PPMA 2024

- PPMA 2024

- Machines on show

- IMA FLX HUB

- IMA ZERO & IMA OPENLab

Array

(

[acf_fc_layout] => welcome_screen

[tab_title] => PPMA 2024

[tab_id] =>

[title] => The IMA Group on show at PPMA 2024

[content] => The IMA Group is taking part in the 2024 edition of PPMA, the largest processing and packaging machinery exhibition in the UK.

Our specialised staff is ready to welcome you on our Stand D10, where some of our cutting-edge technologies will be showcased.

Take the opportunity to see up close IMA Ilapak’s Vegatronic 6000 DZ, the most flexible continuous film motion VFFS machine, featuring a wide range of pack styles and fully automatic change-over solutions and IMA Ilapak’s Delta 3000 flow wrapper equipped with high-speed long dwell sealing technology for Modified Atmosphere Packaging (M.A.P.). During the show, the machine will run a recyclable paper-based film to wrap local baked goods.

IMA Record’s PANDA BS RS, the flexible and versatile flow wrapper equipped with rotating sealing jaws ideal for the bakery industry, will be on display in the PPMA foyer.

Besides IMA Ilapak and IMA Record, IMA Eurosicma experts will also be representing the IMA FLX Hub. Join us and discover all about the IMA Eurosicma feeding & manipulation and flow wrapping solutions for the Biscuit, Choco and Confectionery industries.

Join us to meet our experts from IMA Erca, IMA Hassia, IMA Gasti and IMA Intecma to discover our best technologies to respond to the packaging challenges of the dairy and food industries with state-of-the-art form, fill and seal machines (FFS) for cups, portion packs, stick packs and sachets as well as fill and seal machines (FS) for pre-formed cups, tubs, and bottles.

Don’t miss the chance to explore IMA Teknoweb’s technologies dedicated to converting and packaging hygiene nonwovens products for household and personal care. Our converting lines seamlessly manufacture wet & dry wipes, bathing gloves and cosmetic masks, up to 600 ppm. If you are searching for absorbent hygiene products, get in touch with us: IMA Teknoweb developed OCEAN, a new high speed underpad line. We set new standards providing the lightest pads on the market, with the stunning speed of up to 450 ppm.

Last, but not least, IMA Teknoweb offers high-speed converting and packaging lines to manufacture FFP2/3 foldable facepiece respirators (FFR), with or without exhalation valve.

Explore the IMA world with us in Birmingham, from September 24th to 26th!

[widget] =>

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] =>

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] => NEC – National Exhibition Centre

Birmingham, UK

[content_html] =>

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => link

[button_id] =>

[button_class] =>

[text] => GET DIRECTIONS

[icon] =>

[internal_link] =>

[link] => https://goo.gl/maps/UaASrtDqPrrkmwX3A

[link_page] =>

[tab] => 1

)

)

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => default

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

)

)

The IMA Group on show at PPMA 2024

The IMA Group is taking part in the 2024 edition of PPMA, the largest processing and packaging machinery exhibition in the UK.

Our specialised staff is ready to welcome you on our Stand D10, where some of our cutting-edge technologies will be showcased.

Take the opportunity to see up close IMA Ilapak’s Vegatronic 6000 DZ, the most flexible continuous film motion VFFS machine, featuring a wide range of pack styles and fully automatic change-over solutions and IMA Ilapak’s Delta 3000 flow wrapper equipped with high-speed long dwell sealing technology for Modified Atmosphere Packaging (M.A.P.). During the show, the machine will run a recyclable paper-based film to wrap local baked goods.

IMA Record’s PANDA BS RS, the flexible and versatile flow wrapper equipped with rotating sealing jaws ideal for the bakery industry, will be on display in the PPMA foyer.

Besides IMA Ilapak and IMA Record, IMA Eurosicma experts will also be representing the IMA FLX Hub. Join us and discover all about the IMA Eurosicma feeding & manipulation and flow wrapping solutions for the Biscuit, Choco and Confectionery industries.

Join us to meet our experts from IMA Erca, IMA Hassia, IMA Gasti and IMA Intecma to discover our best technologies to respond to the packaging challenges of the dairy and food industries with state-of-the-art form, fill and seal machines (FFS) for cups, portion packs, stick packs and sachets as well as fill and seal machines (FS) for pre-formed cups, tubs, and bottles.

