IMA Coffee • Packaging Solutions

IMA Coffee Updates

The all-encompassing solution for the coffee packaging

Developing specific and customized solutions able to meet the needs of a rapidly evolving market, IMA Coffee Packaging supplies machines for capsules preparation and filling, for the packaging of soft and hard pods, for cartoning and for vertical form-fill-seal.

Explore Our Coffee Packaging Solutions

-

PODS

-

CAPSULES

-

BAGS

-

Sticks

-

CARTONS

-

END OF LINE

Soft & Hard pods

Both soft and hard coffee pods are processed at different speeds in equipment designed to ensure precision, but also significant flexibility enabling customers to respond rapidly to diverse market requirements. Packaging can be conducted in a modified and conditioned atmosphere, and pods can be stacked individually protected in heat-sealed envelopes and packed into heat-sealed vertical pouches or cartons.

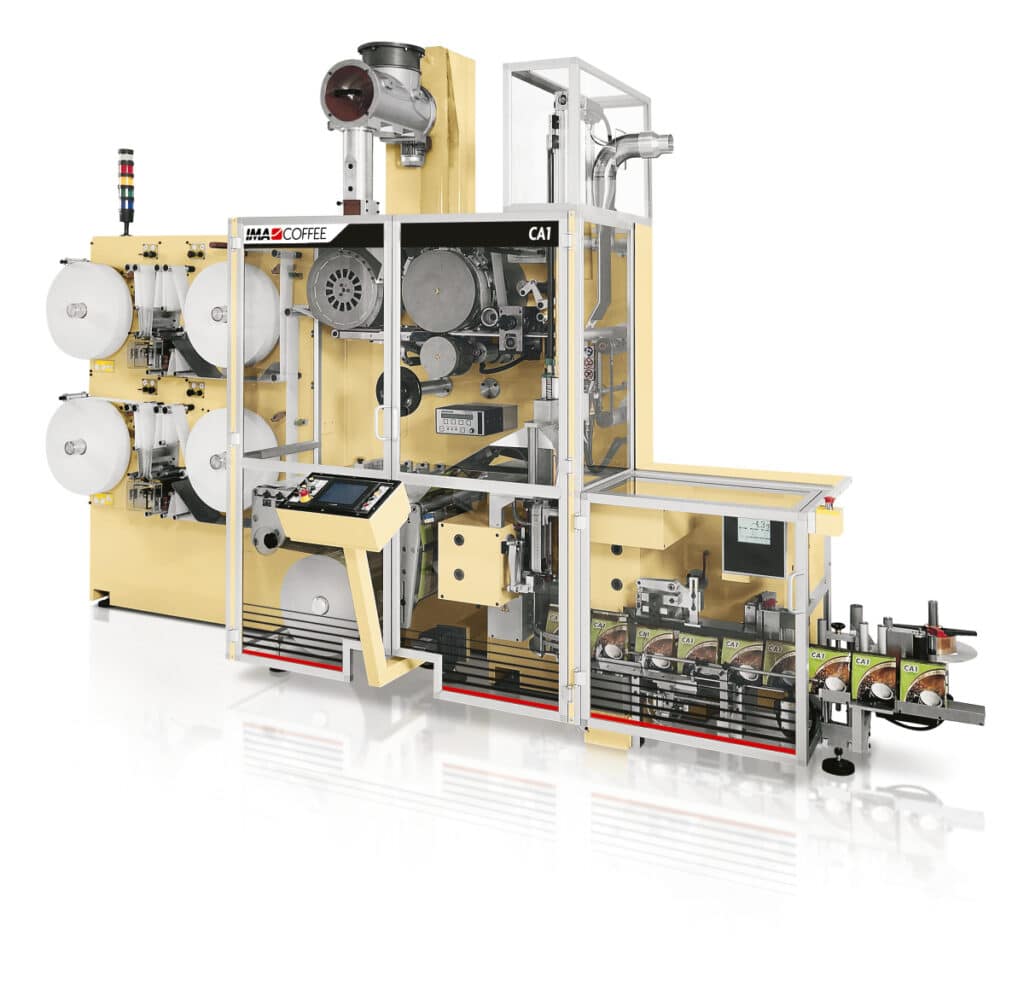

CA1

The CA1 is a unique, high-speed machine able to produce soft pods in one single lane, counted, stacked and packed into a heat-sealed stand-up bag.

