Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |HYWRAP20

Designed to maximize efficiency for high-speed productivity and excellent packaging. The new high speed overwrapping machine ensures ease of use and total access to all machine operations running film and paper.

Designed to maximize efficiency for high-speed productivity and excellent packaging. The new high speed overwrapping machine ensures ease of use and total access to all machine operations running film and paper.

High performance overwrapping

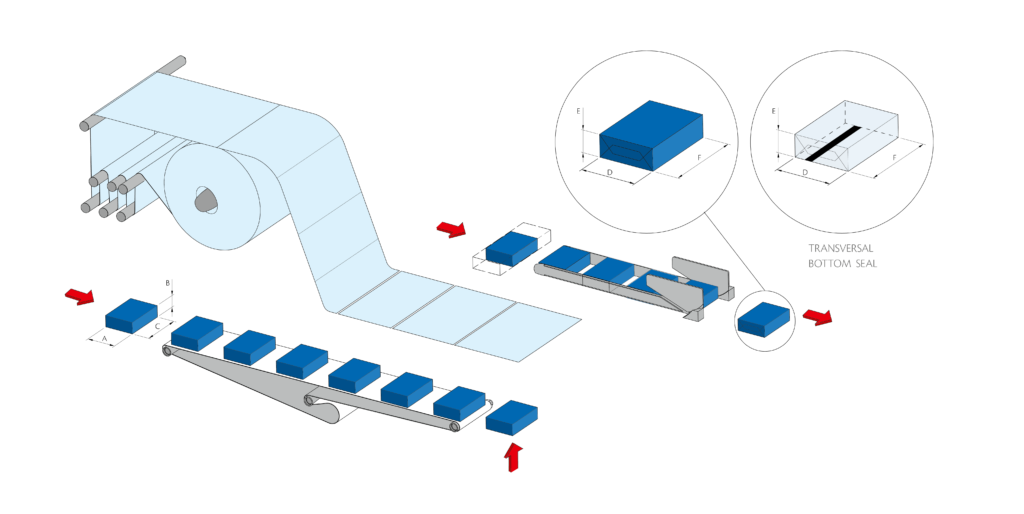

High-speed wrapping machine for single or bundled products, the HYWRAP20 has been conceived as a hybrid solution capable of switching from film to paper without size changeover.

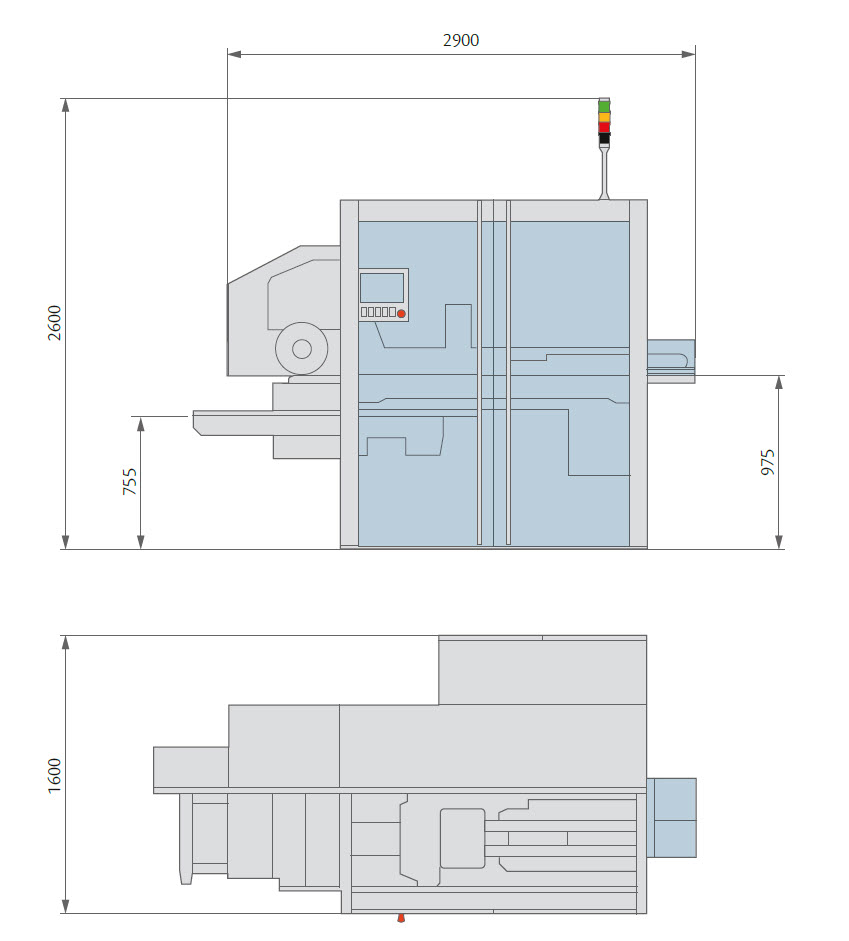

Its compact footprint and cantilever structure allow for accessibility and ease of maintenance. Servomotors are all placed on the back of the machine.

All movements are electronically driven by their own specific brushless motor for accurate performance at high speed.

The size changeover can be carried out in less than 10 minutes with few adjustments.

Sustainability

Impacting present affecting future…overwrapping speaks green.

The HYWRAP20 overwrapping machine can be run both with opp, recyclable and compostable films as well as with paper unrolled from reels where the glue is incorporated into the designated paper sealing areas rather than applied with guns or gluing units. This means that glue quantity and power consumption are reduced to the minimum and waste generation is limited. The goal is to mitigate environmental impacts and allow for a more efficient use of resources.

HYWRAP20 Highlights

- Technical Data

- Machine Layout

| TECHNICAL DATA | ||||||||

| A | B | C | D | E | F | H | L | |

| Product dimensions (MIN) | 30 | 25 | 60 | 30 | 25 | 60 | 100 | 120 |

| Product dimensions (MAX) | 240 | 120 | 280 | 240 | 120 | 280 | 420 | 700 |

|

Speed up to 130 cycles/min. |

||||||||