Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |LUX DD 235-100/8

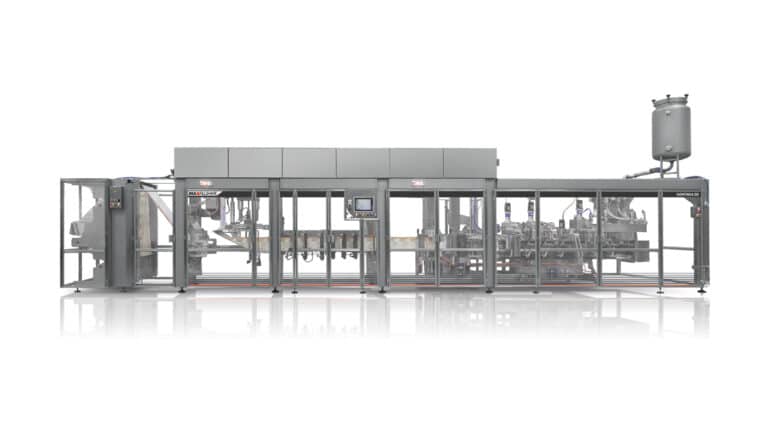

Innovative high-speed stand up Doypacks machine with a unique duel motion system composed of an intermittent module for pouch forming and fitments application, combined with a continuous motion filling unit.

Innovative high-speed stand up Doypacks machine with a unique duel motion system composed of an intermittent module for pouch forming and fitments application, combined with a continuous motion filling unit.

Revolutionary Doy pouch machine for liquids

Designed to form flat film roll stock into high quality Doypack bag, with fully integrated filling solutions for liquid products. Given its versatility, the IMA Ilapak LUX DD 235-100/8 is suitable for a wide range of bag dimensions and filling volumes, as well as the possibility to equip the Doy pouches with corner spout application, shaped round corners and handle punch.

Sustainability

It can manage the new sustainable materials such as paper-based, or recyclable PE and PP mono material films.

LUX DD 235-100/8 Highlights

- Technical Data

- Machine Layout

| LUX DD 235-100/8 | |

| Noise level | within 80db |

| Maximum reel dimension | eØ 600mm – 23.622” |

| Reel core | iØ 76/152mm – 2.992”/ 5.984” |

| Electrical consumption | 400/480VAC – 50/60Hz |

| Pressure and air consumption | 6 bar – 750Nl/min + 600Nl/min |

| Minimum/Maximum pouch width | 120/235 mm – 4.724” / 9.251” |

| Minimum/Maximum pouch height | 190/330 mm – 7.480” / 12.992” |

| Minimum/Maximum pouch gusset height | 15/60 mm – 0.59” / 2.362” |

| Target output – up to 500 ml. | 100 ppm |

| Target output – up to 1,5 lt. | 70 ppm |

| Filling stations | 8 |