Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |Perfume Packaging

In the world of Personal Care, the Perfume Industry plays a significant role. It requires special production conditions due to the high value and precious nature of the products.

Following market trends, perfume bottles often have very unique and irregular shapes and can be delicate, requiring active, controlled, and precise handling for safe movement.

Additionally, the packaging itself can represent a part of the proposal, so it’s important that the pack remains perfectly intact, without any defect or damage.

It requires extreme modularity, flexibility, and expertise.

- Processing

- Filling and closing

- Cartoning

- Over Wrapping

- End of Line Solutions

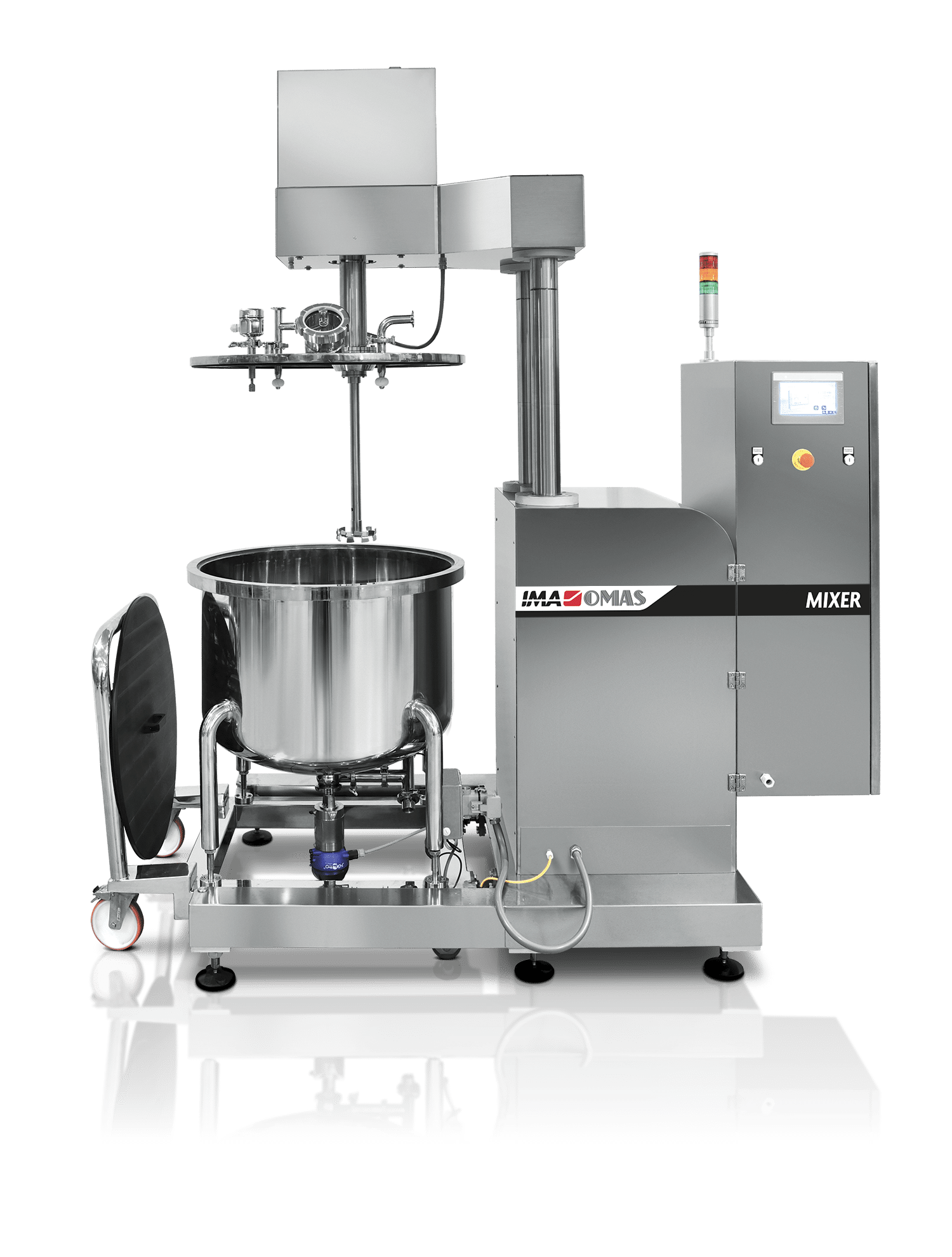

IMA Omas perfume, fragrance and lotion mixing machines are designed to reduce mixing time and to offer high product quality.

