It was in 1970 when IMA Comadis, based in Milan, launched the first of a successful tube filler series.

A course of continuous growth

IMA Comadis tube-filling machines and jar filling machine have been marked by simplicity in change-over sequences, quick dismounting of contact parts and intuitive operator interface.

A course of continuous growth, that in time brought IMA Comadis to gain an enviable experience in the field, testified by the multitude of both large and small customers. A valuable reputation to be proud of, to bring as a heritage in any new project we approach.

Discover and customise your complete tube filling packaging line

A wide choice of flexible tube-filling machines, cartoners and comprehensive end-of-line solutions.

![]()

-

Tube filling

-

Jar filling

Tube filling machines benefit from simplicity in changeover sequences, quick dismantling of contact parts and an intuitive operator interface.

Special execution for handling of oval tubes, cannulae, rigid applicators and dispensers can be provided; including the specific versions when handling flammable products.

New and advanced technologies characterize the sachet machines in terms of quality, easy size change and simple, easy cleaning access. Together, these features make the machines particularly suitable for the cosmetic and pharmaceutical sectors.

Jar filling and capping machine for pharmaceutical and cosmetic products.

Quick to adjust to any containers and caps to be handled, it grants outstanding performance with a high level of efficiency. All work stations are positioned within its small monobloc footprint. Cost-effectively designed and manufactured with complete practicality, it’s easy to change-over and operate.

Complete packaging line

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

[0] => 4

)

[contact] => mktg.packaging@ima.it

[no_index] =>

[cover_macro] => 2719

[cover_name_type] => txt

[cover_name] => DYNAMICA

[cover_descriptor] => Continuous motion cartoner

[cover_focus_on] => 1

[cover_focus_content] => DYNAMICA Series multipurpose continuous motion cartoner is available in different versions, according to the product specifications, carton dimension sizes and speed. It grants the maximum versatility in terms of applications, infeed systems and carton sizes

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 3043

[tab] =>

)

)

)

[news] =>

[thumbnail] => 2474

[tag_line] => Beyond the limit of the maximum flexibility

[overview] => Flexibility as key feature: this Series offers the widest range of products to be packed, carton dimension range and applications. Moreover, DYNAMICA S version is able to combine both the continuous and the intermittent motion depending on the product fed.

The ergonomics, in terms of carton magazine, product flow and leaflet folding unit heights, is maximum. Last but not least, DYNAMICA is also compact but at the same time easy to manage and intuitive to set up.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 3043

[tab] =>

)

)

)

[sustainability] =>

This system allows the use of recycled cardboards.

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Multi-purpose.

)

[1] => Array

(

[highlight] => Feeding systems: wide range of solutions to pack different products.

)

[2] => Array

(

[highlight] => Very wide cartons sizes range.

)

[3] => Array

(

[highlight] => IMA Safe Roll-One, leaflet folding unit.

)

[4] => Array

(

[highlight] => Ergonomic design.

)

[5] => Array

(

[highlight] => Very easy to manage and intuitive.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 2475

[content] => Cost effective and flexible feeding systems are available at IMA Safe, which offer a wide range of solutions for both pharma and extra pharma fields.

[buttons] => Array

(

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 21536

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => Watch and discover our feeding systems

[icon] => play_circle_outline

[link] => zWyrR5uTcDg

[autoplay] => 1

)

)

)

)

[versions_on] =>

[addon_on] => 1

[addon_items] => Array

(

[0] => Array

(

[image] => 5099

[description] => Roll-One - The IMA patented leaflet folding unit is designed to fold flat sheets using a simple but innovative technology indipendent from the leaflet thickness. To change the leaflet size is just a matter of one simple and fast part replacement.

)

[1] => Array

(

[image] => 2298

[description] => Track & Trace - The integrated module to the cartoner, to apply camera and ink-jet system, is the ideal solution for cartoning serialization having a shorter line and higher efficiency.

)

)

[technical_data] => | TECHNICAL DATA DYNAMICA | ||||

| Width (A) | Height (B) | Lenght (H) | Production output | |

| DYNAMICA L | min 25 – 130 max | min 12 – 90 max | min 65 – 200 max | Up to 250 cartons/min. |

| DYNAMICA E | min 30 – 90 max | min 15 – 65 max | min 100 – 250 max | Up to 300 cartons/min. |

| DYNAMICA SLEEVE* | min 48 – 90 max | min 8 – 15 max | min 65 – 106 max | Up to 350 cartons/min. |

| DYNAMICA S | min 25 – 95 max | min 12 – 90 max | min 65 – 200 max | Up to 350 cartons/min. |

| DYNAMICA V | min 25 – 95 max | min 12 – 90 max | min 65 – 150 max | Up to 400 cartons/min. |

