Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |Today, one more challenge here at the LAB.

Our Lab schedule is usually fully packed with customer trials, but with travel restrictions in place we have now one complete week to perform some internal tests to support R&D department. Today I will deal with the beef and chicken soup cubes based recipes.

LAB diary. The contest week - day 2.

Today I will deal with the beef and chicken based recipes. Yesterday my Prexima was performing great, but good flowing of the product helped a lot. On the contrary, flowability for the two blends I will compress today is just fair, so I expect I’m going to spend more time in setting with these products and I have not that much product.

| Veg 1 | Veg 2 | Beef | Chicken | |

| Flowability (IC%) | Excellent (10) | Good (15) | Fair (15.5) | Fair (16) |

| Water content (LOD) | 1.17% | 1.63% | 1.88% | 1.08% |

I decide to start with the beef based recipe and with a 25 mm loading cam: too much refilling could create bridge in the die feeder and I prefer to proceed step by step. I start with the speed of 800 and then 1,000 tablets/minute: production runs smooth, with good quality tablets and low standard deviation. Let’s try something more challenging. I gradually increase the speed at 1,400 tablets/minute, I notice weight is gradually decreasing and starts fluctuating. At 1,600 tablets/minute I can’t produce a solid unit anymore, even increasing paddles rotation speed within the feeder to the maximum value.

I simply can’t feed enough powder into the die and the machine is stopping for consecutive tablets out of specification. My troubles in the feeding are clearly detectable by main compression forces out of the recipe range. I can’t just manage it playing with process parameters, I need to change something in the mechanical configuration. I decide to change once again the loading cam, from 25 to 30 mm: this will allow a deeper volume within the dies under the feeder, but even more important it will increase the “syringe effect” of the punches in recalling more powder into the dies. As blend flowability does not allow for the powder to fall by gravity, we are going to “pull” it in the die.

With the new cam, situation improves considerably; I can reach 1,600 tablets/minute with good process stability, feeding paddles run at the maximum speed of 140 RPM. I try to increase to 1,800 tablets/minute, but same yesterday’s criticalities show up again: keep feeding the press at this speed. The screw feeder taking the powder to the machine hopper is designed to guarantee a throughput of 10 kg/minute and at this speed my machine is requiring almost the double: yesterday with the free flowing powders the device was working well above its intended purpose, but today it can’t manage the required throughput. Today 1,600 tablets/minute is the maximum speed I can reach with this product.

My last contender is the chicken based blend: product flowability is similar to beef, so I decided to start with the 30 mm loading cam. I wonder whether I should change the geometry of the paddles, considering that in the previous test I had to run them at full speed. But, actually, I have few product and I don’t want to have too many different variables, otherwise my comparison would be not fair. Good to keep in mind that I have still cards to play with my Prexima.

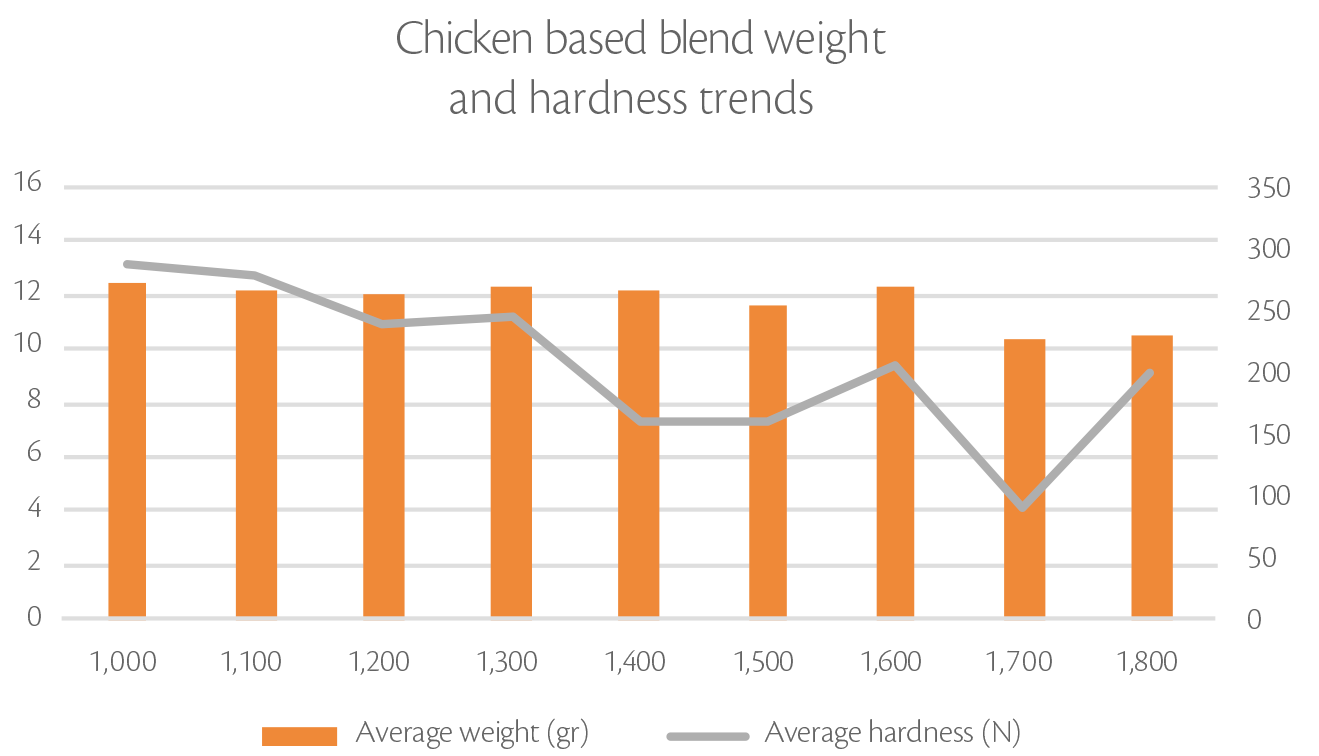

Again, I start from 1,000 tablets/minute without problems and I gradually increase the speed without any major trouble. When I reach 1,600 tablets/minute, tablet hardness starts decreasing and at 1,800 tablets/minute lamination clearly appears, as tablets tend to split in two halves. I need to improve air extraction. I recall I am still using yesterday’s 5 mm penetration to reduce product losses. In this case, I can go back to 1 mm; at that penetration, the taper of the dies allows air to escape from the dies thus reducing lamination. This product is not flowing so good, therefore also product losses shouldn’t be so much at higher speed, even with a smaller penetration.

I play with punch penetration and pre-compression and immediately I can see an improvement: this is the right way! Also tablet hardness, as I test my samples, clearly states that I found the right process parameters: 1,800 tablets/minute is definitely achievable with this product.

I feed I could increase further the speed, maybe changing paddles or feeder geometry; I have so many options still available, although not so much product left. In any case, the bottleneck remains the screw feeder; I will speak with the technical department, we need something capable of higher throughput to find the real limit of our tablet press! So let’s take 1,800 tablets/minute as maximum speed also for the chicken. The contest is finished, and the winner is…Prexima!

The machine has demonstrated to be capable to do much more of what it was designed for, with a wide range of products and has the potential to go even further, it’s just enough to keep on with this pace!

Federica Giatti

Compression Technologist at IMA Active Process Development R&D Laboratory