Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |KAPPA

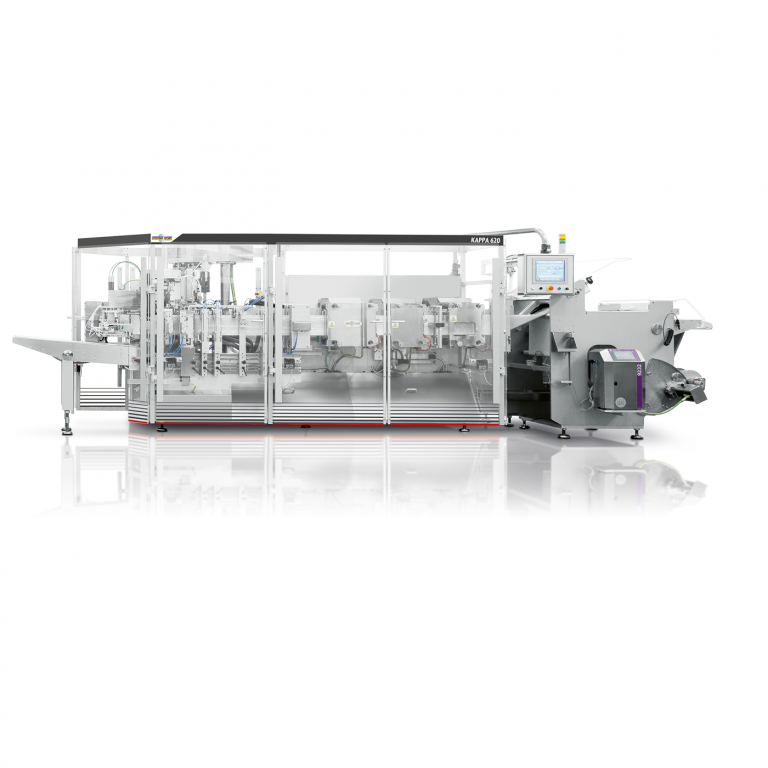

KAPPA Series is simply the highest expression of flexibility. These machines have been conceived to be fully customised according to customer requirements: huge range of sachet configurations handled, products and accessories fed, sachet sizes covered.

KAPPA Series is simply the highest expression of flexibility. These machines have been conceived to be fully customised according to customer requirements: huge range of sachet configurations handled, products and accessories fed, sachet sizes covered.

Simply the highest expression of flexibility

The machine is divided into two modules:

• A linear module which includes the following production functions: sachet vertical sealing,

coding, corners rounding, film pulling and single sachet cutting.

• A rotating module which includes 8 stations to dose one or more products and subsequent

sachet sealing. With this configuration, dosing is performed away from the sealing areas where

the temperature is high, so there is no risk of product heating.

This structure allows extreme compactness even if different dosing systems are installed.

Sustainability

KAPPA machines are designed so that the production process involves minimal environmental impact:

- energy consumption is reduced to a minimum,

- the waste materials are minimized,

- compatibility with the use of recycled materials.

KAPPA Highlights

VERSIONS

KAPPA machines are available in different versions and configurations according to the product characteristics.

Machine versions:

- KAPPA 400

- KAPPA 620 for sachets with big dimensions

Machine configurations:

- Configuration for dense and semi-dense products

- Configuration for powders, free and not free flowing products

- Configuration for fluid products

- Configuration for tablets and capsules

Special applicators:

- Zip

- Cap

- Technical Data

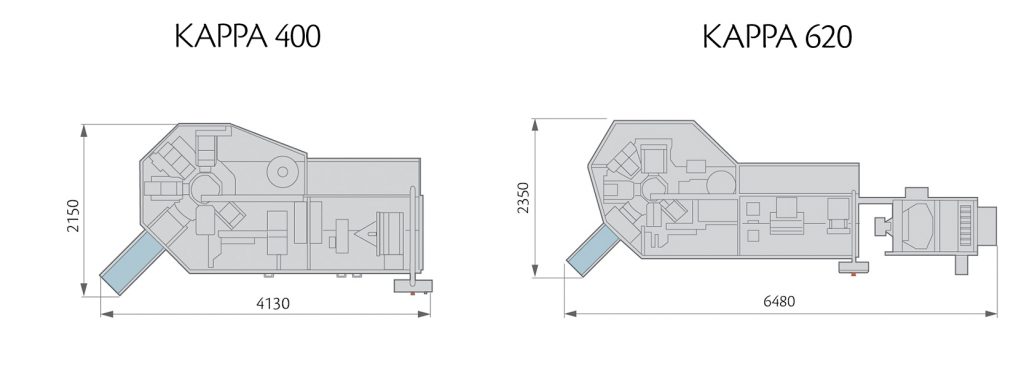

- Machine Layout

| TECHNICAL DATA KAPPA 400 | |||

| Width (mm) | Length (mm) | N. Lanes | Production output |

| 100-200 | 70-180 | 1 | Up to 140 sachets/min. |

| 50-110 | 2 | ||

| TECHNICAL DATA KAPPA 620 | |||

| Width (mm) | Length (mm) | N. Lanes | Production output |

| 100-200 | 70-240 | 1 | Up to 140 sachets/min. |

| 50-125 | 2 | ||