Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |Delta 6000

The Delta 6000 is a fully modular design MAP flow wrapper that offers complete IP65 protection, enabling full wash down capability, even of the sealing elements.

The Delta 6000 is a fully modular design MAP flow wrapper that offers complete IP65 protection, enabling full wash down capability, even of the sealing elements.

MAP and hermetic flow wrapping for food and non-food products.

The Delta 6000 is a fully modular design MAP flow wrapper that offers complete IP65 protection and is able to produce MAP packs with hermetic seals at speeds of up to 200 ppm.

Strong hermetic seals are created on a high speed long-dwell sealing system. The longitudinal sealing unit features patented independent motorisation for more precise fin control. It uses four sets of heated rollers operating at different speeds to create the longitudinal seam, resulting in superior presentation.

Besides offering superior format flexibility, the Delta 6000 offers complete IP65 protection, enabling full wash down capability, even of the sealing elements. Its ultra-hygienic design has been achieved through full stainless-steel execution, isolating the electrical cabinet from the main machine frame and smooth, angled surfaces without recesses.

Users of the Delta 6000 will also benefit from shorter lead times and lower TCO (Total Cost of Ownership) as a result of the machine’s unique modular design. Customers can customise their machine by selecting only the modules they need, and can easily add modules such as film auto-splicing, gusseting, even a completely new jaw set up at a later date.

Delta 6000 Highlights

- Technical Data

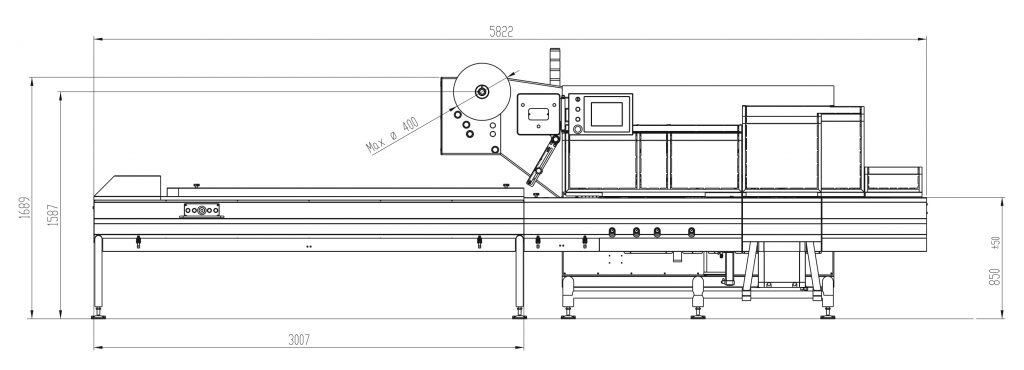

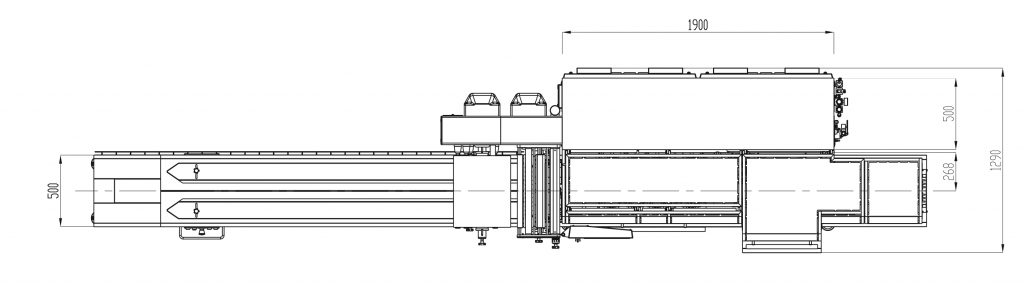

- Machine Layout

| Machine Speed | Up to 200 cycles per minute |

| Production output depends on film sealability and product characteristics | |

| Product Dimensions | |

| Lenght | Up to 650 mm – 25.6” standard |

| Up to 1000 mm – 39.0” on request | |

| Width | 150 mm – 5.9” on request (jaws 190 mm – 7.5”) |

| 300 mm – 11.8” standard (jaws 345 mm – 13.6”) | |

| 420 mm – 16.5” on request (jaws 450 mm – 17.7”) | |

| Height | Up to 110 mm – 4.3” standard (centre – axle 180) |

| Up to 150 mm – 6.0” on request (centre – axle 225) | |

| Up to 60 mm – 2.4” on request (centre – axle 140) | |

| Film Cut-Off | Min 100 mm – 4.0” / Max 1200 mm – 47” |

| Wrapping Materials | Shrink barrier films, laminated, co-extruded and all sealable films |

| Film Reel Dimensions | |

| core ø | 76.2 mm – 3” standard |

| 152.4 mm – 6” on request | |

| outer ø | 350 mm – 13.8” standard for reel web width up to 800-900 mm |

| 400 mm – 15.7” on request for reel web width up to 500-650 mm | |

| width | 500 mm / 650 mm – 19.7” / 25.5” standard |

| 800 mm / 900 mm – 31.5” / 35.5” on request | |

| Film Reel Max Weight | Depending on film reel width, up to 75 kg – 165 lbs |

| Power Requirement | From 220 to 480 V, 50/60 Hz, 7kVA |

| Compressed Air | 6 bar, 200 l/min |

| Machine Weight | 1400 Kg – 3100 lbs |