Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |Tailoring perfume packaging: designed with unique needs in mind

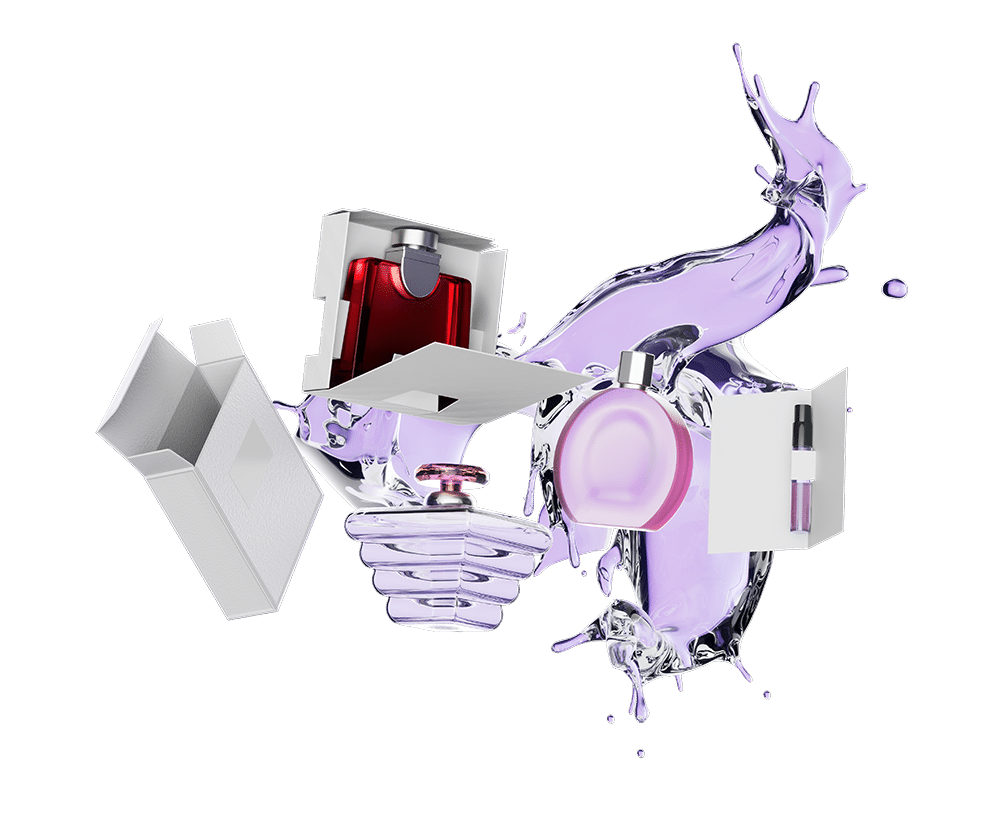

In the world of Personal Care, the Perfume Industry plays a significant role. It requires special production requirements due to the high value and precious nature of the products. The value comes not only from the product contained within the packaging but also from the packaging itself, often being part of the companies’ value proposition and positioning on the market. It is, therefore, crucial to cater to these needs even during the packaging process itself.

To follow market trends, perfume bottles often have very unique and irregular shapes and can be delicate, requiring active, controlled, and precise handling for safe movement. Additionally, the packaging itself, as mentioned, can represent a part of the proposal, so it’s important that the pack remains perfectly intact, without any defect or damage, despite the diverse materials it may be composed of, even velvet in some cases.

Therefore, the components of the automatic packaging process must be designed with utmost consideration for this requirement, selecting materials suitable for extremely delicate handling.

And what else can the fragrance industry demand? Considerable flexibility in formats, the ability to handle various product sizes and, at the same time, different configurations within the packaging: standing or flat perfume positioning, presence of accessories or booklets inside the carton, application of liner to provide stability to the bottle or simply for aesthetic purpose. It requires extreme modularity, flexibility, and expertise.

All of this exists.