The different types of blades are designed to keep the product moving and avoid settling.

IMA Omas technologies ensure that the equipment exceeds the most stringent requirements, providing the tools to produce superior quality products.

Mixer

Mixer for liquid products

Mixer Series equipped with different types of blades are designed to keep the product in motion for perfect mixing. Suitable for shampoo and liquids, witch do not need to be homogenized, our mixers are studied to guarantee high qualitative standard of mixing.

Omas filling and capping machines for lotions, fragrances and perfumes are specifically designed to guarantee maximum reliability and repeatability in production.

Omas offers a wide range of filling solutions for ampoules, samples, even unstable bottles and closures for different types of caps, often very precious and complex to handle, enriched with details or collars and bows to accompany them.

Starting from semi-automatic machines to automatic machines, such as alternating or continuous motion rotary monoblocks, complete filling and closing lines, capable of satisfying every need of both small and medium-sized and large manufacturers.

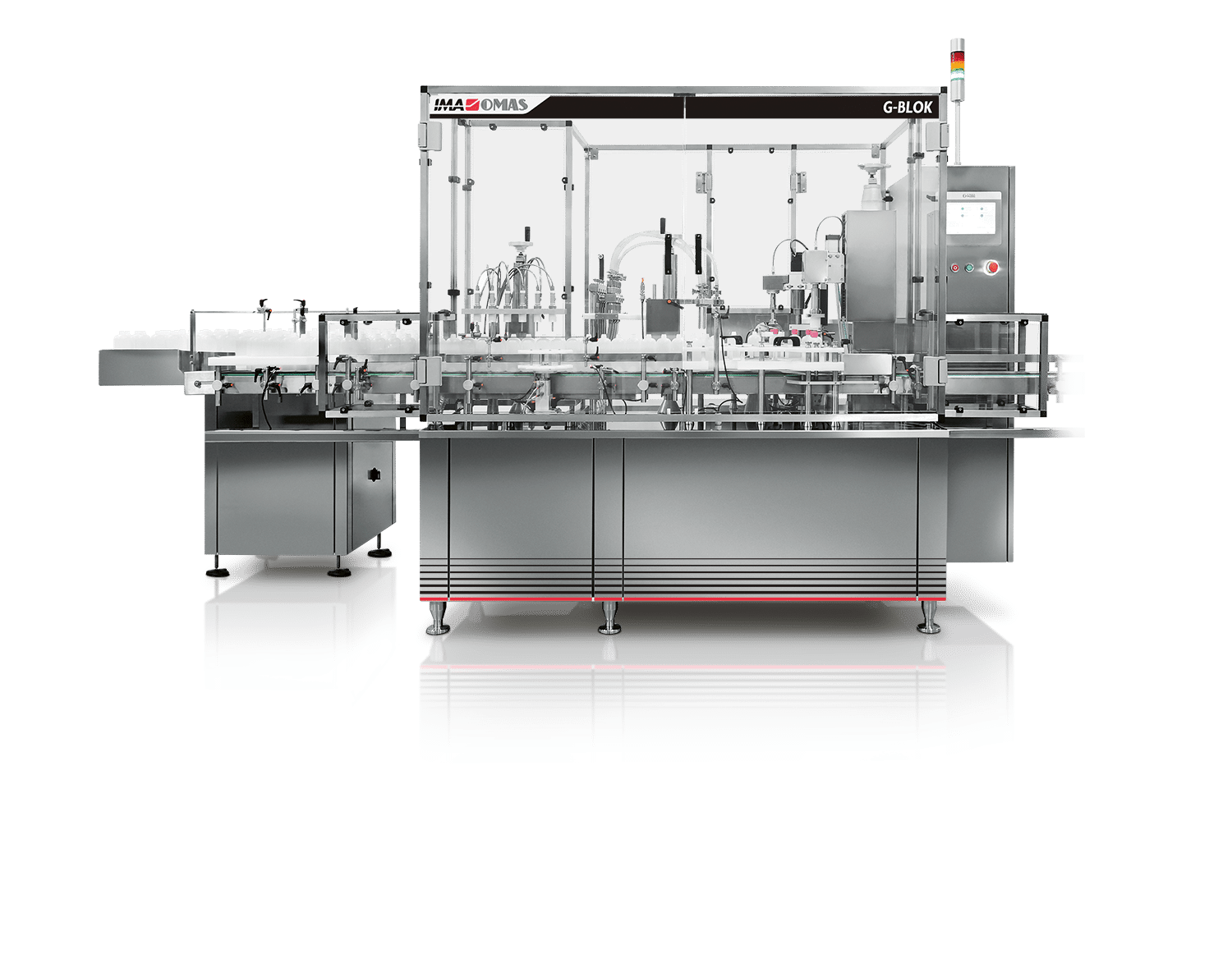

G-BLOCK

Filling and capping with intermittent motion

A family of monoblock machines for intermittent filling and capping of liquid, creamy, or powder products.