Don’t miss the chance to explore IMA Teknoweb’s technologies dedicated to converting and packaging hygiene nonwovens products for household and personal care. Our converting lines seamlessly manufacture wet & dry wipes, bathing gloves and cosmetic masks, up to 600 ppm. If you are searching for absorbent hygiene products, get in touch with us: IMA Teknoweb developed OCEAN, a new high speed underpad line. We set new standards providing the lightest pads on the market, with the stunning speed of up to 450 ppm.

Last, but not least, IMA Teknoweb offers high-speed converting and packaging lines to manufacture FFP2/3 foldable facepiece respirators (FFR), with or without exhalation valve.

Explore the IMA world with us in Birmingham, from September 24th to 26th!

Details

- Food & Dairy

- Birmingham, UK

- Booth D10

- 24/09/2024 to 26/09/2024

Visit us at PPMA

NEC – National Exhibition Centre

Birmingham, UK

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => Machines on show

[tab_id] =>

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] =>

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] => Stop by our Booth D10 and discover our range of technologies on show.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => default

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeTile

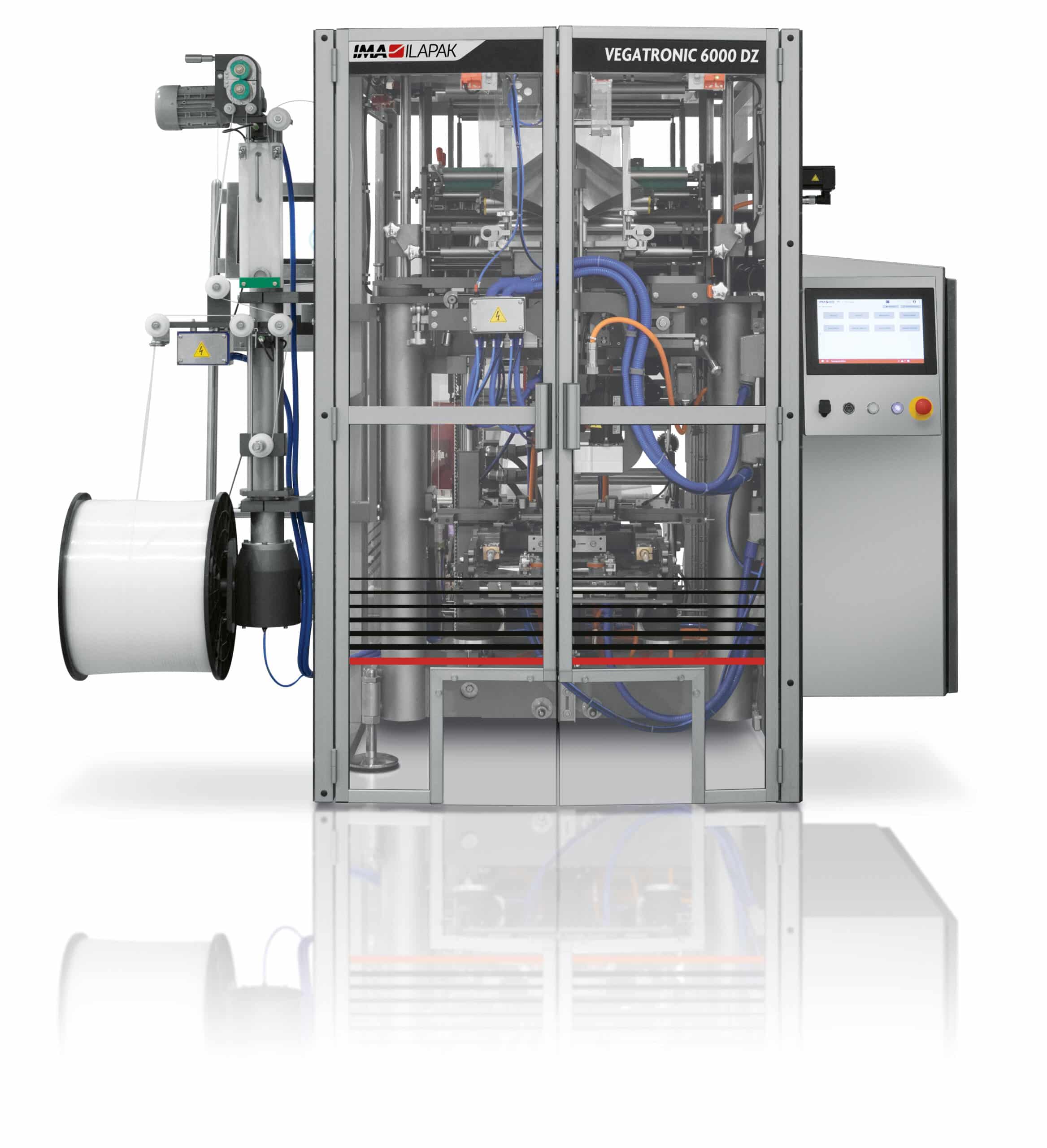

[main_title] => Vegatronic 6000 DZ – Continuous vertical bagging machine

[stripe_view] => all

[full_width] =>

[content] => A brand-new release of IMA Ilapak’s bestselling Vegatronic 6000 has been launched at Interpack 2023 featuring several options making it unique in its category such as a great range of pack styles, fully automatic change-over solutions, minimum change-over time, great accessibility to seal racks, standard components interchangeable with existing Vegatronic 6000 on the field, compact design, and high speed.

The continuous motion VFFS machine Vegatronic 6000 DZ is able to run traditional pillow and block bottom bags, Quattro bags with central or corner seal, Doy Shark pouches with or without inline zipper, 3SS bags up to pyramid bags.