*Version for carton sleeve style

[layouts] => Array ( [0] => Array ( [image] => 5467 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 21536 [id] => 21536 [title] => DYNAMICA SERIES_EN [filename] => DYNAMICA-SERIES_EN.pdf [filesize] => 2764700 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2017/02/DYNAMICA-SERIES_EN.pdf [link] => https://ima.it/pharma/machine/dynamica/dynamica-series_en/ [alt] => [author] => 18 [description] => [caption] => [name] => dynamica-series_en [status] => inherit [uploaded_to] => 2296 [date] => 2022-01-17 14:02:54 [modified] => 2022-01-17 14:03:01 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => M0n9aS9eyfM [gallery] => Array ( [0] => Array ( [image] => 2480 [description] => Product transport ) [1] => Array ( [image] => 2476 [description] => Carton magazine ) [2] => Array ( [image] => 2477 [description] => Carton pick-up and opening ) [3] => Array ( [image] => 2478 [description] => IMA Safe Roll-One ) [4] => Array ( [image] => 2479 [description] => Product insertion into the carton ) ) [related] => no [technologies] => Array ( [0] => 96 [1] => 104 [2] => 87 [3] => 120 [4] => 121 ) [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2176 [1] => 2177 ) [market_brands] => Array ( [0] => 3861 ) [market_plants] => Array ( [0] => 3861 ) [line_step] => Array ( [0] => 11 ) [tile_description] => Continuous motion cartoner. DYNAMICA Series multipurpose continuous motion cartoner is available in different versions, according to the product specifications, carton dimension sizes and speed. It grants the maximum versatility in terms of applications, infeed systems and carton sizes. [tile_speed] => Up to 400 cartons/min [aseptic] => both [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 3043 [tab] => ) ) [thread_tag] => [market_packs_specs] => Array ( ) [output_on] => [addon_title] => Good To Know [embed_iframe] => [form_price] => [no_follow] => [seo_image] => [seo_title] => DYNAMICA: Continuous motion cartoner [seo_description] => DYNAMICA Series multipurpose continuous motion cartoner grants the maximum versatility in terms of applications, infeed systems and carton size range. [body_class] => )

Array

(

[cover_macro] => 2181

[cover_name_type] => txt

[cover_name] => X

[cover_descriptor] => Intermittent motion cartoner

[cover_focus_on] => 1

[cover_focus_content] => X Series multipurpose intermittent motion cartoner, is the best price/performance ratio solution in its product range. Thanks to the use of both mechanical and robotized feeding systems, it can handle the widest product variety in the market.

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 28705

[tag_line] => X, love at first sight

[overview] => X Series is available in four versions:

- X1 and XL1

- X2 and XL2, servo-driven versions

The maximum versatility, in terms of products to be packed and carton dimension sizes, is a key feature of this Series. Moreover, with its compact footprint and balcony design, X offers to you also a huge flexibility in the organizing of lines. The compactness of the machine is also demonstrated with the integrated T&T solution inside the frame, keeping the same standard length.

X is also very intuitive: no special training are needed for the operators. It has very low maintenance costs, central issue in the current marketing strategies of pharmaceutical companies, and a fast changeover thanks to a number of size parts reduced to the minimum.

[overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [sustainability] =>

This system allows the use of recycled cardboards.

[highlights_on] => 1 [highlights] => Array ( [0] => Array ( [highlight] => Multi-purpose. ) [1] => Array ( [highlight] => Best performance price ratio in its class. ) [2] => Array ( [highlight] => Compact foot print. ) [3] => Array ( [highlight] => Feeding systems for a wide range of solutions. ) [4] => Array ( [highlight] => IMA Safe Roll-One, leaflet folding unit. ) [5] => Array ( [highlight] => Easy to handle. ) [6] => Array ( [highlight] => Low maintenance costs. ) ) [focus_on] => 1 [focus] => Array ( [image] => 1101 [content] => Cost effective and flexible feeding systems are available at IMA Safe, which offer a wide range of solutions for both pharma and extra pharma fields. [buttons] => Array ( [buttons_on] => 1 [view_default] => [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => file [button_id] => [button_class] => [text] => DOWNLOAD BROCHURE [icon] => description [link] => 21537 [tab] => ) [1] => Array ( [acf_fc_layout] => video [button_id] => [button_class] => [text] => Watch and Discover our feeding systems [icon] => play_circle_outline [link] => zWyrR5uTcDg [autoplay] => 1 ) ) ) ) [technical_data] =>| X SERIES – TECHNICAL DATA | ||