Hot drink capsule filling

IMA Coffee Packaging machines can package every kind of capsule present on the market both in protected atmosphere and non. Primary packaging of the capsule ensures maximum hygiene and prevents the aggression of external agents, such as moisture, heat and air. The capsule preparation machines can be fitted to work with all kinds of capsules, self-sealing or non self sealing, with different thermoplastic, compostable or biodegradable materials. The company’s flexibility allows it to manufacture units for the insertion of plastic filters or for the cutting and sealing of paper/aluminum filters, alternatively on the bottom or on the outside of the capsule.

UNIKA

A unique solution from which operators, production line managers, producers, and eventually the customers, will benefit. Here is a closer look at UNIKA, processing up to 600 capsules/minute by leading packaging specialists IMA Coffee.

Bags

Coffee is extremely sensitive to exposure to air, light and environmental odours. The fragrance and flavour of coffee is its core value and IMA’s packaging solutions protect the quality and extend the shelf life of this product. Developed over many years of experience in this industry, IMA’s packaging machinery provides excellent hermetic sealing systems, special valve systems for freshness and reclosable systems for consumer convenience.

3C-130

The 3C Series vertical baggers produce high quality pouches providing reliability with the best cost-benefit ratio. The baggers, intermittent or continuous motion, including degassing valve applicator and N2 flushing system, are capable of producing and filling 3 side seal bags from 50 cc up to 5000 cc.

STICKS

Vertical multiline packaging machines to produce tube style pouches to maximize its capacity and optimize packaging material usage. Suitable for liquids, powders and granulated products.

STICK SERIES

Machine capable of producing and filling 3 side seal stick bags from 0,5 cc to 50 cc with outputs up to 1200 sachets per minute.

Secondary Packaging

Secondary packaging ensures product protection and product integrity when it leaves the production site to reach the final consumers. Different secondary packaging methods are usually utilized according to the original capsule nature. IMA Coffee Packaging offers a wide range of cartoning solutions from oriented to bulk configurations, designed to ensure the maximum flexibility and higher productivity.

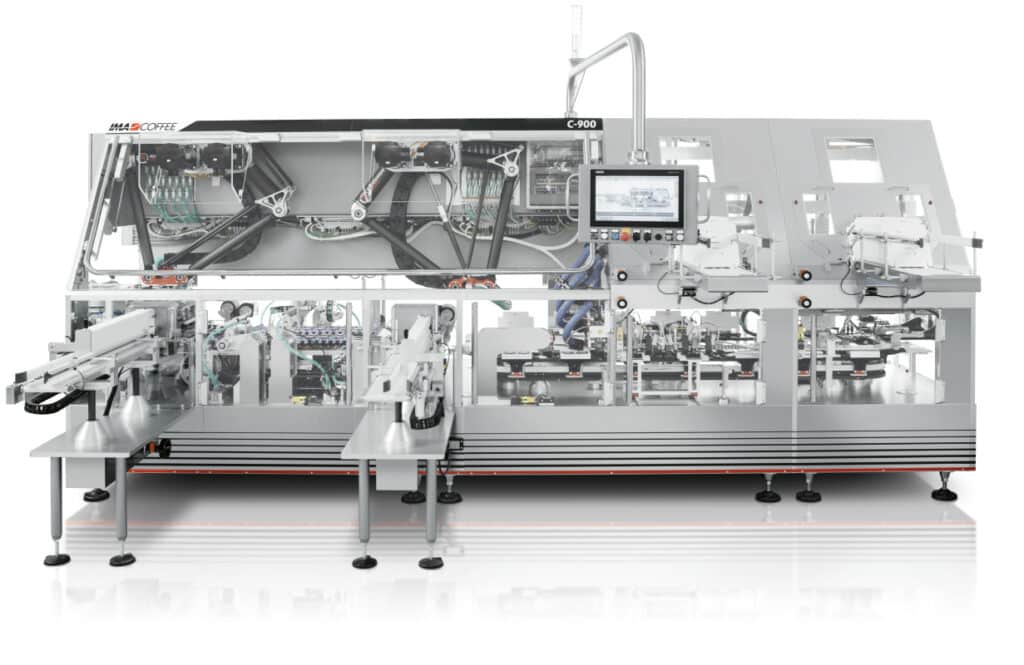

C-900

The last generation capsule cartoner C-900 handles any type of capsule available on the market, in plastic, aluminum, recyclable and compostable material, packing them in a wide range of sizes and carton configurations and styles.