[image] =>

[image_left] => 39915

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

[2] => Array

(

[acf_fc_layout] => stripeTile

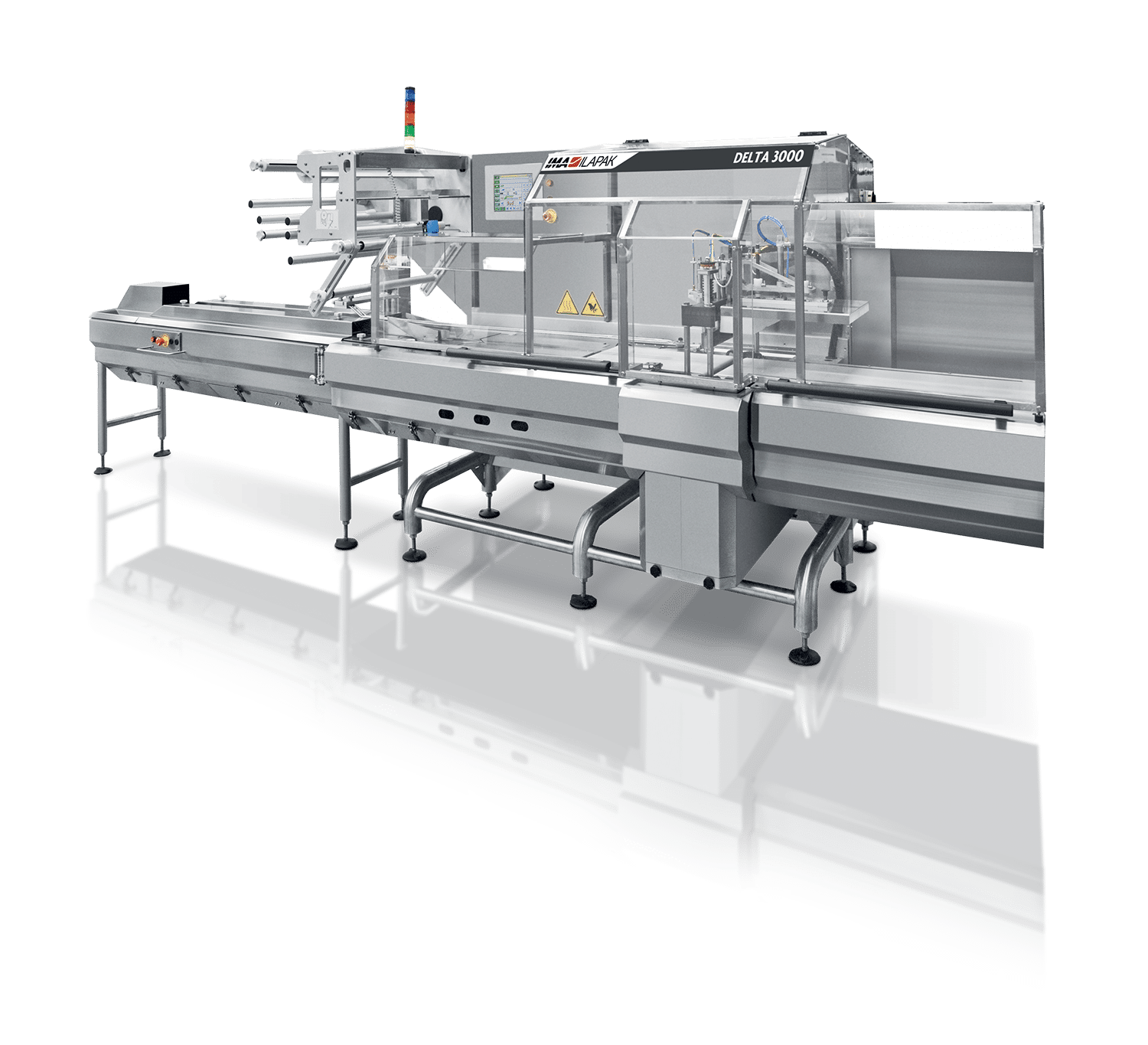

[main_title] => Delta 3000 – M.A.P. Flow wrapping machine with long dwell technology

[stripe_view] => all

[full_width] =>

[content] => The market’s best-known flow wrapper offering M.A.P (Modified Atmosphere Packaging), hermetic sealing and hygienic design.

The Delta 3000 is a PC-controlled flow wrapping machine equipped with long dwell technology for Modified Atmosphere (M.A.P.) to cover the widest range of applications and includes IMA Ilapak’s unique high-speed hermetic sealing technology. Its heavy duty and reliable design allow the Delta 3000 to be easily integrated into automatic packaging systems.

[image] =>

[image_left] => 39882

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

[3] => Array

(

[acf_fc_layout] => stripeTile

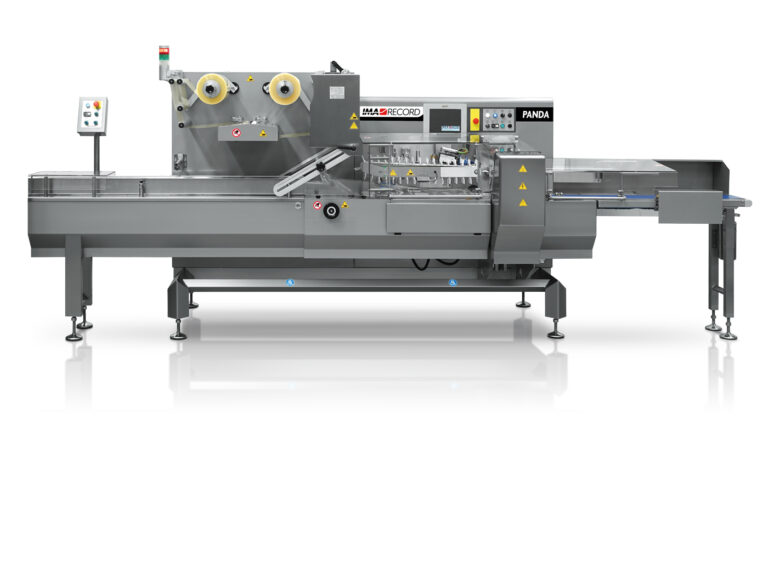

[main_title] => PANDA BS RS – HFFS flow wrapping machine

[stripe_view] => all

[full_width] =>

[content] => The Panda flow wrapping machine in the Bottom Seal version is ideal to pack a wide range of regular small and medium size products, easy to carry. The Panda BS RS can reach the speed of 300 packs per minute. The rotating sealing jaws (single or double) is applied for high-speed packaging with simple wrapping material (even heat-shrinkable); this kind of sealing protects the product and gives the pack a good-looking aspect.

[image] =>

[image_left] => 37532

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_opacity] => none

)

)

)

Stop by our Booth D10 and discover our range of technologies on show.

Vegatronic 6000 DZ – Continuous vertical bagging machine

A brand-new release of IMA Ilapak’s bestselling Vegatronic 6000 has been launched at Interpack 2023 featuring several options making it unique in its category such as a great range of pack styles, fully automatic change-over solutions, minimum change-over time, great accessibility to seal racks, standard components interchangeable with existing Vegatronic 6000 on the field, compact design, and high speed.

The continuous motion VFFS machine Vegatronic 6000 DZ is able to run traditional pillow and block bottom bags, Quattro bags with central or corner seal, Doy Shark pouches with or without inline zipper, 3SS bags up to pyramid bags.

Delta 3000 – M.A.P. Flow wrapping machine with long dwell technology

The market’s best-known flow wrapper offering M.A.P (Modified Atmosphere Packaging), hermetic sealing and hygienic design.