| MODEL | X1 – X2* | XL1 – XL2* |

| Production output | Up to 90 cartons/min. | Up to 60 cartons/min. |

| Carton dimensions | ||

| Width (A) | min. 15-105 max. | min. 15-165 max. |

| Height (B) | min. 12-90 max. | min. 12-100 max. |

| Length (H) | min. 65-220 max. | min. 65-220 max. |

| A+B | 195 max. | 240 max. |

*Servo-driven version

[layouts] => Array ( [0] => Array ( [image] => 17856 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 28483 [id] => 28483 [title] => X SERIES_EN [filename] => X-SERIES_EN-1.pdf [filesize] => 2433291 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2016/12/X-SERIES_EN-1.pdf [link] => https://ima.it/pharma/machine/x1/x-series_en-2/ [alt] => [author] => 19 [description] => [caption] => [name] => x-series_en-2 [status] => inherit [uploaded_to] => 371 [date] => 2024-02-28 09:29:29 [modified] => 2024-02-28 09:29:36 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => 1lb-F4VXEDU [gallery] => Array ( [0] => Array ( [image] => 1105 [description] => Carton magazine ) [1] => Array ( [image] => 1106 [description] => Carton pick-up and opening ) [2] => Array ( [image] => 1110 [description] => Product insertion into the carton ) [3] => Array ( [image] => 1107 [description] => Coding unit ) [4] => Array ( [image] => 1103 [description] => Carton closing ) [5] => Array ( [image] => 1104 [description] => Carton outfeed and rejection ) ) [related] => no [versions_on] => [addon_on] => 1 [technologies] => Array ( [0] => 96 [1] => 104 [2] => 87 [3] => 88 [4] => 120 [5] => 121 ) [rel_market] => Array ( ) [clone_list] => Array ( [0] => 4 ) [contact] => [no_index] => [tile_description] => Intermittent motion cartoner. X Series multipurpose intermittent motion cartoner, is the best price/performance ratio solution in its product range. Thanks to the use of both mechanical and robotized feeding systems, it can handle the widest product variants range in the market. [tile_speed] => Up to 90 cartons/min [line_step] => Array ( [0] => 11 ) [aseptic] => both [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2176 [1] => 2177 ) [market_brands] => Array ( [0] => 3861 ) [market_plants] => Array ( [0] => 3861 ) [thread_tag] => [market_packs_specs] => Array ( ) [addon_items] => Array ( [0] => Array ( [image] => 2478 [description] => Roll-One - The IMA patented leaflet folding unit is designed to fold flat sheets using a simple but innovative technology indipendent from the leaflet thickness. To change the leaflet size is just a matter of one simple and fast part replacement. ) [1] => Array ( [image] => 3806 [description] => Track & Trace - X Series allows a perfect integration inside the frame of the machine, without any extension, with: printing system, camera and gluing system (tamper evident closure) ) ) [output_on] => [addon_title] => Good To Know [embed_iframe] => [seo_title] => X1: Intermittent motion cartoner [seo_description] => X1 Series multipurpose intermittent motion cartoner, is the best price/performance ratio solution in its product range. [no_follow] => [seo_image] => 11893 [form_price] => [body_class] => )

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

[0] => 3

[1] => 4

)

[contact] => mktg.packaging@ima.it

[no_index] =>

[cover_macro] => 2721

[cover_name_type] => txt

[cover_name] => FLEXA

[cover_descriptor] => Intermittent or continuous motion cartoner

[cover_focus_on] => 1

[cover_focus_content] => FLEXA Series includes intermittent and continuous motion versions to better satisfy your demands according to the product to be packed. With FLEXA you choose the maximum flexibility and ergonomics in the most compact machine.

[buttons_on] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 2186

[tab] =>

)

)

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 2186

[tab] =>

)

)

)

[news] =>

[thumbnail] => 17840

[tag_line] => Space-saving design for whatever product to be packed

[overview] => FLEXA, besides being very flexible in terms of carton configurations and dimensions is also extremely versatile in packing the widest range of products thanks to the intermittent motion (single pusher) or the continuous motion (double pusher).

Moreover, FLEXA is one of the most compact machine in its range with a ergonomic design that assures a facility of packaging materials loading.

The changeover is very simple, fast and toolless thanks to the servomotor technology applied.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

This system allows the use of recycled cardboards.

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Feeding systems for a wide range of solutions.

)

[1] => Array

(

[highlight] => Wide range of carton dimensions.

)

[2] => Array

(

[highlight] => Very compact cartoning machine available in either intermittent or continuous motion.

)

[3] => Array

(

[highlight] => Operator friendly.

)

[4] => Array

(

[highlight] => Very easy to clean.

)

)

[focus_on] => 1

[focus] => Array

(

[image] => 2723

[content] => Cost effective and flexible feeding systems are available at IMA Safe, which offer a wide range of solutions for both pharma and extra pharma fields.

[buttons] => Array

(

[buttons_on] => 1

[view_default] =>

[buttons_items] => Array

(

[0] => Array

(

[acf_fc_layout] => file

[button_id] =>

[button_class] =>

[text] => DOWNLOAD BROCHURE

[icon] => description

[link] => 2186

[tab] =>

)

[1] => Array

(

[acf_fc_layout] => video

[button_id] =>

[button_class] =>

[text] => WATCH AND DISCOVER OUR FEEDING SYSTEMS

[icon] => play_circle_outline

[link] => zWyrR5uTcDg

[autoplay] => 1

)

)

)

)

[versions_on] =>

[addon_on] => 1

[technical_data] => | TECHNICAL DATA FLEXA | ||||

| CONTINUOUS MOTION | INTERMITTENT MOTION | |||

| MODEL | FLEXA CLD | FLEXA CLDB | FLEXA ASB | FLEXA ALB |

| Max Speed | 180 cycles/min. | 160 cycles/min. | 120 cycles/min. | 120 cycles/min. |

| Carton dimensions |

||||

| Width (A) | min 15-90 max | min 15-140 max | min 15-140 max | min 15-140 max |

| Height (B) | min 12-90 max | min 12-90 max | min 12-65 max | min 12-90 max |

| Length (C/H) | min 55-220 max | min 55-220 max | min 55-190 max | min 55-220 max |

Array

(

[rel_market] => Array

(

)

[clone_list] => Array

(

)

[embed_iframe] =>

[form_price] =>

[contact] =>

[no_index] =>

[thread_tag] =>

[tile_description] => HIGH SPEED OVERWRAPPING. The HYWRAP20 has been designed to maximize efficiency for high-speed productivity and excellent packaging.

Our challenge is to ensure ease of use and total access to all machine operations.

The machine has been conceived as a hybrid solution capable of switching from film to paper without size changeover.

[tile_speed] => Up to 130 cycles/min.