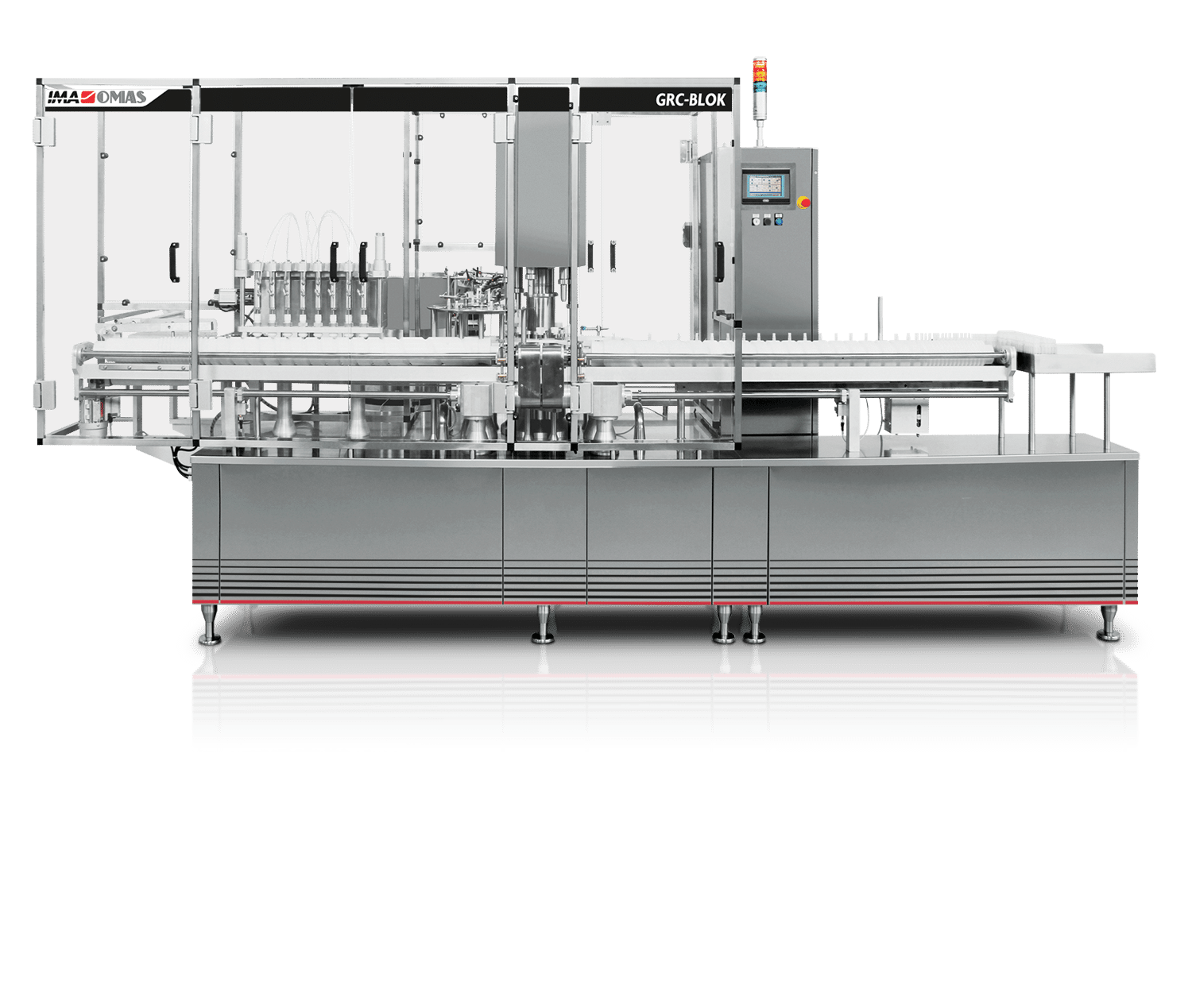

GRC-BLOK

Filling and capping machines in continuous motion

The GRC-BLOK series integrates filling and capping continuous machine. This monoblock solution is designed to optimize production processes, offering precise control and flexibility for different container formats.

The automatic cartoners designed by IMA offer different approaches to meet every need, depending on the specific bottle type and packaging requirements.

Thanks to robotic feeders, any bottle type can be handled with precision. The carton transports are designed to be compatible with the demanding Personal Care sector. Depending on the required final configuration, the cartoners offer the possibility to handle various formats and configurations.

Considerable flexibility in formats, the ability to handle various product sizes and, at the same time, different configurations within the packaging: standing or flat perfume positioning, presence of accessories or booklets inside the carton, application of liner to provide stability to the bottle or simply for aesthetic purpose.

Vertical cartoning

VERTICARE

|

FTC578-C

|

|

Ideal for handling high-value perfumes, VERTICARE is designed to delicately package precious bottle and carton materials. Its modular design allows for a wide range of optional features, enabling customization to accommodate various product configurations and accessories within the packaging. |

Capable of receiving products with or without pucks and handling up to 300 ppm, the FTC578-C is designed for modularity configuration as well as high-speed operation. FTC578-C is able to package products such as perfumes and lotion bottles, having regular and irregular shapes. This modular machine can integrate multiple feeders for liners, booklets, and any other accessory. |

|

|

Horizontal Cartoning

X

|

FLEXA

|

|

The renowned X Series cartoners stands out for its ability to handle an extensive range of formats. With a variety of feeding options, the X family ensures the ability of handling the unique features of different fragrances, making it the ideal choice for a wide array of packaging requirements. |

FLEXA is your go-to solution for efficiently and flawlessly packaging an array of perfume variations, including the delicate art of presenting fragrance samples in various pocket-sized folders. |

