Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |CT 10

The CT10 ensures optimum production capacity for tetrahedral tea bags, ideally suited to long-leaf tea and herbs. Integrating a cartoning unit, the CT10 completes the packaging process without occupying excessive floor space.

The CT10 ensures optimum production capacity for tetrahedral tea bags, ideally suited to long-leaf tea and herbs. Integrating a cartoning unit, the CT10 completes the packaging process without occupying excessive floor space.

Shaping tea naturally

The CT10 processes tetrahedral tea bags with a string and tag at a speed of 300 bags/minute. Thanks to their shape and stability, such bags are ideal for long-leaf products which consequently have more room to move and infuse for a better brew.

A specially designed volumetric rotating doser reduces fragmentation to a minimum so as to preserve the original properties of the product.

Equipped with a dedicated cartoning attachment, the CT10 packs the tea bags into stylish, open and re-closable caddy style cartons. Once closed, carton weight is checked and automatic dose regulation is performed.

All main machine stations incorporate specific product control devices for maximum product quality. Automatic rejection procedures enable non-stop processing maintaining production efficiency at the highest level.

Sustainability

|

|

| The use of ultrasonic technology for packaging material sealing guarantees energy saving if compared to traditional heat-sealing systems. | The CT10 allows the use of sustainable packaging materials for a complete eco-friendly package ensuring outstanding infusion and taste neutrality. |

CT10 Highlights

- Technical Data

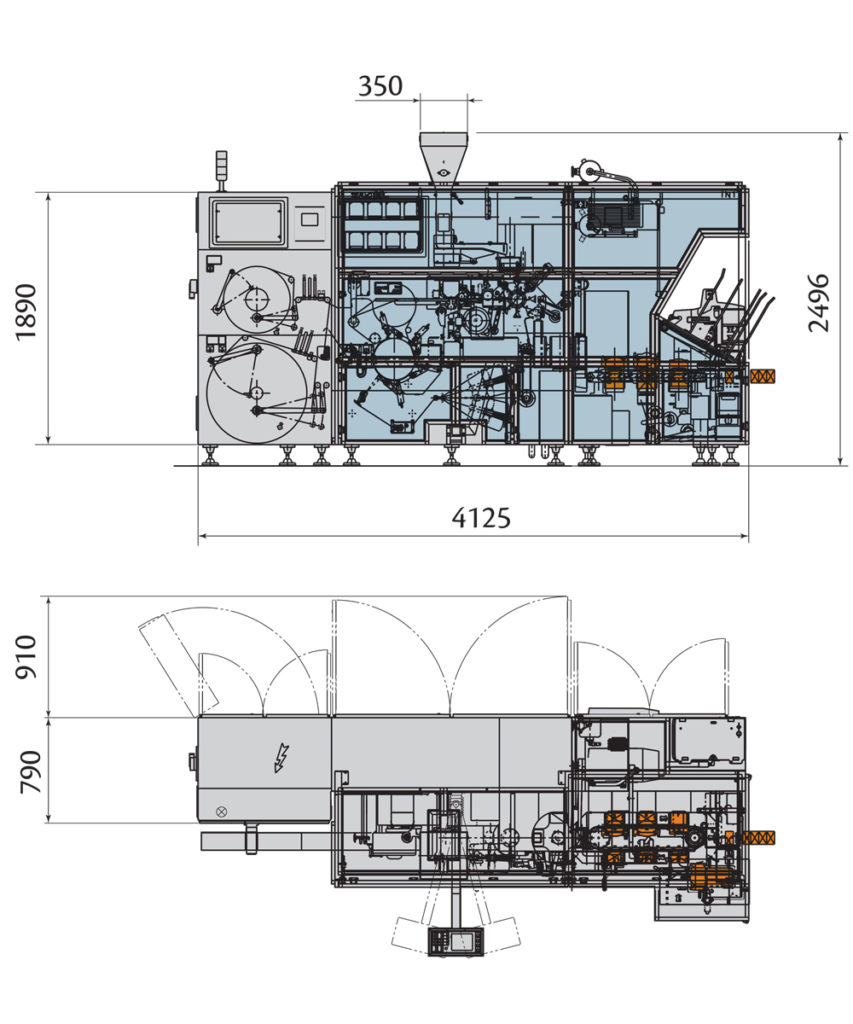

- Machine Layout

| TECHNICAL DATA CT 10 | |

| Machine speed (Bags/minute) | Up to 300 |

| Tea bag capacity | From 2.2 to a maximum of 8.1 cc |

| Power required |

Total installed power: 16 kW Average power consumption: 8 kW Maximum power consumption: 10.5 kW |

| N.b. Power consumption depends on the thermic groups fitted in the machine | |

| Compressed air |

Exercise pressure: 6 bar Consumption: max 880 Nl/min. |

| Machine net weight | Max. 5,850 Kg for machine with cartoning attachment |