[cover_macro] => 19508

[cover_name_type] => txt

[cover_name] => HYWRAP20

[cover_descriptor] => High speed overwrapping machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 28613

[tag_line] => High performance overwrapping

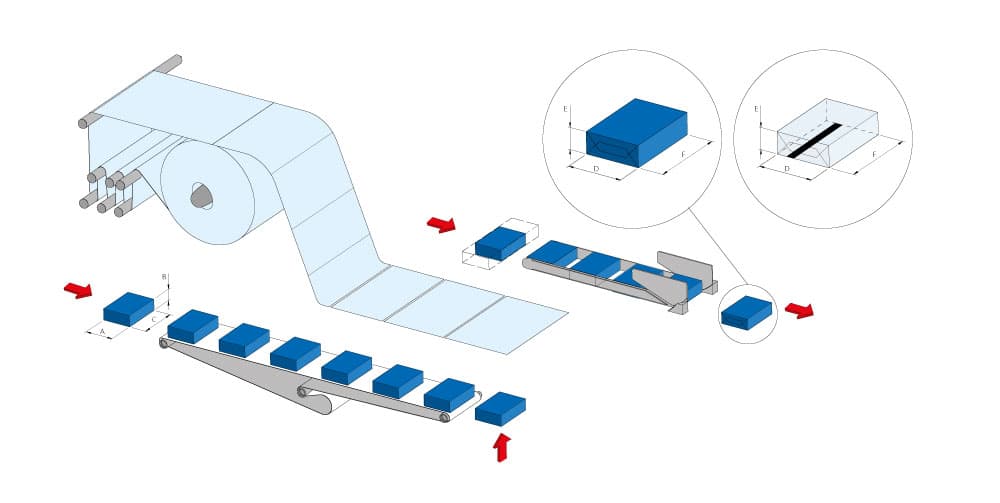

[overview] => High-speed complete wrapping machine for single or bundled products, the HYWRAP20 has been conceived as a hybrid solution capable of switching from film to paper without size changeover.

Its compact footprint and cantilever structure allow for accessibility and ease of maintenance. Servomotors are all placed on the back of the machine.

All movements are electronically driven by their own specific brushless motor for accurate performance at high speed.

The size changeover can be carried out in less than 10 minutes with few adjustments.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] => Impacting present affecting future…overwrapping speaks green.

The HYWRAP20 overwrapping machine can be run both with opp, recyclable and compostable films as well as with paper unrolled from reels where the glue is incorporated into the designated paper sealing areas rather than applied with guns or gluing units. This means that glue quantity and power consumption are reduced to the minimum and waste generation is limited. The goal is to mitigate environmental impacts and allow for a more efficient use of resources.

[highlights_on] => 1

[focus_on] => 1

[versions_on] =>

[addon_on] =>

[output_on] =>

[technical_data] =>

| TECHNICAL DATA | ||||||||

| A | B | C | D | E | F | H | L | |

| Product dimensions (MIN) | 30 | 25 | 60 | 30 | 25 | 60 | 100 | 120 |

| Product dimensions (MAX) | 240 | 120 | 280 | 240 | 120 | 280 | 420 | 700 |

|

Speed up to 130 cycles/min. |

||||||||

The HYWRAP20 overwrapping machine can be run both with opp, recyclable and compostable films as well as with paper unrolled from reels where the glue is incorporated into the designated paper sealing areas rather than applied with guns or gluing units. This means that glue quantity and power consumption are reduced to the minimum and waste generation is limited. The goal is to mitigate environmental impacts and allow for a more efficient use of resources.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [addon_title] => For the highest quality packaging, we have designed a specific outfeed to guarante total control of the position of each carton, as well as the perfect sealing spot of the lateral flaps. [addon_items] => Array ( [0] => Array ( [image] => 19523 [description] => ) ) [related] => no [technologies] => Array ( [0] => 109 [1] => 111 [2] => 110 ) [cover_focus_content] =>Designed to maximize efficiency for high-speed productivity and excellent packaging. The new high speed overwrapping machine ensures ease of use and total access to all machine operations running film and paper.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [body_class] => [no_follow] => [seo_image] => [seo_title] => [seo_description] => )

Array

(

[rel_market] => Array

(

[0] => 3

[1] => 4

[2] => 6

[3] => 7

[4] => 10

)

[clone_list] => Array

(

[0] => 3

[1] => 4

[2] => 6

[3] => 7

)

[contact] => imaeol@ima.it

[no_index] =>

[cover_macro] => 14485

[cover_name_type] => txt

[cover_name] => AF60

[cover_descriptor] => Over wrapping machine

[cover_focus_on] => 1

[cover_focus_content] => Latest-generation, servo driven, technological developments make the AF60 a high-efficiency overwrapper, easy-to-operate and able to process cartons at very high speeds despite its remarkably compact footprint.

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 14440

[tag_line] => High overwrapping speed and compact footprint

[overview] => Ideal for pharmaceutical products, equipped with a high-speed stacking unit capable of stacking up to 225 layers/min., the AF60 can also be set up with a carton tilting unit (AF60AM) capable of standing on edge as many as 400 cartons/min.

Production speeds reaching 60 cycles/min. make it an ideal partner for any high-speed packaging line for cartons. Maximum accessibility to all components is possible due to the balcony design, so that cleaning and maintenance are facilitated.

The machine’s main standard features include a scissor knife, film transport by pincers, transversal edge-sealing, driven movement of bottom and lateral film folders, and reciprocating lateral sealing plates.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Tool-free size changeover in just 5 minutes with digital indicators to assist with adjustments.

)

[1] => Array

(

[highlight] => Suitable for Track and Trace purpose.

)

[2] => Array

(

[highlight] => Ergonomic design with shaft featuring quick expansion lock device for rapid film reel change.