|

|

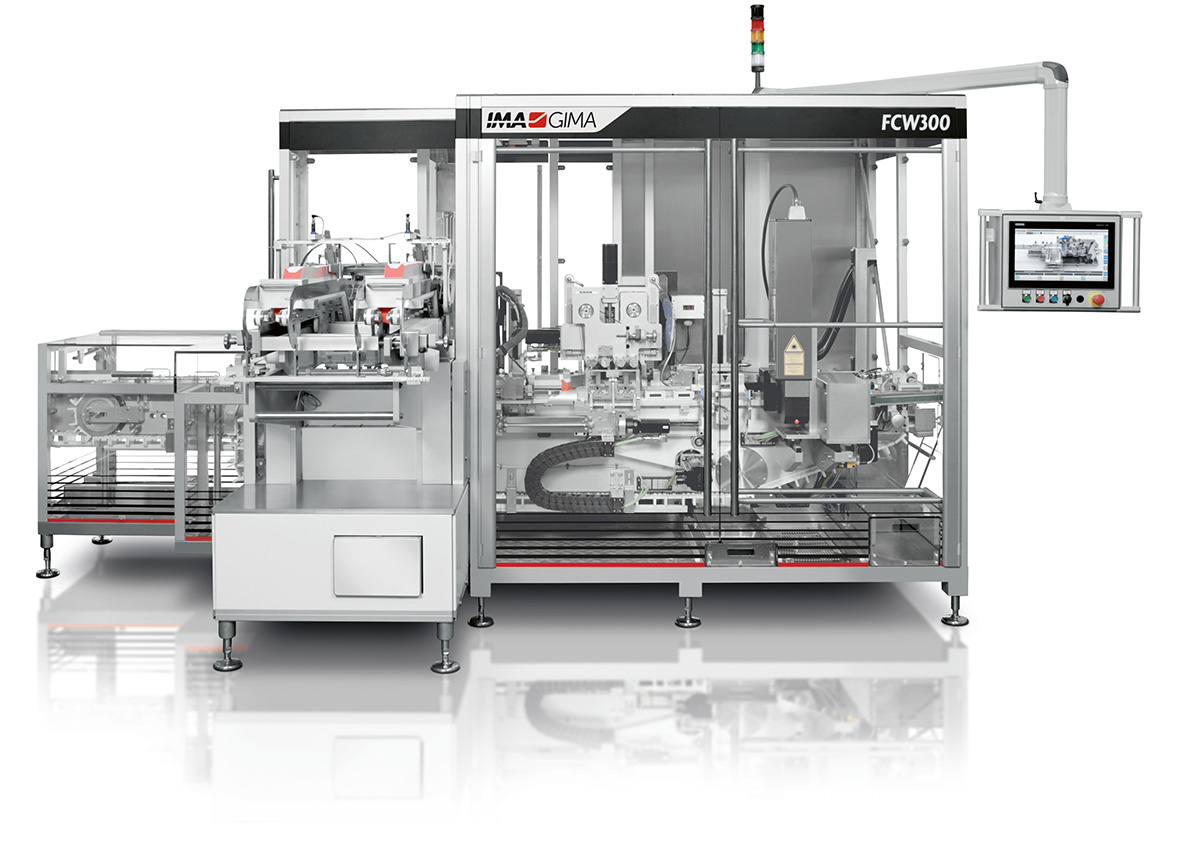

FCW 300

|

|

The FCW300 is a fully automatic cartoner for various packages such as cartons and wallets in different styles and shapes, especially suitable for perfume samples. The product infeed can be custom-designed to align with the release of the upstream machine, facilitating the seamless transfer of relevant products to the flat blank. |

|

IMA has always focused heavily on these processes and has created specific film winding, conveyor, cutting and sealing systems to ensure that the film is always cut with a geometrically precise fold and sealed without wrinkles, air bubbles or other blemishes. Overwrapping machine can run both with opp, recyclable and compostable films as well as with paper to mitigate environmental impacts and allow for a more efficient use of resources.

IMA has always focused heavily on these processes and has created specific film winding, conveyor, cutting and sealing systems to ensure that the film is always cut with a geometrically precise fold and sealed without wrinkles, air bubbles or other blemishes. Overwrapping machine can run both with opp, recyclable and compostable films as well as with paper to mitigate environmental impacts and allow for a more efficient use of resources.

PRIMEWRAP

PRIMEWRAP is the new IMA wrapping solution engineered for the cosmetics and perfumery sector. It ensures precise and secure overwrapping for both single products and bundled packages. The machine integrates transverse side sealing with welder movement, guaranteeing flawless finishes. Its design emphasizes efficiency, flexibility, and consistent quality across diverse formats. By delivering uniform wrapping, PRIMEWRAP enhances brand perception and product appeal. A robust automation system supports quick format changes and reliable production control.

