilities, as a sterilizer and is also used to inactivate the virus or bacteria in a vaccine before it’s administered to the patient. Formaldehyde is readily soluble in water and is commonly distributed as a 37% aqueous solution. Environmentally, formaldehyde may be found in the atmosphere, smoke from fires, automobile exhaust and cigarette smoke, and small amounts are produced during normal metabolic processes in most organisms, including humans. [1]

On an industrial scale, formaldehyde is generally obtained by the catalytic oxidation of methanol. The most common catalysts are silver metal or a mixture of an iron and molybdenum or vanadium oxides. Commonly, methanol and oxygen react at ca. 250–400 °C in the presence of iron oxide in combination with molybdenum and/or vanadium to produce formaldehyde according to the chemical Equation: [2]

2 CH3 + O2 –> 2 Ch2O + 2 H2O

FAMAX® 200, highlights two main benefits: higher formaldehyde yields owing to greater reaction selectivity, and improved low-temperature activity as well as longer catalyst lifetime owing to operation at lower cooling medium temperatures and improved long-term stability. [3]

The aim of recent IMA and Clariant cooperation was to maximise the production output of catalyst tablets (hollow cyclinders with different shapes and dimensions as in Figure 1) made from two different FAMAX®-based blends with two different lubricants. The challenge was to obtain a high tablet press output and enhanced tablet characteristics with a dedicated punch shape while minimising powder loss on a double-sided rotary tablet press.

Figure 1: Catalyst tablets.

Material and methods

Two different FAMAX®-based blends were tested to met the required production and tableting needs: blend A is graphite based whereas blend B is a stearate-based lubricant.

Before tableting, both mixtures were analysed in terms of technological features (flowability, particle size distribution and water content) to vaguely predict their compression behaviour. For both powders, tableting was done on a double-sided Prexima 800 rotary tablet press (IMA, Italy), equipped with a Euro-B turret hosting 81 stations. One challenge that had to be overcome was the hollow-cylinder shape of the tablet: the punches and the cams had to be adapted to accommodate this particular form. The lower punch is hollow and hosts an inner stem (fixed to the turret); it moves inside the punch according to the tableting phase. Both punches and cams were therefore designed to ensure the desired tablet shape could be made and to maximise machine performance. Initial trials had two main objectives: the first was to define the best process parameters to obtain defect-free tablets and the second was to increase the production output as much as possible. In the end, tablets were analysed according to weight, thickness and hardness to ascertain compliance with customer needs.

Results

Both blends were assessed for of flowability, particle size distribution and water content.

Flowability was measured by calculating the Carr Index (C.I.) using Equation 1. The lower the result, the better the ability to flow inside the dies, reducing powder loading issues.

Mixtures showed excellent flowability (blend A=7%, blend B=10.5%) with very low water content at 105°C (both under 0.10%).

![]()

Equation 1: Carr Index (C.I.) calculation.

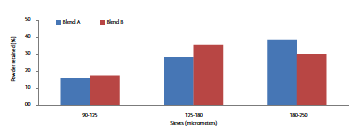

Particle size distribution, measured with vibrating sieves, can be summarised (Figure 2) to compare both powders.

Figure 2: particle size distribution comparison between blend A and blend B.

Figure 2: particle size distribution comparison between blend A and blend B.

The powders also have a relatively unimodal particle size distribution trend that, with the excellent flowability, suggests good loading ability inside the dies. Therefore, very low water content can forewarn of possible issues, such as lamination.

The tableting behaviour was explored in detail (Table 1).

| Parameters | m.u. | Value | |||||||

| Feeder type | – | Standard | |||||||

| Paddles type | – | Round | |||||||

| Blend type | – | Blend B | Blend A | ||||||

| Test | – | A | B | C | D | ||||

| Side | – | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 |

| Upper punch penetration | mm/mm | 2/2.50 | 2/2.50 | 2.50/2.50 | 2.50/2.50 | ||||

| Paddle speed | rpm | 15 | 15 | 18 | 18 | 15 | 15 | 25 | 25 |

| Loading cam | mm | 12 | 12 | 12 | 12 | ||||

| Dosing chamber | mm | 9.30 | 9.30 | 9.40 | 9.50 | ||||

| Compression force | kN | 1.6 | 1.3 | 1.3 | 1.3 | 1.8 | 1.4 | 1.3 | 1.3 |

| Turret speed | rpm | 65 | 75 | 65 | 50 | ||||

| Production output | tab/h | 631,800 | 729,000 | 631,800 | 486,000 | ||||

Table 1: tableting process parameters used.

For blend B, different upper punch penetrations and turret speeds were analysed: an upper penetration of 2/2.5 mm generated an increase in production output of up to 729,000 tab/hour but product loss increased owing to the special punch shape that was used (test A, B). Using 2.5/2.5 mm produced the highest yields by maintaining ahigh machine output rate (631,800 tab/hour, test C).

Keeping the upper punch penetration constant, blend A was tested in comparable conditions: lamination appeared at 65 rpm and was eliminated at 50 rpm (486,000 tab/hour, test D).

This was attributed to lubricant efficiency: graphite tends to better lubricate each particle, reducing the bonding ability of the final blend. In this context, defects such as lamination tend to appear more frequently; such defects have been mitigated by working on tableting parameters.

Paddle profile and speed adjustments enchanced the quality of the final product: a round shape reduced the strain on the rotating rods and the particles, ensuring a smooth flow inside the dies. Confirmed by the Carr Index results, blend B required a slightly higher speed to guarantee the same tablet weight. Upper punch penetration was optimised at 2.5/2.5 mm to maximise machine yield without undermining tablet quality: tablet press speed was perfectly adjusted according to lamination phenomena. The choice of a low compression force ensured both manageable compression and defect-free tablets. Tablets that were defect-free and easy to handle were obtained by using a low compression force.

Tablets have also been analysed in terms of weight, thickness and hardness variation: weight showed a relative standard deviation of less than 0.5%, confirming strong process robustness. With thickness values of approximately 4.30 mm, average tablet strength was higher for blend B (17N) compared to blend A (11N): this was predictable with the issues faced during tableting; graphite provides better lubrication efficiency and minimises the tendency of tablets to laminate.

Conclusions

In the context of the restructuring of the Clariant-Novara plant, two new capital investments were planned and concluded. The tablet press, described in the article, facilitates increased in manufacturing capacity while also providing the company with state-of-the-art equipment, including Industry 4.0 and IoT capabilities.

The close and successful co-operation between IMA and Clariant has been the key to achieving the target: a high output of high-quality tablets using a Prexima 800. To conclude, adjustments regarding some of the process parameters were required for catalyst compression, such as the correct upper punch: penetration ratio and the appropriate speed and paddle shape; when combined with the proper tablet press speed, this resulted in smooth and repeatable production.

References

[1] https://pubchem.ncbi.nlm.nih.gov/compound/712

[2] Reuss G., Disteldorf W., Gamer A. O., Hilt A., “Formaldehyde”. Ullmann’s Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007. a11_619 (2000).

[3] https://www.clariant.com/en/Solutions/Products/2019/04/15/07/20/FAMAX-200-Series.