menu

This is Food & Dairy Website

Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |

Food & Dairy Website

Choose the market

blur_on

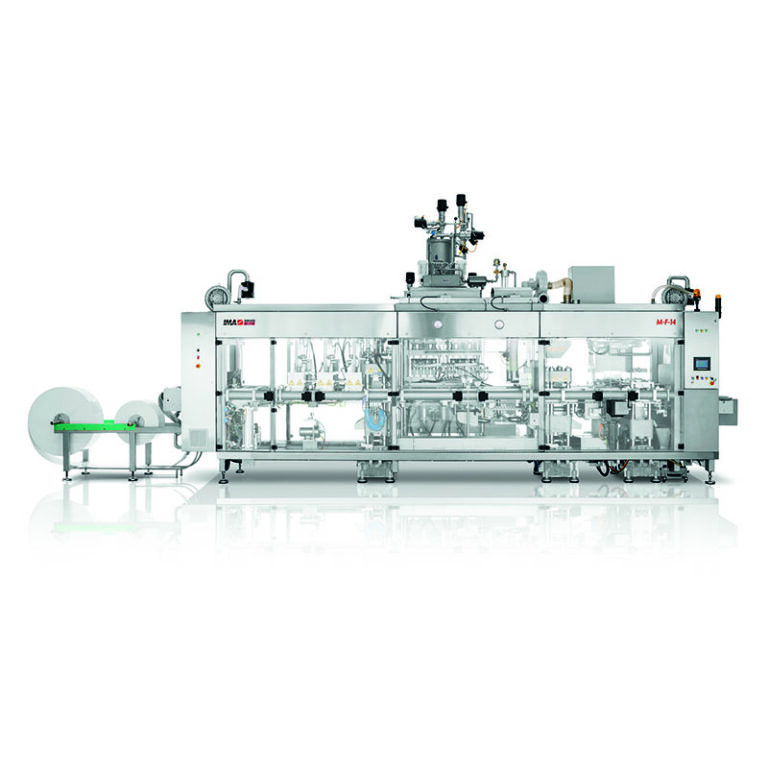

M-F Series

Forming, filling and sealing

Huge value, small footprint

Designed to handle yoghurt, fresh cheese, tomato sauce, fruit puree, water and more, the form, fill and seal machines of the M-F series are one of the market’s most compact solutions for cups in a wide range of shapes and sizes, combining a series of processes on one single machine.

Cups are thermoformed, filled with product, hermetically sealed with a film or foil and cut into singles or multi-packs.

Cups can be designed cost-effectively with interesting labelling solutions and freedom of cup geometry. Not only a marketing tool, the label also strengthens the cup’s sidewall stability, enabling a thinner bottom web resulting in lower material costs.

M-F Series Highlights

1.

Reduced footprint saving up to 30% on floor space.

2.

Integration of electro-pneumatic cabinets and filler in machine base.

3.

Highly versatile equipment: cups from 20 to 500 ml.

4.

Excellent cost efficiency.

Products to be filled

With the form, fill and seal machine of the M-F series you can fill all kinds of liquid-to-pasty products - with or without particulates - such as yogurt, fruit juice, white cheese, desserts, coffee cream, baby food, cereals.

keyboard_arrow_left

keyboard_arrow_right

Filling Solutions

With its' long term experience in filling liquid to pasty products into different kind of cups - in thermoformed as well as in pre-formed cups - Erca offers a large variety of different filling possibilities. The fillers are known for their outstanding filling accuracy, a factor which inevitably leads to minimal product loss and enhanced productivity. Covering a wide range of filling styles, countless customized and tailor-made design possibilities are available to satisfy specific requests.

keyboard_arrow_left

keyboard_arrow_right

Labelling Solutions

Cups can be designed cost-effectively and with a huge variety of different labelling solutions. The label is not only a marketing instrument - it also improves the cup’s sidewall stability – making it more rigid so the bottom web thickness for the cup can be reduced.

keyboard_arrow_left

keyboard_arrow_right

Cup Shapes

Customized and tailor-made cup design possibilities are available to satisfy specific customer requests.

keyboard_arrow_left

keyboard_arrow_right

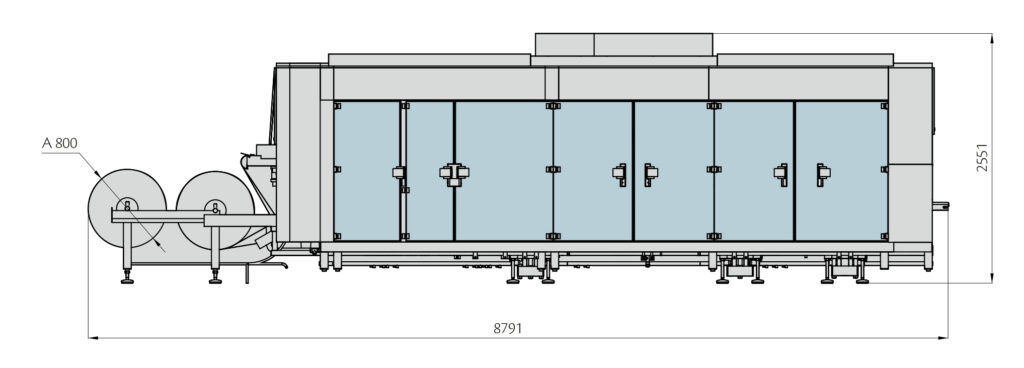

- Technical Data

- Machine Layout

| TECHNICAL DATA M-F 14 | |||

| Cup material width | 400 mm | Draw off length | 150 mm |

| Usable width | 240 mm | Forming depth | 90 mm |

| Materials | |||

| PET/PET, PP and multilayers such as PS/PE, PS/PETG, PS/EVOH/PE, PP/EVOH/PP | |||

| Typical output | |||

| Yoghurt cups 63 x 63 mm, with w.a. label, 2×6 – 30 cycles/min. | 21,600 cups/h | ||

| Standard Equipment | |||

| Components | Controller and Servo motors ELAU, Pneum. FESTO, HMI 15″ touchscreen | ||

| Standard configuration | Bottom web reel : Ø 1200 mm Lid reel: Ø 400 mm Label reel: Ø 600 mm Labelling with tilting mold, drive heating section on 6 pitches, exit conveyor with Intralox chains |

||

| Options | |||

| Hygiene class | Clean*, Ultra-clean* | ||

| Labelling | Labelling, labelling for conical cups, 2 label heights | ||

| Chains | ERCA chains with grippers and magnetic drive | ||

| Fillers | Up to 3 fillers | ||

| * Depending on customer specification | |||

markunread

Contact us