The automatic cartoners designed by IMA Safe offer different approaches to meet every need, depending on the specific bottle type and packaging requirements.

Thanks to robotic feeders, any bottle type can be handled with precision. The carton transports are designed to be compatible with the demanding Personal Care sector. Depending on the required final configuration, the cartoners offer the possibility to handle various formats and configurations.

In short, for every need, there’s a specific answer.

But let’s delve into more specific applications.

|

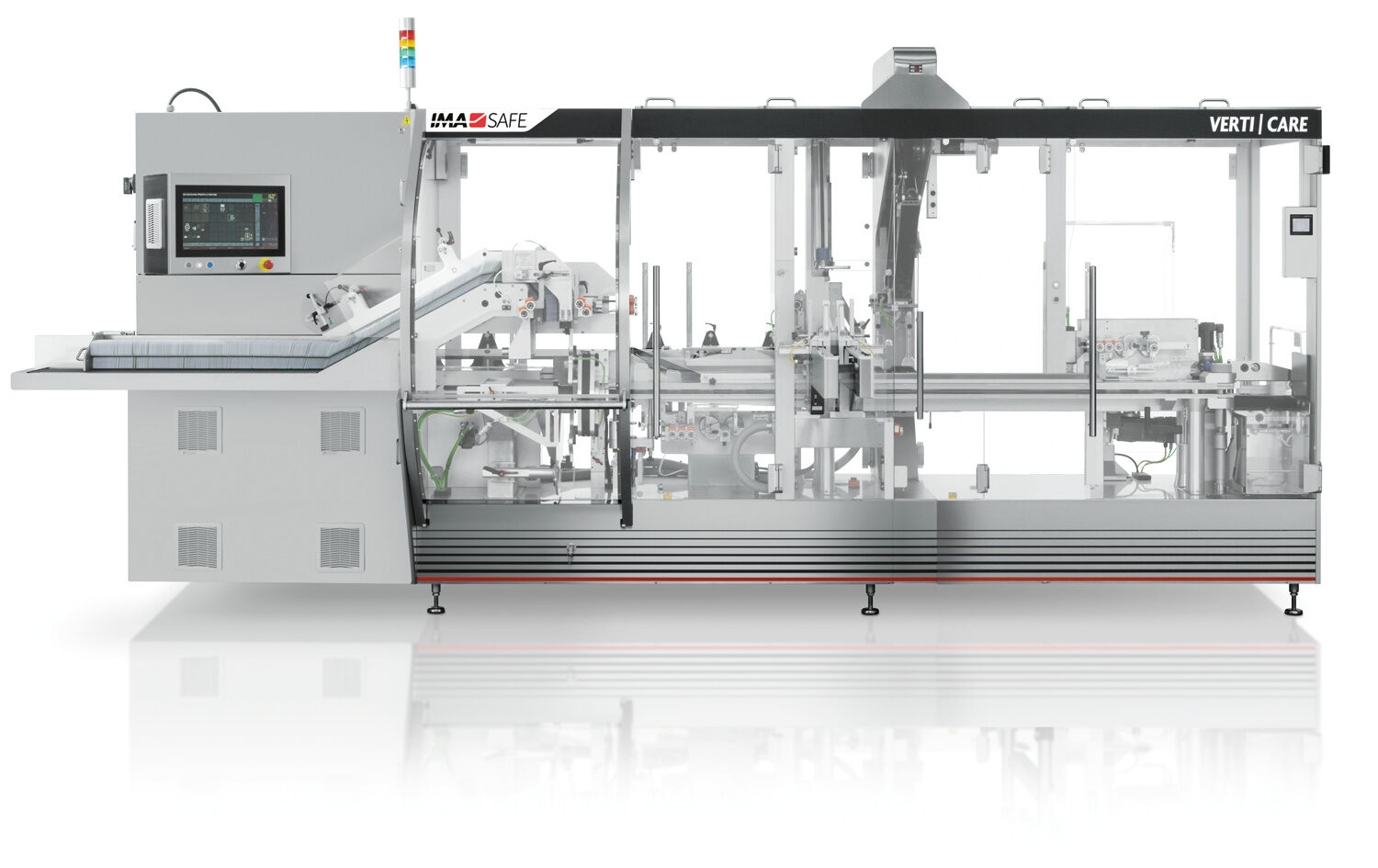

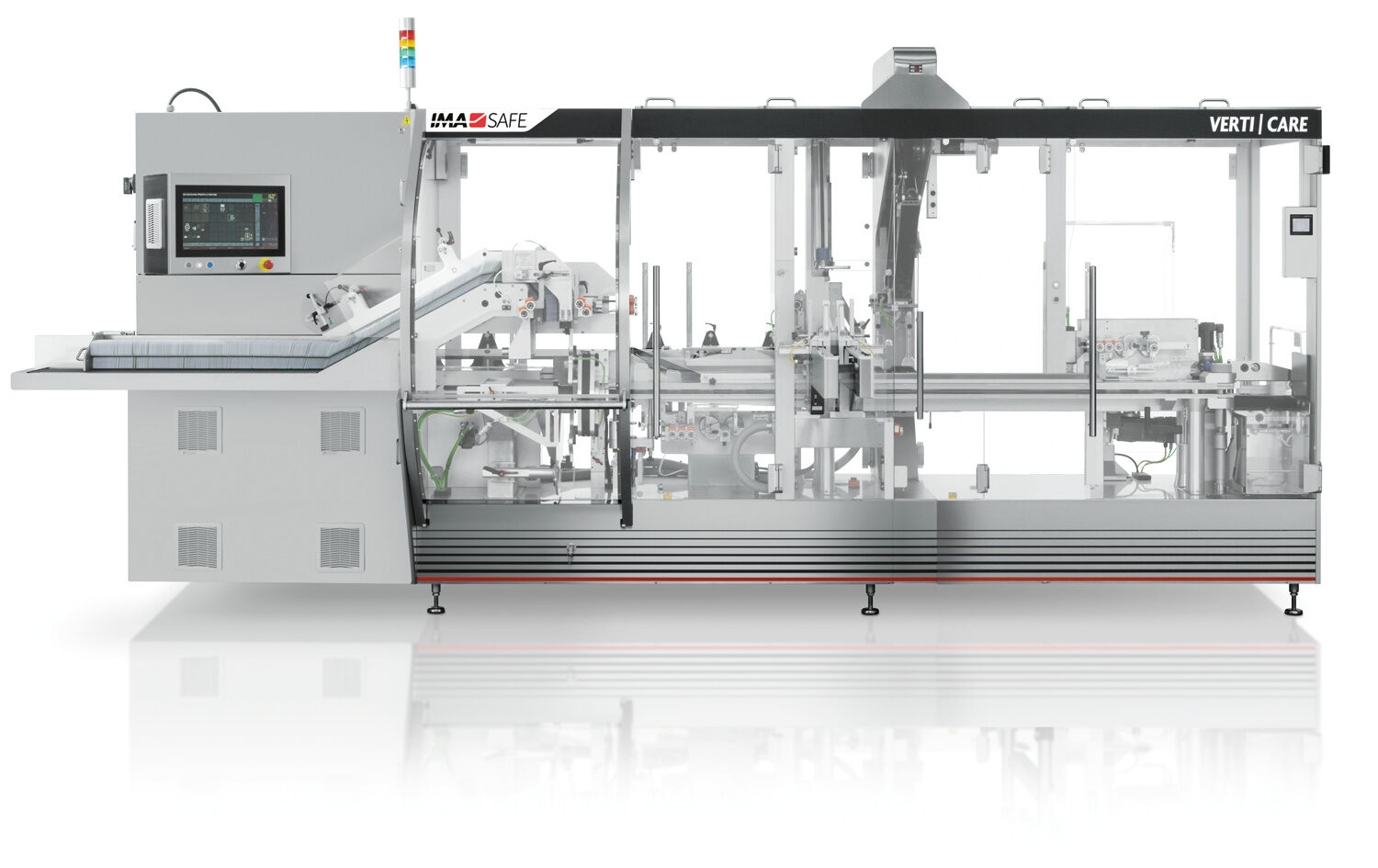

VERTICARE, continuous and/or intermittent motion vertical cartoner. |

|

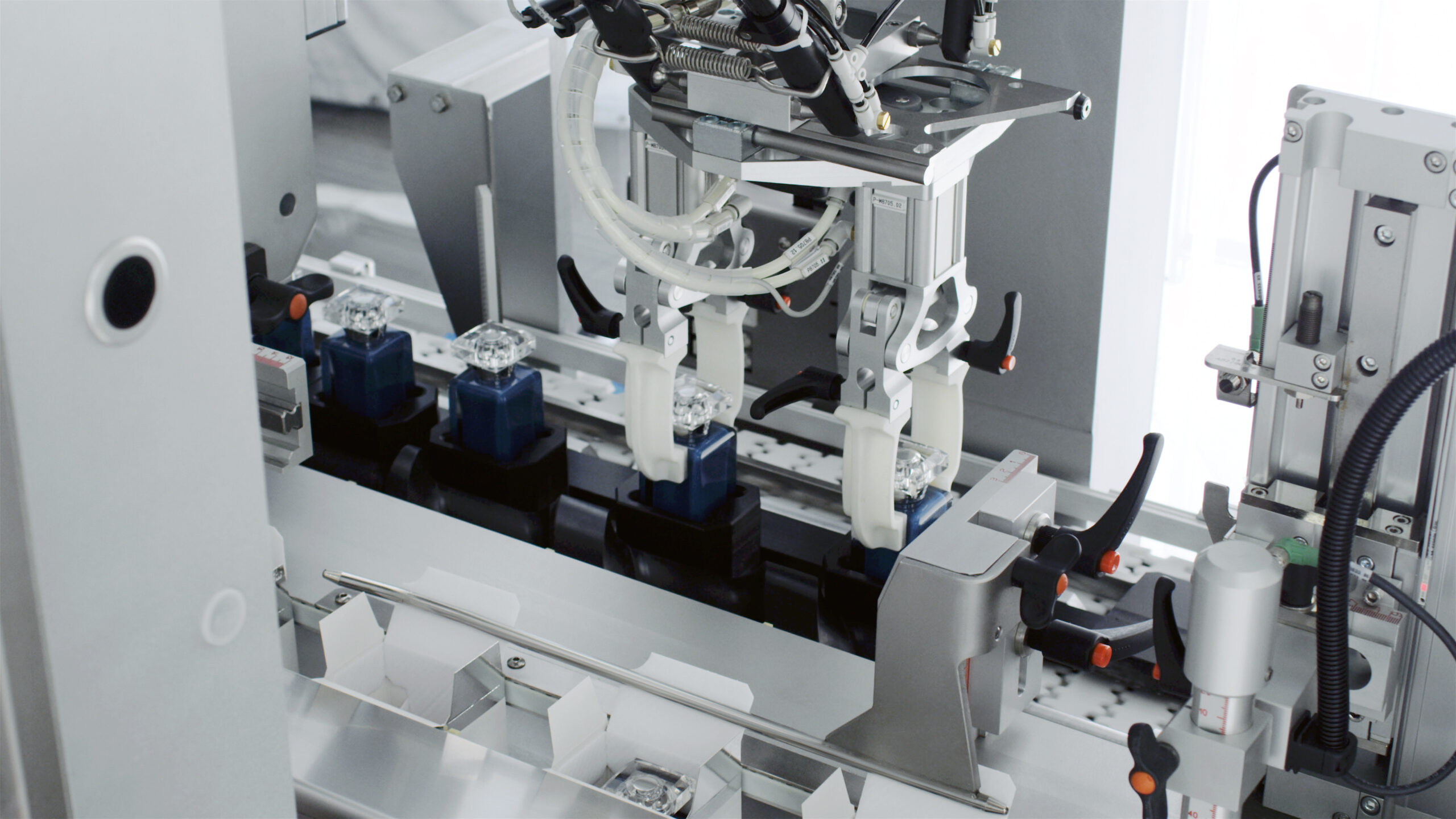

Gentle robotic vertical perfume feeding into the carton. |

In this case, we were packaging a square-sectioned bottle with a push-in cap. Therefore, it wasn’t possible to handle the bottle by the cap, but it was necessary to hold it by the body, paying great attention to avoid damaging the valuable finishes.

|

Perfume bottle and spray pump feeding into the carton. |

With VERTICARE, it is possible to introduce any accessory inside the carton, as in this case, we include a spray pump alongside the perfume bottle. The end consumers will be able to assemble the bottle themselves.