The Delta 3000 is a PC-controlled flow wrapping machine equipped with long dwell technology for Modified Atmosphere (M.A.P.) to cover the widest range of applications and includes IMA Ilapak’s unique high-speed hermetic sealing technology. Its heavy duty and reliable design allow the Delta 3000 to be easily integrated into automatic packaging systems.

PANDA BS RS – HFFS flow wrapping machine

The Panda flow wrapping machine in the Bottom Seal version is ideal to pack a wide range of regular small and medium size products, easy to carry. The Panda BS RS can reach the speed of 300 packs per minute. The rotating sealing jaws (single or double) is applied for high-speed packaging with simple wrapping material (even heat-shrinkable); this kind of sealing protects the product and gives the pack a good-looking aspect.

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => IMA FLX HUB

[tab_id] =>

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => IMA FLX. The One Stop Supplier For Flexible Packaging.

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => default

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[1] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => Discover more about the IMA FLX Hub

[stripe_view] => all

[full_width] =>

[content] => The new IMA FLEXIBLE PACKAGING HUB is where the production of all machines in the flexible packaging chain converge.

Everything needed to process all types of flexible packaging for the Food, Pharma, Wet Wipes and Pet markets is right here.

The full array of leading technologies brought together in one facility, where a one-stop supplier drives the quest for excellence, sustainability, constantly researching innovative solutions and new eco-compatible materials.

[image] => 26794

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

[2] => Array

(

[acf_fc_layout] => stripeContent

[main_title] => The hub companies

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] =>

Besides HFFS flow wrappers and VFFS vertical baggers, IMA Ilapak portfolio includes systems for modified atmosphere applications, feeding, counting and weighing systems and complete, fully automated lines.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[1] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] =>

IMA Delta Systems specializes in the supply of automated flow wrapping solutions for North American market. In addition to our standard product line, we offer custom design engineering which will result in a best in class solution for your unique flow wrapping application.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[2] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] =>

HFFS wrappers and fully automated lines for the packaging of candies, jellies, gums, chocolates, bars, biscuits, wafers and noodles are IMA Eurosicma’s core business. Starting from the end of the processing lines, customized handling, portoning and buffering systems can be supplied with flow and fold wrappers, both single and multipack.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => default

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

[3] => Array

(

[acf_fc_layout] => stripeContent

[main_title] =>

[stripe_view] => all

[single_width] => 100

[single_align] => left

[multiple_align] => top

[boxes] => Array

(

[0] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] =>

IMA Record designs and builds horizontal flow pack machines technologically advanced, durable and reliable, interfaced with modular composed automatic feeders, easy to be integrated into automated packaging systems.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[1] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] =>

IMA Fillshape designs and manufactures pouch making and filling machines for flexible stand-up pouches – with and without spout – for dairy, food, beverage and personal care sectors. It offers the most revolutionary technology in the field of flexible containers, but it leaves the customer free to choose the shape of the pouch, spout and cap.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[2] => Array

(

[acf_fc_layout] => text

[title] =>

[html] =>

[content] =>

IMA Tecmar is a company dedicated to the design and manufacture of packaging machines and flexible packaging systems for South American market. Vertical baggers, 4 side seals multi-lane and sticks machines are the IMA Tecmar’s flagship products.

[content_html] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

)

[stripe_id] =>

[stripe_class] =>

[font_color] => dark

[background_color] => white

[padding_top] => default

[padding_bottom] => default

[background_image] =>

[background_image_size] => cover

[background_image_position] => center

[add_mobile_background] =>

[background_image_mobile] =>

)

)

)

IMA FLX. The One Stop Supplier For Flexible Packaging.

Discover more about the IMA FLX Hub

The new IMA FLEXIBLE PACKAGING HUB is where the production of all machines in the flexible packaging chain converge.

Everything needed to process all types of flexible packaging for the Food, Pharma, Wet Wipes and Pet markets is right here.

The full array of leading technologies brought together in one facility, where a one-stop supplier drives the quest for excellence, sustainability, constantly researching innovative solutions and new eco-compatible materials.

The hub companies

![]()

Besides HFFS flow wrappers and VFFS vertical baggers, IMA Ilapak portfolio includes systems for modified atmosphere applications, feeding, counting and weighing systems and complete, fully automated lines.

![]()

IMA Delta Systems specializes in the supply of automated flow wrapping solutions for North American market. In addition to our standard product line, we offer custom design engineering which will result in a best in class solution for your unique flow wrapping application.