The machine can feed up to 900 capsules per minute and pack up to 90 cartons per minute.

End of Line Packaging

A host of solutions are available to handle any kind of coffee packaging. Whatever the shape or the size of the bags, cartons and capsules may be, the integrity of the content is always preserved, the quality of the final packaging is guaranteed.

MMP400

Electronically driven, high-performance wrap around case packer, the MMP400 benefits from astute ergonomic design features enabling user-friendly operation and optimum productivity, with a flat blanks magazine positioned to allow easy case loading.

Versatile capsule configuration into cartons

Capsule Preparation

UNIKA, by name and by nature.

Our Top Solutions

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[embed_iframe] =>

[form_price] =>

[contact] => sales.coffee@ima.it

[thread_tag] => coffee

[tile_description] =>

[tile_speed] => Up to 1200 capsules/min

[cover_macro] => 3581

[cover_name_type] => txt

[cover_name] => SYNKRO

[cover_descriptor] => Capsule filling and sealing

[cover_focus_on] => 1

[cover_focus_content] => The brand new Synkro is the IMA Coffee fastest technology for coffee capsule filling and sealing based on an innovative capsule transfer system using independent magnetic shuttles.

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => Contact us

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

[cover_focus_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => Contact us

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

[news] =>

[thumbnail] => 3580

[tag_line] => NEW CONCEPT OF PERFORMANCE

[overview] => The SYNKRO is a latest generation machine for coffee capsule filling and sealing. With its high degree of automation in a compact design, it can handle all types of capsules, whatever material they are made of – aluminum, plastic, compostable materials.

Thanks to its innovative capsule transfer system based on the use of independent magnetic shuttles, it guarantees high flexibility, allowing different dwell times at each operating station.

The SYNKRO is equipped with an innovative precise and accurate dosing system guaranteeing an extremely gentle product handling.

The cantilever design ensures great accessibility for maintenance and cleaning operations.

According to the machine configuration, SYNKRO is able to reach up to 1200 capsules per minute.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

|

|

|

The use of the magnetic shuttle transfer system ensures energy saving if compared to traditional capsule transfer systems. The use of ultrasonic technology for packaging material sealing guarantees energy saving if compared to traditional heat-sealing systems. |

The SYNKRO can handle compostable and recyclable materials (capsule, filter, lid). |

[highlights_on] => 1 [focus_on] => [versions_on] => [addon_on] => [output_on] => [technical_data] =>

| SYNKRO | ||

| Production speed (capsule/min) | 800 | 1200 |

| Power consumption (kW) | 40 | |

| Machine weight (kg) | 9000 | |

| Nitrogen consumption (Nl/h) | 650 | |

| Compressed consumption (Nl/h) | 1200 | |

| Compressed air pressure (bar) | 6 | |

Data for SYNKRO 800 ppm version.

Data subjected to possible technical modifications and not necessarily definitive.

The brand new Synkro is the IMA Coffee fastest technology for coffee capsule filling and sealing based on an innovative capsule transfer system using independent magnetic shuttles.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[embed_iframe] =>

[form_price] =>

[contact] => sales.coffee@ima.it

[no_index] =>

[thread_tag] => coffee

[tile_description] =>

[tile_speed] => Up to 600 capsules/min

[cover_macro] => 815

[cover_name_type] => txt

[cover_name] => UNIKA

[cover_descriptor] => Capsule filling and sealing

[cover_focus_on] => 1

[cover_focus_content] => UNIKA is a modular capsule filling and sealing machine and strikes a perfect balance between performance and practicality. The modular construction design allows high flexibility in achieving custom-made solutions for almost any kind of product.

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => Contact us

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

[cover_focus_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => Contact us

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

[news] =>

[thumbnail] => 4519

[tag_line] => ACCURATE DOSING, SUPERIOR EFFICIENCY, UNIQUE QUALITY.