)

[3] => Array

(

[highlight] => Optional bypass mode improves Balcony style concept, ideal for easy line clearance.

)

[4] => Array

(

[highlight] => Product flow through the machine.

)

[5] => Array

(

[highlight] => Further optional groups include automatic bundle discharge, servo-driven step-by-step exit system and lateral sealing belts on exit.

)

)

[focus_on] =>

[versions_on] =>

[addon_on] =>

[technical_data] => | TECHNICAL DATA AF60 | |||||||

| Wrapping film | CELLOPH.PVC.PE.PP | ||||||

| Product dimensions | A | B | C | D | E | F | H |

| Min. | 20 | 12 | 60 | 60 | 25 | 60 | 100 |

| Max. | 360 | 120 | 230 | 360 | 170 | 260 | 450 |

Array

(

[embed_iframe] =>

[form_price] =>

[contact] => imaeol@ima.it

[no_index] =>

[thread_tag] =>

[tile_description] => SIDE LOADING CASE PACKING MACHINE. Medium speed case packer designed to handle the widest range of products and materials used in the pharmaceutical industry.

[tile_speed] => 10 cycles/min.

[cover_macro] => 14803

[cover_name_type] => txt

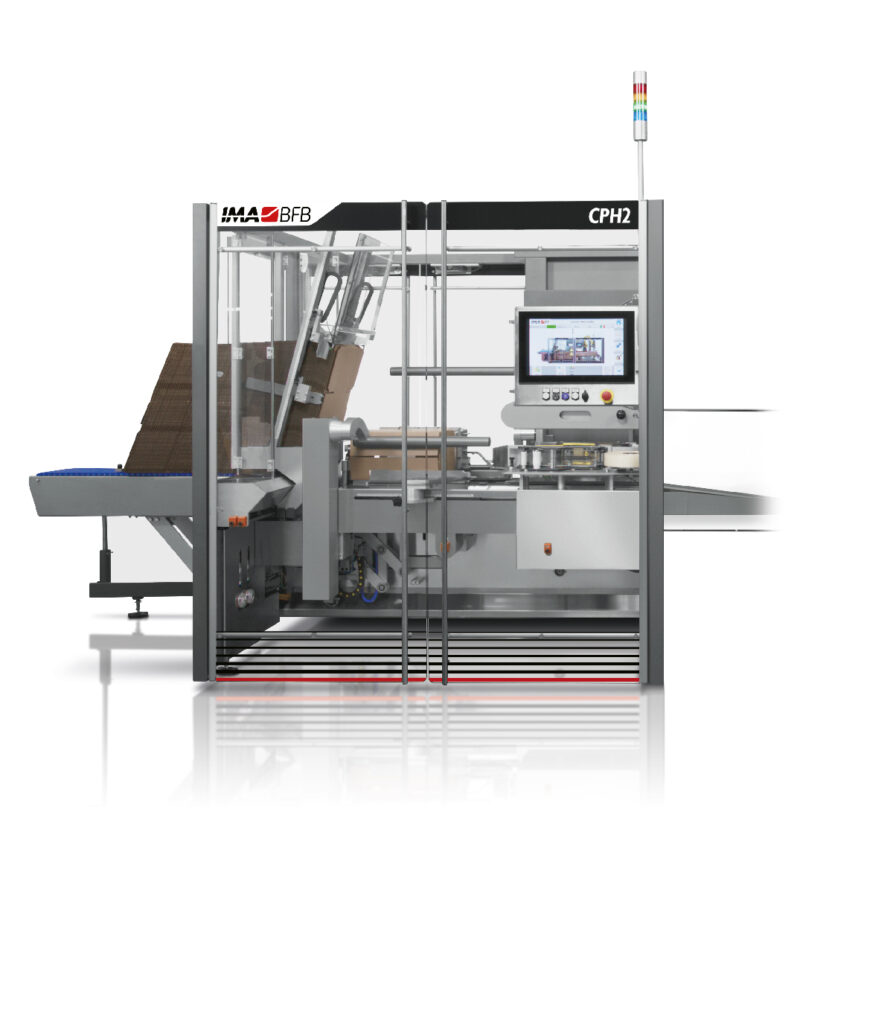

[cover_name] => CPH2

[cover_descriptor] => Side loading case packing machine

[cover_focus_on] => 1

[cover_focus_content] => Medium speed case packer designed to handle the widest range of products and materials used in pharmaceutical, with maximum ease of use and total control of the packaging process

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 27927

[tag_line] => Fit for the future

[overview] => Fully automatic side loading case packer designed to satisfy all of your current and future case packing requirements.

The machine has been built to maximize efficiency and ease of use in an ever increasingly demanding work place, to guarantee complete line clearance and to ensure total access to all modules.

The CPH2 is designed to ensure total control throughout all stages of the serialization process.

Flexibility, maximum efficiency, total access and total control make the CPH2 a casepacker of new generation.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => The new 830 mm high case magazine ensures easy loading of cases. Correct case feeding to the

picking area is guaranteed by a bottom driven belt.

)

[1] => Array

(

[highlight] => Designed to ensure total access to all machine modules: all parts of the machines can be reached from the operator’s side.

)

[2] => Array

(

[highlight] => Forced opening of the case through two arms allows reliable operations even in case of square shippers or low quality material.

)

[3] => Array

(

[highlight] => Simple design servo driven stacking unit with easy access to cartons collating area. Stacking operation is carried out right in front of the erected case.

)

[4] => Array

(

[highlight] => A servo driven movable hopper follows the cartons collation up into the case and guarantees security of case content.

