Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |SENSITIVE ROTO

Where great performance and high-speed labelling of vials and bottles are required, Sensitive Roto comes into play. Versatile and reliable, it ensures an extremely precise application of labels providing information related to the content of the containers.

Where great performance and high-speed labelling of vials and bottles are required, Sensitive Roto comes into play. Versatile and reliable, it ensures an extremely precise application of labels providing information related to the content of the containers.

Perfection is all-around.

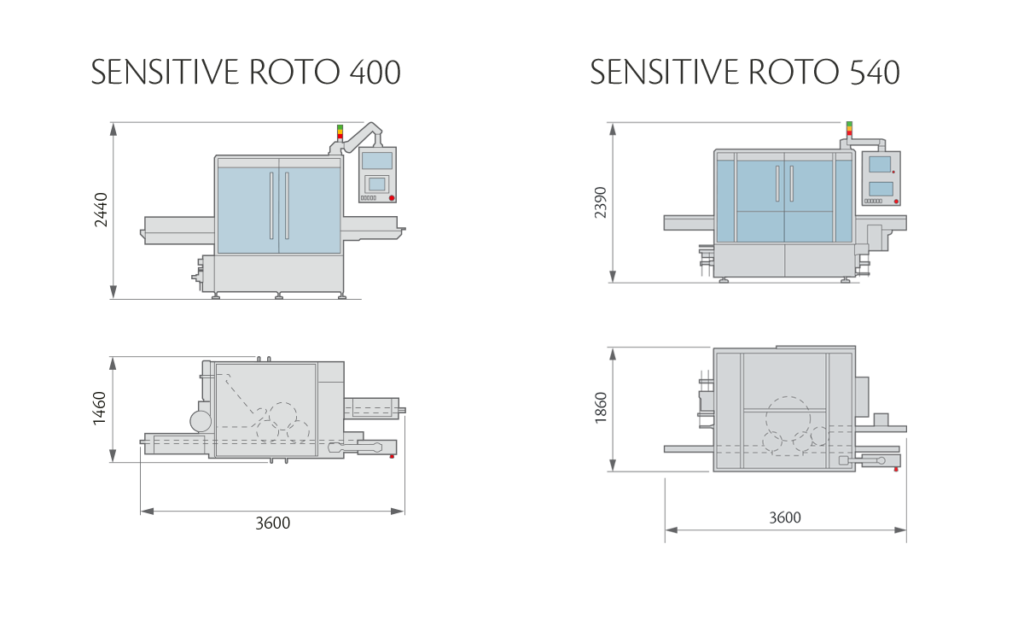

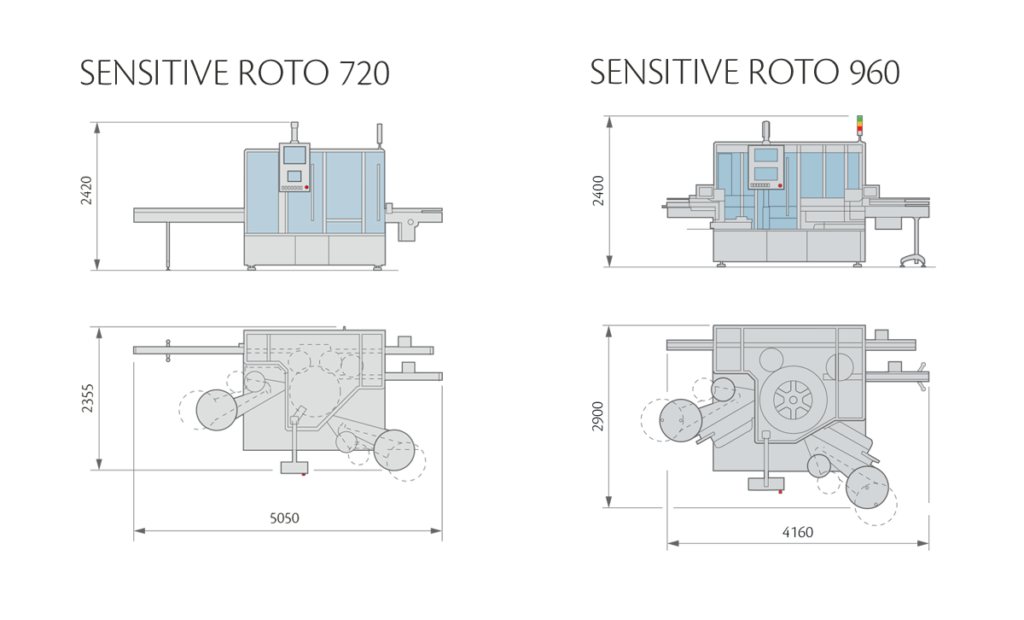

The Sensitive Roto includes four machine models suitable for applying self-adhesive labels to both sides of oval, square or rectangular bottles, vials and cylindrical containers with unusual shapes.

The modular design and range of groups that can be installed on these machines make them the most flexible solution for high-speed labelling.

The machine can be equipped with up to four labelling heads and can also apply outserts, booklets and hanging labels. Additionally it boasts brushless motors which move each holding platform to ensure precise container positioning during the labelling phase.

SENSITIVE ROTO Highlights

- Technical Data

- Machine Layout

| SENSITIVE ROTO Technical data | ||||

| Model | Sensitive Roto 400 | Sensitive Roto 540 | Sensitive Roto 720 | Sensitive Roto 960 |

| Maximum output (pieces/minute) | 400 | 600 | 600 | 600 |

| Installed power (kW) | 3 | |||

| Standard voltage | 400 V – 50 Hz | |||

| Bottle maximum height (mm) | 220 | |||

| Bottle diameter (mm) | 16-86 | |||

| Label height (mm) | 10-100 | |||

| Label length (mm) | 15-250 | |||

| Label reel diameter (mm) | 400 | |||

| Label accuracy (mm) | ±1 | |||