HYWRAP 20

|

FTO513 Series

|

|

The HYWRAP20 has been conceived as a hybrid solution capable of switching from film to paper without size changeover. |

The FTO513 can handle up to 330 ppm and features several technically advanced solutions to ensure top quality appearance of the packages. It accommodates a variety of innovative and sustainable materials. |

|

|

From wrap-around to side or top loading, all our models are conceived with reduced footprints, however assuring ergonomicity and easy operator access for any type of cleaning or maintenance operations.

From wrap-around to side or top loading, all our models are conceived with reduced footprints, however assuring ergonomicity and easy operator access for any type of cleaning or maintenance operations.

Any of our solution is devised to ensure total control throughout all stages of the packaging process.

Our offer includes integrated case packing and palletizing solutions in a compact structure and with an extremely simple pallet management thanks to the latest improvements in robotic technology.

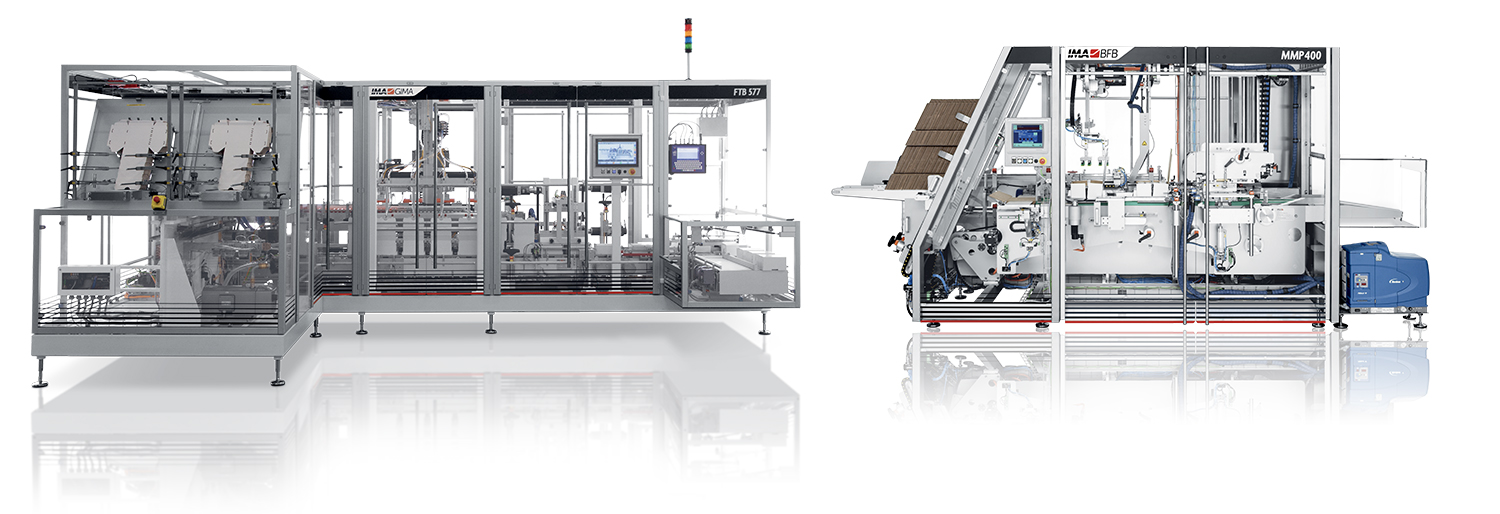

FTB TL Series

|

MMP400

|

|

|

|

CPH2

|

CPV15

|

|

|

|

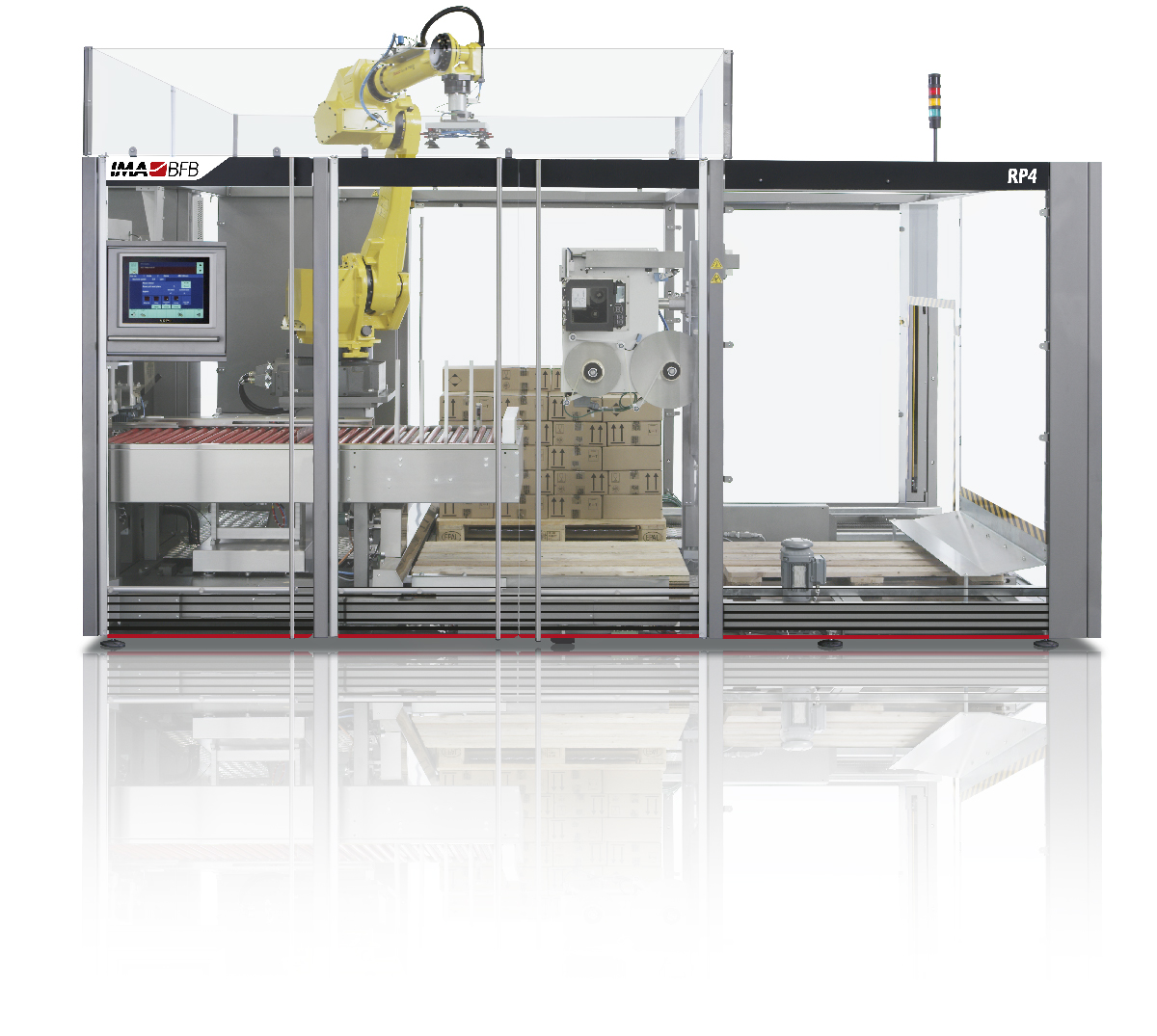

RP2/RP4

|

|

Built to deliver maximum productivity and efficiency, these latest-generation palletizing solutions offer exceptional flexibility. Based around a 6-axis robot which picks up incoming cases, ink-jet printing and labelling or weighing them, everything is carried out efficiently. |

|

|