[overview] => UNIKA is able to handle any capsule type available on the market, fed in bulk or stacked. The denester is a space-saving cost-effective solution to feed stackable capsules. The centrifugal unscrambler allows handling of all capsule types, stackable and non-stackable, granting high autonomy. A robotized depacker unit is available for Nespresso compatible aluminum stacked capsules only.

Capsules can be closed at the top with aluminum film, micro perforated, filter paper, triplex coupled, PP and compostable lid. Filters and diaphragms can be inserted into capsules and on their bottom.

Accurate product dosing is made possible thanks to precise and extremely gentle product handling to suit a wide range of products to be filled – coffee with different densities, tea and soluble powders. Liquid flavor dosing is also possible.

The pull-out operating system significantly reduces line downtimes resulting in a great efficiency increase. The entire production process can easily be monitored by a single operator performing all operations on the front side of the machine. The unique ergonomic cantilever design assures great accessibility for maintenance, service and easy cleaning both from the front and from the back side of the machine.

According to the machine configuration, UNIKA is able to reach up to 600 capsules per minute.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] => 1

[buttons_items] =>

)

[sustainability] =>

|

|

| The use of ultrasonic technology for packaging material sealing guarantees energy saving if compared to traditional heat-sealing systems. | The UNIKA can handle compostable and recyclable materials (capsule, filter, lid). |

[highlights_on] => 1 [highlights] => Array ( [0] => Array ( [highlight] => Compact footprint ) [1] => Array ( [highlight] => Top accessibility ) [2] => Array ( [highlight] => Fast Changeover and reduced maintenance ) [3] => Array ( [highlight] => Aroma doser ) [4] => Array ( [highlight] => Extremely precise dosing system ) [5] => Array ( [highlight] => Nitrogen flushing unit ) [6] => Array ( [highlight] => Special sealing technologies for inner components and lid ) [7] => Array ( [highlight] => Single capsule rejection ) ) [focus_on] => [versions_on] => [addon_on] => [output_on] => [technical_data] =>

| UNIKA 8 | UNIKA 10 | |

| Production speed (capsule/min) | 480 | 600 |

| Power consumption (kW) | 40 | |

| Machine weight (kg) | 8000 | |

| Nitrogen consumption (Nm3/h) | 1500 | |

| Compressed consumption (Nm3/h) | 800 | |

| Compressed air pressure (bar) | 6 | |

Data subjected to possible technical modifications and not necessarily definitive.

[layouts] => Array ( [0] => Array ( [image] => 1299 ) [1] => Array ( [image] => 1300 ) [2] => Array ( [image] => 1301 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 4557 [id] => 4557 [title] => UNIKA_EN [filename] => UNIKA_EN.pdf [filesize] => 1964214 [url] => https://ima.it/coffee/wp-content/uploads/sites/10/2019/06/UNIKA_EN.pdf [link] => https://ima.it/coffee/machine/3c-series/unika_en-2/ [alt] => [author] => 11 [description] => [caption] => [name] => unika_en-2 [status] => inherit [uploaded_to] => 1335 [date] => 2024-07-11 10:36:54 [modified] => 2024-07-11 10:36:54 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/coffee/wp-includes/images/media/document.png ) [main_video] => pzjiX4_SyKg [gallery] => Array ( [0] => Array ( [image] => 815 [description] => Dosing unit ) [1] => Array ( [image] => 1304 [description] => Pressing and cleaning unit ) [2] => Array ( [image] => 1305 [description] => Weighing system ) [3] => Array ( [image] => 1306 [description] => Cutting and sealing unit ) [4] => Array ( [image] => 1307 [description] => Additional sealing unit ) [5] => Array ( [image] => 1308 [description] => Exit pick & place ) ) [line_step] => Array ( [0] => 7 ) [aseptic] => both [market_products] => Array ( [0] => 617 ) [market_packs] => Array ( [0] => 4380 ) [market_packs_specs] => Array ( ) [market_brands] => Array ( [0] => 37959 ) [market_plants] => Array ( [0] => 25318 ) [body_class] => [no_follow] => [seo_image] => [seo_title] => [seo_description] => [related] => no [technologies] => Array ( [0] => 77 ) )

UNIKA is a modular capsule filling and sealing machine and strikes a perfect balance between performance and practicality. The modular construction design allows high flexibility in achieving custom-made solutions for almost any kind of product.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[embed_iframe] =>

[form_price] =>

[contact] => sales.coffee@ima.it

[thread_tag] => coffee

[tile_description] =>

[tile_speed] => up to 120 capsules/min

[cover_macro] => 1816

[cover_name_type] => txt

[cover_name] => SR SMART SERIES

[cover_descriptor] => Capsule filling and sealing

[cover_focus_on] => 1

[cover_focus_content] => Latest-generation machines, the SR SMART Series is a range of versatile and flexible machines equipped for the filling and sealing of capsules on 1 and 2 lanes.