)

[5] => Array

(

[highlight] => Quick tool-free size changeover with limited amount of adjustments. Fast release system by means of clip switches (on/off): no parts need to be unscrewed with keys.

)

)

[focus_on] => 1

[versions_on] => 1

[addon_on] =>

[output_on] => 1

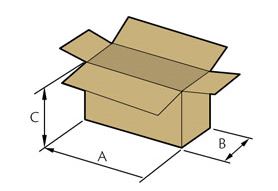

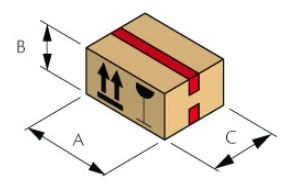

[technical_data] => | CPH2 TECHNICAL DATA | |||

| Case dimensions | A | B | C |

| Min. | 220 | 100 | 90 |

| Max. | 600 | 400 | 400 |

| Product dimensions | a | b | c |

| Min. | 25 | 22 | 60 |

| Max. | 590 | 70/150 | 220 |

| Speed | 10 cases/min. | ||

[layouts] => Array ( [0] => Array ( [image] => 28738 ) ) [technical_video] => [technical_video_image] => [brochure] => Array ( [ID] => 28561 [id] => 28561 [title] => CPH2_EN [filename] => CPH2_EN-1.pdf [filesize] => 1854235 [url] => https://ima.it/pharma/wp-content/uploads/sites/2/2019/03/CPH2_EN-1.pdf [link] => https://ima.it/pharma/machine/cph2/cph2_en-2/ [alt] => [author] => 29 [description] => [caption] => [name] => cph2_en-2 [status] => inherit [uploaded_to] => 14719 [date] => 2024-03-05 21:56:21 [modified] => 2024-03-05 21:56:38 [menu_order] => 0 [mime_type] => application/pdf [type] => application [subtype] => pdf [icon] => https://ima.it/pharma/wp-includes/images/media/document.png ) [main_video] => [gallery] => Array ( [0] => Array ( [image] => 14732 [description] => Case magazine ) [1] => Array ( [image] => 28562 [description] => Case opening and folding ) [2] => Array ( [image] => 28563 [description] => Carton stacking ) [3] => Array ( [image] => 14730 [description] => Main pusher ) [4] => Array ( [image] => 28564 [description] => Case closing ) [5] => Array ( [image] => 28565 [description] => Camera read with liftable pusher ) ) [line_step] => Array ( [0] => 7 ) [aseptic] => non_aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2180 ) [market_packs_specs] => Array ( ) [market_brands] => Array ( [0] => 3869 ) [market_plants] => Array ( [0] => 3869 ) [rel_market] => Array ( [0] => 3 [1] => 4 [2] => 6 [3] => 7 ) [clone_list] => Array ( ) [no_follow] => [seo_image] => [seo_title] => [seo_description] => [output_items] => [related] => no [technologies] => Array ( [0] => 105 [1] => 106 [2] => 120 [3] => 122 ) [versions_thumbnail] => 28741 [versions_tag_line] => Case Packer - Palletizer integrated versions [versions_overview] =>

CPH2 is available in different palletizer-integrated versions, according to the output required:

CPH2-RP2

With automatic replacement of the full pallet and case buffering during pallet replacement or with two pallet stations; once one pallet is complete, the robot starts loading the second pallet

CPH2-RP4

With 4 pallet stations for greater autonomy. When the pallet is complete, the automatic transport moves the pallet to the exit area and replaces it with an empty one.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [focus] => Array ( [image] => 14735 [content] => AGGREGATION MODULE. The overall minimal footprint and the cantilever design for improved accessibility ensure total control throughout all stages of the serialization process. The machine can be equipped with a compact module housing labelling units and cameras for aggregation purposes. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [versions_title] => [versions] => [body_class] => [output_items_stripes] => )

Array

(

[cover_macro] => 15077

[cover_name_type] => txt

[cover_name] => CP38

[cover_descriptor] => Side loading case packing machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 15088

[tag_line] => High-speed case packing with unrivalled operator ergonomics.

[overview] => The only case packer on the market where all the parts of the machine can be reached from the operator’s side without having to walk to the opposite side to reach the carton stacking unit, the CP38 is ideal for handling a wide range of products.

Using servo technology for extremely smooth product handling, the CP38 packs up to 30 cases/min and has a compact footprint. During loading, the case is positively erected and held in position on 2 sides enabling effective use of lower-quality corrugated cardboard.

The case erecting mechanism now ensures extremely low positioning of the horizontal case magazine, thus increasing machine autonomy.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] => The IMA machines are designed so that the production process involves minimal environmental impact:

- energy consumption is reduced to a minimum,

- the waste materials are minimized,

- compatibility with the use of recycled materials.