|

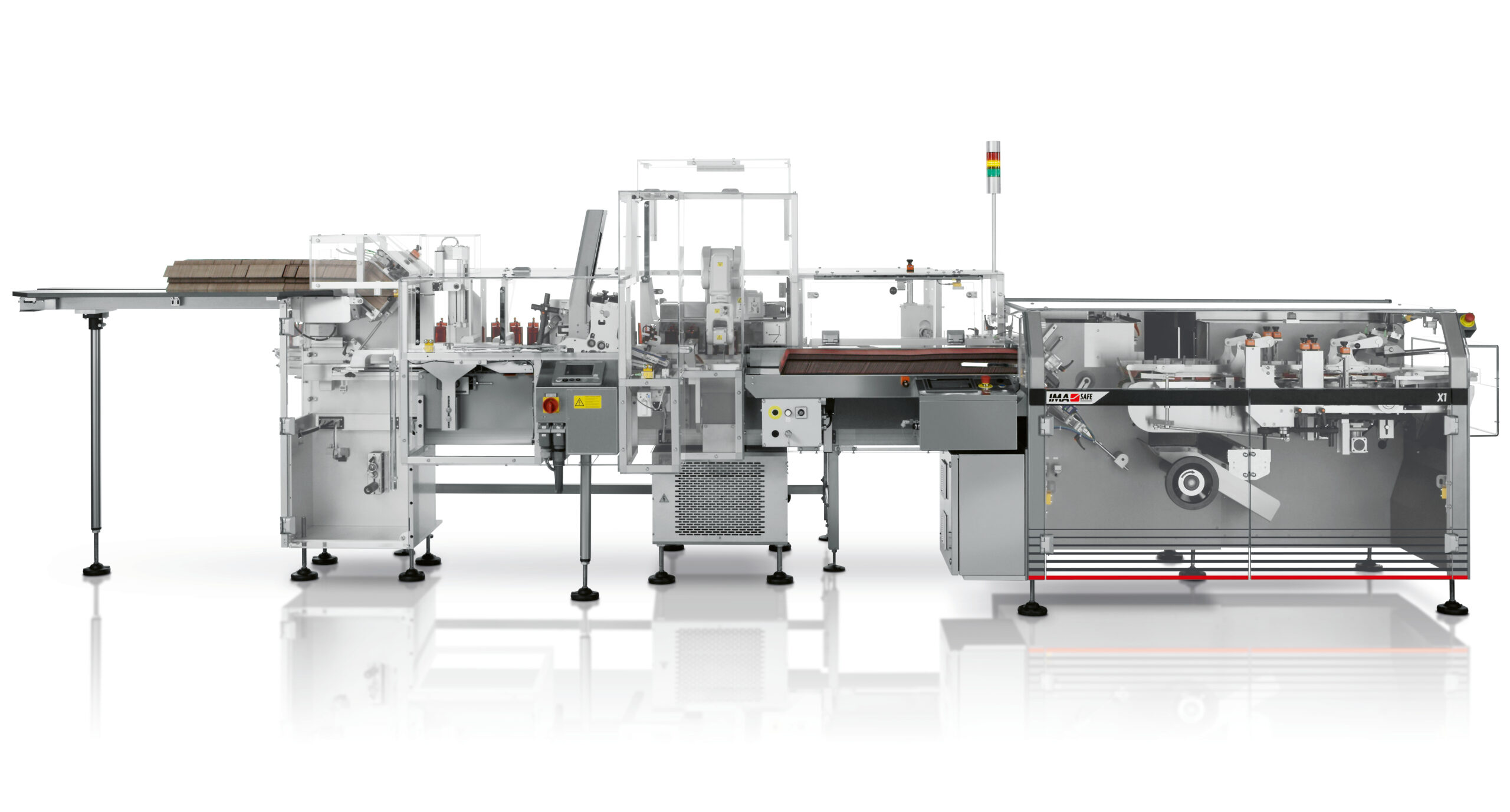

X1, intermittent motion horizontal cartoner. |

|

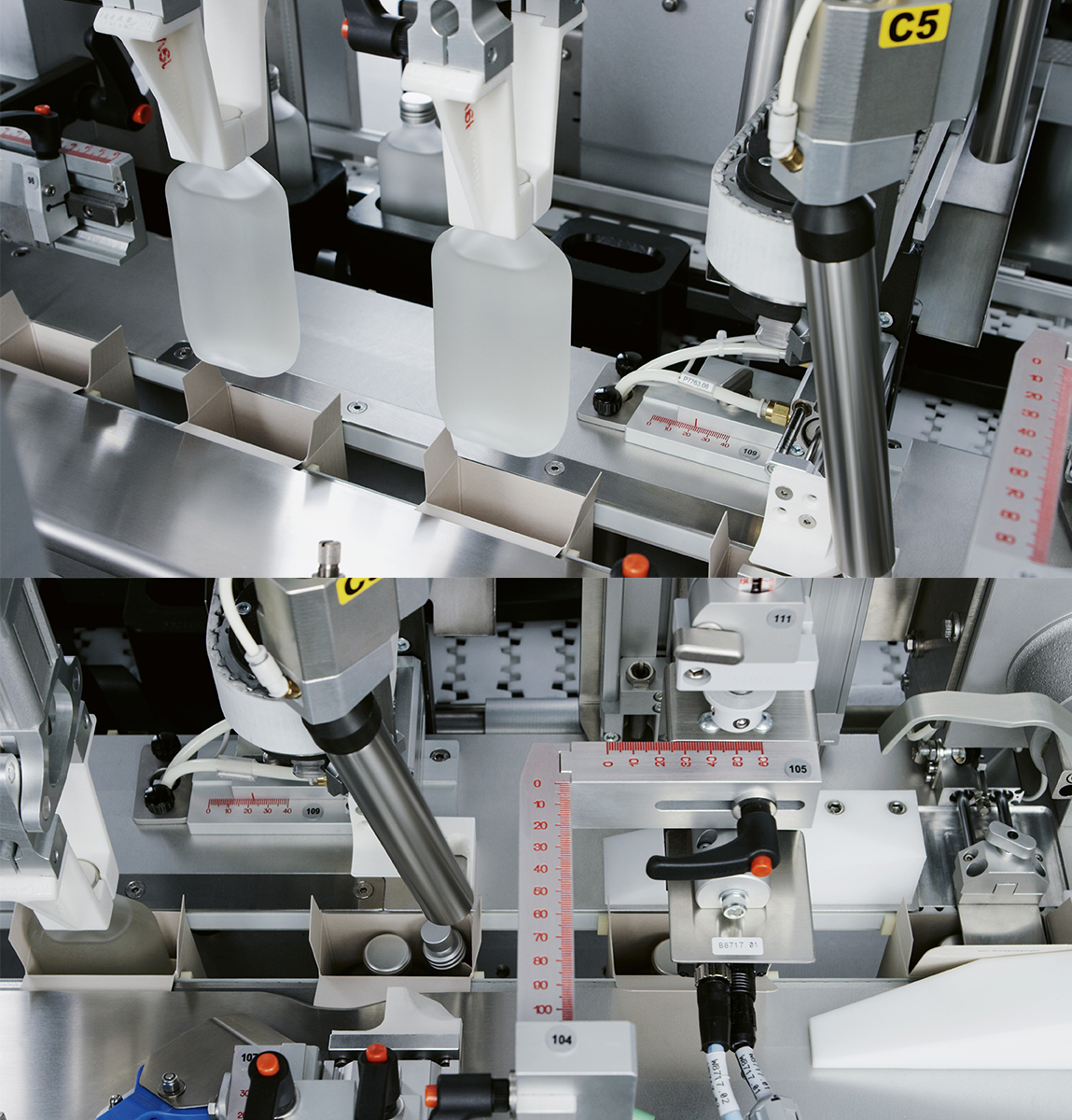

Flat perfume bottle feeding into liner. |

For some types of perfume bottles, a flat disposition is required. In this case, horizontal cartoners with the integration of robotic feeding systems, like the X1 in question, prove to be the optimal choice.

