Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |C58

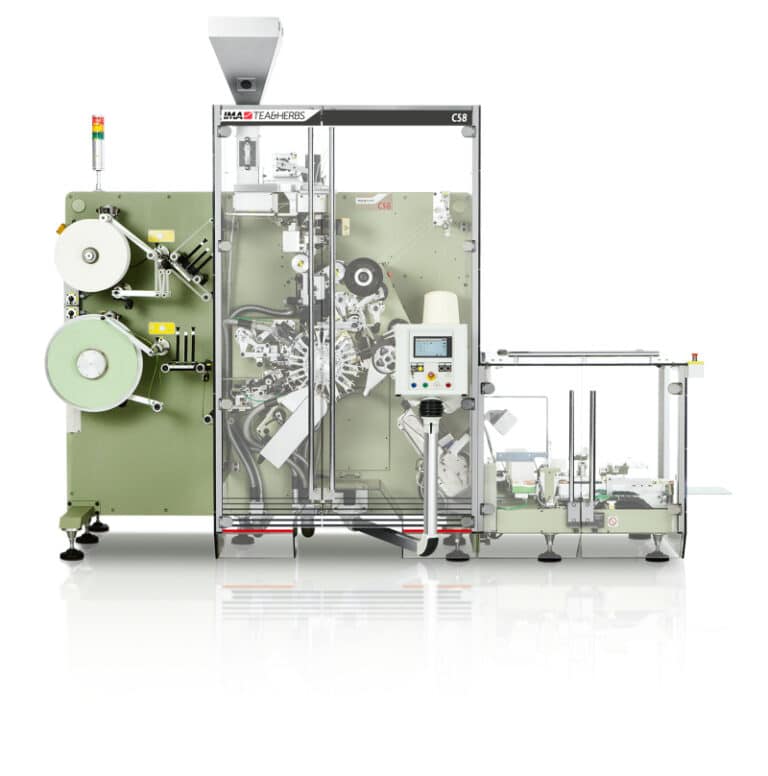

The C58 combines high-speed processing with knot technology for a new generation of single-chamber bags for tea and herbs. Ideal for naked, crimped and heatsealed bags, the C58 offers flexibility in terms of packaging materials and final packaging solutions.

The C58 combines high-speed processing with knot technology for a new generation of single-chamber bags for tea and herbs. Ideal for naked, crimped and heatsealed bags, the C58 offers flexibility in terms of packaging materials and final packaging solutions.

Single by choice

Designed to offer a new generation of single-chamber bags, the C58 benefits from our extensive experience in the tea packaging sector. Producing up to 300 bags/minute, the machine exploits an innovative vertical bag-forming process together with consolidated knot technology.

Lateral gussets on the new single-chamber bags give products more room to move, letting them infuse for a better brew.

Naked, crimped and heatsealed bags are all possible, and ultimate flexibility is achieved with a host of final packaging solutions. Customers can choose to incorporate cartoning units from flat blanks, pre-formed cartons or pre-glued cartons. As an alternative, the C58 can integrate units allowing final packaging in flow-packs or pouches.

Working cycle is achieved by a fully integrated PC which also guarantees quality control together with further specific product control devices.

Sustainability

The C58 allows the use of sustainable packaging materials for a complete eco-friendly package ensuring outstanding infusion and taste neutrality.

C58 Highlights

- Technical Data

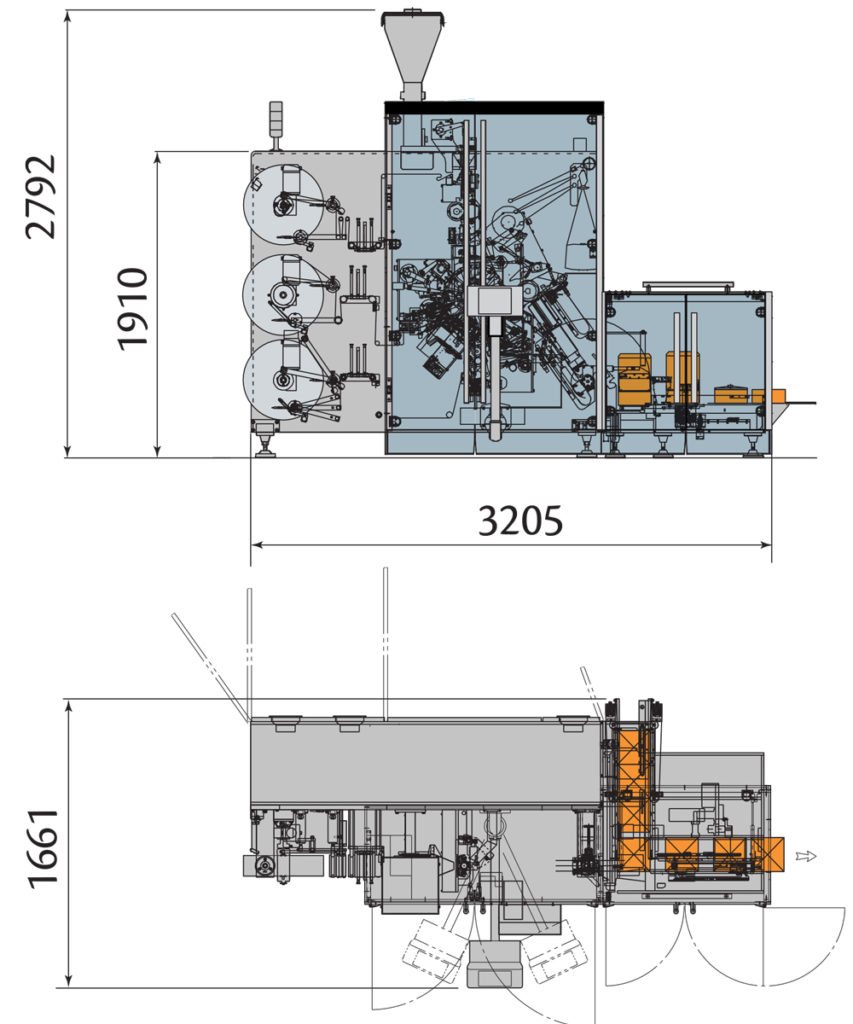

- Machine Layout

| TECHNICAL DATA C58 | |

| Machine speed (envelopes/minute) | Up to 300 bags/minute |

| Filter bag maximum volume | 8.7 cubic centimeters |

| Machine net weight | With hand removal max. 3,100 Kg |