| TECHNICAL DATA CP38 | |||

| Product dimensions | A | B | C |

| Min. | 200 | 110 | 90 |

| Max. | 500 | 350 | 350 |

| Max. speed | Up to 30 Cases/min. | ||

Specifically designed to handle loose or bundled cartons, the CP38 is a high-speed, side-loading case packer benefiting from operator-friendly cantilever design ensuring complete accessibility and easy cleaning.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [highlights] => Array ( [0] => Array ( [highlight] => Tool-free size changeover assisted by large, easy-to-use HMI, for increased speed and simplicity. ) [1] => Array ( [highlight] => Cases can be closed with adhesive tape or hot-melt glue. ) [2] => Array ( [highlight] => Full-size transparent panels interlocked with safety switches in order to ensure operator safety, compliant with European Standards. ) [3] => Array ( [highlight] => Options include case labelling and checking, case rejection at discharge and case overturning at discharge. ) ) [thread_tag] => [tile_description] => SIDE LOADING CASE PACKING MACHINE. Specifically designed to handle loose or bundled cartons, the CP38 is a high-speed, side-loading case packer benefiting from operator-friendly cantilever design ensuring complete accessibility and easy cleaning. [tile_speed] => 30 cycles/min. [output_on] => [line_step] => Array ( [0] => 7 ) [aseptic] => non_aseptic [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2180 ) [market_packs_specs] => Array ( ) [market_brands] => Array ( [0] => 3869 ) [market_plants] => Array ( [0] => 3869 ) [no_follow] => [seo_image] => [seo_title] => CP38 • Case packing [seo_description] => [embed_iframe] => [form_price] => [focus] => Array ( [image] => 14443 [content] => The CP38 side loading case packer is able to achieve high speed running in full aggregation mode. Production speed is one of the key factors impacting on the functionality and successful. Thanks to the case pre-opening station CP38 is able to reach the highest production speed. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [related] => no [technologies] => Array ( [0] => 106 [1] => 120 [2] => 122 ) [versions_thumbnail] => 15092 [versions_tag_line] => Case Packer - Palletizer integrated versions [versions_overview] =>CP38 is available in different palletizer-integrated versions, according to the output speed required.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [body_class] => [versions_title] => [versions] => )

Array

(

[cover_macro] => 5238

[cover_name_type] => txt

[cover_name] => CPV15

[cover_descriptor] => Top loading case packing machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 27925

[tag_line] => Products case packed to perfection.

[overview] => Maximum attention to ergonomics is a hallmark of this case packer.

In order to be as operator-friendly as possible, the case erecting mechanism is designed to ensure low positioning of the horizontal case magazine, which also ensures increased autonomy. Machine parts can be reached without operators needing to move from one side of the machine to the other.

The infeed system is equipped with worm screws (for loose products) for the correct orientation of the containers and a comb which moves sideways to collate the products.

Equipped as standard, the CPV15 features a 2-axis robot to insert the collation into the case.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] =>

[versions_on] => 1

[addon_on] =>

[technical_data] => | TECHNICAL DATA CPV15 | ||||||||

| Product dimensions | A | B | C | |||||

| CPV15 | Min. | 190 | 80 | 100 | ||||

| Max | 600 | 400 | 350 | |||||

| Max. speed | 15 | |||||||

A medium-output, top loading case packer for loose or bundled products, the CPV15 has been conceived to assure maximum ergonomics for operating staff and guarantee smooth handling even for unusually shaped products thanks to servo technology.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [highlights] => Array ( [0] => Array ( [highlight] => Cantilever design, compact footprint. Great emphasis has been given to machine accessibility, easy cleaning and ergonomic position of all components. ) [1] => Array ( [highlight] => Servo technology and innovative solutions allow the smooth handling cartons or difficult and unusually shaped products: bottles, bags, tubes. ) [2] => Array ( [highlight] => Entirely driven by servo-motors which means dedicated strokes and motions for each specific application. ) [3] => Array ( [highlight] => The horizontal magazine allows good accessibility for easy loading. Cases feeding to the picking area is ensured by bottom driven toothed belts. ) [4] => Array ( [highlight] => Forced opening of the case carried out by means of two arms equipped with suction cups keeping the case erect during product insertion for reliable operations. ) [5] => Array ( [highlight] => Different servo driven collation methods are available according to the kind of product to be handled even at high infeed speed. ) [6] => Array ( [highlight] => A driven movable hopper follows the products collation up into the case and ensures the correct layer introduction inside the case. ) [7] => Array ( [highlight] => It can be integrated with the new Palletizers: RP2, with two pallet stations or RP4, with four pallet stations within a compact frame. ) ) [thread_tag] => [tile_description] => A medium-output, top loading case packer for loose or bundled products, the CPV15 has been conceived to assure maximum ergonomics for operating staff and guarantee smooth handling even for unusually shaped products thanks to servo technology. [tile_speed] => 15 cycles/min. [output_on] => [line_step] => Array ( [0] => 7 ) [aseptic] => both [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2180 ) [market_packs_specs] => Array ( ) [market_brands] => Array ( [0] => 3869 ) [market_plants] => Array ( [0] => 3869 ) [related] => no [technologies] => Array ( [0] => 105 [1] => 107 [2] => 120 [3] => 122 [4] => 121 ) [body_class] => [no_follow] => [seo_image] => [seo_title] => CPV15: Case packing [seo_description] => Top-loading case packer for loose or bundled bottles, it guarantee smooth handling even for unusually shaped bottles thanks to servo technology. [embed_iframe] => [form_price] => [versions_thumbnail] => 21210 [versions_tag_line] => Case Packer - Palletizer integrated versions [versions_overview] =>The CPV15 is available as a stand alone machine or in different palletizer-integrated versions, according to the output required:

CPV15-RP2

With automatic replacement of the full pallet and case buffering during pallet replacement or with two pallet stations; once one pallet is complete, the robot starts loading the second pallet

CPV15-RP4

With 4 pallet stations for greater autonomy. When the pallet is complete, the automatic transport moves the pallet to the exit area and replaces it with an empty one.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [versions_title] => [versions] => )

Array

(

[rel_market] => Array

(

[0] => 3

[1] => 4

[2] => 6

[3] => 7

[4] => 10

)

[clone_list] => Array

(

)

[contact] => imaeol@ima.it

[no_index] =>

[cover_macro] => 28747

[cover_name_type] => txt

[cover_name] => RP2/RP4

[cover_descriptor] => Stand alone or integrated palletizing

[cover_focus_on] => 1

[cover_focus_content] => Reduced dimensions of the palletizing section and flexible palletizing options, in line with real market needs; these aspects characterize the RP2/RP4 palletizers, equipped with a 6-axis robot capable of absorbing and working at high speed.

