Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |FR90V

Thanks to the new infeed/bundle formation section, the key feature of the machine, the FR90 Series uses step motor-driven shafts to govern each sequence up to actual product bundle positioning on the carton blank, enabling much improved operational flexibility

Thanks to the new infeed/bundle formation section, the key feature of the machine, the FR90 Series uses step motor-driven shafts to govern each sequence up to actual product bundle positioning on the carton blank, enabling much improved operational flexibility

Display tray packing at its most flexible

Complete with a fully mechanical tray forming section, the advantage of FR90 Series is the infeed/bundle formation section ensuring benefits such as the capability to run a wide range of packaging formats and dimensions.

Sustainability

|

|

| The motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. | It allows the use of sustainable and recyclable packaging materials. |

Product output options preview

- Technical Data

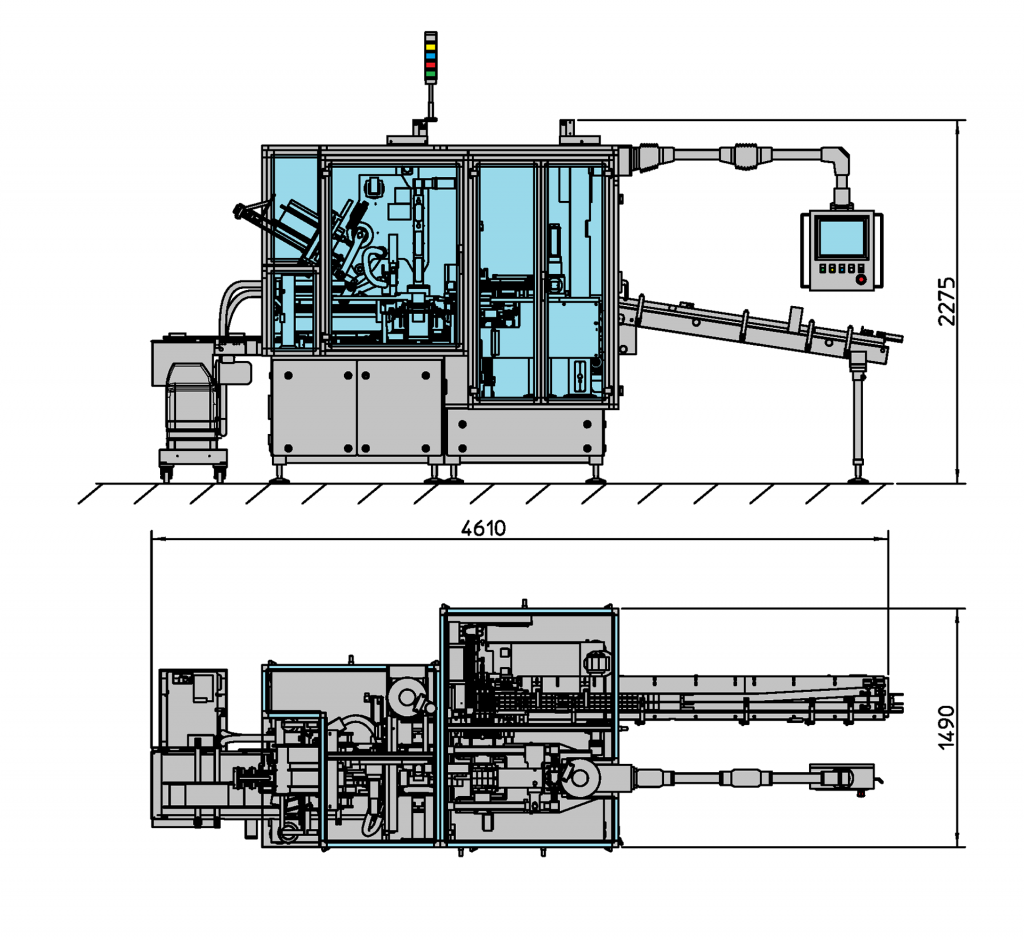

- Machine Layout

| Production capacity | Up to 30 boxes/min. | ||

| Full load current | 3P x 400 Volt – 50Hz – 8 Amp | ||

| Compressed air consumption | 200 Nl/min. (min. op. pressure 6 bar) | ||

| Weight | 2,500 Kg Approx. | ||

|

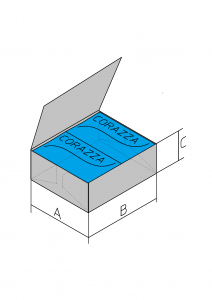

Box dimensions

|

A (min.÷max.) | B (min.÷max.) | C (min.÷max.) |

| 70 ÷ 230 | 70 ÷ 300 | 20 ÷ 200 | |