Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |C27-E

Sporting a clean, compact design, the brand new C27-E is a 300 bags/minute packaging solution with knot technology for tea and herbs, able to process naked bags and sealed outer envelopes, incorporating a newly- conceived flexible cartoning attachment.

Sporting a clean, compact design, the brand new C27-E is a 300 bags/minute packaging solution with knot technology for tea and herbs, able to process naked bags and sealed outer envelopes, incorporating a newly- conceived flexible cartoning attachment.

Clean forever. Clever

Based on extensive research to minimise the amount of tea dust deposited on the machine, the C27-E implements a host of clever solutions such as the incorporation of groups inside the machine frame, also significantly reducing the footprint of the machine.

The C27-E produces knotted tea bags at up to 300 bags/minute and handles tea as well as non-free-flowing products thanks to a special vibrating feeding system for herbs.

The C27-E is a medium-speed solution for all tea and herb varieties. Naked bags and sealed outer envelopes are the two available packaging methods. It is equipped with a new cartoning attachment with a level of flexibility allowing both 1 to 4 row processing, as well as carton types including tuck-in, Kurzlaschen and caddy style.

Complete working cycle control is enabled via a PC with a user-friendly on-board HMI. Machine operators also benefit from remote monitoring on a mobile device (tablet or smartphone) thanks to Open Standard software and full interoperability.

Sustainability

|

|

| The C27-E motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. | The C27-E allows the use of sustainable packaging materials for a complete eco-friendly package. |

C27-E Highlights

- Technical Data

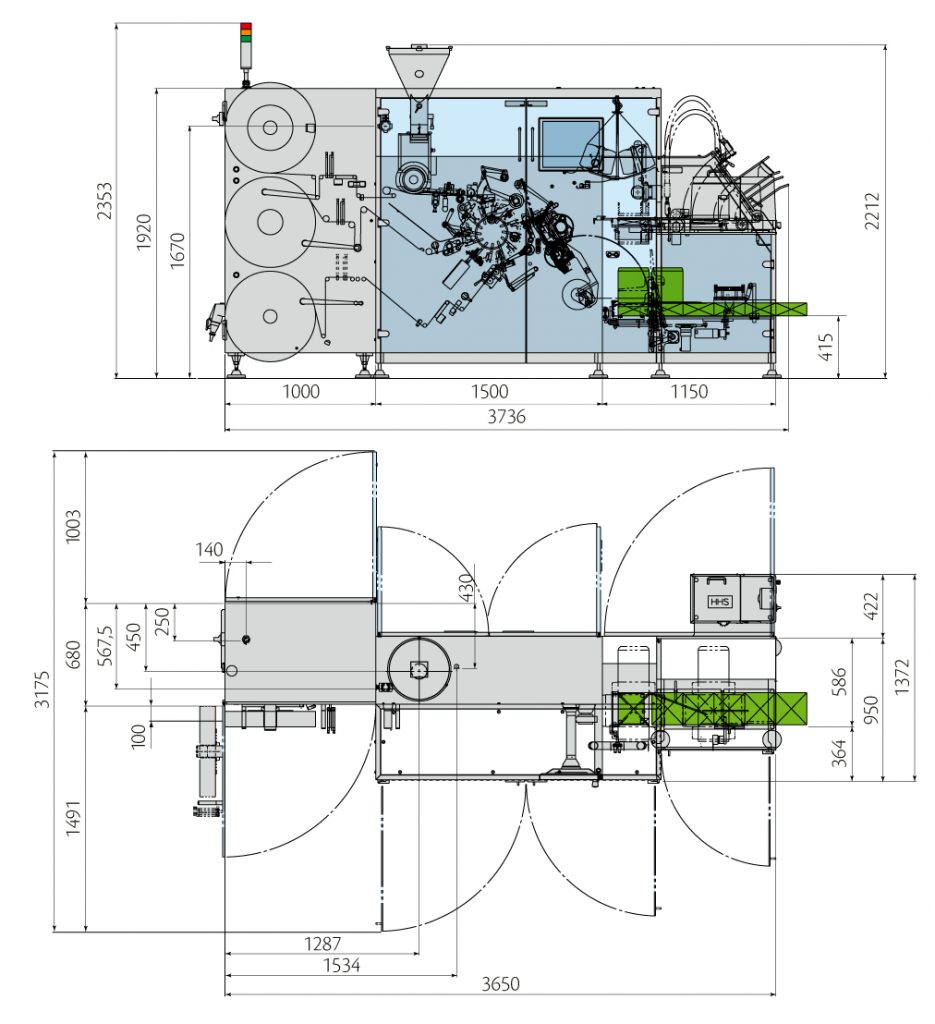

- Machine Layout

| TECHNICAL DATA C27-E | |

| Machines speed | Up to 300 bags/minute |

| Teabag Capacity | Up to approximately 3,0 grams Filter bag maximum volume 9,5 cubic centimeters |

| Power required of basic machine | Total installed power: 16,6 kW Maximum power consumption: 5,7 kW Note: consumption depends on the thermic groups fitted on the machine |

| Compressed air | Exercise pressure: 6 bar Consumption: up to max. 200 Nl/min. |

| Machine net weight (with cartoning unit) | Max 2638 Kg |