[buttons_on] =>

[cover_focus_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[news] =>

[thumbnail] => 27926

[tag_line] => Smart technology for different products and tasks.

[overview] => Built to deliver maximum productivity and efficiency, these latest-generation palletizing solutions offer exceptional flexibility. Based around a 6-axis robot which picks up incoming cases, ink-jet printing and labelling or weighing them, everything is carried out efficiently.

Cases are then placed on the pallet according to pre-set patterns memorised by the operator. Modular design allows for customization of the palletizing section, whose dimensions are kept to a minimum.

RP2/RP4 palletizers are conceived to be stand alone or easily integrated with case packers thanks to their quick plug-in connection.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[highlights] => Array

(

[0] => Array

(

[highlight] => Modular design for efficient use of available space. The modules can be installed in a way that overcomes restrictions presented by existing facility layout. and design.

)

[1] => Array

(

[highlight] => Equipped with their own electrical cabinet they can be easily integrated with any case packing solution.

)

[2] => Array

(

[highlight] => Flexibility in terms of handling various sizes, shapes and weights: these systems can treat single or multiple cases, trays, bags and groups of bottles even at high speed.

)

[3] => Array

(

[highlight] => Enhanced performance thank to fast and simple format changeovers and reduced maintenance operations.

)

[4] => Array

(

[highlight] => Flexible palletizing options: from 1 to 4 stations for pallet transport and palletization.

)

[5] => Array

(

[highlight] => Many options available: slip-sheet magazine, labelling module, rejection station, T&T groups, pre-arrangement for AGV.

)

)

[focus_on] =>

[versions_on] => 1

[addon_on] =>

[technical_data] => | TECHNICAL DATA | |||

| Product dimensions | A | B | C |

| Min. | 800 | 1200 | 1400 |

| Max. | 1000 | 1200 | 1400 |

| Max. speed | up to 10 cycles/min. | ||

RP2

Automatic palletizer with single palletization station suitable for handling RSC cases or naked bundles, picked up by means of a six axes manipulator. When pallet is complete, the robot places the cases on the buffer area, giving the operator time to unload the full pallet while the machine is working.

RP7

Automatic and extremely flexible palletizer with double palletization stations suitable for handling RSC cases or naked bundles, loaded by means of a six axes manipulator. When the pallet is complete, the automatic pallet transport moves the complete pallet to the waiting area on exit and replaces it with a new one, ready to be loaded. Operator removes the full pallet and the machine keeps on working at the same time.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [market_products] => Array ( [0] => 15 [1] => 602 [2] => 613 [3] => 622 [4] => 603 [5] => 618 [6] => 615 [7] => 616 [8] => 627 [9] => 625 [10] => 617 [11] => 621 [12] => 624 [13] => 620 [14] => 626 [15] => 628 [16] => 619 [17] => 2624 [18] => 623 ) [market_packs] => Array ( [0] => 2212 ) [market_brands] => Array ( [0] => 3869 ) [market_plants] => Array ( [0] => 3869 ) [line_step] => Array ( [0] => 7 ) [tile_description] => PALLETIZER. Speed, reduced dimensions of the palletizing area and flexible palletizing options, in line with real market needs: these aspects characterize the RP2/RP4 palletizers, equipped with a 6-axis robot capable of absorbing and working at high speeds. [tile_speed] => 10 cycles/min. [aseptic] => non_aseptic [thread_tag] => [output_on] => [market_packs_specs] => Array ( ) [related] => no [technologies] => Array ( [0] => 112 [1] => 120 [2] => 122 ) [body_class] => [no_follow] => [seo_image] => [seo_title] => RP2/RP4 [seo_description] => Reduced dimensions of the palletizing section and flexible palletizing options, in line with real market needs [embed_iframe] => [form_price] => [versions_title] => [versions] => Array ( [0] => Array ( [version_label] => [version_title] => Case Packer - Palletizer integrated versions [version_thumbnail] => 28404 [version_overview] =>RP2/RP4 palletizers are available in different case packer-palletizer integrated versions, tailored to fit any space constraints and autonomy needs seamlessly.

[version_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [1] => Array ( [version_label] => [version_title] => Different palletizing solutions according to the layout space requests [version_thumbnail] => 28740 [version_overview] =>RP2

Automatic palletizer with single palletization station suitable for handling RSC cases or naked bundles, picked up by means of a six axes manipulator. When pallet is complete, the robot places the cases on the buffer area, giving the operator time to unload the full pallet while the machine is working.

RP4

Automatic and extremely flexible palletizer with double palletization stations suitable for handling RSC cases or naked bundles, loaded by means of a six axes manipulator. When the pallet is complete, the automatic pallet transport moves the complete pallet to the waiting area on exit and replaces it with a new one, ready to be loaded. Operator removes the full pallet and the machine keeps on working at the same time.

[version_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) ) )