|

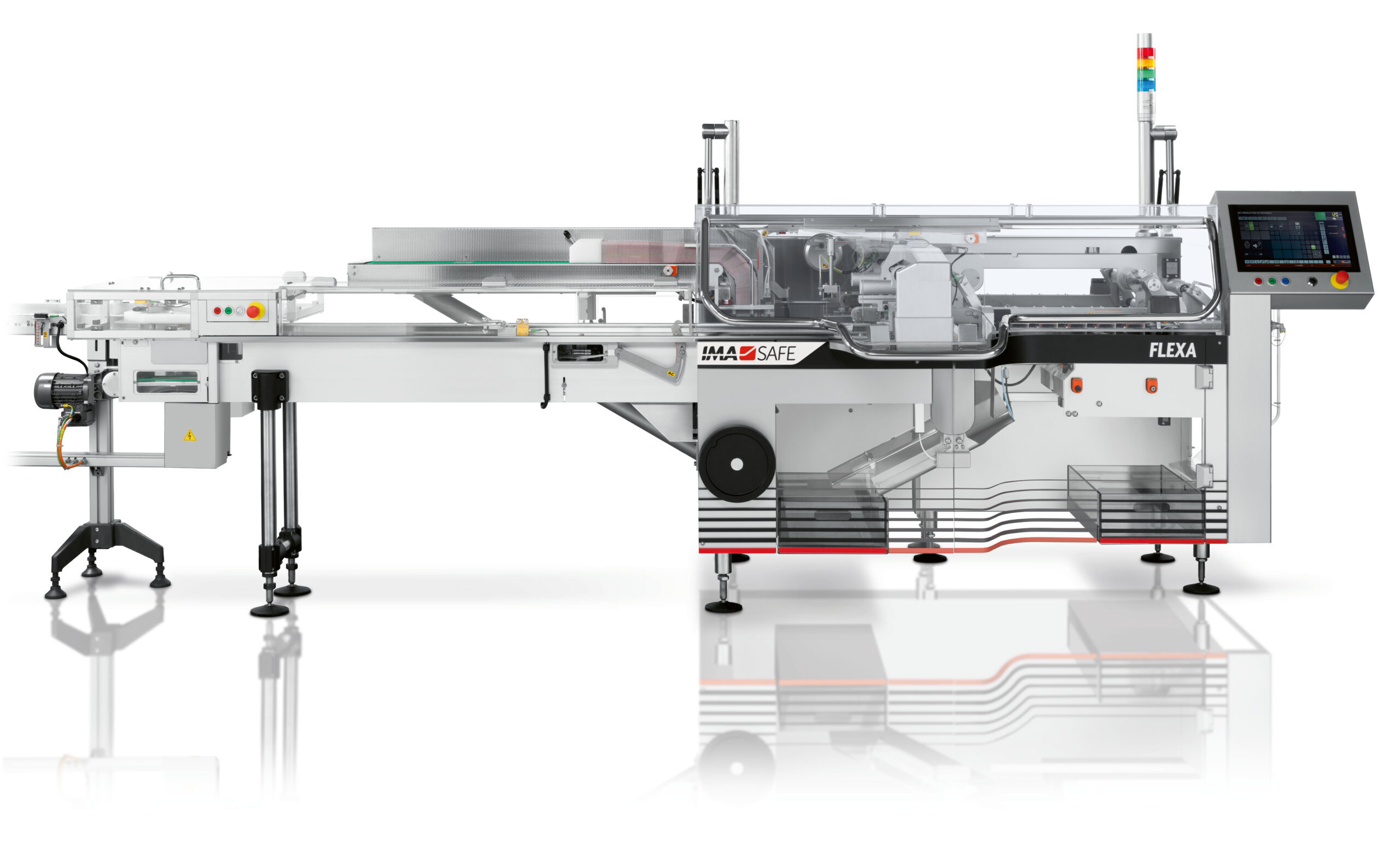

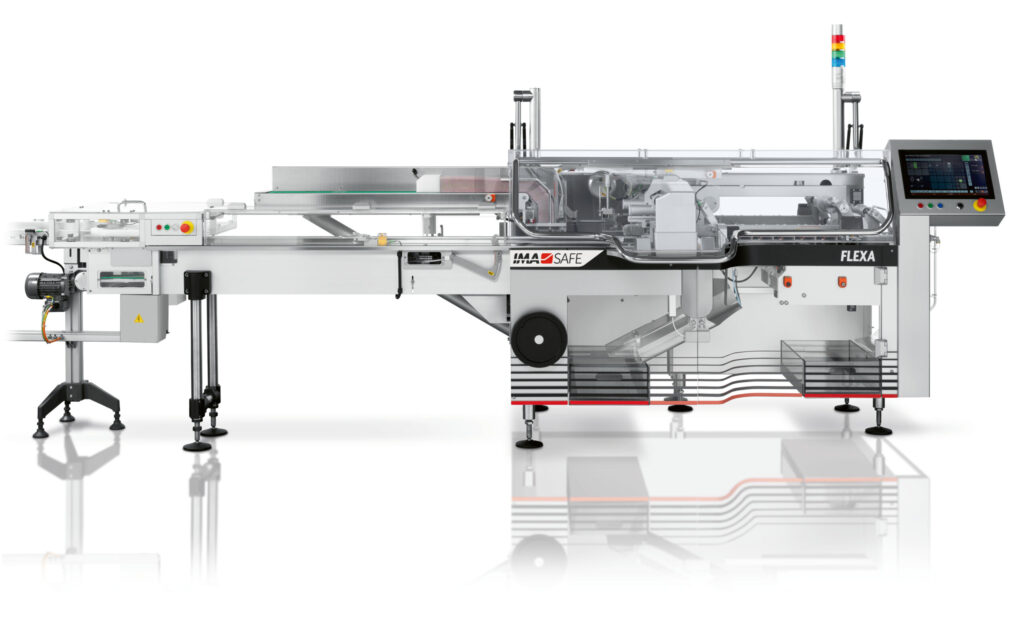

FLEXA, continuous or intermittent motion horizontal cartoner. |

|

Perfume sample introduction into the folder. |

The market demands not only the production of perfume bottles but also, for commercial and marketing purposes, sample vials of the essence. IMA Safe has solutions for this specific type of packaging as well. For instance, on FLEXA, we have a dedicated folder withdrawal system and the ability to handle small perfume dispensers while ensuring quality controls and performance in line with IMA standards.

VERTICARE, continuous and/or intermittent motion vertical cartoner.