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => contact us

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

[cover_focus_buttons] => Array

(

[buttons_on] => 1

[view_default] => 1

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => private

[button_id] =>

[button_class] =>

[text] => contact us

[icon] => mail

[form_email] => sales.coffee@ima.it

[type] => contact

[private_product] =>

[private_exhibition] =>

[form_type] => contact

[form_id] =>

)

)

)

[news] =>

[thumbnail] => 4517

[tag_line] =>

[overview] => The unique ergonomic cantilever design assures great accessibility for maintenance, service and easy cleaning; further more the pullout operating system significantly reduces line downtimes resulting in a great efficiency increase. Lid and waste reels are placed outside the machine, reducing downtime.

Thanks to a very fast size changeover and to an integrated double feeding system, for bulk and stacked capsules, the SR SMART Series can handle any type of capsule in plastic, aluminum and compostable material. Capsules can be closed at the top with aluminum film, micro perforated, filter paper, triplex coupled, PP and compostable lid. Filters and diaphragms can be inserted into capsules and on their bottom.

According to the machine configuration, speed can vary from 60 to 120 capsules per minute.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] =>

[versions_on] =>

[addon_on] =>

[output_on] =>

[technical_data] => | SR1 SMART | SR2 SMART | |

| Production speed (capsules/min) | up to 60 | up to 120 |

| Power consumption (kW) | 27 | 27 |

| Machine weight (kg) | 3280 | 3335 |

| Nitrogen consumption (Nm3/h) | 28 | 28 |

| Compressed air consumption (Nm3/h) | 28 | 38 |

| Compressed air pressure (bar) | 6 | 6 |

Latest-generation machines, the SR SMART Series is a range of versatile and flexible machines equipped for the filling and sealing of capsules on 1 and 2 lanes.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[body_class] =>

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[embed_iframe] =>

[form_price] =>

[contact] => sales.coffee@ima.it

[thread_tag] => coffee

[tile_description] =>

[tile_speed] => Up to 90 cartons/min

[cover_macro] => 2453

[cover_name_type] => txt

[cover_name] => C-900

[cover_descriptor] => High speed capsule cartoning machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 4518

[tag_line] => Infinite capsule arrangement options and carton styles

[overview] => The C-900 represents an excellent choice as a turnkey solution combined with IMA high speed capsule filling machines.

The capsule transfer feeding system is equipped with a buffer and capsules recirculation unit and guarantees extremely gentle handling, avoiding capsules damaging. Capsules are fed in a bucket chain and transferred by a pick & place system equipped with gripper-suction cup type units able to respond to any desired configuration.

According to required machine speed and carton capacity, the C-900 can be completed with a single or double flat blank carton magazine.

A simple size changeover allows the C-900 to handle any capsule type available on the market in any arrangement and carton style. The machine can feed up to 900 capsules per minute and pack up to 90 cartons per minute.

The C-900 can be set up according to the arrangement requirement, alternated or nested, and handles a variety of carton styles, including tubes. Top flexibility is achieved in final carton configuration as the C-900 allows single or multi-layer filling and the insertion of interlayers and/or inlays.

Carton space optimization achieved by smart capsule arrangement solutions contributes to packaging material saving and shelf space reduction.

The variety of carton handled by the C-900 are accompanied by a variety of closure options. Starting from the simplest ones up to the more sophisticated solutions, such as:

- Top Flap, with or without frontal flap

- Additional lateral flaps

- Flip Top closure with or without tamper evident system.

|

|

| The machine motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. | The C-900 can handle capsules made of compostable or recyclable material. Carton material can be recyclable or recycled. |

| C-900 TECHNICAL DATA | |

| Production speed | up to 90 cartons/min |

| Average power consumption | 15 kw |

| Operating Pressure | 6 bar |

| Maximum air consumption | 800 Nl/min |

| Weight | 5000 kg |

The brand new capsule cartoner C-900 can handle any type of capsule available on the market packing them in a wide range of sizes and carton configurations.

[buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sales.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) [cover_focus_buttons] => Array ( [buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sales.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) [related] => no [technologies] => Array ( [0] => 98 ) )

The brand new capsule cartoner C-900 can handle any type of capsule available on the market packing them in a wide range of sizes and carton configurations.

Array

(

[cover_macro] => 1460

[cover_name_type] => txt

[cover_name] => CA1

[cover_descriptor] => Soft pod packaging

[cover_focus_on] => 1

[news] =>

[thumbnail] => 4529

[tag_line] => A soft pod packaging line in one single machine

[overview] => The CA1 is a unique, high-speed machine able to produce soft pods in one single lane, counted, stacked and packed into a block bottom bag.

Auxiliary units for pod counting, stacking, pack forming, filling, closing and weight-checking all fit into little more than a 4.3 metre length layout, making the CA1 an efficient, comprehensive and extremely compact machine processing up to 800 soft pods/minute.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

The CA1 can handle compostable and recyclable materials (filter paper, envelope).

[highlights_on] => 1

[focus_on] =>

[technical_data] => | TECHNICAL DATA CA 1 | |

| Machine speed (coffee pod/minute) | Up to 800 |

| Capacity coffee pod | Up to 14 grams of coffee |

| Heatsaled pack capacity | Min. 8 – Max. 18 pods per pack |

| Power required | Total installed power 23 kW |

| Power consumption | 18 kW |

| N.b. Consumption dipends on the thermics group fitted on the machine | |

| Compressed air | Duty pressure: 6 bar – Consumption: 200 Nl/min. |

| Machine net weight | Max. 4,500 Kg |

| Data subject to possible technical modification and not necessarily definitive | |

The CA1 all-in-one, single-dose coffee packaging machine takes efficiency to new heights, guarantees maximum flexibility and quick changeover procedures, user-friendly operation and saves on packaging material.

[buttons_on] => 1 [cover_focus_buttons] => Array ( [buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sales.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Gas flushing unit to avoid coffee oxidation and maintain flavour - low oxygen residue (<1%). ) [1] => Array ( [highlight] => Automatic filter paper splicing system: smooth and without need to reduce speed for maximum efficiency. ) [2] => Array ( [highlight] => Programmable electronic counting system: ensures correct number of pods in stacking unit at all times. Can switch from 1 to 2 pod stacks. ) [3] => Array ( [highlight] => CA1 is a lubrication-free machine for cleaner processing. ) [4] => Array ( [highlight] => Numerous optional groups available for maximum packaging versatility. ) ) [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => sales.coffee@ima.it [no_index] => [versions_on] => 1 [addon_on] => [versions_thumbnail] => 1471 [versions_tag_line] => Integrated coffee grinder [versions_overview] =>Simple installation of an integrated coffee grinder onto the machine’s product hopper is a way of completing the production cycle of the CA1 without extending the footprint beyond the space-efficient 4.3 metre length layout.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [market_products] => Array ( [0] => 617 ) [market_packs] => Array ( [0] => 2215 ) [market_brands] => Array ( [0] => 37959 ) [market_plants] => Array ( [0] => 37959 ) [line_step] => Array ( [0] => 7 ) [tile_description] => [tile_speed] => Up to 800 pods/min [aseptic] => both [thread_tag] => coffee [market_packs_specs] => Array ( ) [output_on] => [body_class] => [no_follow] => [seo_image] => [seo_title] => [seo_description] => [embed_iframe] => [form_price] => [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sales.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) [versions_title] => [versions] => [related] => no [technologies] => Array ( [0] => 77 ) )

The CA1 all-in-one, single-dose coffee packaging machine takes efficiency to new heights, guarantees maximum flexibility and quick changeover procedures, user-friendly operation and saves on packaging material.

