Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |C59

The highly compact C59 is the new packaging solution for heatsealed, single-chamber bags without string and tag. For tea, and especially for herbs, it accomplishes packaging into flow packs for improved product preservation.

The highly compact C59 is the new packaging solution for heatsealed, single-chamber bags without string and tag. For tea, and especially for herbs, it accomplishes packaging into flow packs for improved product preservation.

Bag and pack. Inside out.

Conceived to enhance the look and feel of essential single-chamber bags, the C59 produces gusseted, string and tag-free, heatsealed filter bags. Reaching speeds of up to 900 bags/minute, it processes black tea and is an ideal choice for non free-flowing products.

Featuring an integrated flow pack unit as standard, the C59 completes the packaging process by inserting counted naked bags into heatsealed flow packs, which can be personalised by the customer.

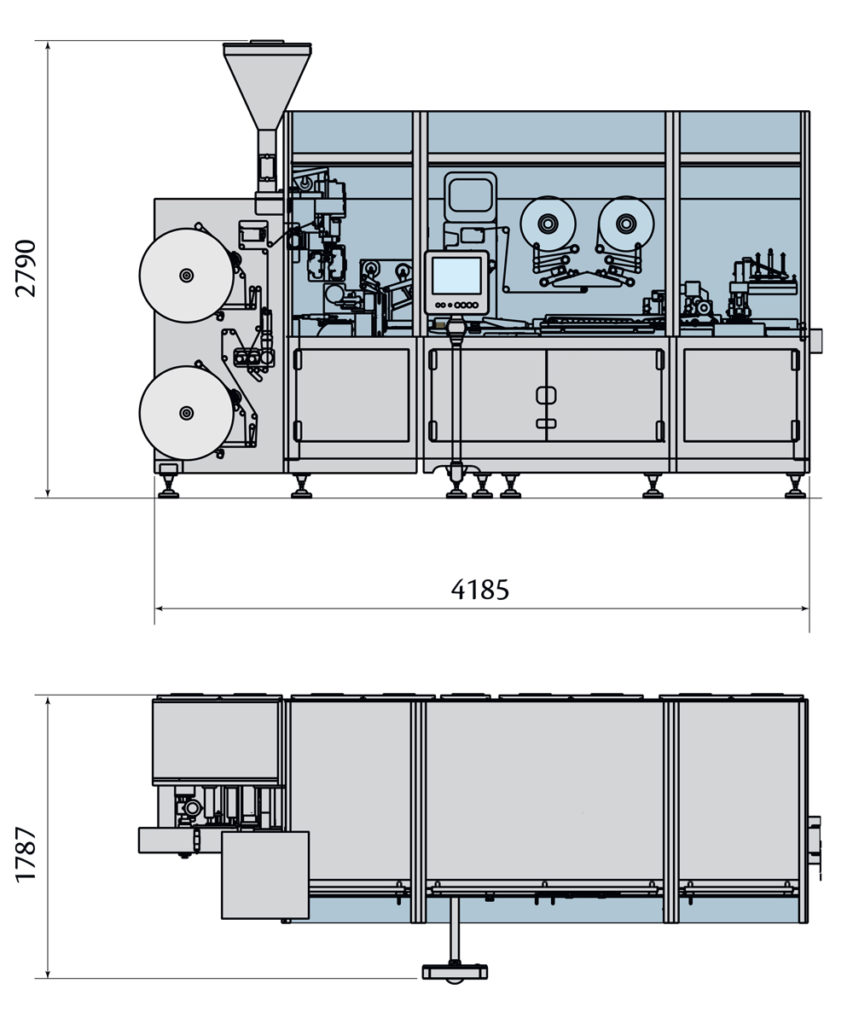

A unique solution as of today, full integration of this unit enables single overall process control covering each step from bag forming to flow pack sealing, as well as enabling a surprisingly limited footprint.

Sustainability

|

|

| The C59 motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is both shared and absorbed by other modules and converted to electrical energy that is regenerated into the power supply system. | The C59 allows the use of sustainable packaging materials for a complete eco-friendly package ensuring outstanding infusion and taste neutrality. |

C59 Highlights

- Technical Data

- Machine Layout

| TECHNICAL DATA C59 | |

| Machines speed | Up to 900 bags/minute |

| Teabag Capacity | Max 3,125 grams Filter bag maximum volume 9,5 cubic centimeters |

| Power required of basic machine | Total installed power: 38 kW Average power consumption: 4,5 kW Maximun power consumption: 8,6 kW Note: consumption depends on the thermic groups fitted on the machine |

| Compressed air | Exercise pressure: 6 bar Consumption: up to max. 235 Nl/min. |

| Machine net weight | Max 4580 Kg |