![]()

HFFS wrappers and fully automated lines for the packaging of candies, jellies, gums, chocolates, bars, biscuits, wafers and noodles are IMA Eurosicma’s core business. Starting from the end of the processing lines, customized handling, portoning and buffering systems can be supplied with flow and fold wrappers, both single and multipack.

![]()

IMA Record designs and builds horizontal flow pack machines technologically advanced, durable and reliable, interfaced with modular composed automatic feeders, easy to be integrated into automated packaging systems.

![]()

IMA Fillshape designs and manufactures pouch making and filling machines for flexible stand-up pouches – with and without spout – for dairy, food, beverage and personal care sectors. It offers the most revolutionary technology in the field of flexible containers, but it leaves the customer free to choose the shape of the pouch, spout and cap.

![]()

IMA Tecmar is a company dedicated to the design and manufacture of packaging machines and flexible packaging systems for South American market. Vertical baggers, 4 side seals multi-lane and sticks machines are the IMA Tecmar’s flagship products.

Array

(

[acf_fc_layout] => generic_tab

[tab_title] => IMA ZERO & IMA OPENLab

[tab_id] =>

[stripes] => Array

(

[0] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => IMA ZERO is the foundation of our sustainable development program.

[stripe_view] => all

[full_width] =>

[content] => It includes all practices already in place, plus those we are currently implementing, and has the ultimate goal of minimizing environmental impact in industrial manufacturing, and promoting and creating a working and living habitat that always puts people at the centre.

Economic results and social benefits are complementary objectives through which we have always generated value for our company, customers, employees, suppliers and for the entire community.

We know that, to proceed on our growth path, it is necessary to redirect our mentality towards newer and greater goals. At this point in history, we must do it not only for our business, but mostly for the environment and for the society we live and operate in: IMA ZERO definitely represents and embodies the Group’s will and dedication to change and give a positive and eco-friendly impact.

Starting from innovation, IMA ZERO is our very latest promise to create products, production processes and services, benefitting from a renewed logic of sustainability and from the awareness that our commitment today will help to shape the world of tomorrow.

[image] => 36753

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

[1] => Array

(

[acf_fc_layout] => stripeTile

[main_title] => IMA OPENLab

[stripe_view] => all

[full_width] =>

[content] => Part of the IMA ZERO project, OPENLab is the IMA Group’s network of technological laboratories and testing areas, dedicated to the research on sustainable materials, technologies and production optimisation processes.

OPENLab’s objective is to create partnerships, finding new sustainable materials, sharing competences and creating synergy with packaging manufacturers and customers.

The Lab aims to maximise equipment’s efficiency, reduce waste whilst maintaining pack presentation and seal integrity, testing in advance new and more sustainable packaging materials.

Stop by our Booth D10 and discover more!

[image] => 36752

[image_left] =>

[buttons_on] =>

[view_default] =>

[buttons_items] =>

[stripe_id] =>

[stripe_class] =>

[font_color] => light

[background_opacity] => dark

)

)

)

IMA ZERO is the foundation of our sustainable development program.

It includes all practices already in place, plus those we are currently implementing, and has the ultimate goal of minimizing environmental impact in industrial manufacturing, and promoting and creating a working and living habitat that always puts people at the centre.

Economic results and social benefits are complementary objectives through which we have always generated value for our company, customers, employees, suppliers and for the entire community.

We know that, to proceed on our growth path, it is necessary to redirect our mentality towards newer and greater goals. At this point in history, we must do it not only for our business, but mostly for the environment and for the society we live and operate in: IMA ZERO definitely represents and embodies the Group’s will and dedication to change and give a positive and eco-friendly impact.

Starting from innovation, IMA ZERO is our very latest promise to create products, production processes and services, benefitting from a renewed logic of sustainability and from the awareness that our commitment today will help to shape the world of tomorrow.

IMA OPENLab

Part of the IMA ZERO project, OPENLab is the IMA Group’s network of technological laboratories and testing areas, dedicated to the research on sustainable materials, technologies and production optimisation processes.

OPENLab’s objective is to create partnerships, finding new sustainable materials, sharing competences and creating synergy with packaging manufacturers and customers.

The Lab aims to maximise equipment’s efficiency, reduce waste whilst maintaining pack presentation and seal integrity, testing in advance new and more sustainable packaging materials.

Stop by our Booth D10 and discover more!