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[no_index] =>

[no_follow] =>

[seo_image] =>

[seo_title] =>

[seo_description] =>

[embed_iframe] =>

[form_price] =>

[contact] => sales.coffee@ima.it

[thread_tag] => coffee

[tile_description] =>

[tile_speed] => Up to 150 bags/min

[cover_macro] => 1336

[cover_name_type] => txt

[cover_name] => 3C Series

[cover_descriptor] => Vertical baggers

[cover_focus_on] => 1

[news] =>

[thumbnail] => 4532

[tag_line] => 3C Series

[overview] => The 3SS bagger models guarantee a high performance output in the packaging of ground coffee and beans.

The design of the machines is based on an Open Frame architecture that provides easy cleaning and accessibility for maintenance and operational adjustments. The machines are controlled by a PLC and equipped with a user friendly HMI, a motorized film unwinding unit, a pneumatic film tension controller and a motorized film alignment system. The baggers, intermittent or continuous motion, including degassing valve applicator and N2 flushing system, are capable of producing and filling 3 side seal bags from 50 cc up to 5000 cc.

- 3C-130/OF intermittent or continuous motion – up to 150 p/min

- 3C-200/OF intermittent motion – up to 60 p/min

- 3C-360 intermittent motion – up to 15 p/min

- 3C-80 Dual intermittent motion – up to 70 p/min

- 3C-130 Twin intermittent motion – up to 80 p/min

- PRYSMA intermittent motion – up to 50 p/min

3C Series machines can handle compostable and recyclable materials (bag).

[highlights_on] => 1 [highlights] => Array ( [0] => Array ( [highlight] => Servo driven mechanisms ) [1] => Array ( [highlight] => Design to perform bags with laminated and/or PE packaging materials ) [2] => Array ( [highlight] => Capable to dose two or more products simultaneously ) [3] => Array ( [highlight] => Configurable for gusseted bags, flat bottom, flat top and stabile bags ) [4] => Array ( [highlight] => Integrated systems with automatic collator, cartoning and end of lines ) [5] => Array ( [highlight] => In line weight control, coding systems, conveyors, products infeed chargers, inert gas flush and other optional features ) [6] => Array ( [highlight] => Vacuum film pulling system ) [7] => Array ( [highlight] => Automatic reel splicer ) ) [focus_on] => [versions_on] => [addon_on] => [output_on] => [technical_data] =>| Width | Length | Numb. Of lines | Reel | Speed Strokes/min | |

| INTERMITTENT MOTION | |||||

| 3C-130/OF | 65-235 mm | 100-410 mm | 1 | 505 mm | 100 |

| 3C-200/OF | 135-360 mm | 200-500 mm | 1 | 750 mm | 60 |

| 3C-360 | 250-500 mm | 500-800 mm | 1 | 1200 mm | 10 |

| 3C-80 DUAL | 65-125 mm | 100-225 mm | 2 | 540 mm | 70 |

| 3C-130 TWIN | 65-235 mm | 100-410 mm | 2 | (2x) 505 mm | 100 |

| PRYSMA (flat top) | 65-220 mm | 100-250 mm | 1 | 505 | 50 |

| CONTINUOUS MOTION | |||||

| 3C-130 C | 65-205 mm | 100-350 mm | 1 | 445 | 150 |

The 3C Series vertical baggers produce high quality pouches providing reliability with the best cost-benefit ratio.

[buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sales.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) [cover_focus_buttons] => Array ( [buttons_on] => 1 [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sales.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) [body_class] => [related] => manual [technologies] => Array ( [0] => 77 [1] => 234 ) [related_products] => Array ( [0] => 10_949 [1] => 6_3622 ) )Contacts us:

Headquarter and Registered Office:

IMA S.p.A. – Coffee Division

Via Emilia Levante 428-442

Ozzano Emilia, 40064 (Bologna) • Italy Tel. +39 051 6514111

Fax +39 051 6514080

Production sites:

IMA S.p.A. – Coffee Division

Via Emilia Levante 428-442

Ozzano Emilia, 40064 (Bologna) • Italy Tel. +39 051 6514111

Spreafico Automation s.r.l.

Via E. Fermi 9

Calolziocorte, 23801 (Lecco) • Italy Tel. +39 0341 240311

Tecmar S.A.

G. Matteotti, 64

Mar del Plata, B7608BJB (Buenos Aires) • Argentina Tel. +54 223 481-0008