Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |P500

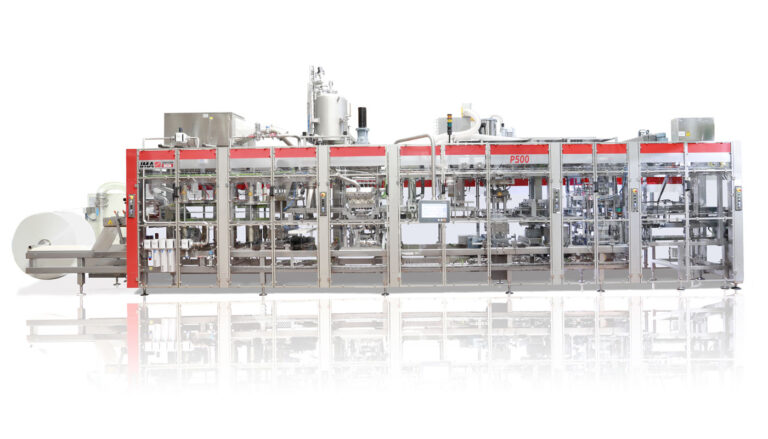

The P500 is a high-performance form, fill and seal machine processing portion cups for a lot of dairy and food applications like fresh cheese, butter, spreads, jam, dressings and sauces, etc., also handling a huge variety of cup designs.

The P500 is a high-performance form, fill and seal machine processing portion cups for a lot of dairy and food applications like fresh cheese, butter, spreads, jam, dressings and sauces, etc., also handling a huge variety of cup designs.

High performance, impressive variety of cup shapes

Ensuring a nominal output of up to 129.600 portion cups/h, the FFS machine ‘P500’ represents the ultimate solution, also integrating case packaging for maximum efficiency.

Ideal for hygienic mini-portions of jam, honey, spreads and sauces used on airlines, at hotels or for simple catering purposes, the P500 is available for clean, ultra-clean and aseptic hygienic standards, and ensures accuracy, precise product cut-off and gentle product handling.

Able to handle a large variety of materials such as PS, PET and PP, one of the key characteristics of this high output machine is the significant saving on packaging material, made possible thanks to a series of exclusive features.

P500 Highlights

Products to be filled in portion cups

Cup shapes for portion cups

- Technical Data

| TECHNICAL DATA P500(A) | |

| Material width | max. 550 mm |

| Draw-off length |

max. 320 mm |

| Forming depth | max. 40 mm |

| TYPICAL MATERIALS | |

| Bottom web | PET, PP, PP multilayer, PLA, PS, PS multilayer, PVC |

| Lid material | Paper-, PET-, Alu-based or other heat sealable materials |

| TYPICAL OUTPUT RANGE and APPLICATION EXAMPLES | |

| Range | up to 151.200 cups/h |

| STANDARD EQUIPMENT | |

| Control system | Controller and servo motors SCHNEIDER ELECTRIC |

| Reel diameters | Bottom web: max. 1.200 mm Lid material: max. 400 mm |

| Punching principle | Grid |

| Hygiene Class | Clean (VDMA I + II) |

| OPTIONS | |

| Bottom web | PP processing |

| Lid material | Lateral reel feed with reel diameter max. 600 mm |

| Punching principle | Low waste, multi punch |

| Filler | Hot fill 85°C, CIP accessories, compensator, agitator |

| Control system | Rockwell Automation |

| Hygiene class | Ultra-clean (VDMA III+IV), Aseptic (VDMA V), FDA-Aseptic version, other versions on request |

| Other equipment | Walking beam, pick & place systems or other end-of line equipment |